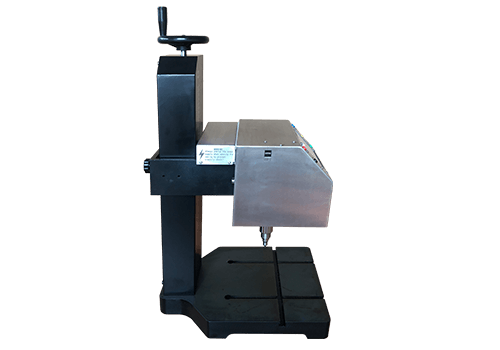

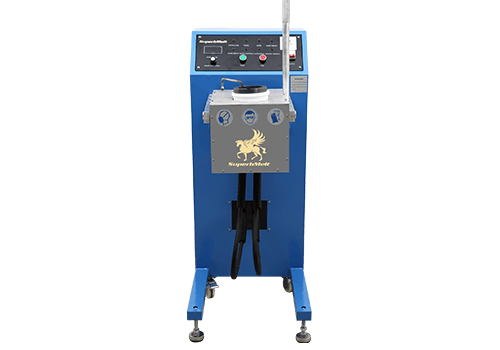

Dot Peen Marking Machine

Superbmelt dot peen marking machine is software-controlled marking peen that moves according to a specific guide rail in the X, Y two-dimensional plane. The marking peen performs high-frequency impact motion under the action of electric power, thereby engraving a mark with a certain depth on your product surface.

Superbmelt desktop metal marking machine is integrated design, extremely stable and easy to use, a good engraving depth, high speed direct parts marking, marking result clear, support some uneven surface marking.

The dot peen marking machine (SPB-DE) is mainly used for metal parts, cars and motorcycle parts, instrumentation, machinery, metal tag engraving, and other industries small and medium parts engraving and marking.

1. Integrated industrial 5-inch touch screen with software for increased machine stability and ease of operation.

2. Superbmelt dot peen marking machine series adopt HEF technology, which can support some uneven surface marking.

3. This device does not need to be connected to a computer or to an air compressor, greatly reducing your later use costs.

4. The equipment complies with the EMC electromagnetic compatibility specification and has an independent EMC processing module to filter the power system interference effectively. It can let the electrical system runs more stable.

5. Powerful software can mark any characters,numbers,logo, vin code, 2D datamatrix code, graphic outline, variable data and so on.

| Model number | SPB-DPM5 |

| Standard Marking Area | 140mm x 90mm |

| Marking Speed | 40mm~50mm/s |

| Impact Frequency | 300 times/s |

| Precise Repeatability | 0.02mm |

| Marking Depth | 0.05mm~1 mm(per material) |

| Power Supply | AC 100V~240V 50HZ60HZ |

| Energy Consumption | 125W |

| Controller Type | Integrated 5 inch touch screen and powerful software |

| Marking Type | Automation |

| Marking Machine Type | Desktop, Tabletop |

| Marked content | All English Characters, All Numbers,Variety of Graphics outlines, Logos, Dot Matrix 2D codes, Circle Letters, Serial Numbers, etc. |

| Usage | Metal machine for etching, marking, engraving – Stylus printer, dot peen header |

| Marking Materials | Metal or nonmetals with hardness under HRC 60 |

| HEF Technology | Support some uneven surface marking(height differ within 3mm) |

| Other device request | No need connect other outside device like computer or air compressor, just plug and play. |

1. Engraving Marking on engines, pistons, bodies, frames, chassis, vin, connecting rods, engines, cylinders, etc. for numbers, names, trademarks, and production dates;

2.Electric car, bicycle, motorcycle and other additional number marking;

3. nameplate engraving of various commodities, vehicles and equipment products marking;

4. It can mark on all kinds of mechanical parts, machine tools, hardware, metal tubes, gears, pumps, pipes,valves, fasteners, steel parts, flanges etc.

5. It can do various metal marking such as engraving on stainless steel equipment parts;

Why SuperbMelt Dot Peen Marking Machine

Helpful Resource For Your Reference ( An expert about SuperbMelt dot peen marking machine )

More Gold Melting and Casting Machinery For Your Choice

Any Question About SuperbMelt Dot Peen Marking Machine

Dot Peen Marking Machine Guide

Introduction

A dot peen marking machine is an industrial marking solution that uses a carbide or diamond-tipped stylus to indent a series of precise, controlled dots onto a material surface. These dots form permanent marks such as serial numbers, barcodes, logos, or traceability codes.

Unlike ink printing or labeling, dot peen marking creates deep, durable marks that can withstand wear, heat, and corrosion, making it ideal for metals and hard plastics. The technology is widely used in automotive, aerospace, machinery, and manufacturing industries for product identification and traceability.

Modern dot peen machines can be manual, pneumatic, or CNC-driven, with options for portable or integrated marking systems. Many models also support data connectivity, allowing seamless integration with production lines for efficient and automated marking.

1.1, Why Dot Peen Marking Machines Matter

In today’s competitive manufacturing world, product identification and traceability are more than just requirements—they are essential for quality control, compliance, and customer trust. Dot peen marking machines stand out because they deliver permanent, tamper-proof, and highly legible marks directly onto the material surface.

Unlike ink or labels that fade, peel, or wear off, dot peen markings remain intact even under extreme conditions such as high temperatures, abrasion, or chemical exposure. This makes them indispensable in industries like aerospace, automotive, energy, and heavy machinery, where reliability and safety depend on traceable components.

Moreover, the flexibility of dot peen technology allows manufacturers to mark metals, hard plastics, and coated materials with precision—whether it’s serial numbers, barcodes, logos, or compliance codes. By integrating with digital production systems, dot peen machines also streamline automation and improve overall manufacturing efficiency.

In short, dot peen marking machines matter because they combine durability, accuracy, and compliance in a cost-effective solution, ensuring products remain identifiable throughout their lifecycle.

Working Principle of Dot Printer

In modern manufacturing, product identification is no longer optional—it is critical for traceability, compliance, and brand reputation. Dot peen marking machines provide one of the most reliable solutions by delivering permanent, tamper-proof marks directly onto a component’s surface.

Unlike labels or ink printing that may fade, peel, or get damaged, dot peen marks are deeply engraved into the material. They withstand harsh conditions such as heat, abrasion, corrosion, and chemicals, ensuring lifetime readability. This durability is especially vital in automotive, aerospace, heavy machinery, and energy sectors, where safety and accountability depend on accurate part identification.

At the same time, dot peen technology is versatile. It can mark metals, plastics, and coated materials, and can handle a variety of formats—from serial numbers and barcodes to logos and QR codes. Integrated with digital systems, these machines also support automated production lines, boosting efficiency and reducing human error.

In essence, dot peen marking machines matter because they combine strength, accuracy, and compliance, giving manufacturers a cost-effective way to guarantee that every product remains traceable throughout its lifecycle.

2.1, Key Features & Advantages

Dot peen marking machines are designed to meet the high demands of modern manufacturing. Their unique features make them a preferred choice for industries requiring permanent and reliable marking. Below are the key features and the advantages they bring:

Key Features

Permanent Marking – Creates deep, durable impressions that withstand heat, wear, and corrosion.

Wide Material Compatibility – Capable of marking metals (steel, aluminum, brass, etc.), plastics, and coated surfaces.

Precision & Accuracy – Delivers consistent marking quality with high legibility, even for small characters and intricate logos.

Programmable Control – Supports customizable texts, serial numbers, barcodes, DataMatrix, and logos via software integration.

Versatile Mounting Options – Available in desktop, handheld, and integrated models for different production needs.

Low Maintenance – Simple mechanical design with minimal consumables required.

Advantages

Traceability & Compliance – Ensures every product is identifiable, meeting industry standards and regulatory requirements.

Cost-Effective Solution – No need for inks, labels, or additional consumables, reducing ongoing costs.

Durability of Marks – Unlike labels or ink, marks do not fade, ensuring long-term visibility.

Flexibility in Use – Suitable for flat, curved, or irregular surfaces, offering versatility across industries.

Integration with Automation – Easily incorporated into production lines, improving efficiency and reducing human error.

Brand Protection & Authenticity – Permanent markings help fight counterfeiting by ensuring product authenticity.

2.2, Applications Across Industries

Dot peen marking machines are widely adopted because of their versatility and ability to produce permanent, tamper-proof markings. Their use spans multiple industries where precision, traceability, and durability are essential.

Automotive & Aerospace

Marking VIN numbers, engine parts, pistons, chassis, and frames.

Ensures compliance with safety and traceability standards.

Manufacturing & Engineering

Engraving serial numbers, part codes, and logos on gears, valves, pumps, pipes, fasteners, and flanges.

Provides permanent identification for quality control and maintenance tracking.

Electronics & Industrial Equipment

Component labeling on machinery, hardware, and metal tags.

Supports barcode and DataMatrix code marking for automated inventory systems.

Energy & Heavy Industries

Marking equipment used in oil, gas, and power industries where parts must endure extreme environments.

Engravings remain intact even under corrosion, heat, or pressure.

Jewelry & Consumer Goods

Engraving names, logos, and serial numbers on stainless steel accessories, tools, or equipment.

Adds brand value and supports anti-counterfeiting.

Transportation & Mobility

Numbering and coding for bicycles, motorcycles, and electric vehicles.

Enhances theft prevention and traceability.

Benefits Over Traditional Methods

Compared to stamping, laser engraving, or manual marking, dot peen marking machines offer several clear advantages:

1. Permanent and Durable Marks

Unlike ink printing or labeling, dot peen marks cannot fade, peel, or be erased.

Engravings withstand wear, corrosion, and extreme environments.

2. Flexibility of Marking

Supports characters, numbers, logos, VIN codes, and DataMatrix codes.

Can engrave on flat, curved, or slightly uneven surfaces.

3. Cost-Effective Operation

No consumables such as ink, chemicals, or labels are required.

Low energy consumption and minimal maintenance reduce long-term costs.

4. High Precision and Repeatability

Accurate marking depth (0.05mm–1mm) with repeatability up to 0.02mm.

Ensures consistent quality across large production batches.

5. Easy Integration and Use

Plug-and-play design with integrated touch screen—no need for external computers or air compressors.

User-friendly software simplifies programming for variable data or serial numbers.

6. Compliance and Traceability

Helps companies meet industry regulations for product identification.

Enhances traceability in automotive, aerospace, medical, and industrial sectors.

Conclusion

Dot peen marking machines represent a reliable, efficient, and cost-effective solution for permanent part identification. By combining precision with flexibility, they overcome the limitations of traditional methods such as stamping, manual marking, or ink labeling. Their ability to create clear, durable marks on a wide range of materials ensures long-term traceability and compliance with industry standards.

Whether used in automotive, aerospace, machinery, or jewelry applications, dot peen marking delivers consistent quality while minimizing operational costs. With user-friendly design, integrated software, and minimal maintenance needs, it has become an indispensable tool for manufacturers seeking accuracy, productivity, and durability in product marking.

1. How does a dot peen machine work?

- A dot peen machine, also known as a dot marking machine or dot peen engraver, is a type of marking technology used to create permanent markings on various materials. It works by using a stylus to create a series of closely spaced dots, forming characters, numbers, symbols, or codes on the surface of the material.

- Stylus and Impact Mechanism: The dot peen machine consists of a stylus or marking pin and an impact mechanism. The stylus is a small, pointed tool that makes contact with the surface of the material to be marked. The impact mechanism is responsible for driving the stylus to create the markings.

- Pneumatic or Electric Power: The impact mechanism can be powered either pneumatically (using compressed air) or electrically. In the case of pneumatic machines, the compressed air is controlled to provide the necessary force for the stylus to make an indentation on the material. Electric machines use an electric motor to generate the force required for marking.

- Controlled Movement: The material to be marked is usually placed on a flat surface or fixture within the machine. The dot peen machine is equipped with a CNC (Computer Numerical Control) system that controls the movement of the stylus in both the X and Y directions. This allows for precise positioning of the markings.

- Dot Formation: As the stylus moves over the material’s surface, it is driven downward by the impact mechanism. The stylus makes a rapid succession of controlled impacts, creating a series of closely spaced dots. These dots form the characters or patterns desired for marking.

- Dot Matrix Creation: By adjusting the spacing and arrangement of the dots, the dot peen machine can create various characters, numbers, and symbols. Dot matrix patterns can also be used to generate QR codes, barcodes, and other machine-readable codes.

- Depth Control: The dot peen machine allows for control over the depth of the marks by adjusting the force applied to the stylus. This is important for creating legible and durable markings without damaging the material.

- Material Compatibility: Dot peen machines can mark a wide range of materials, including metals, plastics, ceramics, glass, and more. The type of stylus and settings used may vary based on the material’s hardness and characteristics.

- Permanent Markings: The markings created by the dot peen machine are permanent and resistant to wear, making them suitable for various applications, including product identification, branding, serial numbers, and part traceability.

2. What is a dot peen marking machine?

A sort of industrial tool called a dot peen marking machine is used to leave permanent traces on a variety of materials, including metals, polymers, ceramics, and more. It makes use of the dot peen engraving marking technique, which involves striking the surface of the material with a stylus or marking pin to produce a grid of tightly spaced dots. These dots can be used to create logos, QR codes, barcodes, characters, numbers, and other patterns for branding, product labelling, identification, and traceability.

Dot peen marking has a number of benefits, including longevity, readability, and resistance to abrasion and the elements. Industries like manufacturing, automotive, aerospace, electronics, medical devices, and more frequently employ dot peen marks. They offer a dependable way to stably mark components, parts, and goods with crucial data for verification, quality control, and tracking.

Dot peen marking tools come in a variety of designs, including automatic systems built into manufacturing lines and handheld portable devices for manual marking. For precise positioning and accurate marking, these machines frequently have CNC (Computer Numerical Control) systems. The stylus may be driven by pneumatic or electric movements.

3. Is dot peen better than laser marking?

Depending on the particular needs of the application and the properties of the materials being marked, dot peen marking or laser marking may be preferable. The decision should be decided on aspects including marking speed, depth, accuracy, material type, and desired marking appearance since both procedures have benefits and drawbacks.

- Dot Peen Marking Benefits:

Depth: Dot peen marking leaves deeper impressions on the surface of the material, making it appropriate for uses that call for a more emphatic marking.

Durability: Dot peen marks can withstand tough settings since they are extremely strong and resistant to wear.

Dot peen marking can be quicker in some circumstances, especially when marking straightforward alphanumeric characters.

Dot peen marking systems are frequently less expensive to purchase than laser marking systems.

- The benefits of laser marking:

Versatility: A variety of materials, including metals, polymers, ceramics, glass, and more, can be marked with a laser.

Precision: Laser marking is ideal for elaborate designs and microscopic markings because it provides high precision and exquisite detail.

Laser marking is non-contact, making it the perfect procedure for delicate or sensitive materials that shouldn’t be handled.

Variety: Different marks, such as surface annealing, engraving, etching, and colour changes, can be produced using laser marking.

Laser marking requires no consumables, such as ink or stylus pins, which lowers continuing operational costs.

4. What is the difference between vibro etch and dot peen?

Permanent surface marking techniques like vibro etching and dot peening are also used, but they differ in terms of the technology they employ, the marking procedure, and the outcomes they produce.

Vibratory Etching:

- Technology: Vibro etching, sometimes referred to as vibration engraving or scratch engraving, physically scratches the surface of the material with the use of a vibrating stylus or needle.

- Process: As the stylus passes over the material’s surface, it makes a succession of tiny scratches that come together to form the desired mark. The pressure used and the speed of the stylus influence the depth of the mark.

- Vibro etching normally produces shallow surface markings, however the depth might change depending on the parameters and the characteristics of the material.

- Materials: Softer materials like plastic, wood, and some metals are frequently subjected to vibro etching.

- Speed: Because physical touch is necessary to make the marks, the marking process might be somewhat slow.

- Vibro etching has a higher potential for noise than other marking techniques.

DOT PEENSCREENING

- Technology: Dot peen marking, often referred to as dot matrix marking or micro-percussion, indentifies a material’s surface with a series of dots using a stylus that is controlled by a computer.

- Process: Characters, symbols, or codes are formed by the stylus striking the surface of the material repeatedly with controlled impacts. The force used determines the depth of the mark.

- Dot peen marking produces deeper indentations than vibro etching, which increases durability.

5. What is dot marking?

Dot marking, often referred to as dot peen marking or micro-percussion marking, is a technique for leaving a permanent mark on a variety of materials, including metals, polymers, ceramics, and more. To make characters, symbols, codes, or other markings, a sequence of tiny dots or indentations must be made on the surface of the material. Dot marking is frequently used in sectors like manufacturing, automotive, aerospace, electronics, and more for traceability, product identification, branding, and part serialisation.

Dot marking commonly uses a computer-controlled marking device with an impacting stylus or needle on the surface of the material. The stylus glides along a predetermined path, swiftly striking the surface to form dots at particular locations. Together, these dots make up the required mark. To get the desired visibility and persistence of the mark, the dots’ depth and spacing can be changed.

Dot marking has a number of benefits, including the capacity to mark on uneven or irregular surfaces, excellent durability, and deeply indented marks that are resistant to wear and corrosion. It can generate clear and legible marks even in difficult industrial situations, making it a flexible and dependable approach for marking a variety of materials.

The size and complexity of dot marking machines can vary, ranging from hand-held portable devices to fully automated systems integrated into production lines. Dot marking is frequently a preferred option for applications where accuracy and durability are crucial since the marks it produces are typically exact and constant.

6. What is dot peen marking machine

Using a series of closely spaced dots or indentations, a dot matrix marking machine is a specialised piece of equipment used for dot matrix marking, a technique for leaving permanent imprints on a variety of materials. Micro-impact marking is another name for this kind of marking. For product identification, traceability, branding, and serialisation, dot matrix marking machines are extensively employed in the manufacturing, automotive, aerospace, electronics, and other sectors of the economy.

The following elements are typically found in dot matrix marking machines:

The controller, which houses the software that manages the marking process, is the machine’s brain. The user can insert any marking data they desire, including text, numbers, barcodes, and pictures.

The component of the machine that houses the marking needle is called the “marking head.” Based on a pre-programmed design, it moves along the X, Y, and Z axes to produce a dot pattern.

A stylus or needle is a tool that physically presses a material’s surface to produce a dot. Depending on the sort of mark required and the substance to be marked, it varies in size and shape.

The material that has to be marked is placed on the working surface. To hold the material in place while being marked, it can be a flat surface or a fixture.

Pneumatic or Electromagnetic System: A dot peen marking machine drives a stylus that leaves a dot mark on the material using a pneumatic or electromagnetic system.

Dot peen markers have the advantages of producing markings that are long-lasting, extremely readable, and resistant to wear, corrosion, and environmental factors. They work well for marking on a variety of materials, including ceramics, metals, and plastics. For high-volume marking applications, they can be operated manually or integrated into automated manufacturing processes. Dot peen markers are a flexible option for a variety of industrial marking purposes because the depth and spacing of the dots may be changed to obtain the required marking appearance and depth.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited