Tube Drawing Machine

SuperbMelt is a leading machinery manufacturer in China, specializing in the production of round tube manufacturing machines for gold, silver, alloy, and other metals.

SuperbMelt Tube Drawing Machine has the capability to reduce the thickness of the tube wall and adjust the diameter of the wire, facilitating the production of various jewelry items such as rings, bracelets, necklaces, jewelry components, as well as decorative crafts, assisting jewelry industry factory owners in achieving high-quality jewelry processing and production.

The machine produces cylindrical hollow tubes made of materials such as gold, silver, K gold, alloys, etc., with lengths ranging from 0 to 8 meters every 8 minutes. These tubes are utilized in various applications.

Furthermore, the Tube Drawing Machine is not limited to the jewelry industry; it also finds extensive applications in other sectors. For example, it is utilized in the aerospace industry for manufacturing precision tube components, in the medical industry for producing surgical instruments and implants, and in the electronics industry for manufacturing electronic components and connectors. This versatility helps customers address high-quality production challenges across different industries.

If you wish to learn more about other metal tube manufacturing machines offered by SuperbMelt, please feel free to contact us for customized solutions!

| Model number | SPB-DHW-3 |

| Power | 4kw |

| Voltage | 3 phase 380V, 50/60Hz |

| Diameter | 10mm (Personalized) |

| Thickness | 0.32 -0.5mm (Frequency control) |

| Efficiency | 0-8M/8min |

| Control method | Switch control |

| Size | 890*1000*1380mm |

| Weight | 520kg |

| Large tube diameter | 10MM |

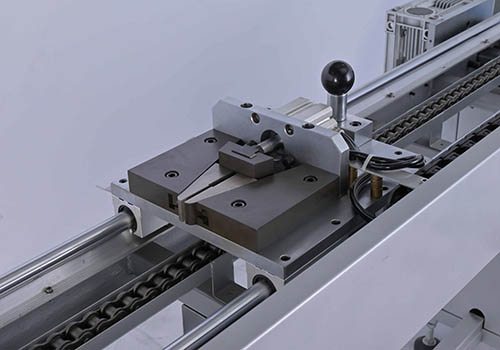

| Pipe clamping method | Automatic pneumatic clamp |

| Operation mode | linear guide sliding |

- High-speed Operation: Capable of producing tube materials at a rate of 8 meters per minute, with adjustable speed settings to accommodate various production needs.

- Unparalleled Precision: Achieves a minimum wall thickness of 0.15mm for hollow tubes and a minimum diameter of 1.0mm for solid wire, ensuring the highest standards of product quality.

- Versatile Options: Suitable for a wide range of specifications for hollow tubes and solid wires, catering to diverse customer requirements.

- Stable Drawing: Utilizes pneumatic clamping mechanisms to ensure stability and smoothness during the drawing process, enhancing production efficiency.

- User-Friendly Operation: Featuring a simple mechanical switch design for easy and straightforward operation, reducing operational complexity and improving work efficiency.

- Jewelry Industry: Used to make solid wires and hollow tubes for making jewelry components like rings, bracelets, and necklaces. It makes accurate sculpting and scaling of metal materials easier, which makes it easier for jewelry producers to create complex designs.

- Precision tube components needed in airplanes and spacecraft are manufactured by those employed in the aerospace industry. The machine guarantees the manufacturing of parts with precise dimensions and excellent quality, which are essential for the safety and functionality of aircraft systems.

- Medical Industry: Used in the production of surgical tools, implants, and other medical components that need to have exact tube dimensions. It contributes to the production of medical devices that fulfill strict quality criteria for healthcare applications and are remarkably accurate and consistent.

Why SuperbMelt Tube Drawing Machine

More Gold Melting Furnace and Gold Casting Machines for Your Choice

Any Question About SuperbMelt Tube Drawing Machine

Comprehensive Guide to Tube Drawing Machine Applications in the Jewelry Industry

Comprehensive Guide to Tube Drawing Machine Applications in the Jewelry Industry

In the jewelry sector, tubular structures are the core form for chains, components, and shaped ornaments (e.g., the tubular links of a snake chain, the fine needle of an earring post, or the hollow frame of a pendant). The Tube Drawing Machine (TDM) is the essential equipment that executes the transformation from “precious metal blank” to “precision tube.” Its status and value are manifested in three dimensions:

1.1, Irreplaceable Association: Supporting the Mass Production of Tubular Jewelry

Traditional manual methods cannot achieve uniform forming of fine-diameter ($0.3\text{mm}-5\text{mm}$) and thin-wall ($0.05\text{mm}-0.5\text{mm}$) precious metal tubes, often resulting in high raw material loss (manual processing loss can exceed 20%). TDM uses precise matching of dies and pulling force to consistently produce fine tubes that meet jewelry requirements. TDM’s capability for efficient production and material saving makes it a cost-effective method for high-volume production.3 This capability is the prerequisite for scaling up tubular jewelry from “small-batch customization” to “mass production,” especially critical for high-value processing of gold, silver, and platinum.

1.2, Core Value Manifestation: Precisely Addressing Three Major Industry Pain Points

-

Optimizing Precious Metal Utilization: Raw materials like gold, silver, and platinum are costly. TDM, through micron-level dimensional control, increases material utilization from the traditional 70% to over 90%, with some precision models achieving up to 95%. Only the small percentage of scrap (below 5%) needs to be recycled, significantly reducing material waste.

-

Ensuring Jewelry Refinement: Jewelry demands extremely high standards for tube roundness, straightness, and surface finish (e.g., a $0.5\text{mm}$ fine tube link requires a roundness deviation $\le 0.01\text{mm}$ and surface roughness $Ra \le 0.4 \mu\text{m}$). TDM ensures stable compliance with these metrics through multi-pass drawing and high-precision dies, preventing issues like chain jamming or loose component assembly caused by dimensional variance. High-spec industries, such as medical manufacturing, aim for an $Ra$ below $0.1$ microns , setting the benchmark for premium jewelry finish.

-

Optimizing Production Efficiency: Small precision TDM units can produce hundreds of meters of precious metal tubing per day, while multi-die continuous models can exceed thousands of meters, vastly surpassing manual output (which is typically tens of meters daily). Furthermore, mold changeover time can be controlled to within 1 hour, adapting well to the “small batch, multi-specification” nature of jewelry orders.

1.3, Adapted Jewelry Types: Covering Mainstream Tubular Scenarios

-

Chain Components: Basic tube stock for snake chains, bamboo chains, O-chains, and other tubular link styles, requiring uniform tubes with diameters of $1\text{mm}-3\text{mm}$ and wall thicknesses of $0.1\text{mm}-0.3\text{mm}$. For example, snake chain machines require input materials to produce finished chains with a minimum round diameter .

-

Accessory Components: Fine components like earring posts , pendant bails, and bracelet clasps ($2\text{mm}-5\text{mm}$ diameter), requiring high strength and dimensional accuracy.

-

Special-Shaped Jewelry: Square, rhombic, or oval cross-section tubes used for geometric pendants and personalized bangles, requiring customized dies to achieve special shapes via the TDM

Common TDM Types and Selection in the Jewelry Industry: Precision Matching for Specific Needs

TDM selection in the jewelry industry must combine material characteristics, tube specifications, and production scale to ensure precise matching.

2.1, Mainstream Machine Types and Characteristics

| Machine Type | Core Characteristics | Adapted Scenarios |

| Small Precision TDM | Compact, fast die changeover ($\le 1$ hour), high precision (deviation $\pm 0.005\text{mm}$) |

Small-batch custom jewelry, fine precious metal tubes ($\le 1\text{mm}$ finish diameter) 1 |

| Multi-Die Continuous TDM | Multi-pass continuous drawing, high capacity (thousands of meters daily), high automation | Scaled production of tubular jewelry (e.g., standard silver chains), mid-spec tubes ($1\text{mm}-3\text{mm}$) |

| Vacuum TDM | Drawing in a vacuum environment, prevents oxidation, high surface cleanliness |

Easily oxidized precious metals (e.g., silver, palladium), high-purity gold tubes, prevents surface discoloration 7 |

2.2, Core Selection Criteria: Four Steps to Identify the Right Model

(1) Selection by Precious Metal Type

-

Stable Precious Metals (Gold, Platinum): Standard small precision or multi-die continuous TDM can be chosen, with no extra anti-oxidation design needed.

-

Easily Oxidized Precious Metals (Silver, Palladium): Prioritize Vacuum TDM to prevent the formation of an oxide layer during drawing, which could cause uneven plating or surface blackening later.

-

Alloys (K Gold, Silver-Copper Alloys): Must select machines with an “intermediate annealing” function, as alloys harden easily during drawing, requiring regular softening (e.g., K Gold requires annealing every 2–3 passes).

(2) Selection by Tube Specification

-

Fine Diameter Tubes ($\le 1\text{mm}$, e.g., earring posts): Must select small precision TDM, paired with natural diamond dies for high precision and low wear, ensuring diameter tolerance $\le \pm 0.01\text{mm}$.

-

Mid-Spec Tubes ($1\text{mm}-3\text{mm}$, e.g., standard chain stock): Multi-die continuous TDM can be chosen to balance precision and capacity.

-

Coarse Diameter Tubes ($3\text{mm}-5\text{mm}$, e.g., bangle frames): Enhanced small TDM models can be used, focusing on uniform wall thickness rather than continuous production features.

(3) Selection by Production Scale

-

Customization Studios (Monthly Capacity $\le 100$ meters): Select 1–2 Small Precision TDM units to meet multi-spec, small-batch needs, avoiding idle equipment.

-

Medium Jewelry Factories (Monthly Capacity $1,000\text{m}-5,000\text{m}$): Configure 1 Multi-Die Continuous TDM (for regular orders) + 1 Small Precision TDM (for custom orders).

-

Large Brand Factories (Monthly Capacity $\ge 10,000$ meters): Multiple Multi-Die Continuous TDM units linked together, featuring automated loading/unloading systems for continuous production.

(4) Selection Pitfalls to Avoid

-

Avoiding “Capacity-Only” Mindset: Small studios choosing high-capacity multi-die machines may face complex changeovers and high equipment costs, increasing the burden.

-

Do Not Neglect “After-Sales Service”: Prioritize manufacturers who offer mold customization and equipment calibration services, which are crucial for the jewelry industry’s frequent need for custom and special-shaped dies.

-

Focusing on “Energy Consumption and Space”: Small studios should choose energy-efficient models

Full Operation Procedure of the TDM: Fine-Tuned Management from Preparation to Completion

TDM operation directly impacts the quality of precious metal tubes and raw material loss. Strict adherence to the “Pre-Operation – Core Operation – Post-Operation” three-stage process is necessary, with each step adapted to the refined demands of the jewelry industry.

3.1, Pre-Operation Phase: Laying the Foundation for Quality

(1) Differentiated Drawing Parameters for Precious Metals

| Precious Metal | Annealing Temp. (∘C) | Single Pass Reduction (%) | Drawing Speed (m/min) | Lubricant Viscosity (cSt) |

| Pure Silver (999) | 280–320 | 18–20 | 0.5–1.5 | 50–60 |

| Pure Gold (999) | 600–700 | 15–18 | 0.8–2.0 | 60–70 |

| 18K Gold | 550–600 | 10–15 | 0.5–1.2 | 70–80 |

| Platinum (950) | 700–750 | 15–20 | 0.6–1.8 | 60–70 |

3.2, Core Operation Phase: Precise Control at Every Step

2) Vacuum Drawing Technology for Easily Oxidized Precious Metals

-

Vacuum Level Control: Vacuum TDM must operate with a stable vacuum level . The system should feature a real-time pressure monitoring and alarm device to notify the operator if the vacuum deviates by more than , ensuring continuous oxidation protection.

-

Atmosphere Protection: Inert gases (Argon or Nitrogen) can be introduced into the vacuum chamber to create a positive pressure layer. Argon protection is recommended for high-purity silver or palladium tubes to prevent surface yellowing or oxide film formation.

-

Cooling Method: Vacuum TDM requires a circulating water-cooling + air-cooling combination to dissipate heat while maintaining vacuum integrity, preventing high temperatures from causing silver discoloration or grain coarsening.

-

Vacuum Environment Lubricants: Specialized vacuum-compatible lubricants (low volatility, high lubricity), such as synthetic ester-based vacuum oils, should be used, with viscosity controlled

(3) Maintenance of Vacuum TDM

-

Vacuum System Maintenance: Check the vacuum pump oil cleanliness and replace the filter core every 100 hours of operation. Inspect and replace chamber seals every 500 hours to maintain air tightness.

-

Sensor Calibration: Calibrate the vacuum pressure sensor, temperature controller, and tension sensor quarterly to ensure precision monitoring.

How to get pure platinum

1. Dimensional Precision Control: The Pursuit of Micron-Level Excellence

(1) Diameter and Wall Thickness Deviation Control

-

Mold Wear Compensation: Tungsten carbide molds should be checked for bore wear every 200 meters of use. If wear exceeds $0.005\text{mm}$, the mold should be replaced or drawing parameters should be adjusted.

-

Environmental Temperature Control: Maintain workshop temperature at $18^\circ\text{C}-25^\circ\text{C}$ to prevent thermal expansion/contraction of equipment parts from affecting drawing precision.

(2) Roundness and Straightness Assurance

-

Straightness Control: Drawn tubes must pass through a straightening mechanism (such as rotating anti-bending rollers).2 The straightening pressure is adjusted based on the tube specification. After straightening, the deviation should be $\le 0.1\text{mm/m}$.

-

Roundness Control: Ensure the concentricity between the die and the traction mechanism is $\le 0.01\text{mm}$ and drawing speed stability is $\le \pm 5\%$ fluctuation.

2. Surface Quality Assurance: The Leap from “Standard” to “Premium”

(1) Prevention of Scratches and Drawing Marks

-

Die Entrance Treatment: Die entrances must be rounded (radius $0.1\text{mm}-0.2\text{mm}$) to prevent sharp edges from scratching the tube.

-

Sufficient Lubricant Supply: Ensure a constant supply of drawing oil at the die entrance to avoid “dry drawing,” which causes friction damage.

(2) Anti-Oxidation and Discoloration Control

-

Material-Specific Equipment: Easily oxidized materials like silver and palladium must use Vacuum TDM. The vacuum level needs to be $\ge 0.001\text{Pa}$ to completely isolate the atmosphere.

-

Rapid Post-Processing: Drawn tubes must be cleaned, dried, and sealed within 30 minutes, or temporarily stored in an inert gas protection box.

(3) Surface Finish Enhancement

-

Die Polishing: Before using new dies, polish the inner surface with diamond abrasive paste to reduce surface roughness.

-

Multi-Pass Fine Drawing: The final 1–2 passes should use a small deformation rate (10%–15% reduction) to achieve the final size, which effectively enhances the final surface finish.

3. Precious Metal Specific Technology: Addressing Material Challenges

(1) Differentiated Drawing Parameters for Precious Metals

| Precious Metal | Annealing Temp. (∘C) | Single Pass Reduction (%) | Drawing Speed (m/min) | Lubricant Viscosity (cSt) |

| Pure Silver (999) | 280–320 | 18–20 | 0.5–1.5 | 50–60 |

| Pure Gold (999) | 600–700 | 15–18 | 0.8–2.0 | 60–70 |

| 18K Gold | 550–600 | 10–15 | 0.5–1.2 | 70–80 |

| Platinum (950) | 700–750 | 15–20 | 0.6–1.8 | 60–70 |

(2) Vacuum Drawing Technology for Easily Oxidized Precious Metals

-

Vacuum Level Control: Vacuum TDM must operate with a stable vacuum level of $0.001\text{Pa}-0.005\text{Pa}$. The system should feature a real-time pressure monitoring and alarm device to notify the operator if the vacuum deviates by more than $\pm 0.002\text{Pa}$, ensuring continuous oxidation protection.

-

Atmosphere Protection: Inert gases (Argon or Nitrogen) can be introduced into the vacuum chamber to create a positive pressure layer. Argon protection is recommended for high-purity silver or palladium tubes to prevent surface yellowing or oxide film formation.

-

Cooling Method: Vacuum TDM requires a circulating water-cooling + air-cooling combination to dissipate heat while maintaining vacuum integrity, preventing high temperatures from causing silver discoloration or grain coarsening.

-

Vacuum Environment Lubricants: Specialized vacuum-compatible lubricants (low volatility, high lubricity), such as synthetic ester-based vacuum oils, should be used, with viscosity controlled at $40\text{cSt}-60\text{cSt}$.

(3) Maintenance of Vacuum TDM

-

Vacuum System Maintenance: Check the vacuum pump oil cleanliness and replace the filter core every 100 hours of operation. Inspect and replace chamber seals every 500 hours to maintain air tightness.

-

Sensor Calibration: Calibrate the vacuum pressure sensor, temperature controller, and tension sensor quarterly to ensure precision monitoring.

Future Technology Trends: Integration of Intelligence and Micro-Machining

As demand for micro-tube structures, special shapes, and automated precision processing in the jewelry industry increases, the TDM is evolving toward intelligent, energy-efficient, and highly integrated systems.

-

Intelligent Monitoring and Adaptive Control: Future TDM units will integrate AI temperature control and self-learning algorithms to realize “human-free, constant-quality output” by automatically adjusting drawing speed and pulling force.15 High-end models already feature online dimensional inspection (laser diameter gauge) and automated compensation systems, which automatically adjust parameters upon detecting a deviation.

-

Micro-Machining and Special-Shaped Tube Technology: To address micro-tube ($\le 0.3\text{mm}$) and special cross-section demands, TDM is introducing micro-servo systems and multi-axis linkage drawing mechanisms to support the integrated forming of various geometric shapes (oval, square, wavy).

-

Green Manufacturing and Energy Optimization: Modern TDM uses variable frequency energy-saving motors and low-viscosity biodegradable lubricants, reducing energy consumption by 20%–30% compared to traditional models.

-

Digital Quality Traceability System: Advanced TDM will feature MES (Manufacturing Execution System) interfaces to record the process parameters (speed, vacuum level, mold number) of every tube. This full-process data traceability, often achieved through barcode and data matrix marking systems , provides verifiable production records for high-end brand jewelry, meeting compliance and quality verification needs.

Conclusion

The Tube Drawing Machine (TDM) is not just a piece of production equipment; it is the critical process core connecting precious metal raw materials to high-end jewelry products. Through the synergistic operation of precision molds, stable vacuum environments, and intelligent control systems, it achieves the combination of micron-level precision, high material utilization, and sustainable manufacturing.

Moving forward, with the widespread adoption of digital manufacturing and smart factory concepts, the TDM will serve as a strategic fulcrum for the jewelry industry to realize “high-precision + customization + efficient production,” providing a solid foundation for the innovative design and global mass production of gold, silver, and platinum jewelry.

FAQ Guide of Tube Drawing Machine

- 1. What are the advantages of tube drawing process?

- 2. Why is tubing better than solid material?

- 3. What is the difference between wire and tube drawing process?

- 4. What is a Tube Drawing Machine?

- 5. How does a Tube Drawing Machine work?

- 6. What materials can be processed using a Tube Drawing Machine?

- 7. What are the typical applications of Tube Drawing Machines?

- 8. What are the advantages of tube drawing over other manufacturing methods?

- 9. What factors determine the quality of tubes produced by a Tube Drawing Machine?

- 10. What types of tubes can be produced with a Tube Drawing Machine?

- 11. How does tube drawing contribute to material efficiency and waste reduction?

- 12. What maintenance is required for a Tube Drawing Machine?

- 13. Is operator training necessary for operating a Tube Drawing Machine?

1. What are the advantages of tube drawing process?

- Precision: The ability to precisely regulate dimensions through tube drawing yields exact diameters and homogeneous wall thicknesses for the drawn tubes or wires.

- Customization: To accommodate diverse uses, manufacturers can modify the tube drawing process to fit specific needs, such as changing the wall thickness, diameter, and length of the tubes.

- Improved Mechanical Properties: The drawing process can improve the material’s tensile strength and surface smoothness, among other mechanical qualities that make the drawn tubes appropriate for demanding applications.

- Material Savings: Tube drawing effectively reduces waste and maximizes material use by converting larger diameter tubes or bars into smaller diameter tubes or wires.

- Versatility: A wide range of materials, including metals like gold, silver, platinum, copper, and alloys, may be drawn into tubes. This allows for the production of varied components for a variety of sectors.

- Cost-Effectiveness: Because tube drawing may save material and has efficient production processes, it can be a cost-effective manufacturing method in the long term, especially for high-volume production, despite the startup expenses.

- Consistency: For applications needing accuracy and dependability, tube drawing guarantees consistency in tube dimensions and quality, producing homogenous results with little fluctuation.

2. Why is tubing better than solid material?

- Weight reduction: Tubing may be used to create components that are lighter than solid materials, which is helpful in areas like the aerospace and automobile industries where weight is a crucial consideration.

- Material Savings: When creating components in large quantities, tubing utilizes less material than solid components, which reduces waste and costs expenses.

- Flexibility & Versatility: When it comes to design and application, tubing is more versatile than solid material. It is ideal for a variety of purposes since it can readily molded, bent, and curved into different forms.

- Enhanced Strength-to-Weight Ratio: Tubing has a stronger strength-to-weight ratio than solid materials, which makes it perfect for uses like structural components where strength is needed without adding extra weight.

- Enhanced Fluid Flow: Because tubing has a hollow interior that permits the flow of gasses or fluids, it is perfect for applications that need to transfer fluids, such hydraulic, HVAC, and plumbing systems.

- Heat Dissipation: Hollow tubing has superior heat dissipation than solid material, which makes it appropriate for uses in cooling systems and heat exchangers where thermal control is essential.

- Decreased Cost: Tubing may frequently be produced at a lower cost than solid material, particularly for complicated designs or big numbers, which results in cost reductions overall.

3. What is the difference between wire and tube drawing process?

A metal workpiece’s diameter can be decreased using one of two metal forming techniques: wire drawing or tube drawing. They vary, meanwhile, in how they are applied and how the workpiece being treated is shaped:

Procedure for Wire Drawing:

Application: The main purpose of wire drawing is to make metal workpieces with wire or rod shapes smaller in diameter.

Procedure: When drawing wire, a metal rod or wire is drawn through a sequence of dies that get smaller and smaller in diameter. This causes the wire to become longer and less wide while growing in length.

Result: A long, continuous wire or rod with a smaller diameter and a better surface polish is what wire drawing ultimately produces.

Process of Drawing Tubes:

Use: Hollow cylindrical metal pipes or tubes can have their diameter reduced by using tube drawing.

Method: In the tube drawing process, a hollow, cylindrical metal tube or pipe is drawn through a sequence of dies that get smaller and smaller in diameter. This results in a tube with a smaller diameter and thinner walls by decreasing the outer diameter of the tube and also decreasing the thickness of its walls.

Result: A hollow cylindrical tube with a smaller outer diameter and maybe thinner walls, depending on the required criteria, is what is produced when a tube is drawn.

4. What is a Tube Drawing Machine?

A Tube Drawing Machine is a piece of equipment used in metalworking industries to reduce the diameter and thickness of hollow cylindrical metal tubes through a process called tube drawing.

5. How does a Tube Drawing Machine work?

The machine pulls a hollow cylindrical metal tube through a series of dies with progressively smaller diameters. As the tube passes through these dies, its outer diameter and wall thickness are reduced to the desired dimensions.

6. What materials can be processed using a Tube Drawing Machine?

Tube Drawing Machines are capable of processing various metals, including steel, stainless steel, copper, aluminum, brass, and alloys thereof.

7. What are the typical applications of Tube Drawing Machines?

Tube Drawing Machines are commonly used in industries such as manufacturing, automotive, aerospace, medical devices, and construction for producing tubes used in applications ranging from fluid transport to structural components.

8. What are the advantages of tube drawing over other manufacturing methods?

Tube drawing offers advantages such as precise dimensional control, improved surface finish, and the ability to produce tubes with complex geometries and tight tolerances.

9. What factors determine the quality of tubes produced by a Tube Drawing Machine?

Tube Drawing Machines can produce a wide range of tubes, including seamless tubes, welded tubes, round tubes, square tubes, and rectangular tubes, depending on the machine’s capabilities and tooling.

10. What types of tubes can be produced with a Tube Drawing Machine?

Tube Drawing Machines can produce a wide range of tubes, including seamless tubes, welded tubes, round tubes, square tubes, and rectangular tubes, depending on the machine’s capabilities and tooling.

11. How does tube drawing contribute to material efficiency and waste reduction?

Tube drawing enables manufacturers to produce tubes with precise dimensions, reducing material waste compared to traditional machining methods where excess material is removed.

12. What maintenance is required for a Tube Drawing Machine?

Regular maintenance tasks for Tube Drawing Machines include lubrication of components, inspection of dies for wear, alignment checks, and cleaning to prevent buildup of debris.

13. Is operator training necessary for operating a Tube Drawing Machine?

Yes, operators should receive training on machine operation, safety protocols, maintenance procedures, and troubleshooting to ensure safe and efficient operation of the Tube Drawing Machine.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited