Electric Rolling Mill Machine

Using a rolling mill simplifies the jewelry-making process for jewelers and improves the overall quality of the finished pieces.

SuperbMelt Jewelers Rolling Mill is specially designed for jewelry casting, primarily used for pressing and forming metal sheets of gold, silver, copper, platinum, and more. It is ideal for creating necklaces, bracelets, rings, and various other jewelry pieces.

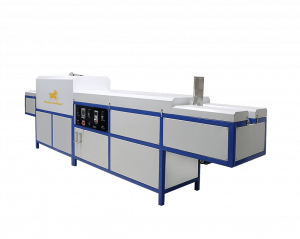

Compared to traditional manual rolling mills, the SuperbMelt rolling mill offers significantly higher efficiency and productivity. With its electric-powered rolling system, it makes mass production of jewelry effortless.

SuperbMelt rolling mills are also customizable, offering options such as double-head rolling mills, continuous rolling mills, and other high-efficiency solutions tailored to meet specific customer requirements.

SuperbMelt Electric Rolling Mill Machine

| Model number | SPB-YX-5P | SPB-YBP-10P | SPB-2YXP-10P | SPB-JM-5.5P |

| Photo |  |  | ||

| Type | 5.5P Sheet Rolling Machine | 10P Four Roller Sheet Rolling Machine | 10P Double-head Rolling Machine | 5.5P Tungsten Steel Sheet Rolling Machine |

| Power source(V) | 380 | 380 | 380 | 380 |

| Power(kw) | 4 | 7.5 | 7.5 | 4 |

| Roller Size(D*L mm) | 105*200 | Large Shaft:180*180;Small Shaft:48*180 | 120*200 | Tungsten Steel 110*80 |

| Max Thickness(mm) | 9 | 0.3 | 11 | 7 |

| Revolving Speed(rpm) | 22 | 0-22 Adjustable Speed | 0-22 double speed | 12 |

| Lubricating System | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply |

| Wire Rolling Size(mm) | / | / | 14-0.8mm (Customized) | / |

| Max Rolling Width | 50 | 100 | 50 | 50 |

| Dimensions(mm) | 530*600*1380 | 250*1020*1520 | 980*650*1450 | 780*540*1470 |

| Weight(kg) | 370 | 820 | 980 | 400 |

| Model number | SPB-YP-10PZQ | SPB-YP-10PZQ-B | SPB-YP-20A | SPB-LY5D |

| Photo |  |  | ||

| Type | 10P Enhanced Sheet Rolling Machine | 10P Automatic Sheet Rolling Machine | 20P Sheet Rolling Machine | 5 Track Continuous Sheet Rolling Machine |

| Power source(V) | 380 | 380 | 380 | 380 |

| Power(kw) | 7.5 | 7.5 | 15 | 7.5 |

| Roller Size(D*L mm) | 140*180 | 140*180 | 200*300 | 120*80 |

| Max Thickness(mm) | 28 | 28 | 30 | 5 |

| Revolving Speed(rpm) | 18 | 0-24 Adjustable Speed | 0-12 | 0-18 |

| Lubricating System | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply |

| Wire Rolling Size(mm) | / | / | / | / |

| Max Rolling Width(mm) | 60 | 60 | 200 | 30 |

| Dimensions(mm) | 1030*715*1350 | 1250*1160*1350 | 1630*770*1640 | 1230*680*1250 |

| Weight(kg) | 700 | 620 | 1800 | 700 |

- Precision Crafting: SuperbMelt rolling mills are engineered with precision, ensuring consistent and detailed results in jewelry production.

- Versatility: These rolling mills are perfect for shaping various metals, including gold, silver, copper, and platinum, making them versatile for jewelry making.

- Increased Efficiency: Compared to traditional manual rolling mills, SuperbMelt rolling mills offer higher efficiency and productivity, thanks to their electrically-powered operation.

- Customization: SuperbMelt provides options for customization, including double-head rolling mills and continuous rolling mills, to meet specific customer needs.

- Quality and Durability: Crafted from high-quality materials, SuperbMelt rolling mills are built to last, ensuring long-term performance and reliability in jewelry manufacturing.

- Professional-Grade Tools: Trusted by artisans and jewelers worldwide, these rolling mills deliver professional-level results in jewelry craftsmanship.

These features and advantages make SuperbMelt rolling mills an ideal choice for jewelry manufacturers, enabling precision, efficiency, and reliability in the production of exquisite jewelry pieces.

SuperbMelt Electric Rolling Mill Machine, are versatile metalworking tools used for shaping, flattening, and texturing various metals, particularly in jewelry production, metalworking, and craftsmanship, offering precision, efficiency, and customization.

Why SuperbMelt Electric Rolling Mill Machine

Any Question About SuperbMelt Electric Rolling Mill Machine

About Guide to the SuperbMelt Electric Rolling Mill Machine

How to Use a Jeweler’s Rolling Mill

Each morning, as you step into your workshop, you simply press the start button on the SuperbMelt electric jewelry rolling mill. Smoothly and effortlessly, it comes to life—no cranking, no strain. Gold, silver, or copper sheets glide between the rollers, thinning evenly with precision. Whether you’re preparing metal for rings, bracelets, or pendants, the process is quick, quiet, and controlled. Compared to manual rolling, it’s faster, more efficient, and far less labor-intensive. The electric mill doesn’t just roll metal—it streamlines your work, enhances consistency, and brings craftsmanship to a new level of ease. It’s a true game-changer for any jeweler looking to save time and improve quality.

| Feature | Electric Rolling Mill | Manual Rolling Mill |

|---|---|---|

| Operation | Motor-driven – no physical effort | Hand-cranked – requires manual strength and endurance |

| Efficiency | High – ideal for batch production | Moderate – better for small jobs or occasional use |

| Speed Control | Adjustable speed settings for precise control | Speed depends on user – less consistent |

| Consistency | Uniform pressure for accurate results | Results can vary depending on force applied manually |

| Fatigue Level | Very low – operator can work longer | High – can be tiring with thicker metals or longer jobs |

| Suitability | Best for professional workshops and mass production | Suitable for hobbyists or low-volume jewelers |

| Cost | Higher initial investment, but long-term time-saving | Lower cost, but more labor-intensive |

1.1,Safe Installation and Operation of a Rolling Mill

Before you power up your rolling mill, it’s important to start with a safe and proper setup. Choose a stable, vibration-free workbench or stand, preferably bolted down to prevent any movement during operation. Make sure the mill is level and the rollers are clean and free from rust or debris. For electric models, connect to a reliable power source with proper grounding

Once installed, always wear protective gear: safety glasses to protect from flying particles, and avoid loose clothing or jewelry that could get caught in the rollers. Check the gap between the rollers before feeding any material, and never force metal that’s too thick

During use, feed the metal smoothly and steadily—never pull with your hands from the other side

After each use, clean the rollers with a soft, dry cloth. Lightly oil the rollers

By following these steps, you not only protect your equipment but also ensure a safe and efficient jewelry-making environment.

1.2, Basic Techniques: Annealing, Multiple Passes, Thickness Control

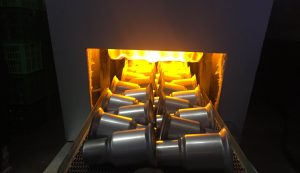

To get the best results from your rolling mill, mastering a few key techniques is essential. One of the most important is annealing. Before rolling, metal should be softened through annealing — a process of heating it to a specific temperature and then letting it cool slowly. This makes the metal less brittle and more malleable, preventing cracks or breakage as it passes through the rollers.

Next, always use multiple passes when reducing thickness. Don’t try to compress your metal in one go — it stresses both the metal and the machine. Instead, roll the metal a little at a time, tightening the rollers gradually with each pass. A good rule of thumb is to reduce thickness by no more than 10% per pass.

Finally, thickness control is critical. Always use calipers or a thickness gauge to measure your metal before and after each pass. This ensures even reduction and helps you achieve the exact dimensions you need for your design. By being consistent and precise, you’ll produce smooth, professional-quality sheets and wires ready for forming, soldering, or setting.

1.3, Common Beginner Mistakes and Solutions

- 1. Mistake: Rolling Without Annealing

Many beginners try to roll hardened metal without annealing it first. This leads to cracking, uneven edges, or broken pieces.

Solution: Always anneal your metal first. Heat it to the appropriate temperature and let it air cool or quench (depending on the metal). Soft metal rolls more easily and safely. - 2. Mistake: Reducing Thickness Too Quickly

Trying to thin the metal in one or two passes can stress the rollers, warp the sheet, or even jam the machine.

Solution: Take your time. Reduce the thickness by no more than 10% per pass, and alternate directions to relieve stress. - 3. Mistake: Forgetting to Clean the Rollers

Dirt, grease, or metal shavings left on the rollers can mark your metal or even damage the rollers themselves.

Solution: Wipe the rollers with a clean, dry cloth after each use. Lightly oil them when storing to prevent rust. - 4. Mistake: Uneven Feeding

Feeding metal at an angle or with too much pressure on one side can result in crooked, warped sheets.

Solution: Always feed the metal straight and centered. If needed, mark the center point of your rollers to guide alignment. - 5. Mistake: Using the Wrong Type of Metal

Rolling unknown or inappropriate metals (e.g., too hard or brittle) can break your equipment.

Solution: Know your material. Use copper, silver, gold, or other metals suitable for rolling, and anneal them when needed. - 6. Mistake: Skipping Lubrication in Wire Rolling

When rolling wire, friction can cause dragging or uneven tension.

Solution: Apply a small amount of lubricant like beeswax to your wire before rolling—it improves glide and protects the rollers. - 7. Mistake: Ignoring

Loose sleeves, jewelry, or hair can get caught in the rollers.

Solution: Always tie back long hair, remove rings and bracelets, and wear fitted clothing when using the machine.

Jewelry Studio Setup with a Rolling Mill

Setting up your jewelry studio begins with choosing the right spot for your rolling mill — ideally on a solid, vibration-free workbench, near a well-lit area where you can easily monitor fine details. The rolling mill should be bolted down securely to prevent any movement during operation. If you’re using an electric model, make sure it’s near a grounded outlet with enough power capacity.

Next, organize your tools nearby: calipers for measuring thickness, annealing torch or kiln, metal shears, and polishing equipment. Position your annealing station (torch and firebrick or kiln) nearby for quick softening between rolling sessions. Keep a designated tray for metal scraps — they’re valuable and can be reused.

To support workflow, arrange your studio into zones: a rolling zone, a forming zone, and a finishing zone with tumblers or polishing wheels. Add safety gear like eye protection and gloves within reach, and label all materials to avoid cross-contamination between metals.

With a rolling mill at the heart of your studio, you’ll find it easier to shape, thin, and texture metal sheets for rings, bracelets, pendants, and more. It’s not just a tool — it’s your gateway to turning raw metal into refined art.

2.1, Essential Equipment List for a Small Jewelry Studio

1. Jeweler’s Rolling Mill

For thinning and texturing metal sheets or wire. A compact electric or manual rolling mill is essential for shaping gold, silver, and copper into the right thickness for rings, pendants, or bracelets.

2. Annealing Torch or Kiln

Used to soften metal (annealing) before rolling or forming. A small propane torch works for most small-scale work, but a kiln is ideal for consistent heating and batch annealing.

3. Digital Caliper

To precisely measure the thickness of metal before and after each rolling pass, ensuring accuracy in every design.

4. 3D Scanner & 3D Printer (Optional for Modern Studios)

Useful for custom jewelry design. Programs like Rhino or MatrixGold paired with a resin or wax 3D printer allow you to create detailed models for casting.

5. Soldering Station

Includes a soldering torch, fireproof brick, flux, and tweezers. Essential for joining metal components in ring bands, chains, or prong settings.

6. Polishing Tools

Magnetic tumblers, rotary polishers, or even hand-held polishing wheels help give your jewelry a clean, professional finish.

7. Safety Gear

Don’t skip this! Eye protection, gloves, dust masks, and proper ventilation are key to a safe working space.

8. Workbench with Bench Pin

A sturdy, dedicated work surface with a bench pin for sawing, filing, and shaping. Often the heart of the jewelry studio.

9. Ultrasonic Cleaner

Used for cleaning finished pieces and removing polishing compounds or dirt from fine crevices.

10. Storage for Tools and Materials

Trays, bins, and labeled containers keep everything organized—from gemstones and wire to pliers and files.

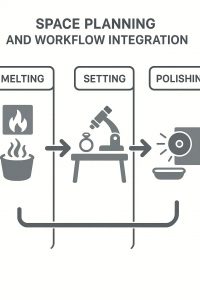

2.2, Space Planning and Workflow Integration (Melting, Setting, Polishing)

A well-designed jewelry studio arranges its workspace into distinct zones to optimize workflow and efficiency. The melting area, equipped with induction furnaces and casting machines, is placed in a fire-safe, well-ventilated section. Adjacent to this, the stone setting zone features a sturdy workbench, precise lighting, and setting tools to ensure accuracy and comfort. The polishing and finishing area houses tumblers, ultrasonic cleaners, and plating baths, ideally near water sources and ventilation systems. Organizing the studio in a linear or U-shaped layout—from melting, to setting, to polishing—minimizes movement, improves productivity, and maintains a clean, safe working environment.

2.3, The Core Role of a Rolling Mill in the Studio

The rolling mill plays a fundamental role in a jewelry studio by enabling precise thinning, shaping, and texturing of metal sheets and wires. It allows jewelers to reduce metal thickness uniformly, create consistent textures, and prepare materials for further forming or setting. By providing accurate control over metal dimensions and surface finishes, the rolling mill is essential for producing high-quality rings, bracelets, necklaces, and other fine jewelry components efficiently and reliably.

Professional Tips: Advanced Techniques with Rolling Mills

A rolling mill helps shape and thin metal sheets or wires by passing them through rollers. To keep the metal from breaking, jewelers often heat (anneal) it between passes to make it softer. Instead of thinning all at once, they roll the metal several times gradually for better control. Sometimes, they turn the metal between rolls to get an even finish. Rolling mills can also add patterns or textures using special rollers. Measuring thickness after each roll ensures accuracy. Using lubricant helps protect the metal and the machine. Always remember to follow safety rules to avoid accidents. These simple steps help make high-quality jewelry efficiently.

3.1, Creating Embossed Textures, Composite Metals, and Pattern Imprinting

Creating embossed textures, composite metals, and pattern imprinting involves using a rolling mill equipped with special rollers or plates. Embossing adds raised or recessed designs on metal surfaces, enhancing jewelry’s visual appeal. Composite metals are made by layering or bonding different metals together, then rolling them to create unique patterns and color effects. Pattern imprinting uses engraved rollers or plates to press detailed designs onto metal sheets or wires, allowing for consistent decoration across multiple pieces. These techniques expand creative possibilities and add value to finished jewelry products.

3.2, Enhancing Personalized Jewelry Value with a Rolling Mill

A rolling mill is a powerful tool for creating personalized jewelry that stands out. By enabling precise shaping, thinning, and texturing of metals, it allows artisans to add unique patterns, custom textures, and layered metal effects. This level of detail enhances the beauty and individuality of each piece, increasing its perceived value. With a rolling mill, jewelers can efficiently produce high-quality, customized designs that appeal to customers seeking one-of-a-kind jewelry.

3.3, Combining with Laser Engraving, 3D Printing, and Other Techniques

Combining a rolling mill with laser engraving, 3D printing, and other advanced techniques allows jewelers to create highly detailed and customized pieces. The rolling mill provides precise metal shaping and texturing, while laser engraving adds intricate patterns and fine details that are difficult to achieve manually. Meanwhile, 3D printing enables the production of complex models and molds for casting. Together, these technologies enhance creativity, improve efficiency, and enable the production of unique, high-quality jewelry that meets modern design demands.

FAQ Guide of Jewelers Rolling Mill Used

- 1. What is 4 high rolling mills?

- 2. What is the best rolling mill?

- 3. What is 6 high rolling mill?

- 4. What are the disadvantages of a 4-high rolling mill?

- 5. How do I choose a rolling mill?

- 6. Is a two roll mill better than a three roll mill?

- 7. What is jewelry rolling machine?

- 8. Do you need a rolling mill for jewelry?

- 9. How do I choose a rolling mill?

- 10. What is the purpose of rolling machine?

1. What is 4 high rolling mills?

A 4-high rolling mill is a type of rolling mill with four rolls in two pairs, which can be arranged in various configurations. This setup allows for greater precision and control in shaping and reducing the thickness of metal sheets or wire. It is commonly used in metalworking, including in the production of sheet metal, foils, and wire, to achieve desired thickness and surface finish.

2. What is the best rolling mill?

The best rolling mill depends on the specific needs and requirements of the user. Some popular and well-regarded rolling mill brands in the market include Durston, PepeTools, and SuperbMelt. To determine the best rolling mill, one should consider factors like the type of materials to be rolled, the desired features (such as the number of rolls, width capacity, and the ability to create specific textures), and the budget. It’s advisable to research and compare different brands and models to find the one that suits your individual needs.

3. What is 6 high rolling mill?

A 6-high rolling mill is a type of rolling mill with six rolls in two sets of three rolls. This configuration allows for greater precision and control in the rolling process, particularly in terms of reducing the thickness of metal sheets and achieving desired surface finishes. 6-high rolling mills are commonly used in industries such as metalworking, steel manufacturing, and aluminum production, where precise thickness control and a high degree of flatness are essential for the final product.

4. What are the disadvantages of a 4-high rolling mill?

Limited Thickness Reduction: 4-high rolling mills may have limitations in achieving extremely high levels of thickness reduction compared to other types of rolling mills like the 6-high or 20-high mills.

Reduced Surface Finish: Achieving a very smooth surface finish can be more challenging with a 4-high mill, particularly when rolling materials with intricate patterns or textures.

Roll Deflection: In some cases, 4-high mills can experience roll deflection, which may affect the precision of the rolling process, especially when working with thicker materials.

Complex Setup: The setup and adjustment of the rolls in a 4-high rolling mill can be more complex compared to simpler mills, potentially requiring more time and effort.

Cost: These mills can be relatively expensive, and their complexity may lead to higher maintenance and operating costs.

It’s important to note that the specific disadvantages of a 4-high rolling mill can vary depending on factors such as the design and quality of the mill, the materials being processed, and the operator’s skill and experience. Despite these potential disadvantages, 4-high rolling mills are widely used in various industries and offer many advantages in terms of precision and control.

5. How do I choose a rolling mill?

Choosing a rolling mill involves considering several factors to ensure it meets your specific needs. Here’s a guide on how to choose a rolling mill:

- Material and Thickness: Determine the type of materials (e.g., metal, jewelry, wire) and their thickness you plan to work with. Ensure the mill you choose can handle these materials effectively.

- Width Capacity: Consider the maximum width you need for your projects. Some rolling mills have limited width capacities, so choose one that accommodates your requirements.

- Roller Type: Decide on the number of rolls and their configuration. Options include 2-high, 4-high, 6-high, and more. Each has its advantages, with more rolls typically offering greater precision.

- Texture and Design Needs: If you require textured or patterned surfaces, look for mills that offer features like pattern rollers or the ability to add textures.

- Budget: Set a budget based on your requirements. Quality rolling mills come in a range of prices, so balance your budget with the features you need.

- Brand and Quality: Research reputable brands known for producing durable, high-quality mills. Read reviews and seek recommendations from experienced users.

- Durability: Assess the build quality and materials used in the rolling mill to ensure it will withstand regular use.

- Maintenance and Support: Inquire about maintenance requirements and the availability of customer support. Reliable customer service can be invaluable.

- Used vs. New: Consider whether a new or used rolling mill suits your needs and budget.

- Customization: If you have specific requirements, look for mills that can be customized to meet your needs.

- Safety Features: Check for safety features, such as emergency stop buttons and safety guards, to ensure safe operation.

- Warranty: Find out if the mill comes with a warranty and what it covers.

- Size and Portability: Assess the size and weight of the mill and determine if it’s portable or needs a permanent location.

- Training and Manuals: Consider mills that provide training resources and comprehensive user manuals for beginners.

- User Reviews: Read user reviews and seek feedback from experienced users to gain insights into the mill’s performance and ease of use.

Remember that the best rolling mill for you depends on your specific needs, so take your time to research and evaluate your options before making a decision.

6. Is a two roll mill better than a three roll mill?

The choice between a two-roll mill and a three-roll mill depends on your specific application and requirements. Both types have their advantages and disadvantages.

- Two-Roll Mill:

Simplicity: Two-roll mills have a simpler design with two rolls that rotate in opposite directions. They are relatively easy to operate and maintain.

Cost-Effective: Generally, two-roll mills are more cost-effective compared to three-roll mills, making them a good choice for those with budget constraints.

Compact: They are often more compact, making them suitable for smaller workspaces.

Less Precision: Two-roll mills may offer less precision compared to three-roll mills, which can be a limitation for certain applications.

Smaller Batch Sizes: They are typically used for smaller batch sizes.

- Three-Roll Mill:

Enhanced Precision: Three-roll mills provide better precision and control, making them suitable for applications where high precision is required.

Uniform Dispersion: They are excellent for achieving uniform dispersion and particle size reduction, making them suitable for industries like cosmetics and pharmaceuticals.

Adjustable Gaps: Three-roll mills often have adjustable gaps between the rolls, allowing for precise control over the thickness or fineness of the material.

Larger Production Capacity: These mills are generally more suitable for larger production capacities due to their precision and consistency.

Wider Range of Applications: They are versatile and can be used in a wider range of industries, including paints, inks, and adhesives.

In summary, a two-roll mill is a more cost-effective and straightforward option for simpler applications, smaller batch sizes, and limited precision requirements. On the other hand, a three-roll mill offers superior precision, better dispersion, and greater versatility, making it the preferred choice for applications where these characteristics are crucial. Your choice should align with your specific needs and the nature of your production process.

7. What is jewelry rolling machine?

A jewelry rolling machine, also known as a jewelry rolling mill, is a specialized tool used in jewelry making and metalworking. It plays a pivotal role in the production of jewelry, especially in shaping and forming metal materials. The machine consists of two or more metal rollers that can be adjusted to various positions.

Here are some key functions and uses of a jewelry rolling machine:

- Sheet Metal Reduction: Jewelry rolling machines are primarily used to reduce the thickness of metal sheets or wires. This process is crucial for creating uniform and precise metal sheets for various jewelry pieces.

- Texture and Pattern: Jewelry artisans use rolling mills to add texture, patterns, or designs to metal surfaces. By passing metal through the rollers, they can achieve unique textures that enhance the aesthetics of the final jewelry.

- Wire Production: Rolling machines are used to produce jewelry wires of various thicknesses and shapes. These wires are then used in creating intricate designs for necklaces, bracelets, and other jewelry.

- Wire Drawing: The rolling mill can also be equipped with additional attachments to draw metal wires into thinner diameters for specific jewelry designs.

- Flatting and Shaping: The machine is essential for flattening, shaping, and resizing metal pieces with precision, which is crucial for achieving consistent results in jewelry production.

jewelry rolling machine is a versatile and indispensable tool for jewelry makers and metalworkers. It enables them to work with various metals, control thickness, and add unique textures and patterns to create stunning and finely crafted jewelry pieces.

8. Do you need a rolling mill for jewelry?

Whether you need a rolling mill for jewelry-making depends on your specific jewelry design and production requirements. Rolling mills are valuable tools for many jewelry artisans, but their necessity can vary based on the following factors:

- Design Complexity: If your jewelry designs involve intricate patterns, textures, or unique shapes on metal surfaces, a rolling mill can be highly beneficial. It allows you to add these elements with precision and consistency.

- Metal Thickness Control: Rolling mills are essential for controlling the thickness of metal sheets or wires. If your jewelry pieces require uniform metal components, a rolling mill becomes indispensable.

- Wire Production: If your jewelry designs include custom wires of various diameters, rolling mills are excellent for producing these wires with the desired thickness and shape.

- Customization: Rolling mills provide the flexibility to customize metal components, which is crucial if you create one-of-a-kind or personalized jewelry.

- Material Selection: The need for a rolling mill also depends on the type of metals you work with. If you primarily use precious metals like gold, silver, or platinum, a rolling mill is often essential. It’s less necessary for materials like beads, gemstones, or non-metal components.

- Production Scale: For small-scale jewelry making or hobbyist projects, a rolling mill may not be as critical. However, for larger-scale production or professional jewelry making, a rolling mill significantly enhances efficiency and precision.

In conclusion, a rolling mill can greatly benefit jewelry makers by providing control over metal thickness, facilitating design customization, and enabling the creation of unique textures and patterns. However, its necessity depends on the nature of your jewelry designs and the scale of your production.

9. How do I choose a rolling mill?

Choosing the right rolling mill for your jewelry-making or metalworking needs is crucial for achieving your desired results. Here are some key factors to consider when selecting a rolling mill:

- Type of Mill:

Combination vs. Flat vs. Wire Rolling Mill: Determine the type of mill you need based on your specific requirements. Combination mills offer more versatility, while flat mills are ideal for sheet metal, and wire mills are designed for creating wire.

- Roller Width and Diameter:

Consider the roller width and diameter. Wider rollers allow for working with larger metal sheets, while smaller rollers are suitable for finer details.

- Construction and Durability:

Look for mills made from high-quality materials, such as hardened steel. A sturdy frame and construction are essential for long-term use.

- Reduction Gear Ratio:

The gear ratio affects the force applied to the metal. A higher gear ratio offers more reduction, allowing for thinner sheet metal or wire.

- Texture Rollers and Attachments:

Some rolling mills come with texture rollers or attachments for adding patterns and designs to metal. Consider if this feature is important for your work.

- Maintenance and Ease of Use:

Check if the mill is easy to maintain and clean. It’s essential for the longevity of your equipment.

- Budget:

Determine your budget and find a rolling mill that offers the features you need within your price range. Keep in mind that quality is crucial for durability and precision.

- Brand and Reviews:

Research reputable brands and read reviews from other users to gauge the quality and performance of the rolling mill.

- Available Space:

Consider the available space in your workshop or studio. Ensure that the mill fits comfortably in your workspace.

- Intended Use:

Think about the type of jewelry or metalwork you’ll be creating. If you work with precious metals and require precise results, invest in a high-quality rolling mill.

- Customer Support and Warranty:

Check if the manufacturer offers good customer support and a warranty. This can be valuable for troubleshooting and addressing issues.

- Weight and Portability:

If you plan to move your rolling mill, consider its weight and portability. Some mills are more compact and easier to transport.

- Safety Features:

Look for safety features, such as emergency stop buttons, to ensure a safe working environment.

By considering these factors, you can choose a rolling mill that aligns with your specific needs and helps you achieve your jewelry-making or metalworking goals.

10. What is the purpose of rolling machine?

A rolling machine, also known as a rolling mill, serves the primary purpose of shaping and reducing the thickness of metal sheets or wires through a series of compressive forces. The key purposes of a rolling machine are:

- Thickness Reduction: Rolling machines are used to reduce the thickness of metal sheets or wires. This is essential for creating materials of various thicknesses for different applications.

- Shape Modification: They can alter the shape of metal, forming it into flat sheets, coils, or specific profiles. The rolling process can also be used to create textured or patterned surfaces on metals.

- Improved Surface Finish: Rolling can enhance the surface finish of metals, making them smoother and more polished. This is particularly important in jewelry making and precision metalworking.

- Work-Hardening: The rolling process can work-harden metals, making them stronger and more resilient. This is valuable in applications where durability is essential.

- Uniformity: Rolling ensures uniform thickness and quality throughout the material, making it ideal for consistent production of items like jewelry, coins, and metal sheets.

- Material Strength: It increases the material’s tensile strength, allowing it to withstand higher stress and pressure.

- Customization: Rolling machines enable the customization of metal materials to suit specific project requirements. This flexibility is valuable in various industries.

- Cost Efficiency: They offer a cost-effective means of producing metal materials in large quantities with precision and minimal waste.

- Versatility: Rolling machines are versatile and find applications in various industries, including jewelry making, metalworking, construction, and manufacturing.

In summary, rolling machines play a pivotal role in metalworking and manufacturing, providing a versatile and efficient means of processing metal materials to meet a wide range of industrial and artistic needs.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited