Gold Melting Machine 1kg

SuperbMelt 1kg Melting Furnace: The Optimal Choice for Small Jewelry Businesses

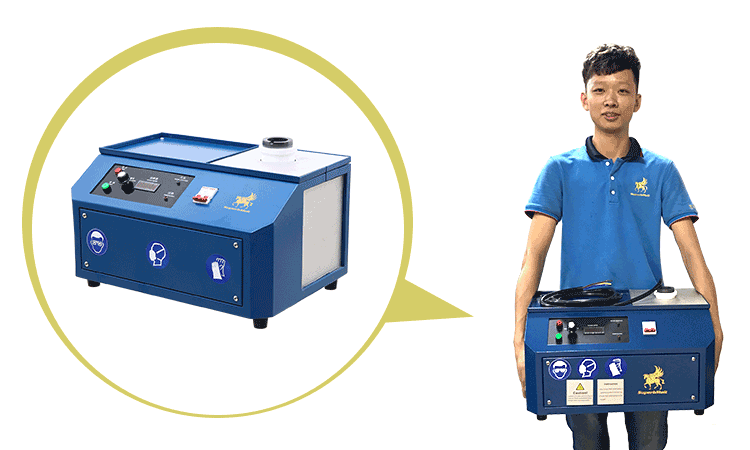

SuperbMelt 1kg Gold Melting Machine is specially designed for small jewelry studios, gold shops, and DIY jewelry makers who need professional melting performance in a compact desktop unit.

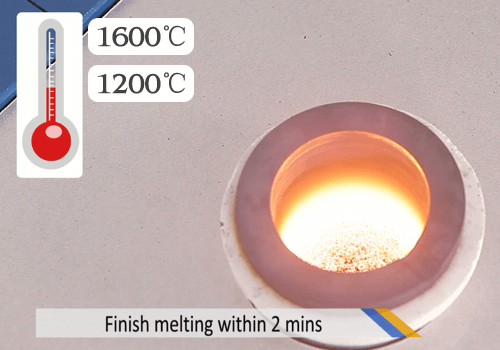

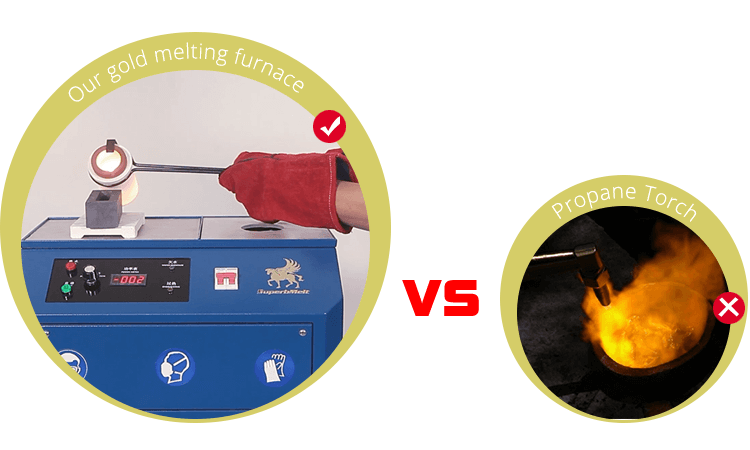

With a powerful heating system reaching up to 1600°C, this 1kg gold melting machine melts 1–2kg of gold or silver in just 2–5 minutes, helping you complete casting, refining, and recycling tasks with maximum speed.

Thanks to its durable design, the machine supports 24-hour continuous operation, ensuring higher productivity and stable performance even during peak workloads.

Its compact footprint saves valuable workspace, and the simple, user-friendly interface makes it easy for beginners and professionals alike.

If you want a high-efficiency, space-saving, and professional Gold Melting Machine 1kg, SuperbMelt gives you the perfect solution to elevate your jewelry production.

| Model number | SPB-DH1 | SPB-DH2 |

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm |

| Weight | 21 kg | 22 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

- Desktop Design: Compact and practical, suitable for small spaces.

- High Temperature: Reaches up to 1600°C for rapid melting.

- Quick Melting: Melts 1kg of gold or silver in approximately 2-5 minutes.

- Continuous Operation: Can run continuously for 24 hours to increase output.

- Durable Construction: Built to last with reliable performance.

- Energy Efficiency: Reduces energy usage without compromising functionality.

- Safety Features: Includes safety measures to protect users and ensure reliable operation.

- Fast Melting: Achieves melting in 1-2 minutes.

- Compact but High Capacity: This small furnace can melt batches of 1-2kg.

- Increased Productivity: Quick melting times and continuous operation improve efficiency.

- Versatility: Suitable for melting various metals, including gold and silver.

Jewelry retailers and DIY enthusiasts can use the SuperbMelt 1kg Gold Melting Machine to effectively manage their jewelry processing tasks in a simple, safe, and accurate manner.

Jewelry Manufacturing:

Ideal for small jewelry workshops and factories.

Used for melting gold, silver, and other precious metals to create rings, necklaces, bracelets, and other jewelry pieces.

Jewelry Retail:

- Useful for retail stores offering custom jewelry services.

- Allows for on-site melting and crafting of custom pieces to meet specific customer demands.

DIY Enthusiasts:

- Perfect for hobbyists and artisans who create jewelry at home.

- Enables precise and safe melting of metals for various DIY projects.

Prototyping and Small Batch Production:

- Suitable for rapid prototyping and small-scale production runs.

- Helps designers and craftsmen quickly melt and test new designs.

Research and Development:

- Used in R&D labs for studying the properties of melted metals.

- Facilitates experiments and innovations in metalworking techniques.

Educational Institutions:

- Utilized in universities and technical schools for teaching metalworking and jewelry design.

- Provides hands-on experience for students in melting and casting metals.

Gold and Silver Refining:

- Applicable in refining facilities for melting down gold and silver scrap for purification processes.

- Helps in recovering and recycling precious metals efficiently.

Why SuperbMelt 1kg Gold Melting Machine

Any Question About SuperbMelt 1kg Gold Melting Machine

Here's What Our Satisfied Customers Have to Say

SuperbMelt 1kg Gold Melting Machine FAQ

To melt gold, professional equipment such as crucibles, electric or gas furnaces, torches, kilns, induction heating systems, and casting machines are needed. Each type of equipment has its specific use, depending on the scale of operation and the precision required. Essential accessories include graphite or ceramic crucibles, crucible tongs, heat-resistant gloves, and safety goggles. The choice of equipment depends on factors like the amount of gold to be melted, budget, and safety requirements.

Yes, a jeweler can melt gold and create a new ring, necklace, bracelet, or other jewelry by melting old gold, casting it into a mold, and then finishing and polishing the new piece.

Prepare professional smelting furnace equipment (crucible, crucible tongs, protective safety facilities), then place the pre-weighed gold into the equipment for smelting. Note that smelting furnaces come in various capacities. You can contact SuperbMelt sales personnel to send your requirements and receive a customized solution.

- Furnace, crucible, smelting tools, and safety gear should all be set up.

- To clean the gold and get rid of contaminants, use an acidic solution or a cleaning agent.

- Heat the furnace: Raise the temperature inside the furnace to around 1064 degrees Celsius (1947 degrees F).

- Melt the gold by putting the cleaned metal into a crucible and heating it up until it melts completely.

Usually, melting gold requires a temperature of around 1064 degrees Celsius (1947 degrees Fahrenheit). At this temperature, pure gold may melt at its melting point, which is around 1064 degrees Celsius. In order to efficiently melt the gold into a molten condition for further processing or casting into desired forms, the melting machine or furnace must attain and sustain this temperature.

Protective atmospheres or fluxes to prevent oxidation, careful temperature control, and effective handling procedures are used to minimize losses. These losses may be greatly decreased by using expert workers and high-quality melting equipment. When melting gold under regulated circumstances, professional jewelers and refiners often strive for loss rates of less than 1%.

Jewelers often utilize crucibles composed of materials resistant to high temperatures and chemical reactions that occur during melting to melt gold. The crucibles that are most often used to melt gold are as follows:

- 1. Graphite Crucibles: Graphite crucibles are widely used because they are generally inert—that is, they do not chemically react with molten gold—and they can tolerate high temperatures—up to around 3000 degrees Celsius. If properly cared for, they can withstand numerous melts and are long-lasting.

- 2. Silica Crucibles: Gold may also be melted in silica or clay-graphite crucibles. Compared to graphite crucibles, they are less costly, but they may not last as long and could shatter more easily over time.

- 3.Ceramic crucibles, crafted from substances such as zirconia or alumina, may also be used for melting gold. They could be more brittle than graphite crucibles, but they are strong and able to tolerate high temperatures.

- 4. Crucibles with Flux: A flux liner or coating is a particular feature of several crucible designs. Flux may increase the melting process’ efficiency and assist shield the crucible and the molten gold from oxidation.

The quantity of gold being melted, how often it is melted, financial constraints, and the unique needs of the jeweler or refiner all play a role in the crucible selection process. Because of its strength, ability to withstand high temperatures, and little contact with molten gold, graphite crucibles are a popular choice for industrial and small-scale melting processes.

SuperbMelt melting furnaces can melt various precious metals such as gold, silver, platinum, K gold, and palladium gold.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Which Industries Can Benefit From the 1kg Gold Melting Machine: A Complete Guide

Is the 1kg Gold Melting Machine Suitable for Your Industry?

In today’s fast-paced world of industrial production and handcrafted manufacturing, are you looking for equipment that can efficiently melt metals? Do you often feel confused about which melting machine to choose? Today, we will unveil the secrets of the Gold Melting Machine 1kg and explore in depth which industries it is suitable for.

Perhaps you operate a small jewelry shop and are eager to create exquisite, uniquely crafted pieces. Maybe you work in the scientific research field and require precise metal melting for experimental studies. Or you might be a precious metal recycling professional hoping to improve efficiency and reduce costs. No matter which industry you belong to, as long as metal melting is involved, the Gold Melting Machine 1kg could become your reliable assistant.

Among the many melting devices available, choosing the right Gold Melting Machine 1kg is crucial. Different melting machines vary significantly in melting temperature and operation modes. In terms of temperature, some low-quality devices may not reach the precise melting points required by certain metals, leading to incomplete melting, residue of impurities, and compromised final product quality. The Gold Melting Machine 1kg, however, features highly accurate temperature control technology and can consistently reach the high temperatures needed for various metal types, ensuring complete melting and purity.

From an operational perspective, complicated and cumbersome procedures not only increase labor and time costs but also raise the risk of errors during operation. The Gold Melting Machine 1kg fully considers user experience with its simple and intuitive interface and workflow. Even beginners can quickly learn and operate it efficiently. Additionally, it is designed and optimized to meet the characteristics and needs of different industries—whether it is the highly detailed jewelry manufacturing sector or high-efficiency industrial production—making it a perfect fit.

Choosing the Ideal Melting Equipment

When choosing a melting machine, it’s safe to say we all share the same expectations. Efficiency is one of the key goals we pursue. Who wouldn’t want to complete metal melting in a short time, boost production efficiency, and turn every second into real output? Whether it’s a company rushing to meet urgent orders or researchers with limited time, an efficient melting machine can save a significant amount of time and create greater value.

Precision is equally essential. Accurate temperature control ensures that metals are heated precisely to their optimal melting points, preventing quality issues caused by overheating or insufficient temperature. In the jewelry manufacturing industry, precise melting guarantees the best color and texture of each piece, meeting consumers’ expectations for high-quality jewelry. In scientific research, precise experimental data depends on precise melting equipment—it is the foundation for exploring new materials and innovative processes.

Safety and stability are also major concerns. During operation, everyone hopes the equipment runs smoothly without unexpected failures that could jeopardize safety or interrupt production. Stable machine performance ensures continuous workflow, reduces maintenance costs and downtime, and keeps business operations running efficiently.

The Gold Melting Machine 1kg is designed exactly with these needs in mind. It excels in efficiency, precision, safety, and stability—making it an ideal choice that fulfills all your expectations for a perfect melting machine.

Carefully Selected: Key Factors in Choosing the Right Melting Machine

3.1, Key Parameters Revealed

In the field of metal melting, temperature is the core factor that determines melting effectiveness. Different metals have different melting points—for example, the melting point of gold is about 1064.18°C, while some rare metals require even higher temperatures. The excellence of the Gold Melting Machine 1kg lies in its ability to stably reach 1600°C, which is sufficient to meet the melting requirements of most common metals as well as certain rare metals. This ensures that the metals are fully melted, laying a solid foundation for subsequent processing steps.

The convenience of operation is equally important. For operators, complicated procedures not only increase the difficulty of operation but also lead to mistakes during the process, affecting both production efficiency and product quality. The Gold Melting Machine 1kg takes this into full consideration and adopts a simple and intuitive operational design. Its interface is clear and straightforward, with well-arranged functional buttons. Operators can easily get started with minimal training, quickly mastering the machine and achieving efficient metal melting operations.

3.2, Different Industries, Different Needs

Different industries have unique requirements for melting equipment due to their production characteristics and product demands. The jewelry industry, known for its pursuit of exquisite craftsmanship and high-quality pieces, requires extreme precision during the metal melting stage. Every piece of jewelry carries the creativity of designers and the meticulous effort of artisans, making accuracy in metal melting crucial. The Gold Melting Machine 1kg, with its precise temperature control and stable performance, ensures that the metal maintains an even temperature throughout the melting process, avoiding localized overheating or underheating. This guarantees the purity and ideal texture of the metal, providing strong support for producing high-quality jewelry. For example, when casting complex jewelry molds, the machine melts the metal precisely to the optimal temperature, allowing the molten metal to smoothly fill every tiny corner of the mold and produce jewelry blanks with rich details and smooth surfaces.

Mining, on the other hand, presents a completely different scenario. Mining operations are large in scale and require high output. In the metal melting phase of mining, equipment must offer high efficiency and large capacity. Although the Gold Melting Machine 1kg melts 1kg per batch, it features fast melting speed and the ability to operate continuously. In actual production, multiple units can be used together to meet the large-scale melting demands of mining operations. Additionally, its stability and durability have been verified in real-world applications, allowing it to run reliably for long periods even in harsh mining environments. This reduces downtime caused by equipment failures, improves production efficiency, and lowers operational costs.

Why Trust SuperbMelt

In the broad field of precious metal processing equipment, SuperbMelt has become a trusted brand thanks to its deep industry expertise. Since its establishment, SuperbMelt has been dedicated to the precious metal equipment industry for more than a decade. Over these years, we have witnessed the industry’s ups and downs, accumulated valuable hands-on experience, and gained deep insight into technological trends and market demands in precious metal processing. From early-stage technology exploration to becoming an industry leader, every step reflects the dedication, innovation, and hard work of the SuperbMelt team.

Our business scope is extensive—not limited to selling precious metal melting furnaces. We also specialize in jewelry casting equipment, gold bar casting machines, and more, providing customers with a complete one-stop equipment procurement solution. In jewelry casting, our equipment supports the production of both simple accessories and highly intricate pieces, helping jewelry brands create stunning, high-quality products. Our gold bar casting equipment offers high precision and high efficiency, enabling precious metals to be cast into standard gold bars that meet the strict requirements of financial markets and industrial production. This comprehensive product lineup allows us to deliver tailored solutions for various customer needs and build a complete, integrated industrial service chain.

Today, SuperbMelt’s equipment has helped establish dozens of jewelry production lines worldwide, spanning companies of all sizes. From small jewelry workshops in Southeast Asia to large-scale jewelry manufacturers in Europe and the United States, our machines play a key role in improving production efficiency and elevating product quality, earning widespread trust and praise. For example, after adopting our jewelry casting equipment, one internationally renowned jewelry brand significantly reduced its defect rate and increased production efficiency by 30%, resulting in substantial economic benefits—and further strengthening SuperbMelt’s reputation in the industry.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited