Bracelet Welding Machine

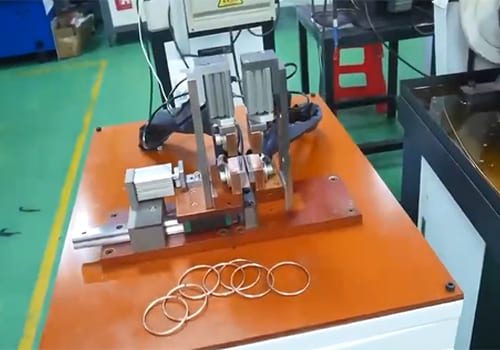

Equipment uses welding technology to connect metal materials (such as gold, silver, copper, etc.) through the application of heat and pressure, forming a perfect bracelet structure.

SuperbMelt Bracelet Welding Machine is specially designed for efficient and precise bracelet production. It ensures seamless and accurate welding, creating smooth, high-quality joints while minimizing material waste.

This welding machine can weld 6–10 hollow or solid bracelets per minute made from precious metals such as gold and silver, making it an ideal choice for mass production.

It supports processing solid metal wires with diameters ranging from 1.5 mm to 6.0 mm and hollow tubes with a thickness of 0.5 mm or more.

If you need more information about bracelet production, please feel free to contact us!

| Model number | SPB-HBW882 |

| Power source | 220V |

| Power | 8 kw |

| Applicable metal | Gold, Silver, Platinum, Palladium, and their alloys |

| Processing range | solid wire 1.5-6.0mm, hollow tube thickness above 0.5mm |

| Working efficiency | 6-10pcs/min |

| Machine weight | 50KG |

| Operation mode | switch control |

Features

- Efficient Welding: Capable of welding 6-10 bracelets per minute, making it ideal for mass production and improving work efficiency.

- Wide Applicability: Supports solid wires with diameters ranging from 1.5mm to 6.0mm and hollow tubes with thickness ≥0.5mm, accommodating various bracelet designs.

- Precise Seamless Welding: Ensures smooth and high-quality joints, minimizing the need for extensive post-processing and enhancing the final product’s appearance.

- Suitable for Various Precious Metals: Works with gold, silver, copper, and other precious metals, meeting diverse material needs in bracelet production.

- User-Friendly Operation: Features a switch control mode, making it simple to operate with minimal technical expertise required.

Advantages

- Minimized Material Waste: Precise welding reduces material loss, ensuring cost efficiency and high-quality output.

- Enhanced Productivity: High-speed welding functionality supports large-scale production, significantly reducing production time.

- Versatility: Accommodates different materials and designs, offering flexibility to meet unique customer requirements.

- Lower Labor Costs: Automated operation reduces manual intervention, cutting labor costs while ensuring consistent quality and accuracy.

SuperbMelt Bracelet Welder has a wide range of applications in the jewelry manufacturing industry. These include:

- Hollow and Solid Bracelet Welding: Designed specifically for welding hollow or solid bracelets made from precious metals such as gold, silver, and copper.

- Custom Jewelry Production: Ideal for creating customized bracelet designs in various shapes and sizes, catering to different customer needs.

- Mass Production: With its high efficiency of welding 6-10 bracelets per minute, it is well-suited for large-scale manufacturing in jewelry factories.

- Precious Metal Processing: Besides bracelets, it can be used to weld other jewelry components made of similar materials, making it versatile for various precious metal products.

- Repair and Maintenance: Useful for repairing damaged bracelets or restoring seamless connections on worn jewelry pieces.

- Artisanal and Industrial Jewelry Production: Perfect for both small-scale artisan workshops and large industrial jewelry manufacturers due to its precision and efficiency.

This machine supports the production of high-quality, aesthetically pleasing bracelets while ensuring cost efficiency and reduced material wastage, making it a valuable tool for modern jewelry-making processes.

Why SuperbMelt Bracelet Welder

Any Question About SuperbMelt Bracelet Welder

Bracelet Welding Machine: Guide to the SuperbMelt Bracelet Welder

Introduction to Bracelet Manufacturing

Bracelet manufacturing has evolved from traditional handcrafting to modern automated production methods, reflecting both the artistry and efficiency required in today’s jewelry industry. In the past, skilled artisans relied on simple tools to cut, shape, and join precious metals like gold, silver, and copper, producing unique and highly detailed designs. While this handmade approach allowed for creativity and personalization, it was limited in scale and efficiency.

With the rise of industrial techniques such as casting, machining, and 3D printing, manufacturers can now produce bracelets with greater speed, precision, and consistency. At the same time, the growing demand for fashionable, lightweight, and high-quality jewelry has led to the adoption of specialized equipment such as the Bracelet Welder. This advanced technology ensures seamless welding, smooth finishes, and minimal material waste, making it ideal for both custom designs and mass production.

Bracelet manufacturing today strikes a balance between artistic expression and industrial efficiency, offering solutions that cater to luxury markets, everyday wear, and large-scale jewelry businesses alike.

1.1 Early Bracelet Making

The history of bracelet making dates back thousands of years, when ancient civilizations used natural materials such as bones, shells, stones, and plant fibers to create decorative wrist adornments. These early bracelets often carried cultural or spiritual significance, serving as symbols of wealth, protection, or social status.

As metalworking techniques developed, artisans began crafting bracelets from copper, bronze, silver, and gold. Simple hand tools like hammers, chisels, and files were used to cut and shape the metals into circular forms. The ends were joined by heating and hammering, forming the earliest examples of welded or fused bracelets.

Unlike modern mass production, early bracelet making was entirely handcrafted, requiring great skill and patience. Each piece was unique, reflecting the artistry of its maker and the resources available at the time. These methods laid the foundation for the sophisticated bracelet manufacturing processes used today.

1.2 Evolution of Modern Bracelet Production

With the advancement of technology and industrialization, bracelet manufacturing shifted from purely handcrafted methods to more efficient and precise production techniques. The introduction of specialized machines and tools enabled manufacturers to meet the growing demand for both fine jewelry and affordable fashion accessories.

In the modern era, several key innovations have shaped bracelet production:

Casting Techniques – Lost-wax casting allowed artisans to reproduce intricate designs in larger quantities, ensuring consistency while preserving fine details.

Machining & Automation – CNC machines, lathes, and laser cutters introduced high accuracy in shaping and cutting metals, leading to standardized production.

Welding Technology – Bracelet welders now make it possible to seamlessly connect hollow and solid metal tubes, increasing efficiency and reducing material waste.

3D Printing – Digital manufacturing enables designers to create complex and customized bracelet designs with unprecedented precision, bridging the gap between artistry and technology.

Decorative Enhancements – Modern techniques such as stone setting, engraving, electroplating, and texturing expand creative possibilities, adding both value and beauty.

The evolution from handcrafted artistry to technologically advanced processes has transformed bracelet making into a balance of tradition and innovation. Today, manufacturers can produce lightweight, durable, and aesthetically appealing bracelets in both mass production and custom design markets.

1.3 Demand for Precision and Efficiency

As the jewelry market expanded and consumer expectations grew, bracelet manufacturers faced increasing pressure to deliver products that combined aesthetic beauty, durability, and affordability. Traditional handcrafting, while valuable for unique and artistic designs, often lacked the speed and uniformity required for large-scale production.

This demand created a shift toward precision-focused and efficiency-driven solutions in bracelet making:

- Accuracy in Design – Consumers now expect flawless symmetry and seamless joints in bracelets, requiring machines that can deliver high-precision results.

- Consistency in Mass Production – Automated machines, such as bracelet welders, rolling mills, and tube-forming machines, ensure that every bracelet meets the same quality standards.

- Material Optimization – Modern welding and forming technologies minimize waste, allowing manufacturers to maximize the use of expensive metals like gold and silver.

- Time Efficiency – Machines capable of producing multiple bracelets per minute enable businesses to scale quickly and remain competitive.

- Customization with Speed – By combining digital tools (CAD/CAM, 3D printing, scanning) with advanced production equipment, manufacturers can meet the rising demand for personalized jewelry without sacrificing efficiency.

The jewelry industry’s focus on precision and efficiency reflects a broader trend: blending artistry with technology. This evolution ensures that bracelets are not only beautiful but also consistently high in quality, produced at the speed modern markets demand.

1.4 Why Welding Technology Matters in Jewelry

Welding plays a critical role in modern jewelry production, especially in bracelet manufacturing where durability, appearance, and precision are equally important. Unlike traditional soldering, which may leave visible seams or weaken under stress, welding technology creates seamless, high-strength joints that preserve both the beauty and integrity of the jewelry.

Key reasons welding technology is essential in jewelry:

Seamless Aesthetics – Advanced welders ensure smooth, invisible joints that enhance the overall elegance of the bracelet.

Structural Strength – Welding produces strong bonds that can withstand daily wear, preventing breakage or deformation.

Compatibility with Precious Metals – Modern welders are capable of handling gold, silver, platinum, and other metals without compromising their quality.

Efficiency in Mass Production – Machines like the SuperbMelt Bracelet Welder can weld multiple hollow or solid bracelets per minute, ideal for large-scale jewelry manufacturing.

Reduced Material Waste – High-precision welding minimizes excess use of costly metals, making production more economical.

Support for Complex Designs – Welding enables jewelers to bring intricate and delicate bracelet patterns to life without sacrificing strength.

In today’s jewelry industry, welding is not just a technical necessity—it is the backbone of precision manufacturing, allowing jewelers to merge artistry with durability while keeping up with modern production demands.

Types of Bracelet Manufacturing Methods

Bracelet production has evolved through centuries, moving from purely handcrafted techniques to advanced digital and machine-based processes. Each manufacturing method has its own advantages, depending on the design complexity, production scale, and material requirements.

2.1 Handmade Method

The handmade approach is the oldest and most traditional method of bracelet production. It relies on the skill, creativity, and precision of artisans who transform raw materials into wearable works of art using only hand tools.

Process Steps

Design & Measurement – The artisan sketches the bracelet design and determines accurate dimensions.

Material Preparation – Precious metals such as gold, silver, or copper are cut into strips or wires of suitable lengths.

Shaping – Using hammers, pliers, and molds, the metal is bent or hammered into a circular or oval bracelet shape.

Welding/Joining – The open ends are joined by heating and welding, ensuring stability.

Finishing & Polishing – The bracelet is filed, smoothed, and polished to enhance its shine and appearance.

Applications

Custom-made or one-of-a-kind jewelry.

Luxury pieces requiring intricate craftsmanship.

Artistic and symbolic designs.

Benefits

Produces unique and detailed jewelry that machines cannot easily replicate.

Offers high flexibility for creativity and personalization.

Appeals to customers who value handcrafted artistry and exclusivity.

The handmade method, while time-consuming, remains highly valued for its artistry and cultural significance. It is particularly suited for boutique jewelers, custom orders, and premium markets where uniqueness matters more than production volume.

2.2 Casting Method

The casting method is a widely used bracelet manufacturing technique, especially for producing large quantities of intricate designs. It allows jewelers to replicate detailed patterns efficiently while maintaining high precision.

Process Steps

Mold Creation – A wax model of the bracelet design is created and then encased in plaster or investment material to form a mold.

Lost-Wax Casting – The wax is melted away, leaving a hollow cavity in the shape of the bracelet.

Metal Pouring – Molten metal (gold, silver, copper, etc.) is poured into the mold to form the bracelet.

Finishing – After cooling, the bracelet is removed from the mold, cleaned of excess material or burrs, and polished.

Decorative Enhancements (Optional) – Additional processes like engraving, stone setting, or plating can be applied.

Applications

Mass production of bracelets with complex textures or patterns.

Designs that require consistent replication of details across multiple pieces.

Both luxury and fashion jewelry markets.

Benefits

High detail retention – Even intricate designs can be replicated accurately.

Scalable production – Efficient for producing multiple units simultaneously.

Versatile design possibilities – Supports various metals and finishes.

Casting bridges the gap between traditional handcrafting and modern mass production, providing a balance of efficiency, accuracy, and design complexity.

2.3 Machining Method

Machining is a modern, technology-driven approach to bracelet manufacturing. It leverages precision tools and automated equipment to produce bracelets that are uniform, durable, and suitable for large-scale production. This method bridges the gap between traditional craftsmanship and mass production, allowing for consistent quality with minimal manual labor.

Process Steps

Material Preparation & Cutting – Metal wires or sheets (gold, silver, copper, etc.) are cut to precise lengths using CNC machines, laser cutters, or lathes.

Shaping – The cut materials are bent or formed into circular or custom shapes using automated bending machines or shaping tools.

Joining & Welding – Automated welding machines, such as the SuperbMelt Bracelet Welder, create seamless and strong connections between metal components.

Surface Finishing – Polishing, engraving, or other treatments refine the bracelet for a smooth and appealing final look.

Applications

Large-scale, standardized bracelet production.

Minimalistic or simple designs that require high uniformity.

Factory production lines where speed and consistency are priorities.

Benefits

High Precision & Consistency – Ensures every bracelet meets exact design specifications.

Efficient Production – Reduces manual labor and time required for each unit.

Scalable – Easily supports large production volumes without compromising quality.

Cost-Effective – Reduces material waste and labor costs compared to purely handmade methods.

Machining is ideal for manufacturers who aim to produce high-quality, reliable, and consistent bracelets in bulk, combining modern technology with efficient processes.

2.4 3D Printing Method

3D printing is a digital and highly flexible method of bracelet manufacturing, enabling designers to produce intricate, customized, and complex designs that are difficult to achieve with traditional methods. It combines computer-aided design (CAD) with additive manufacturing to create precise models and final products.

Process Steps

Digital Modeling – Designers create a 3D model of the bracelet using CAD software, ensuring accuracy in dimensions and intricate details.

3D Printing – The model is printed using materials such as resin, wax, or metal, depending on whether the print is for a prototype or direct production.

Post-Processing – Printed pieces are cleaned, polished, electroplated, or decorated with stones and finishes as needed.

Applications

Rapid prototyping and design validation.

Custom, one-of-a-kind bracelet designs.

Complex geometries such as lattice structures, hollow sections, or layered patterns.

Benefits

High Precision – Accurately reproduces intricate designs.

Design Freedom – Enables innovative and complex structures that are difficult or impossible with traditional techniques.

Fast Turnaround – Accelerates the prototyping and production process.

Material Efficiency – Reduces waste by using only the required material for the design.

3D printing allows jewelry manufacturers to combine creativity with efficiency, making it ideal for both personalized designs and small-batch production where complexity and uniqueness are priorities.

2.5 Welding Hollow Tubes

Welding hollow tubes is a modern and efficient method for producing lightweight, durable bracelets, especially suitable for large-scale manufacturing. This method uses specialized welding equipment to seamlessly join metal tubes into finished bracelet forms, ensuring both strength and aesthetics.

Process Steps

Material Preparation – Hollow metal tubes, typically made of gold, silver, or other precious metals, are cut to the desired lengths.

Shaping – Tubes are bent or formed into circular or oval bracelet shapes using forming machines.

Welding – Specialized equipment, such as the SuperbMelt Bracelet Welder, is used to create precise, seamless welds.

Surface Finishing – Polishing and other finishing processes ensure a smooth, high-quality appearance.

Applications

Lightweight, everyday wear bracelets.

High-volume production where speed and consistency are required.

Designs that require strong yet delicate structures.

Benefits

Material Efficiency – Uses hollow tubes to reduce metal consumption while maintaining strength.

High Precision – Welding ensures seamless joints with no visible marks.

Rapid Production – Capable of producing multiple bracelets per minute.

Durable and Wear-Resistant – Welded bracelets maintain their shape and integrity over time.

Hollow tube welding combines efficiency, durability, and elegance, making it a preferred method for both mass production and high-quality bracelet designs.

2.6 Decorative Methods

Decorative methods enhance the aesthetic appeal and value of bracelets, transforming them from simple metal forms into beautiful, eye-catching jewelry. These techniques can be applied after the basic structure of the bracelet is complete, whether it is handmade, cast, machined, 3D-printed, or welded.

Common Decorative Techniques

Stone Setting – Embedding gemstones, diamonds, or semi-precious stones to add sparkle and elegance.

Engraving – Carving patterns, logos, or personalized messages onto the bracelet surface.

Electroplating & Coating – Applying gold, silver, or other metal coatings to achieve desired colors or finishes.

Texturing & Polishing – Creating unique surface effects, such as matte, brushed, or hammered finishes.

Applications

High-end and luxury jewelry.

Personalized gifts or commemorative pieces.

Market segments requiring visually striking and unique designs.

Benefits

Increased Market Value – Enhances the perceived and actual worth of the bracelet.

Customization – Enables bespoke designs for individual clients.

Versatility – Can be applied to a wide range of bracelet materials and styles.

Aesthetic Enhancement – Adds beauty, uniqueness, and sophistication to the final product.

Decorative methods allow jewelers to combine artistry with craftsmanship, providing a final touch that elevates a bracelet from a functional accessory to a treasured piece of jewelry.

Why Bracelet Welding Machines Are Essential

Bracelet welding machines, such as the SuperbMelt Bracelet Welder, are essential in modern bracelet manufacturing because they combine precision, efficiency, and durability. They create seamless and invisible joints, ensuring both the aesthetic appeal and structural strength of the bracelet, while reducing material waste—especially important for precious metals like gold, silver, or platinum. These machines enable high-speed production, welding multiple hollow or solid bracelets per minute, and guarantee consistent quality across all units. Additionally, they support intricate designs and hollow structures that are difficult to assemble manually, and are compatible with a wide range of metals. In short, bracelet welding machines bridge traditional craftsmanship with modern production demands, making them indispensable for producing durable, elegant, and high-quality bracelets efficiently.

3.1 Increasing Market Demand

The global bracelet market has experienced rapid growth in recent years, driven by rising consumer interest in fashion, personalization, and luxury jewelry. Consumers are seeking bracelets that are not only stylish but also high-quality, durable, and unique, creating opportunities for both small boutique jewelers and large-scale manufacturers.

Key Drivers of Demand

Personalization & Customization – Customized bracelets, including engraved, gemstone-set, or digitally designed pieces, are increasingly popular.

Fashion Trends – Bracelets have become versatile accessories, complementing outfits and expressing personal style.

Gift & Commemorative Market – Bracelets are a preferred choice for special occasions such as anniversaries, birthdays, and weddings.

Affordable Luxury – Advances in manufacturing technology, including 3D printing and automated welding, make high-quality bracelets accessible to a wider audience.

Global Reach – E-commerce and social media platforms allow jewelers to reach international customers, increasing demand for both unique and mass-produced designs.

Implications for Manufacturers

Higher demand emphasizes the need for efficient production methods and consistent quality.

Modern equipment, such as the SuperbMelt Bracelet Welder, 3D printers, and machining tools, allows manufacturers to meet market demand while maintaining precision and reducing costs.

The combination of innovation, automation, and craftsmanship positions manufacturers to capitalize on the growing market for bracelets.

In summary, the increasing market demand encourages the adoption of advanced manufacturing technologies, enabling jewelers to produce stylish, durable, and customizable bracelets that meet the expectations of modern consumers.

3.2 Efficient Processing

Efficiency is a critical factor in modern bracelet manufacturing, especially for businesses aiming to meet high market demand while maintaining quality. Advanced equipment, such as the SuperbMelt Bracelet Welder, 3D printers, and machining tools, allows manufacturers to streamline production, reduce manual labor, and optimize material usage.

Key Aspects of Efficient Processing

High-Speed Production – Machines can weld multiple bracelets per minute or produce consistent prototypes rapidly, significantly shortening production cycles.

Reduced Material Waste – Precise cutting, shaping, and welding minimize metal loss, which is particularly important for precious metals like gold and silver.

Consistency & Accuracy – Automated processes ensure each bracelet meets exact specifications, eliminating variations common in manual methods.

Integration of Multiple Steps – Equipment can combine forming, cutting, welding, and finishing, reducing the need for multiple handling stages.

Adaptability for Various Designs – Modern machines can handle solid wires, hollow tubes, and complex patterns, supporting both mass production and custom designs.

By focusing on efficient processing, jewelers can produce high-quality bracelets at scale, reduce production costs, and respond quickly to market trends without compromising on craftsmanship or durability.

3.3 Versatility of Materials

Modern bracelet manufacturing requires machines that can work with a wide range of metals and alloys, ensuring flexibility in design, production, and market offerings. Equipment like the SuperbMelt Bracelet Welder can process various materials, from precious metals such as gold, silver, and platinum to more affordable metals like copper and brass.

Key Advantages of Material Versatility

Supports Different Designs – Jewelers can create everything from delicate, lightweight bracelets to bold, solid pieces.

Accommodates Hollow and Solid Structures – Machines can handle both hollow tubes and solid wires, expanding design possibilities while optimizing material usage.

Enables Customization – Clients can request bracelets in different metals or mixed-metal designs, enhancing personalization options.

Cost Management – By using less expensive metals for prototypes or parts of a design, manufacturers can control costs without compromising quality.

Market Adaptability – The ability to process multiple materials allows jewelers to cater to different price points and consumer preferences.

The versatility of materials ensures that manufacturers are not limited by metal type or structure, making it possible to produce a broad range of bracelets that meet diverse design and market demands.

3.4 Waste Reduction

Waste reduction is a crucial consideration in modern bracelet manufacturing, particularly when working with precious metals such as gold, silver, or platinum. Advanced equipment, like the SuperbMelt Bracelet Welder, 3D printers, and precision machining tools, helps minimize material loss while maintaining high-quality production.

Key Strategies for Waste Reduction

Precise Cutting & Shaping – Automated cutting and forming reduce excess metal compared to manual methods.

Efficient Welding – Seamless and accurate welding avoids material loss from errors or rework.

Hollow Structures – Using hollow tubes instead of solid metals reduces the amount of material required without compromising durability.

Optimized Prototyping – 3D printing allows designers to create prototypes or small batches efficiently, avoiding waste from trial-and-error in metal casting.

Recycling Scraps – Excess metal from cutting, trimming, or polishing can be melted and reused in production, further reducing waste.

By implementing these strategies, manufacturers can maximize material utilization, reduce costs, and maintain environmental responsibility, all while producing high-quality, durable bracelets suitable for both mass production and custom designs.

How the SuperbMelt Bracelet Welder Works

The SuperbMelt Bracelet Welder is a high-precision, efficient, and versatile machine designed for seamless bracelet production. It works by preparing solid wires or hollow tubes of metals like gold, silver, or copper, shaping them into circular forms, and then fusing the ends using controlled heat and pressure. This process ensures strong, durable joints without compromising the metal’s quality. Capable of welding 6–10 bracelets per minute, the welder handles solid wires from 1.5mm to 6.0mm and hollow tubes ≥0.5mm thick. Its precise operation minimizes material waste, maintains consistent quality, and supports both mass production and intricate custom designs, effectively bridging traditional craftsmanship with modern automated efficiency.

4.1 Supported Materials

The SuperbMelt Bracelet Welder is designed to work with a wide range of metals, making it highly versatile for modern bracelet manufacturing. It can process precious metals, including gold, silver, and platinum, as well as base metals like copper and brass.

Key Advantages of Supported Materials

Flexibility in Design – Jewelers can create bracelets in different metals or even combine multiple metals for mixed designs.

Adaptable to Hollow and Solid Structures – The welder accommodates both solid wires and hollow tubes, expanding the possibilities for lightweight or heavy-duty designs.

Preserves Material Quality – The welding process is precise and controlled, ensuring that the metal’s properties, color, and strength remain intact.

Supports Customization – Enables bespoke designs with various metals, allowing personalized creations for clients.

Cost Optimization – Less expensive metals can be used for prototypes or mixed-metal pieces, reducing overall material costs.

By supporting a broad spectrum of metals and structures, the SuperbMelt Bracelet Welder allows manufacturers to produce a wide variety of bracelets, from high-end luxury pieces to everyday wear, without compromising quality or durability.

4.2 Welding Process

The welding process is the core function of the SuperbMelt Bracelet Welder, designed to produce strong, seamless, and precise joints in bracelets. By combining controlled heat and pressure, the machine fuses metal components without altering their structural integrity or aesthetic appearance.

Key Steps in the Welding Process

Preparation – Cut and shape solid wires or hollow tubes into the desired bracelet form.

Positioning – Place the bracelet ends or rings in the welding fixture for accurate alignment.

Controlled Welding – The machine applies precise heat and pressure to join the metals, ensuring a smooth and durable bond.

Inspection & Adjustment – After welding, each joint is inspected for strength and uniformity; minor adjustments or polishing are applied if needed.

Finishing – Polishing and surface treatment are performed to remove any marks and achieve a flawless appearance.

Advantages of the Welding Process

Seamless Joints – Creates invisible, high-quality welds that enhance the bracelet’s aesthetic.

Material Safety – Prevents discoloration or weakening of precious metals.

High Efficiency – Can weld multiple bracelets per minute, ideal for large-scale production.

Consistency – Ensures uniform quality across all units.

Supports Complex Designs – Capable of welding hollow tubes, intricate shapes, and delicate structures.

The SuperbMelt welding process allows manufacturers to combine precision, durability, and efficiency, making it an essential step in both custom and mass-produced bracelet manufacturing.

4.3 Advantages Over Traditional Methods

The SuperbMelt Bracelet Welder offers several advantages compared to traditional soldering or manual welding techniques, transforming bracelet manufacturing with greater efficiency, precision, and reliability.

Key Advantages

Seamless and Strong Joints – Unlike manual soldering, the machine creates smooth, invisible welds that are highly durable.

Reduced Material Waste – Precise welding minimizes metal loss, which is especially important when working with precious metals.

Faster Production – The automated process can weld multiple bracelets per minute, greatly increasing output.

Consistent Quality – Each bracelet meets exact specifications, eliminating inconsistencies common in manual methods.

Supports Complex and Hollow Designs – Capable of handling delicate, intricate, or hollow structures that are difficult to weld manually.

Lower Risk of Metal Damage – Controlled heat and pressure protect the metal from discoloration, deformation, or weakening.

By combining precision, efficiency, and material safety, the SuperbMelt Bracelet Welder outperforms traditional techniques, enabling jewelers to produce high-quality, durable, and visually flawless bracelets for both custom and mass production.

Providing Custom Bracelet Manufacturing Solutions with SuperbMelt

SuperbMelt provides comprehensive solutions for custom bracelet manufacturing, combining advanced equipment, automated welding, and digital design tools to meet diverse client needs. The process begins with continuous casting of precious metals into uniform strips, followed by rolling into smooth sheets and forming hollow tubes with precise dimensions. These tubes are shaped into rings, cut, and seamlessly welded using the SuperbMelt Bracelet Welder, producing strong and durable joints. Decorative finishing, including polishing, engraving, electroplating, or stone-setting, adds aesthetic appeal and personalization. This integrated approach ensures high efficiency, consistent quality, versatility across metals and designs, and minimized material waste, enabling jewelers to create elegant, customizable bracelets for both small batches and mass production.

5.1 Continuous Casting of Precious Metals

Continuous casting is the first step in bracelet manufacturing, providing a high-quality foundation for subsequent processes. Precious metals such as gold, silver, and copper are melted and cast into uniform metal strips, ensuring consistent thickness, purity, and surface quality.

Key Advantages of Continuous Casting

Consistent Material Quality – Produces strips with uniform composition and minimal impurities.

Efficient Production – Continuous operation allows large volumes of metal to be prepared quickly.

Material Optimization – Reduces waste compared to traditional batch casting methods.

Stable Foundation for Processing – The uniform strips facilitate subsequent rolling, tube forming, and shaping processes.

Support for Various Metals – Compatible with a wide range of precious metals used in bracelet manufacturing.

By starting with continuous casting, manufacturers ensure that all bracelets are built on a reliable, high-quality metal base, setting the stage for efficient and precise production in the later steps.

5.2 Rolling into Thin Sheets

After continuous casting, the metal strips are processed through a rolling mill to produce thin, uniform sheets. This step adjusts the metal’s thickness according to design requirements and prepares it for forming hollow tubes or other bracelet components.

Key Advantages of Rolling

Precise Thickness Control – Ensures consistent sheet thickness for uniform bracelet parts.

Enhanced Surface Quality – Rolling smooths the metal, reducing imperfections and preparing it for further processing.

Material Efficiency – Minimizes waste by producing accurately dimensioned sheets.

Versatility – Supports different metals, including gold, silver, copper, and alloys.

Preparation for Tube Forming – The uniform sheets are ideal for forming hollow tubes or bending into other bracelet shapes.

Rolling metal strips into thin sheets is a critical step in bracelet manufacturing, ensuring precision, efficiency, and high-quality material for the subsequent forming and welding processes.

5.3 Hollow Tube Forming

Hollow tube forming transforms the rolled metal sheets into cylindrical tubes, which serve as the primary structure for many bracelets. This step allows manufacturers to create lightweight, durable, and aesthetically pleasing designs.

Key Advantages of Hollow Tube Forming

Material Efficiency – Hollow tubes use less metal than solid structures, reducing costs while maintaining strength.

Lightweight Designs – Creates comfortable bracelets suitable for daily wear.

Precision Control – Machines like the SuperbMelt tube forming equipment ensure accurate diameter and wall thickness for consistency.

Versatility in Design – Supports various tube sizes, allowing different bracelet styles, including solid and hollow designs.

Foundation for Welding – The uniform tubes provide ideal surfaces for precise welding and assembly.

By forming hollow tubes, manufacturers can balance durability, style, and cost-effectiveness, making it a crucial step in efficient bracelet production.

5.4 Tube Drawing & Adjustment

After forming hollow tubes, the next step is tube drawing and adjustment, which refines the tube’s diameter and wall thickness to meet specific bracelet design requirements. This ensures precise dimensions for seamless assembly and consistent quality.

Key Advantages of Tube Drawing & Adjustment

- Accurate Dimensions – Adjusts tube diameter and wall thickness to match design specifications precisely.

- Improved Metal Strength – Drawing enhances the structural integrity of the metal, preventing deformation during shaping or welding.

- Consistency – Ensures uniformity across multiple tubes, essential for mass production.

- Supports Complex Designs – Enables the creation of delicate or custom bracelet styles with exact measurements.

- Material Efficiency – Reduces the need for additional trimming or rework, minimizing material waste.

Tube drawing and adjustment provide a reliable, precise foundation for shaping and welding, making it a critical step in producing high-quality, durable bracelets.

5.5 Ring Forming & Cutting

Once the tubes are drawn and adjusted, they are shaped into circular or oval rings, forming the basic structure of bracelets. After forming, the rings are precisely cut to prepare them for seamless welding.

Key Advantages of Ring Forming & Cutting

Consistent Shapes – Ensures each ring has uniform dimensions for smooth assembly.

Precision Cutting – Reduces material waste and maintains accuracy for a perfect fit.

Supports Hollow and Solid Designs – Works for both lightweight hollow tubes and solid wires.

Efficiency – Machines can produce multiple rings rapidly, ideal for mass production.

Foundation for Welding – Accurately cut rings enable seamless, durable welds in the final bracelet assembly.

By combining ring forming and precise cutting, manufacturers create a reliable, uniform

5.6 Welding into Bracelets

The final step in bracelet production is welding individual rings or components into a complete bracelet. Using the SuperbMelt Bracelet Welder, manufacturers achieve seamless, strong, and durable joints that maintain the bracelet’s integrity and appearance.

Key Advantages of Welding into Finished Bracelets

Seamless Joints – Creates invisible welds for a polished, professional look.

Durable Structure – High-precision welding ensures long-lasting bracelets that withstand daily wear.

Supports Hollow and Solid Designs – Works effectively on both delicate hollow tubes and solid wires.

High Efficiency – Capable of welding multiple bracelets per minute, enabling large-scale production.

Material Safety – Maintains the quality, color, and strength of precious metals.

Foundation for Decorative Finishing – After welding, bracelets can be polished, engraved, or embellished with stones for customized designs.

By integrating precise welding technology, this step bridges all prior manufacturing processes, delivering high-quality, durable, and visually flawless bracelets ready for finishing and market distribution.

Conclusion

The SuperbMelt Bracelet Welder provides a comprehensive, efficient, and precise solution for modern bracelet manufacturing. By integrating advanced machinery for casting, rolling, tube forming, drawing, ring shaping, cutting, and welding, it ensures consistent quality, strong structural integrity, and seamless joints across both hollow and solid bracelets. This technology supports a wide range of metals, including gold, silver, copper, and alloys, while minimizing material waste and production time.

With its combination of high precision, versatility, and efficiency, the SuperbMelt Bracelet Welder enables jewelers to meet increasing market demand, produce large quantities with consistent quality, and create intricate custom designs. Whether for small-scale artisanal production or large-scale industrial manufacturing, SuperbMelt delivers a reliable, cost-effective, and high-quality solution, bridging traditional craftsmanship with modern automation.

FAQ Guide of Bracelet Welder

- 1. how long do welded bracelets last?

- 2. What materials can be welded with a bracelet welder?

- 3. What is the welding accuracy of the bracelet welding machine?

- 4. What are the main benefits of using a bracelet welder?

- 5. What is the power requirement for a bracelet welding machine?

- 6. What is the processing range of a bracelet welder?

- 7. Does bracelet welding damage the metal or affect its quality?

1. how long do welded bracelets last?

The durability of welded bracelets depends on several factors, including the materials used (e.g., gold, silver, platinum), the quality of the welding process, and how the bracelet is worn and maintained.

- Key Factors Influencing Longevity:

Material Quality:

High-quality metals like gold, silver, and platinum are less prone to corrosion or wear, ensuring a longer lifespan. - Welding Precision:

A properly welded bracelet with seamless joints, such as those made using machines like the SuperbMelt bracelet welder, creates strong bonds that are durable under normal wear conditions. - Usage and Maintenance:

Regular cleaning and proper handling (e.g., avoiding harsh chemicals, physical impacts, or over-stretching) significantly extend a bracelet’s life. - Type of Bracelet:

Hollow bracelets may require extra care compared to solid ones because they are more prone to deformation under pressure.

With proper welding and care, welded bracelets can last for decades, maintaining their structural integrity and appearance. Fine jewelry, particularly bracelets made from durable materials and using advanced welding technology, is often designed to last a lifetime if treated well. For bracelets worn daily or exposed to rough conditions, periodic inspection by a jeweler can ensure long-term durability.

2. What materials can be welded with a bracelet welder?

Bracelet welding machines use heat and pressure to fuse two metal pieces, creating a durable bond without compromising the bracelet’s design or structure.

3. What is the welding accuracy of the bracelet welding machine?

High-precision machines ensure a seamless weld, leaving no visible marks or defects on the bracelet’s surface.

4. What are the main benefits of using a bracelet welder?

Key benefits include faster production, higher welding precision, minimal material waste, and consistent quality for large-scale manufacturing.

5. What is the power requirement for a bracelet welding machine?

Most bracelet welders operate on a standard voltage of 220V with power consumption around 8KW, but specifications may vary by model.

6. What is the processing range of a bracelet welder?

Many machines can handle solid wire with diameters from 1.5mm to 6.0mm and hollow tube thicknesses above 0.5mm.

7. Does bracelet welding damage the metal or affect its quality?

No, modern welding machines are designed to protect the integrity of the metal while creating a strong and smooth bond.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited