Tube Making Machine

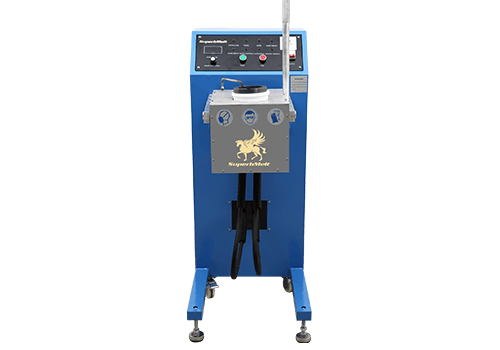

SuperbMelt Professional Gold, Silver, Aluminum Metal Tube Making machine

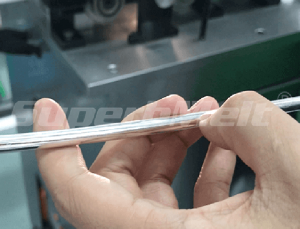

The hollow tube forming machines from SuperbMelt are created to make it simple and effective for you to produce tubes of all different shapes and sizes. SuperbMelt hollow tube forming machines specialize in creating various metal hollow tubes, including hollow gold, silver, copper, and aluminum tubes.

Metal tubing may be produced using SuperbMelt’s tubing equipment for a variety of uses, such as manufacturing, construction, and jewelry. Our equipment is made to last, with long-lasting components and meticulous engineering to guarantee reliable results each and every time.

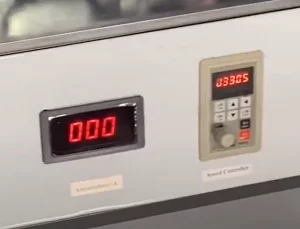

| Model number | SPB-DHW-2 |

| Power | 4kw |

| Voltage | 3 phase 220V, 50/60Hz |

| Diameter | 3.2mm (Personalized) |

| Thickness | 0.32 -0.5mm (Personalized) |

| Efficiency | 1000 – 2000mm/min |

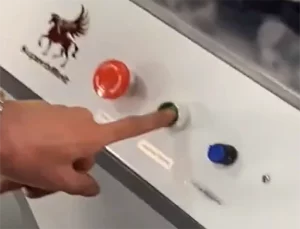

| Control method | Switch control |

| Size | 890*1000*1380mm |

| Weight | 520kg |

A piece of machinery called a copper tube producing machine is used to create copper tubes in a variety of forms and sizes. The machine converts copper rods or billets into seamless or welded copper tubes using a mix of processes, including heating, rolling, and drawing. In the plumbing, HVAC, and refrigeration sectors, where copper tubes are widely utilized, these devices are crucial.

A top-of-the-line copper tube manufacturing equipment from SuperbMelt is effective, dependable, and simple to operate. Our hollow tube forming equipment is outfitted with cutting-edge technology to guarantee accurate and reliable outcomes. Our machine can accommodate a variety of manufacturing demands since it has adjustable choices for tube diameter, thickness, and length.

By purchasing a copper tube producing equipment from SuperbMelt, you can optimize your production workflow, boost productivity, and guarantee the finest quality output. To find out more about our copper tube-making machine and how it may help your company, get in touch with us right now.

Metal Tube Making Machine

A sort of machinery called a metal pipe producing machine is used to create different kinds of metal pipes. Various metals, including gold, silver, steel, copper, aluminum, and brass, can be processed by the equipment. It is employed to create tubing in a range of diameters and forms in a number of sectors, including jewelry, construction, automotive, and HVAC.

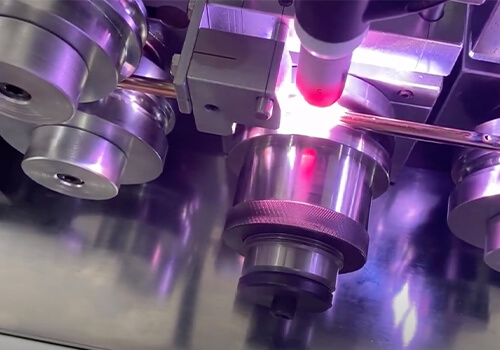

Metal tubes are formed using a variety of methods, including welding, rolling, and bending, by metal tube forming machinery. Additionally, it is capable of numerous processing tasks including drilling, punching, and cutting. Metal tube production equipment from SuperbMelt creates hollow metal tubes by welding and extrusion.

A metal pipe producing machine can boost productivity and cut expenses, which is one of its key advantages. It can make a lot of metal tubes more quickly than the old-fashioned ways. Additionally, the machine provides a high degree of precision and accuracy, guaranteeing that every tube produced meets the necessary standards.

Utilizing a metal pipe forming machine also lessens material waste, which is an advantage. By efficiently cutting and shaping metal, the machine maximizes the utilization of raw resources. By doing so, waste is minimized and expenses are kept to a minimum.

Why SuperbMelt Hollow Tube Forming Machine

Helpful Resource For Your Reference ( An expert about SuperbMelt hollow tube forming machine )

More Gold Melting and Casting Machinery For Your Choice

Any Question About SuperbMelt Hollow Tube Forming Machine

Tube Making Machine Guide

Introduction of mining of platinum

The development of the tube making machine marked a turning point in both jewelry craftsmanship and industrial production. Traditionally, metal tubes were created manually through rolling and shaping, a process that was not only slow but also inconsistent in terms of precision and quality. With the rise of industrialization, the demand for metal tubes—whether for fine jewelry or large-scale construction—grew rapidly, which led to the invention of the tube making machine.

Origin and Invention

The first generations of tube making machines were designed to solve two key problems: efficiency and consistency. Manual methods could not keep up with industrial demand, nor could they guarantee uniform tube dimensions. By automating the processes of heating, rolling, and forming, early tube making machines enabled the mass production of seamless or welded tubes. Over time, technology improvements introduced advanced features such as CNC control, adjustable molds, and multi-step finishing systems, making tube production faster, more precise, and more versatile.

Why Tube Making Machines Were Invented

Tube making machines were created to overcome the limitations of traditional manual tube production. In the past, artisans relied on hand tools to roll and shape metal into tubes, which was slow, labor-intensive, and prone to inconsistencies. As industries such as jewelry, construction, plumbing, and refrigeration expanded, the need for faster, more precise, and scalable production became urgent.

The invention of tube making machines solved these problems by:

Improving Efficiency: Automating rolling, forming, and cutting processes drastically reduced production time.

Ensuring Consistency: Machines guaranteed uniform tube thickness, diameter, and length, something manual work struggled to achieve.

Reducing Costs: Less labor and minimized raw material waste made production more economical, especially when using precious metals like gold and silver.

Meeting Industrial Demand: From delicate jewelry components to large copper or aluminum pipes, machines enabled mass production to keep pace with global needs.

In short, tube making machines were invented to deliver speed, precision, and reliability, allowing manufacturers to create high-quality tubes that meet the requirements of both fine craftsmanship and large-scale industries.

Applications Across Industries

Jewelry Industry

Producing hollow gold and silver tubes for bangles, rings, chains, and pendants.

Creating lightweight yet durable designs while reducing precious metal usage.

Construction & Architecture

Manufacturing stainless steel and aluminum tubes for frameworks, railings, and decorative elements.

Ensuring strength, precision, and consistency for structural applications.

Automotive & Aerospace

Producing copper and aluminum tubes for fuel lines, exhaust systems, and hydraulic applications.

Meeting strict standards of durability and safety.

Plumbing & Refrigeration

Forming copper and stainless-steel pipes used in water supply, HVAC, and cooling systems.

Delivering reliable, leak-resistant tubing for long-term use.

Medical Equipment

Creating fine, precision tubes for surgical instruments, catheters, and implants.

Ensuring biocompatibility and accuracy in sensitive applications.

Conclusion

The evolution of tube making machines reflects the growing demand for precision, efficiency, and versatility across industries. From their invention to modern advancements, these machines have transformed how metals are shaped, enabling manufacturers to balance quality with cost-effectiveness. By providing reliable solutions for jewelry, construction, automotive, medical, and many other fields, tube making machines have become indispensable in today’s production landscape. Looking ahead, innovations such as automation, digital monitoring, and sustainable manufacturing will continue to enhance their role, ensuring that tube production remains at the forefront of technological progress and global industry needs.

what is a tube mill?

A tube mill is a device that shapes metal strips into tubes and then welds the ends together to create tubes or pipes. A number of sets of rollers gradually shape the metal strip as it is passed through them. The strip’s edges are then heated and joined by welding to form a continuous tube or pipe. Steel pipes are frequently produced at tube mills for a variety of sectors, including oil and gas, automotive, construction, and a wide range of pipe diameters and thicknesses.

How do you manufacture metal tubes?

Extrusion equipment used to make plastic pipes

Machine for rotating molding that produces metal pipes

Mandrel milling equipment is used to make seamless steel pipes.

For the manufacturing of welded steel pipes, a pipe welding machine

For the manufacturing of elbows, an elbow-forming machine

Pipe benders are used to produce pipes with certain bends and forms.

Metal tubes made by SuperbMelt tube-making machine include copper, gold, and silver tubes.

Each equipment in the steel pipe manufacturing process has a specific function and is made to manufacture steel pipes that are effective and of high quality.

How do you manufacture stainless steel tubes?

In the hot extrusion method, a billet of stainless steel is heated and then pushed through a die to shape it into a tube.

A stainless steel billet is heated before being pushed through a succession of dies in the cold drawing process, which reduces the diameter and length of the billet.

Tubes that have been welded together can also be made of stainless steel. In the production of tubes, laser welding and TIG (tungsten inert gas) welding are both employed.

Pipe that is seamless is produced using a mix of cold drawing and hot extrusion. The procedure entails heating a billet of stainless steel, which is afterwards punctured by a mandrel to create a hollow tube. Cold drawing is then used to further decrease the tube’s size.

Finishing: To attain the necessary surface finish and dimensional precision, the pipe must go through a number of finishing operations after it is made, including heat treatment, polishing, and cleaning.

What is the process for making steel tube?

The intended form and characteristics of the completed product determine the steel pipe manufacturing process. But first, a quick rundown of the procedures:

To create billets or billets, steel is first melted in a furnace and then poured into a continuous caster.

After being rolled into sheets or strips, the billet or billets are then fed into machinery that create pipes.

Steel is formed into pipe using one of many techniques using pipe-making equipment. The production of seamless pipes using a mandrel to pierce a solid billet or billet, which is subsequently rolled into seamless pipe, is one popular technique. Another technique is called “welded tubing,” which entails joining the edges of flat steel strips into a tube by welding.

The pipe is heat treated after it has been manufactured to improve its strength and ductility. In order to do this, the pipe must first be heated to a high temperature before being quenched in oil or water.

The tube is next put through a series of quality checks to determine its size, surface polish, and mechanical characteristics.

Which machine is used in pipe manufacturing?

Several machines are used in various operations during pipe manufacture. Among the equipment used in the production of pipes are:

Electric resistance welded (ERW) tubes are created using this machine, the electric welded tube mill.

The seamless tube mill is a device that creates seamless tubes.

Cold drawing table: This device is used to draw pipes to lengthen them and lower their diameter.

Pipes are tested using a hydrostatic testing equipment to see whether they are leak-free and fulfill the necessary quality requirements.

Pipe Threading equipment: To thread pipes for simple installation and connection, use this equipment.

This device, called a pipe bender, is used to bend pipes into the correct angles and forms.

Pipe Coater: This device coats pipes with a protective layer to ward off corrosion and improve their toughness.

Depending on the type of pipe being manufactured and the manufacturing technique being employed, several equipment are used in pipe fabrication.

How does a pipe machine work?

A pipe machine, often called a tube mill, progressively shapes flat metal sheets or strips into a cylindrical shape by passing the material constantly through many pairs of rollers. The metal sheets’ edges are joined by welding to create a seam, which is then sent through a welding machine to produce a continuous weld. After welding, sizing rollers are used to shape and size the tube to the appropriate specifications. After being cut to the necessary length, the tube may next go through additional processing procedures like heating, smoothing, or inspection. Depending on the kind of pipe being made and the particular needs of the producer, the precise procedure and equipment might change.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited