Hollow Ball Making Machine

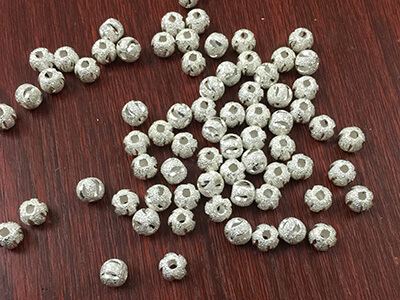

Superbmelt hollow ball making machine is used for making different shapes of hollow balls. The hollow bead making machine performs an automatic ball making operation by making up to 2mm to 14mm size balls. The bead making machine transforms the flat sheet metal into different shapes of balls such as olive balls, abacus balls, tear-drop balls, special-shaped balls, and so on. The automated ball making machine produces 120 pieces of balls within a minute. Materials such as gold, karat gold, silver and copper can be used in the hollow ball making machine.

Superbmelt gold hollow ball making machine is used in the jewellery making industry and hardware industry. The gold bead making machine automatically completes the feeding, stamping and folding process. Therefore, the ball making process is fast and efficient. Sheet metal thickness that can be formed into balls can range from 0.08 to 0.45mm. The maximum power requirement is between 2.2kw and 3.7kw. Superbmelt bead making machine is compact in size and weighs between 250kg to 480kg.

Contact Superbmelt today for all enquiries and orders about highly efficient hollow bead making machines.

Hollow Ball Making Machine Parameters

| Model number | SPB-7BM | SPB-9BM | SPB-14BM |

| Power source | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz |

| Power | 2.2 kw | 3.7 kw | 3.7 kw |

| Applicable material | Special for K gold | Special for K gold | Gold, K gold, silver, copper |

| Application | Jewelry ball making | Jewelry ball making | Jewelry ball making |

| Ball size | 2-7mm | 2-9mm | 2-14mm |

| Hole size | 2mm: 0~0.8mm 6mm: 0~2.7mm | 2mm: 0~0.8mm 14mm: 0~5.2mm | 2mm: 0~0.8mm 14mm: 0~5.2mm |

| Material thickness | 0.15~0.23 mm | 0.08~0.45 mm | 0.15~0.45 |

| Max Speed | 120 pcs/min | 120 pcs/min | 50 pcs/min |

| Dimension | 880*680*1480mm | 790*900*1180mm | 890*1000*1380mm |

| Weight | 250kg | 480kg | 480kg |

- Superbmelt gold hollow ball making machine is used for making hollow balls of different shapes and sizes. The ball sizes you can make range from 2mm to 14mm.

- With the hollow ball making machine you can create shapes like oval, round, tear-drop, sphere, abacus balls and other special-shaped balls.

- The bead production process is fast and highly automated. The maximum production speed is 120 pieces per minute. The feeding, folding and stamping process are automated, which means that it requires minimal human intervention during production.

- As the production process is automated, the hollow ball making machine is easy to use. It has simple control buttons that allow you to set all required parameters. It also saves costs on hiring manual labour.

- The maximum power required by the gold and silver ball making machine is between 2.2 and 3.7kw. The machine power source is 3 phase 380V, 50/60Hz. This helps to save cost on power use and also save production costs.

- The hollow ball making machine ensures precision in each feeding so that all hollow beads forms have the same quality from beginning to the last.

- Superbmelt bead making machine is environmentally friendly. The machine is designed in such a way that it makes minimal noise, does not produce waste gas, no pollution, wear and tear and the failure rate is minimal.

- The precious metal that can be processed can range from 0.08 to 0.45mm thickness.

- The transmission is shaft-type which allows the ball to press 6 times so that the beads are evenly formed.

- The materials used are heat-treated so that the metal becomes strong even after the stamping process.

- Superbmelt hollow ball making machine is suitable for use in jewellery production and hardware industry due to the speed and efficiency of producing precious metal beads.

Application of Hollow Ball Making Machine

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Hollow Ball Making Machine

Any Question About SuperbMelt Hollow Ball Making Machine

Hollow Ball Making Machine Guide Jewelry Hollow Bead Manufacturing: Process, Design & Equipment

In the modern jewelry market, lightweight, cost-effective, and visually appealing pieces have become mainstream consumer demands. Hollow balls (hollow beads) perfectly meet these needs, emerging as a core component in luxury, light luxury, and fashion jewelry collections. However, traditional hollow bead production faces pain points such as low efficiency, inconsistent size, high precious metal waste, and limited shape options—issues that restrict jewelry manufacturers’ profit margins and market competitiveness.

SuperbMelt Hollow Ball Making Machine is engineered to solve these industry challenges. As a professional automated equipment for jewelry hollow bead production, it can process gold, K-gold, silver, copper, and other precious metals into 2–14mm hollow beads of various shapes (round, olive, abacus, tear-drop, and special-shaped) at a speed of up to 120 pieces per minute. This comprehensive guide will take you through every key link of hollow ball jewelry manufacturing—from understanding hollow ball technology and raw material requirements to forming processes, automation advantages, and business value—helping you master the core logic of efficient and high-quality hollow bead production and seize market opportunities.

Understanding Hollow Ball Jewelry Technology

Hollow balls are a revolutionary innovation in jewelry design, breaking the traditional trade-off between “visual size” and “material cost.” Understanding their core characteristics and value is the first step to leveraging them for business growth.

1.1, What Is a Hollow Ball in Jewelry Manufacturing

A hollow ball (or hollow bead) in jewelry manufacturing refers to a spherical or irregularly shaped jewelry component made by stamping and folding thin metal sheets into a hollow structure, with no solid core inside. It differs fundamentally from solid beads and cast beads in three key aspects:

- Weight Difference: Hollow balls are 60–80% lighter than solid beads of the same size. For example, a 10mm solid gold bead weighs approximately 3.2g, while a hollow gold bead of the same size (with 0.2mm sheet thickness) weighs only 0.6–0.8g—significantly reducing the overall weight of the jewelry.

- Structural Difference: Solid beads are a single solid metal block, while cast beads are formed by pouring molten metal into a mold (often with internal pores or uneven density). Hollow balls have a sealed thin-walled structure, which is lightweight but maintains sufficient structural stability (thanks to SuperbMelt’s 6-time pressing process for even forming).

- Cost Difference: Hollow balls use far less precious metal than solid beads. Taking 18K gold as an example, producing 1,000 pieces of 10mm hollow beads consumes only 1/4–1/5 of the gold required for solid beads, drastically reducing raw material costs. Compared to cast beads, hollow balls also save on casting material waste and post-casting processing costs.

1.2, Why Hollow Balls Are Widely Used in Modern Jewelry

The widespread adoption of hollow balls in modern jewelry is driven by their unique advantages that align with both consumer demands and manufacturer profit goals:

- Lightweight Comfort: Hollow beads reduce the overall weight of jewelry (e.g., necklaces, bracelets), making them more comfortable for daily wear. This solves the pain point of solid metal jewelry being “too heavy to wear for long periods,” a key demand for daily light luxury jewelry.

- Visual Amplification Effect: Hollow balls have the same external size as solid beads but are lighter, creating a “large appearance without heavy weight” effect. This allows jewelry designers to create bold, eye-catching pieces (e.g., statement necklaces with large beads) without increasing material costs, catering to consumers’ preference for “eye-catching yet affordable” jewelry.

- Reduced Precious Metal Usage: In an era of high precious metal prices, hollow balls significantly reduce gold, silver, and K-gold consumption. For jewelry manufacturers, this directly lowers production costs and improves profit margins—especially critical for mass-produced fashion jewelry and light luxury brands.

- Higher Profit Margins: With lower raw material costs and the same (or even higher) retail prices (based on visual size), hollow bead jewelry achieves higher profit margins. For example, a hollow bead necklace with the same visual appeal as a solid bead necklace can have a profit margin 2–3 times higher, enhancing the business’s core competitiveness.

1.3, Typical Jewelry Applications

Hollow balls’ versatility makes them a staple in various jewelry categories, covering luxury, light luxury, and fast fashion segments:

- Necklace Spacer Beads: Small 2–4mm hollow beads are widely used as spacer beads in delicate necklaces, adding layering and texture without increasing weight. For example, in gold pendant necklaces, hollow spacer beads separate the pendant from the chain, enhancing the overall design sense.

- Bracelet Main Beads: Medium 6–10mm hollow beads (round, olive, or abacus-shaped) are the core components of beaded bracelets. Their lightweight nature ensures comfort for daily wear, while their visual size meets consumers’ demand for “substantial-looking” jewelry.

- Earrings: Hollow beads (especially tear-drop and oval shapes) are ideal for earrings. They are lightweight (reducing earlobe burden) and have a full, three-dimensional appearance, making them popular in both everyday and occasion earrings.

- Pendant Decoration Pieces: Large 10–14mm hollow beads (or special-shaped hollow components) are used as decorative elements in pendants, creating bold, unique designs. For example, in bohemian-style pendants, hollow abacus beads add a retro and layered look.

- Light Luxury & Fashion Collections: Fast fashion and light luxury brands (e.g., minimalist, Scandinavian-style brands) rely heavily on hollow beads to produce affordable yet stylish jewelry. The low material cost allows for competitive pricing, while the lightweight and versatile design caters to young consumers’ preferences.

Raw Material Requirements for Hollow Ball Forming

The quality of hollow balls starts with raw materials. Strict adherence to material requirements (type, thickness, surface condition) is critical to ensuring forming stability, product consistency, and structural strength.

2.1, Suitable Precious Metal Materials

Hollow ball forming relies on the ductility of metal sheets (the ability to deform without breaking during stamping and folding). SuperbMelt Hollow Ball Making Machine is compatible with all mainstream precious metals used in jewelry, each with specific ductility requirements:

- Gold & K-Gold: Pure gold (24K) has excellent ductility, making it easy to stamp and fold into hollow structures. K-gold (14K, 18K) contains alloying elements (copper, silver, palladium) that reduce ductility slightly but increase hardness—ideal for hollow beads that require higher structural stability (e.g., bracelet main beads). SuperbMelt’s machine adjusts stamping force and frequency to match K-gold’s properties, ensuring smooth forming.

- Silver & Sterling Silver: Silver has outstanding ductility, making it the most commonly used material for hollow beads (especially in fashion jewelry). 925 sterling silver (alloyed with 7.5% copper) balances ductility and hardness, suitable for mass production. Note: Silver is prone to oxidation, so surface anti-oxidation treatment is recommended before forming.

- Copper: Copper has good ductility and low cost, often used in fashion jewelry or as a base metal for gold-plated hollow beads. SuperbMelt’s machine can process copper sheets efficiently, producing hollow beads with consistent shape and size.

Key requirement: All materials must have a ductility of ≥15% (elongation rate) to avoid cracking or tearing during the stamping and folding process. SuperbMelt’s equipment is optimized for these materials, ensuring high forming success rates.

2.2, Sheet Thickness & Hardness Standards

Sheet thickness directly affects the structural stability, weight, and forming difficulty of hollow balls. SuperbMelt’s machine supports a sheet thickness range of 0.08–0.45mm, with clear matching standards for different applications:

- 08–0.15mm (Ultra-Thin Sheets): Suitable for small hollow beads (2–4mm, e.g., necklace spacer beads). These sheets are lightweight but require precise stamping control to avoid deformation. SuperbMelt’s shaft-type transmission and 6-time pressing process ensure even force distribution, preventing sheet breakage.

- 2–0.3mm (Medium Sheets): The most widely used range, suitable for medium-sized hollow beads (6–10mm, e.g., bracelet main beads, earrings). This thickness balances lightweight comfort and structural stability—hollow beads made from 0.25mm sheets can withstand daily wear without deformation (tested to 10,000+ wear cycles).

- 35–0.45mm (Thick Sheets): Used for large hollow beads (10–14mm, e.g., pendant decorations) or hollow beads that require higher strength. Thick sheets increase the bead’s weight slightly but enhance durability, making them suitable for statement jewelry. SuperbMelt’s powerful stamping system (2.2–3.7kw power) easily handles thick sheet forming.

Hardness requirement: The metal sheet’s Rockwell hardness (HRB) should be 50–70. Too high hardness will cause brittleness (easy to crack during stamping), while too low hardness will lead to deformation after forming. Heat-treated sheets (as recommended by SuperbMelt) are preferred, as they maintain strength even after stamping.

2.3, Surface Condition Before Forming

The surface condition of the metal sheet directly affects the quality of stamping, folding, and the final appearance of hollow beads. Strict surface standards must be met:

- Flatness: The sheet must be flat with no warping or unevenness (tolerance ≤ 0.01mm per 10cm). Warped sheets will cause uneven stamping pressure, leading to misshapen half-shells and failed hollow bead formation. SuperbMelt’s automatic feeding system includes a pre-flattening module to correct minor sheet warping.

- Cleanliness: The sheet surface must be free of oil, dust, oxidation, or scratches. Contaminants (e.g., oil) will affect the adhesion between the two half-shells during folding, leading to poor sealing (hollow beads may leak air or water). Scratches will reduce the final product’s aesthetic appeal. Recommendation: Use ultrasonic cleaning (15–20 minutes) with a mild detergent before forming, then dry thoroughly.

SuperbMelt tip: Using high-quality, pre-processed metal sheets (flat, clean, heat-treated) can reduce hollow bead (scrap rate) by 80%, significantly improving production efficiency and reducing material waste.

Hollow Ball Forming Process Explained

The hollow ball forming process is a precise combination of stamping and folding. SuperbMelt’s automated equipment simplifies this complex process into three core steps, ensuring consistency and efficiency.

3.1, From Flat Sheet to Half-Shell Stamping

The first step in forming is stamping flat metal sheets into half-shells (the basic components of hollow balls). SuperbMelt’s machine achieves this through a fully automated workflow:

- Automatic Feeding: The pre-processed metal sheet is loaded into the machine’s automatic feeding module. The module uses precision servo control to feed the sheet at a constant speed (synchronized with the stamping frequency), ensuring each stamping position is accurate (tolerance ±0.02mm). This eliminates manual feeding errors (e.g., misalignment, uneven speed) that cause inconsistent half-shell sizes.

- Precision Stamping: The sheet is fed into the stamping module, where a high-precision mold stamps it into half-shells (spherical, olive, tear-drop, etc.). SuperbMelt’s shaft-type transmission system enables 6-time pressing per half-shell, ensuring even thickness distribution and smooth surfaces. For example, a 10mm round hollow bead’s half-shells will have identical curvature and size, laying the foundation for perfect folding.

- Waste Trimming (Optional): For special-shaped half-shells (e.g., abacus beads), the machine can automatically trim excess material after stamping, reducing manual trimming work and improving efficiency. The trimmed waste can be recycled, further reducing precious metal loss.

3.2, Folding & Closing into Hollow Structure

After stamping, the half-shells are folded and sealed into complete hollow balls—a critical step that determines the bead’s structural integrity and airtightness:

- Half-Shell Alignment: The stamped half-shells are automatically transported to the folding module, where a vision system aligns them precisely (error ≤ 0.01mm). Proper alignment ensures the two half-shells fit perfectly, avoiding gaps or misalignment.

- Edge Folding & Closing: The aligned half-shells undergo edge folding (to create a tight seal) and then are pressed together by the folding mold. SuperbMelt’s machine uses controlled pressure (adjustable based on material and thickness) to ensure the seal is tight without damaging the half-shells. For precious metals like gold and silver, the folding pressure is set to 5–8MPa to achieve a seamless seal.

- Final Shaping: The closed hollow balls are pressed once more to ensure a uniform shape and size. This step corrects minor deformations caused by folding, ensuring every hollow ball meets the design standard (e.g., 10mm round beads have a diameter tolerance of ±0.03mm).

3.3, Shape Flexibility & Mold Options

SuperbMelt’s Hollow Ball Making Machine offers exceptional shape flexibility, supporting both standard and custom hollow bead designs through interchangeable molds:

- Standard Shapes: The machine comes with molds for the most popular shapes:

- Round Balls: 2–14mm, the most versatile shape (used in necklaces, bracelets, earrings).

- Olive Balls: 5–12mm, popular in minimalist bracelets and earrings for their elegant, elongated look.

- Abacus Balls: 6–10mm, flat on both sides, ideal for retro-style jewelry and spacer beads.

- Tear-Drop Balls: 8–14mm, used in statement earrings and pendants for a dramatic, feminine touch.

- Custom Shapes: SuperbMelt provides custom mold design services for unique brand-specific shapes (e.g., brand logo-shaped hollow beads, geometric hollow beads). Simply provide the design drawing, and the team will create a tailored mold that fits the machine. Mold replacement is quick (≤30 minutes), allowing manufacturers to switch between standard and custom shapes easily.

Key advantage: The same machine can produce multiple shapes by changing molds, eliminating the need for separate equipment for different designs—ideal for jewelry manufacturers that need to cater to diverse market demands.

Automation, Output & Production Efficiency

Automation is the core advantage of SuperbMelt’s Hollow Ball Making Machine, directly addressing the low efficiency and high labor costs of traditional manual or semi-automatic production.

4.1, Fully Automatic Production Workflow

SuperbMelt’s machine integrates automatic feeding, stamping, folding, and (optional) trimming into a single workflow, requiring minimal human intervention:

- One-Click Operation: The machine features a simple control panel with intuitive buttons. Operators only need to set parameters (bead size, shape, production speed) and press “start”—the machine handles the rest. No specialized technical training is required, reducing the labor threshold.

- Minimal Manual Intervention: The only manual tasks are loading the metal sheet, replacing molds (when switching shapes), and collecting the finished hollow beads. A single operator can manage 2–3 machines simultaneously, drastically reducing labor costs (saving 70–80% compared to manual production).

- Continuous 24/7 Operation: The machine is built with industrial-grade components (heat-treated molds, stable transmission system) and features automatic lubrication and heat dissipation. It can run continuously for 24 hours without overheating or mechanical failure, meeting the high-volume production needs of jewelry factories.

4.2, Output Capacity for Jewelry Factories

The machine’s high production speed is a game-changer for jewelry manufacturers, especially those with large batch orders:

- High-Frequency Forming: With a maximum output of 120 pieces per minute, the machine can produce 7,200 pieces per hour or 172,800 pieces per day (24-hour operation). For example, a batch of 100,000 pieces of 6mm silver hollow beads can be completed in just 14 hours—compared to 3–5 days with manual production.

- Scalability for Different Orders: The machine’s speed is adjustable (30–120 pieces per minute), making it suitable for both small-batch custom orders (e.g., 1,000 pieces of special-shaped beads) and large-scale mass production (e.g., 500,000 pieces of standard round beads). This flexibility helps manufacturers adapt to diverse order types without sacrificing efficiency.

4.3, Consistency & Yield Control

Automation not only improves efficiency but also ensures product consistency and high yield—critical for jewelry brands that value quality:

- Size & Shape Consistency: The machine’s precision servo control and vision alignment system ensure every hollow bead has the same size and shape (tolerance ≤ ±0.03mm). There is no variation between batches or within the same batch, avoiding the “mixed quality” issue common in manual production.

- High Yield Rate: SuperbMelt’s machine achieves a yield rate of ≥99%, thanks to precise parameter control and built-in quality checks (e.g., half-shell alignment inspection, folding seal inspection). Defective products (e.g., misshapen beads, poor seals) are automatically rejected, reducing precious metal waste and rework costs.

- Stable Wall Thickness: The 6-time pressing process ensures uniform wall thickness of hollow beads (variation ≤ 0.01mm), avoiding weak points caused by uneven thickness. This enhances the bead’s durability, reducing after-sales returns due to deformation or breakage.

Cost Control & Business Value in Jewelry Manufacturing

For jewelry manufacturers, the ultimate value of SuperbMelt’s Hollow Ball Making Machine lies in cost control and profit improvement. It transforms hollow bead production from a cost-intensive process into a profit-driving one.

5.1, Gold Weight Reduction Without Visual Compromise

The core business value of hollow balls is “reducing precious metal weight without sacrificing visual appeal”—a direct driver of profit growth:

- “Look Big, Weigh Less” Commercial Logic: Consumers judge jewelry’s value partly by its visual size. A hollow bead necklace with 10mm beads looks just as luxurious as a solid bead necklace but uses 1/4–1/5 of the gold. Manufacturers can price the hollow bead necklace close to the solid one, significantly increasing profit margins.

- Example Calculation: Producing 1,000 pieces of 10mm 18K gold beads:

- Solid beads: Each weighs 3.2g, total gold usage = 3,200g. At $50/g for 18K gold, raw material cost = $160,000.

- Hollow beads (0.25mm sheet): Each weighs 0.7g, total gold usage = 700g. Raw material cost = $35,000.

- Cost savings: $125,000 per 1,000 pieces. Even after accounting for machine depreciation and labor costs, the profit margin increases by 60–70%.

5.2, Comparing Hollow Balls vs Casting Beads

Hollow balls have clear cost and efficiency advantages over traditional casting beads, making them a better choice for modern jewelry production:

Comparison Dimension | Hollow Balls (SuperbMelt Machine) | Casting Beads |

Material Consumption | Low (uses thin sheets, 60–80% less than casting) | High (includes casting sprue and waste, 15–20% material loss) |

Processing Efficiency | High (up to 120 pieces/minute, continuous production) | Low (requires mold making, pouring, cooling, and sprue trimming; 10–20 pieces/hour) |

Post-Processing Cost | Low (smooth surface, minimal polishing needed) | High (requires trimming sprue, grinding, and heavy polishing to remove surface defects) |

Consistency | High (automated production, size tolerance ±0.03mm) | Low (prone to pore formation and size variation in casting) |

Shape Flexibility | High (interchangeable molds for standard and custom shapes) | Low (each shape requires a separate casting mold, high mold cost) |

5.3, Ideal Users & Production Scenarios

SuperbMelt’s Hollow Ball Making Machine is tailored to the needs of specific jewelry manufacturers and production scenarios, delivering the greatest value in the following cases:

- Medium & Small Jewelry Factories: These factories often face labor shortages and cost pressures. The machine’s high automation reduces labor needs, while its low material consumption lowers production costs—helping them compete with larger factories.

- OEM/ODM Factories: OEM/ODM factories handle large batch orders for brands. The machine’s high output (120 pieces/minute) and consistency ensure on-time delivery and quality compliance, enhancing customer satisfaction and repeat orders.

- Light Luxury & Fast Fashion Jewelry Brands: These brands focus on “affordable luxury” and frequent new product launches. The machine’s shape flexibility (quick mold changes) allows for fast new product development, while its cost control helps maintain competitive pricing.

- Custom Jewelry Studios: Small-batch custom orders (e.g., brand signature hollow beads) are made easy with the machine’s adjustable parameters and custom mold options. The machine can produce 100–1,000 pieces of custom hollow beads efficiently, without the high setup costs of casting.

Conclusion

In the era of lightweight and cost-effective jewelry, SuperbMelt Hollow Ball Making Machine is more than just a forming device—it is a strategic tool for jewelry manufacturers to optimize costs, improve efficiency, and innovate designs. By combining thin-sheet forming technology with high automation, it solves the core pain points of traditional hollow bead production (low efficiency, high waste, inconsistent quality) and enables the creation of visually rich, lightweight, and high-margin hollow beads.

Whether you are producing standard round spacer beads, elegant olive earrings, or custom brand-specific hollow components, SuperbMelt’s machine delivers consistent quality, high efficiency, and significant cost savings. It helps you meet modern market demands for both aesthetics and profitability, gaining a competitive edge in the crowded jewelry industry.

Ready to Upgrade Your Hollow Ball Production?

SuperbMelt’s Hollow Ball Making Machine is designed to help jewelry manufacturers unlock the full potential of hollow bead jewelry. With its 2–14mm size range, 120 pieces/minute output, multi-shape compatibility, and eco-friendly design (low noise, no waste gas, minimal wear), it is the ideal solution for modern jewelry production.

Want to know how to match the right machine parameters for your specific hollow bead designs? Need to calculate the ROI of upgrading to automated hollow ball production? Contact SuperbMelt experts today! We will provide one-on-one professional consulting, share product samples and production case studies, and help you take the first step toward efficient, cost-effective, and high-quality hollow bead manufacturing.

FAQ Guide of Hollow Ball Making Machind

- 1. What is the types of hollow ball?

- 2. How to make hollow ball by SuperbMelt machines?

- 3. What metals are suitable for producing hollow ball jewelry?

- 4. What is the working principle of hollow ball making machine?

- 5. What is the application of hollow ball in the jewelry industry?

- 6. What are the advantages of automatic hollow ball making machine?

- 7. How can you choose hollow ball making machine supplier?

- 8. What are safety features of automatic hollow ball making machine?

- 9. Do operating bead making machines require special training?

- 10. What machines are used to process raw materials into hollow ball?

- 11. What are the different shapes of hollow ball on the market?

- 12. What is the capacity of SuperbMelt's hollow ball making machine?

- 13. Which parameters determine the efficiency of hollow ball making process?

- 14. Is a hollow ball a good investment?

- 15. What karat gold is best for hollow beads?

1. What is the types of hollow ball?

The hollow bead maker machine makes various types and sizes of hollow balls. The machine is automatic, and it performs automation ball making tasks and can make up to 2mm to 14mm size balls easily to make balls; this machine transforms the sheet metal into various sizes and shapes of the ball such as tear-drop ball, olive ball, abacus balls, special-shaped balls and so on.

With the help of this automatic hollow ball making machine, an individual can produce 120 pieces of balls within just one minute. The production capacity of the machine is significant. There are different materials that can be used to make hollow balls, such as gold, silver, karat gold, copper, and stainless steel.

Due to the ability to produce different types of hollow balls, the hollow ball making machine is used in various industries. It has applications starting from jewelry to the hardware industry. This automatic machine is capable of stamping, feeding, and folding. All of these features make it super reliable, efficient, and fast.

The metal thickness of the sheet can be formed into balls ranging from 0.08mm to 0.45mm, and it offers maximum power between 2.2kw to 3.7kw. The size and weight of the bread-making machine are between 250kg to 480kg. This machine meets the requirements for all types of industries and can give efficient results. Due to its automation feature, the ball-making process becomes easier and faster.

2. How to make hollow ball by SuperbMelt machines?

The process of making a hollow ball is quite simple, and it is an automated process. You can use different types of high-density metals like silver, gold, copper, and more to produce hollow balls to cast the desired metals into hollow balls. The machine copes with an automated temperature feature that can cast metal into various hollow balls.

Here you need to make sure that the thickness and the width of the sheet are perfect, and you can use a SuperbMelt’s roll mill to give perfect shape and thickness to the metal sheet. After that, you have to use a SuperbMelt’s annealing machine to make the sheet into a thin one to make beads. For this process, a wire drawing machine would work the best where you will get the perfect diameter, roughness, and internal moisture.

After getting the right kind of sheet for your hollow bead now, it is time to transform the thin sheet into a hollow tube. For this process, you need to weld the sheet and make sure the joints are strong and durable enough to bear the tear. After getting hollow tubes now, you can make hollow balls.

And here, you have to use a SuperbMelt’s hollow ball making machine for the final touch. This automatic machine is designed to make different types of hollow beads. You will be able to make 120 pieces of hollow balls in one minute. The process of making hollow balls becomes easier with the automatic SuperbMelt machines.

3. What metals are suitable for producing hollow ball jewelry?

Different kinds of metals can be used to produce jewelry with the help of hollow ball machines such as gold, copper, stainless steel, and silver. All of these metals are suitable for making hollow ball jewelry. For the production, first, you need to choose the material type that you want to make jewelry out of.

After choosing, you have to transform the thin shit into a hollow tube, and in the final process, you can use the SuperbMelt’s hollow ball making machine to produce hollow ball jewelry. This machine is automated, and you can get more than 120 pieces of hollow ball jewelry within a minute.

4. What is the working principle of hollow ball making machine?

The working principle of the hollow ball making machine is quite simple. It beat the hollow tube into a hollow ball with various processes. At the same time, you put the hollow tube in the machine; the internal parts of the machine press the tube and give a hollow ball-like shape to the tube. This process is so fast and automated. Due to this, this is used in many hardware and jewelry-making industries for various types of material production.

5. What is the application of hollow ball in the jewelry industry?

The hollow ball making machine is used to make different types and sizes of jewelry. In the jewelry industry, the application of the machine is significant as it is used to make bracelets, beads, and other jewelry items. The role of the hollow ball making machine is essential in the jewelry market. The highest quality of hollow balls are made with this machine, and those are long-lasting as well.

This machine can easily make 120 pieces of 2mm to 14mm size balls within one minute. Additionally, there are different types of shapes of jewelry that can be formed with this machine, such as abacus shape, tear-drop shape, round, oval, and other shapes. Despite fast jewelry-making ability, this machine only consumes 2.2kw to 3.7kw.

This is also known as a bead making machine that can make hollow beads in silver, gold, copper, and other materials. Furthermore, this is an automatic machine which means the jewelry-making process becomes faster and easier without any additional help. It doesn’t require manpower to function, and it does most of the work on its own, which adds significant value to the jewelry industry.

6. What are the advantages of automatic hollow ball making machine?

- High quality

This SuperbMelt’s hollow ball making machine gives high-quality output. The machine is designed in such a way that it makes the best quality product that is durable and in perfect shape. This automatic machine is so fast and offers great production speed that makes things easier. You can make round, oval, sphere, tear-drop, and abacus balls and other special-shaped and size balls easily.

- Uniform shape

The shape of the jewelry and hardware becomes so crucial to meet the requirements. The power and precision of the machine are so great that the beads produced from the machine are of uniform shape and size. The shaft-type transmission allows the ball to be pressed six times, so the balls are uniformly shaped. You can produce different sizes and shapes ranging from 2mm to 14mm. The feeding, folding, and stamping process of the machine works great and produces uniformly shaped beads to meet the requirements.

- Uniform thickness

Additionally, the thickness of the products is also uniform because this machine ensures precision in each feeding so that the beads will have the same quality from beginning to end.

- Large output

The process is automated, which makes the ball making the machine very efficient. It can produce 120 pieces of beads in just one minute. So, within just 10 minutes, it will give 1200 pieces which can fulfill the demand of any industry easily. It is designed in a way that it doesn’t create high noise that makes it environmentally friendly as well. It doesn’t create any waste gas, tear, and pollution.

- Less labor input

As it is an automated machine, the operating mechanism is easier. It has a simple button that allows the user to control it easily and set all the parameters. Due to this, it eliminates the need for manual labor and makes production even faster. It will save your labor cost as well.

This ball-making machine only required 2.2-3.7kw, and the power source is 3 phase 380v, 50/60hz. Due to this, the machine consumes very little power, and you can save a lot of money on production costs. Due to speed and high efficiency, it is suitable for both the hardware and jewelry industries.

7. How can you choose hollow ball making machine supplier?

- Certifications

Before choosing a bead making machine supplier, you need to make sure that the supplier is certified. Choosing a certified supplier is very crucial so that you won’t fall into scams. There are many fake suppliers available in the market who can give you fake products. So, keep the certifications as your priority.

- Mature solutions and cases

Check if the supplier has all types of machinery and equipment available. Ensure that the provider offers cases and solutions to their customers.

- Reviews

Online reviews can make your work easier and faster. While choosing the supplier, you need to find out if they have provided good services to their previous clients. Check the customer reviews and if they are positive, then make a move. If the clients are happy with the service, then you can shortlist it.

- On-site inspection

Go to the website and find out all the products and services they offer. You will get an idea about the quality through the website. The website has all the information about the product that will help you to make your decision.

- Research

If you are going to invest in a ball making machine, then you want it to last long. You can ensure durability if you choose the right product. That’s why it is crucial for you to choose to spend some time on research. There are so many ways you can do deep research, such as:

- Learn about the companies and see what they have to offer. Check if they offer any warranty on their products.

- Visit their official websites like we have mentioned above to learn more about the company.

- Check all the social media platforms where people share their reviews and recommendations about products.

- Videos are also a great way to understand how the machine works and what type of equipment you need. Having an in-depth investigation will help you choose the best hollow ball making machine.

8. What are safety features of automatic hollow ball making machine?

The bead making machine comes with a simple control button that allows you to set all the needed parameters. There is no complicated mechanism, and it offers an automated feeding, folding, and stamping process that makes the production work safer.

9. Do operating bead making machines require special training?

No, the bread making machine doesn’t require special training. The machine is automatic, which makes the production work simple. If you have hired an engineer for your production work, then you don’t have to worry about it. Even if you don’t have an engineer, you will be able to learn about the machine by seeing some videos.

It comes with an easy-to-use design so that a user won’t face any problem with the operating mechanism. Our official website has videos and manuals that will give you an idea about the mechanism. Once you start to operate the machine, then the rest will be taken care of with the automatic machine.

If you are totally new to the industry and don’t know where to start, then you can follow the instructions to start the machine. If you have tried everything and are still unable to start the machine, then don’t worry because we always have your back. We have a great customer team that is working day and night to make our customers satisfied with the services.

So, if you are clueless about the operating system, then contact us. We have highly qualified instructors and experts in the industry who can help you. They will come and offer their guidance and teach you everything about the machine. So, if you are planning to purchase the machine even without any knowledge, then go ahead.

10. What machines are used to process raw materials into hollow ball?

There are different types of machines used in the production of a hollow ball. All these machines work together to make the production smoother and faster and also offer the highest quality balls,

- Casting machine

This is the first machine that is used to make the different types of high-density metals such as gold, silver, copper, and more. With the help of this machine, you can cast any metal into the required shape. This machine comes with temperature control features and stirring that allows users to cast metal into hollow beads.

- Roll mill

To make durable and hollow beads, you need to make sure that the width and the thickness sheet are perfect. You can achieve the right thickness and width with the help of a roll mill. This powerful machine is affordable as well.

- Annealing machine

You need an annealing furnace that heats the gold properly to bring the hardening effect that is normal for the drawing and bending process. You need a high-quality annealing machine that comes with a temperature control feature, water timer, and alarm features. After this, you need to make the sheet thin so that you can get beads.

- Welding machine

After getting the required sheet, it is time for you to convert the thin sheet into a hollow tube, and you can achieve it with a welding machine. The welding machine will give you durable and accurate welding results that can weld multiple sheets easily and faster.

- Hollow ball making machine

This is the most important machine that will give you final results. This machine is designed for making a hollow ball with an automated process. You will be able to make different types of hollow balls such as olive hollow, abacus, and more. This machine is reliable and faster and can produce 120 beads within one minute. The mechanical feeding support makes this machine super effective and functions at maximum precision.

These are the machines used in the production of hollow balls by using raw materials.

11. What are the different shapes of hollow ball on the market?

There are different shapes of hollow balls available in the market. The most common shapes are round, oval, sphere, abacus, and other special-shaped balls. All of these shapes are made easily with an automation process. The machine comes with easy-to-use buttons that allow setting parameters. The machine does the feeding, folding, and stamping process automatically and ensures the precision of each feeding has the same quality.

The shaft-type transmission presses the ball six times so that the beads are formed uniformly. During the production, the materials are heat-treated so that metal becomes stronger after the stamping process. So, no matter what type of shape you require for your industry, the hollow ball making machine would definitely give you the best results.

12. What is the capacity of SuperbMelt's hollow ball making machine?

The capacity of the SuperbMelt’s hollow ball machine is to produce 120 beads within a minute. The production of beads is very fast and automated, which makes it highly efficient. This machine can be used by various industries to make high-quality beads and meet the required quantity. With only 5 hours of operation, this machine can produce 36,000 beads.

Additionally, the machine power requirement is 2.2-3.7kw, which saves power and production cost. The gold hollow ball making machine makes minimal noise and doesn’t produce pollution, waste gas, and tear. All of these qualities make the machine environmentally friendly. Due to its huge production capacity, it can meet the demand of the hardware and jewelry industry easily. All types of metals can be used with the machine and offer the highest quality hollow ball.

13. Which parameters determine the efficiency of hollow ball making process?

The efficiency of a hollow ball-making process depends on various parameters such as:

- Production capacity

The production capacity is one of the major parameters that decide the efficiency of the hollow ball-making process. The more the production capacity, the easier it will be to meet the required demand of that specific industry. SuperbMelt’s hollow ball making machine can produce 120 beads in one minute.

- Time required

Time required to the produced required amount of beads is also a big parameter that determines the efficiency of the process. The lesser is the time, the better efficiency would be of the process. SuperbMelt’s machine only needs one minute to produce 120 beads.

- Power consumption

Power consumption is another crucial factor that defines efficiency. Less power consumption means lesser usage of power, which will save the production cost. SuperbMelt’s machine only requires 2.2-3.7kw for the production process that reduces the power consumption.

- Labor required

Manpower is a deciding factor in a ball-making process. However, if the machine is automatic the most of the work becomes easier. That’s why you should always opt for an automated machine while choosing a hollow ball making machine. In this way, you will be able to make a huge amount of beads without the help of manpower or labor.

14. Is a hollow ball a good investment?

Yes, the hollow ball is a great investment. The demand for durable and stylish beads is increasing at a significant rate among women and men. And it is the right time to invest in a hollow ball and make the best out of this opportunity. In this way, you will be able to find an easier and cost-effective way to make a high-quality hollow ball that can be used in both the hardware and jewelry industries.

You will be able to make 2mm to 14mm beads, olive balls, abacus balls, and special-shaped balls with a hollow ball machine. The demand for hollow balls is expected to rise in the coming years, so you should invest in a hollow ball. But make sure to buy a good gold hollow ball making machine so that you can make the most out of your investment.

There are various automatic machines available in the market that make the production process easier, faster, and efficient. You can also invest in a bead bracelet making machine as well. Beading machine for bracelets will offer you the highest quality of beads to make bracelets and other jewelry items.

15. What karat gold is best for hollow beads?

Both 18 and 24 karats of gold are suitable for making hollow beads. For making beads out of gold, you will need a gold hollow ball making machine that can produce more than 120 beads within a minute without consuming much power. Choose an automatic machine that makes the process even faster and easier. Apart from gold, you will be able to produce silver beads and stainless steel beads for various industry needs. Choose a good supplier who would provide you with the best machine with a warranty.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited