Magnetic Jewelry Polisher

Using magnetic force to agitate polishing powder and tiny polishing balls, it achieves uniform polishing on the surfaces of intricately shaped jewelry. It is especially suitable for jewelry with holes, grooves, cutouts, and detailed designs.

SuperbMelt Magnetic Jewelry Polisher offers three polishing methods—walnut shell polishing, magnetic polishing, and stone polishing—suitable for polishing gold, silver, copper, and other metal jewelry. Jewelers can flexibly choose the appropriate process based on the material and surface requirements of their pieces.

- Walnut Shell Polishing:Ideal for jewelry that does not require a high-gloss finish. This method quickly removes light scratches and restores a natural shine to the surface. It is easy to operate and has low material loss, making it perfect for quick finishing.

- Magnetic Polishing:Recommended for jewelry requiring high surface brightness and smoothness. By rotating magnetic pins at high speed in a liquid medium, this process can reach intricate areas such as holes, grooves, and fine details, achieving a mirror-like finish. It is especially suitable for gold and K-gold jewelry, with a precious metal recovery rate of over 98%.

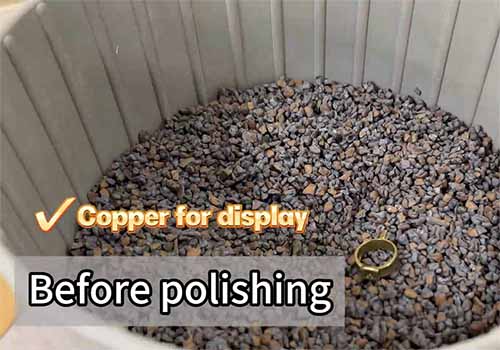

- Stone Polishing:For rough-surfaced silver or copper jewelry, stone polishing is used as the initial step to remove burrs and level the surface before proceeding with magnetic and walnut shell polishing for optimal results.

| Parameter(SPB-MP1) | Value / Range | Notes |

| Voltage | 230 V / 50 Hz | Single-phase |

| Power | 0.8 kVA | Maximum power |

| Container capacity | 6 L | SuperbMelt standard tray |

| Maximum workpiece weight | Magnetic polishing: 300 g Wet polishing: 300 g Dry polishing: 200 g | Single workpiece for dry processing ≤ 8 g |

| Speed range | 100–800 rpm | Adjustable |

| Timer | 0–6 h | Starts rotating clockwise |

| Minimum abrasive particle size | Wet grinding: ≥3 mm Dry grinding: ≥1 mm | Smaller sizes may damage machine or workpiece |

| Ratio of Abrasives and Polishing Liquid | ||

| Magnetic polishing | Steel pins up to 160 g Workpiece ≤300 g | Add water and polishing liquid |

| Wet grinding | Ceramic media ≤3 kg / Steel balls ≤12 kg Workpiece ≤300 g | Add SC series polishing liquid |

| Dry grinding | Walnut shell abrasive 3 kg Workpiece ≤200 g | Add polishing paste |

| Wet polishing | Ceramic needles or stainless steel balls Workpiece ≤300 g | Add water + polishing liquid |

| Dry polishing | Dry polishing media Workpiece ≤200 g | Add polishing paste |

| Workpiece Size Limitations | ||

| Magnetic polishing / Wet processing: ≥4 mm Dry processing: single piece ≤8 g Not suitable for hollow chains, pearls, or loose gemstones | ||

| Typical Processing Time | ||

| Magnetic polishing | 0.5 h | |

| Wet grinding | 3–5 h | |

| Wet polishing | 0.5–2 h | |

| Dry grinding | 4–10 h | |

| Dry polishing | 2–3 h | |

| Abrasive Types and Data | ||

| Steel pins | 0.4 mm × 4–10 mm ≤160 g | Magnetic polishing |

| Stainless steel balls | ≥2.4 mm ≤12 kg | Wet polishing |

| Ceramic needles | 3–5 mm ≤4 kg | Wet grinding |

| Walnut shell media | ≥1 mm 3 kg | Dry grinding |

Three-in-One Polishing System

- Combines walnut shell, magnetic, and stone polishing in one machine, allowing jewelers to handle rough finishing, precision polishing, and mirror finishing with a single device.

Wide Material Compatibility

- Suitable for gold, K-gold, silver, copper, platinum, and other precious metals — meeting the needs of jewelry workshops, manufacturers, and repair studios.

High-Precision Magnetic Polishing

- The high-speed rotation of magnetic pins ensures a mirror-like finish, reaching grooves, holes, and fine details that traditional polishing methods cannot access.

High Metal Recovery Rate

- Especially for gold and K-gold jewelry, the polishing process achieves a precious metal recovery rate of over 98%, minimizing material loss and maximizing value.

Efficient and Time-Saving

- Compared to manual or traditional tumbling polishing, this machine significantly reduces processing time while maintaining superior surface quality.

Environmentally Friendly and Safe Operation

- Requires no strong acids or hazardous chemicals, producing no harmful residues, making it safer for operators and more eco-friendly.

Flexible Process Customization

- Users can freely adjust speed, time, and polishing media, adapting the machine for different jewelry types and desired surface finishes.

Durable and Low Maintenance

- Built with high-quality materials and advanced design, ensuring stable operation, long service life, and easy maintenance.

Compact Design with Quiet Operation

- Small footprint and low noise output, ideal for jewelry studios or production environments requiring quiet operation.

The SuperbMelt Magnetic Jewelry Polisher is widely used across various industries, especially those requiring high-precision and high-gloss metal finishing.

Industries:

- Jewelry manufacturing and repair workshops

- Gold and silver processing plants

- Watch and accessory production

- Handicraft and metal art studios

- Research and educational institutions related to metalworking

Application Scope:

- Ideal for polishing gold, K-gold, silver, copper, and other precious metal jewelry

- Suitable for polishing rings, pendants, earrings, bracelets, beads, and other intricate or detailed jewelry pieces

- Perfect for both rough and fine polishing, from removing surface burrs to achieving mirror-like shine

- Applicable for small batch jewelry production, prototype testing, and finishing of high-value custom pieces

The magnetic pins rotate at high speed in liquid, reaching into holes, grooves, and detailed areas to achieve a mirror-like polishing effect.

For jewelry with lower surface gloss requirements, walnut shell polishing can be used directly. This process quickly removes minor scratches and gives the jewelry a natural shine.

For rough silver and copper jewelry, they should first be ground with glue stone polishing to remove burrs and make the surface smooth, and then magnetic polishing and walnut shell polishing should be performed.

Why SuperbMelt Magnetic Jewelry Polisher

Any Question About SuperbMelt Magnetic Jewelry Polisher

SuperbMelt Magnetic Jewelry Polisher: A Comprehensive Guide

Introduction to the SuperbMelt Magnetic Jewelry Polisher

1.1, Early Development of Jewelry Polishing Technology

1.2, Core Advantages of the SuperbMelt Magnetic Jewelry Polisher

- Multi-process integration: It combines three core polishing methods—walnut shell polishing, magnetic polishing, and stone polishing—in one machine, eliminating the need to switch between multiple devices for rough finishing, fine polishing, and mirror finishing.

- High precision for details: Magnetic polishing uses high-speed rotating magnetic pins to reach hard-to-access areas (e.g., small holes in pendant settings, narrow grooves on ring bands) that traditional tumblers or manual tools cannot, ensuring uniform shine across the entire piece.

- Low material loss & high metal recovery: For precious metals like gold and K-gold, the magnetic polishing process achieves a recovery rate of over 98%, minimizing loss of valuable materials (traditional tumbling often leads to 5-10% material wear).

- Eco-friendly & safe operation: It requires no strong acids, alkalis, or hazardous chemicals (common in traditional chemical polishing), producing no toxic residues—protecting both operators’ health and the environment.

1.3, History of the SuperbMelt Magnetic Jewelry Polisher as a Professional Tool

1.4, Key Performance Indicator: Polishing Effect vs. Material Ductility

- Gold & K-gold (high ductility): Magnetic polishing is ideal here, as the high-speed magnetic pins gently smooth the surface without causing deformation (traditional tumbling may stretch or scratch ductile gold). The machine’s low material loss (≤2%) preserves the metal’s integrity, critical for high-value gold pieces.

- Silver (moderate ductility): Stone polishing (for rough silver blanks) followed by walnut shell polishing (for natural shine) works best. Silver is prone to tarnishing, so the machine’s dry polishing option (using walnut shells) avoids moisture that could accelerate tarnish, while still restoring luster.

- Copper (lower ductility): Copper is harder and more prone to scratching during polishing. The machine’s wet grinding process (with ceramic needles) first levels rough surfaces, and magnetic polishing then achieves a smooth finish—without the excessive pressure that would crack or chip copper.

Types of SuperbMelt Magnetic Jewelry Polishing Processes (and Their Applications)

While the SuperbMelt Magnetic Jewelry Polisher is a single machine, it supports three distinct polishing processes, each designed for specific jewelry materials, surface conditions, and finish requirements. Below is a detailed breakdown of each process, including how it works and when to use it.

2.1, Walnut Shell Polishing (Dry Polishing)

How it works

Key features

- Low material loss (<2%), making it ideal for delicate pieces (e.g., thin silver chains).

- No moisture required, so it won’t cause tarnishing on silver or oxidation on copper.

- Easy to operate: simply load the walnut shells, add polishing paste, and set the timer (2-3 hours for dry polishing, 4-10 hours for dry grinding).

Suitable scenarios

- Jewelry that does not require a high-gloss finish (e.g., vintage-style silver rings, matte copper bracelets).

- Quick of daily-wear jewelry with light scratches (e.g., a gold pendant with minor surface marks).

- Post-magnetic polishing touch-ups to soften an overly “mirror-like” finish (for a more understated look).

2.2, Magnetic Polishing (Wet Polishing)

How it works

Key features

- High precision: Can polish intricate areas that traditional tumblers or manual tools miss.

- High metal recovery rate (over 98% for gold/K-gold), critical for high-value pieces.

- Fast processing time (0.5 hours per batch), making it suitable for small-batch production.

Suitable scenarios

- Jewelry requiring a high-gloss, mirror finish (e.g., K-gold engagement rings, platinum watch cases).

- Pieces with complex details (e.g., engraved pendants, multi-groove earrings).

- Precious metals like gold and platinum, where minimizing material loss is a priority.

2.3, Stone Polishing (Rough Finishing/Wet Grinding)

How it works

Key features

- Aggressive yet controlled: Removes imperfections without damaging the jewelry’s base shape.

- Compatible with rough materials: Ideal for unprocessed blanks straight from casting.

- Works with wet media: The liquid medium flushes away debris, preventing scratches from re-adhering to the surface.

Suitable scenarios

- Initial processing of rough jewelry blanks (e.g., cast copper pendants with sharp edges).

- Removing burrs from soldered joints (e.g., a silver bracelet with soldered links).

- Preparing hard metals like copper for subsequent fine polishing (magnetic or walnut shell).

Why Specialized Equipment Is Needed for Jewelry Polishing

3.1, History of Jewelry Polishing: From Manual to Mechanized

- Skill dependence: Only master craftsmen could produce consistent results, leading to high labor costs.

- Time inefficiency: A single intricate piece could take days to polish.

- Material waste: Over-polishing often removed excess precious metal, reducing the piece’s value.

3.2, Sources of Jewelry Materials (and Their Impact on Polishing)

- Gold (24K, 18K, 14K): Pure 24K gold is soft (ductile), so it requires gentle polishing to avoid deformation. Alloyed K-gold (e.g., 18K) is harder but still prone to scratching—requiring a balance of speed and pressure.

- Silver: Silver is soft and tarnishes easily; polishing must avoid moisture (to prevent tarnish) and excessive abrasion (to preserve detail).

- Copper: Copper is hard but brittle; rough polishing can cause chipping, so a “rough finish + fine polish” two-step process is needed.

- Platinum: Platinum is dense and hard, requiring high-speed abrasives (like magnetic pins) to achieve a shine—traditional methods often fail to penetrate its tough surface.

3.3, Essential Auxiliary Equipment for the SuperbMelt Magnetic Jewelry Polisher

| Auxiliary Equipment/Material | Purpose | Selection Tips |

|---|---|---|

| Quartz Crucible | Holds abrasives and jewelry during polishing; resistant to high temperatures and chemical corrosion (for wet processes). | Choose a 6L capacity (matching the machine’s ECO-MAXI tray) with a smooth inner surface (to avoid scratching jewelry). |

| Abrasives | The “grinding medium” that polishes the jewelry (e.g., walnut shells, steel pins, ceramic needles). | Match to the process: Steel pins for magnetic polishing, walnut shells for dry polishing, ceramic needles for stone polishing. Ensure particle size meets standards (dry grinding ≥1mm, wet grinding ≥3mm). |

| Polishing Liquids/Pastes | Enhances shine and reduces friction between abrasives and jewelry. | Use SC series polishing liquid for wet grinding, magnetic polishing liquid for magnetic processes, and dry polishing paste for walnut shell polishing. Avoid generic chemicals (they may damage precious metals). |

| Filter Screens | Separates jewelry from abrasives after polishing; prevents small pieces from being lost in abrasive media. | Choose a mesh size smaller than the smallest jewelry piece (e.g., 2mm mesh for 4mm jewelry) to avoid loss. |

| Dust Mask & Gloves | Protects operators from dry abrasive dust (e.g., walnut shell particles) and wet polishing liquids. | Use N95 masks for dry processes and chemical-resistant gloves for wet processes. |

3.4, How to Choose a Quartz Crucible for the SuperbMelt Polisher

- Match the machine’s capacity: The SuperbMelt polisher uses a 6L SuperbMelt standard tray, so select a 6L quartz crucible to ensure a perfect fit (a too-small crucible will cause abrasives to overflow; a too-large one will reduce polishing efficiency).

- Prioritize high-purity quartz: Look for crucibles made from 99.9% pure quartz—impure quartz may contain minerals that scratch or contaminate jewelry (e.g., iron particles in low-quality quartz can leave rust marks on silver).

- Check the inner surface: The crucible’s inner wall should be smooth and free of cracks, chips, or unevenness. Rough surfaces can catch on jewelry details (e.g., small prongs) and cause bending or breakage.

- Consider heat resistance: For wet processes (e.g., magnetic polishing), the crucible may be exposed to mild heat from high-speed rotation. Choose a crucible with a heat resistance rating of ≥1200℃ to avoid warping.

- Avoid reused crucibles for precious metals: If polishing gold or platinum, use a new or dedicated crucible—reused crucibles may have residual abrasives from previous copper or silver polishing, which can contaminate high-value metals.

How to Achieve Optimal Polishing Results with the SuperbMelt Machine

4.1, Step-by-Step Polishing Process (From Preparation to Finish)

Step 1: Inspect the Jewelry

- Check for defects: Ensure the jewelry has no loose parts (e.g., unfastened gemstones, fragile prongs) that could break during polishing. Remove any non-metal components (e.g., pearls, enamel) — the machine is only for metal jewelry.

- Verify size and weight: Confirm the piece meets the machine’s limits (magnetic/wet processing ≥4mm, dry processing single piece ≤8g, total weight ≤300g for wet, ≤200g for dry).

Step 2: Select the Process and Gather Materials

- Choose the process based on the jewelry’s material and desired finish (e.g., magnetic polishing for 18K gold rings, stone polishing for copper blanks).

- Prepare abrasives, polishing liquid/paste, and the quartz crucible (clean and dry for dry processes, rinsed for wet processes).

Step 3: Load the Machine

- Wet processes (magnetic/stone): First add abrasives to the crucible (e.g., 120-160g steel pins for magnetic polishing), then place the jewelry (spread evenly to avoid stacking), and finally add water + polishing liquid (liquid level should cover abrasives by 1-2cm).

- Dry processes (walnut shell): Add 3kg walnut shell abrasives to the crucible, place the jewelry, and sprinkle 15-30g dry polishing paste (mix gently to distribute the paste).

Step 4: Set Parameters

- Adjust speed: Refer to the process’s recommended range (e.g., 400-600 rpm for magnetic, 200-300 rpm for walnut shell).

- Set the timer: Use the typical processing time as a guide (e.g., 0.5 hours for magnetic, 2-3 hours for dry polishing).

Step 5: Run the Machine and Monitor

- Start the machine and observe for 30 seconds: Check for abnormal noise (e.g., grinding or rattling) or abrasive overflow. If issues occur, stop immediately and adjust.

- For long processes (e.g., 3-5 hours of wet grinding), check every 1 hour to ensure the liquid level is sufficient (add water if needed) and the jewelry is not stuck.

Step 6: Finish and Clean

- Once the timer ends, turn off the machine and disconnect power.

- Use a filter screen to separate the jewelry from abrasives. Rinse wet-processed jewelry with clean water to remove polishing liquid; brush dry-processed jewelry with a soft brush to remove abrasive dust.

- Inspect the finish: If the shine is uneven, repeat the process with adjusted speed (e.g., increase by 100 rpm for magnetic polishing) or add more polishing paste.

4.2, Chemical Processing Compatibility (Avoiding Damage)

- Never use strong acids/alkalis: Acids (e.g., hydrochloric acid) or alkalis (e.g., sodium hydroxide) can corrode precious metals (e.g., dissolve silver) and etch the quartz crucible. Stick to SuperbMelt’s recommended SC series polishing liquid or dedicated magnetic polishing liquid.

- Match chemicals to metals: Use copper-specific polishing paste for copper jewelry (to prevent discoloration) and gold-compatible liquid for K-gold (to avoid alloy separation).

- Control chemical concentration: For wet processes, mix polishing liquid with water at a 1:10 ratio (1 part liquid to 10 parts water). Too high a concentration can leave a sticky residue on jewelry; too low will reduce polishing efficiency.

- Clean chemicals thoroughly: After wet polishing, rinse jewelry with warm water and dry immediately—residual polishing liquid can cause tarnishing on silver or spotting on gold.

4.3, Polishing Processes for Jewelry and Decorative Pieces

| Jewelry Type | Material | Recommended Process | Key Tips |

|---|---|---|---|

| Rings (with grooves/engravings) | 18K Gold | Magnetic Polishing | Use 120g steel pins and 0.5-hour timer; avoid high speed (≤500 rpm) to protect engravings. |

| Silver Pendants (matte finish) | Sterling Silver | Walnut Shell Pol |

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited