Automatic Coin Making Equipment

SuperbMelt Automatic Coin Making Equipment – Efficient Coin Production Without Changing Molds

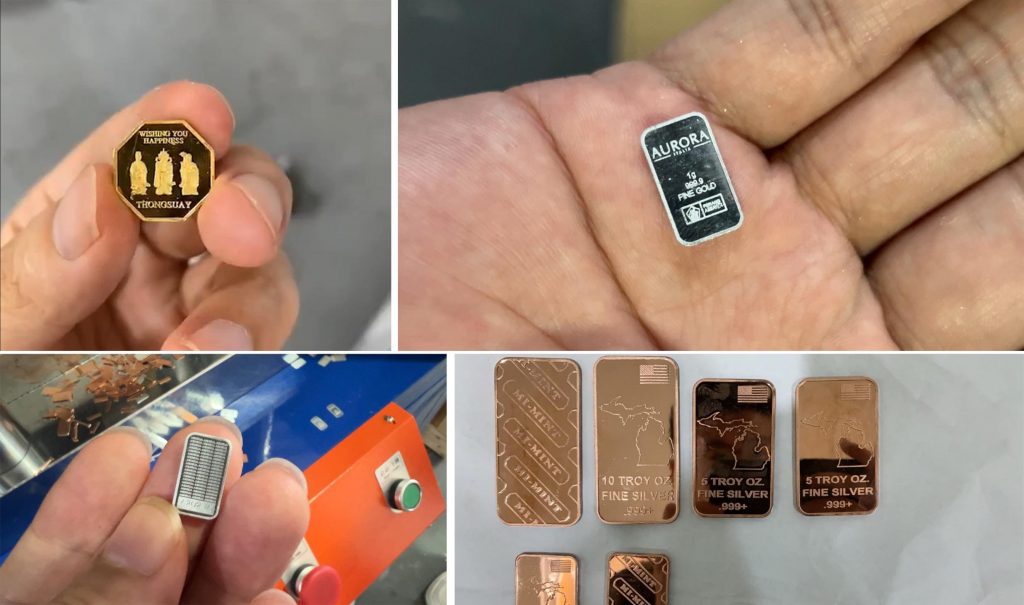

SuperbMelt Automatic Coin Making Equipment is designed to streamline the coin production process by combining stamping and blanking into one seamless operation—no need to change molds. This innovation significantly reduces both time and labor costs.

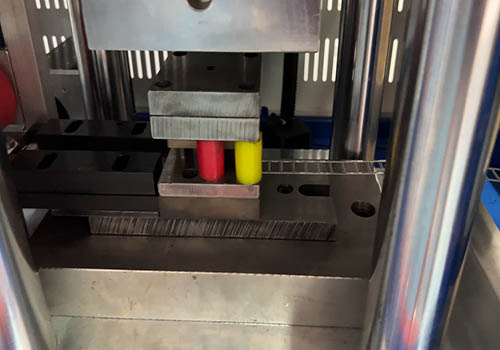

Fully automated and operator-free, this machine uses 20–50 tons of pressure to produce up to 20 pieces of 1–20g gold or silver coins per minute. The entire process, including feeding, blanking, pressing, and discharge, is completed automatically with high precision.

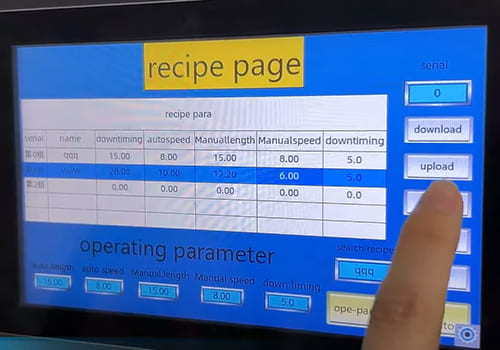

Equipped with a self-developed PLC control system, the machine can store all die stamping parameters. This means you won’t need to readjust settings every time you switch molds, ensuring consistent quality and greatly improving production efficiency.

This advanced coin press is ideal for small to medium-sized jewelers and refiners seeking to scale their minting operations. For more information or to request a quote, feel free to contact us today!

| Model number | SPB-HLP10A | SPB-HLP20A | SPB-HLP50A |

| Nominal/ton | 2.5-10 | 5-20 | 15-50 |

| Max stroke/mm | 100-200 | 100-250 | 300 |

| Opening height/mm | 300 | 350 | 400 |

| Descending speed/mm | 88 | 68 | 38 |

| Rising speed/mm | 88 | 68 | 38 |

| Worktable area/mm | 450*350 | 500*400 | 600*500 |

| Table height from the ground/mm | 850 | 850 | 850 |

| Voltage/V | 380 | 380 | 380 |

| Motor power/kw | 3.75 | 3.75 | 5.5 |

| Weight/kg | 580 | 660 | 1200 |

- Fully Integrated Automation

Combines feeding, blanking, stamping, and discharging into one automated process.

Eliminates the need for manual labor and supervision. - No Mold Changing Required

Capable of performing both blanking and stamping simultaneously without switching molds.

Ideal for efficiently producing various types of small gold and silver coins. - High-Pressure Coin Forming

Equipped with 20–50 tons of pressing force.

Capable of producing 1–20g gold or silver coins at a rate of up to 20 pieces per minute. - Smart PLC Control System

Features a self-developed PLC program that stores and recalls mold parameters automatically.

Eliminates the need to reconfigure settings when changing molds, saving time and ensuring accuracy. - Compact and Space-Saving Design

Small footprint, making it suitable for small-scale workshops and jewelry factories. - Increased Production Efficiency

Streamlined operations boost productivity by 2–3 times compared to traditional coin stamping methods. - Reduced Labor Costs

Fully automated design eliminates the need for manual operation, saving on workforce expenses. - Time-Saving Mold Management

Auto memory and parameter recall functionality reduce downtime during mold changes. - Consistent Coin Quality

High-precision pressure control ensures uniform coin weight, thickness, and engraving detail. - Versatile Material Compatibility

Suitable for minting coins from gold, silver, copper, platinum, and other precious metals. - Perfect for Small to Medium Jewelers and Refiners

An ideal solution for brands that require customized coin production with minimal setup and space requirements.

Integrated blanking and stamping — a single machine can cut sheet materials and perform stamping in one process, greatly saving time and costs.

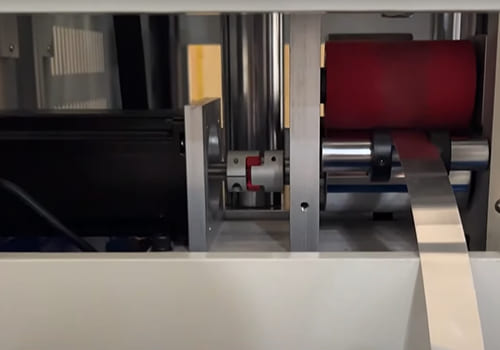

Equipped with an automatic feeding and discharging system, driven by a motor to carry out feeding, blanking, stamping, and unloading processes—completely eliminating the need for manual operation.

Equipped with a self-developed PLC program, the system can store all stamping parameters for your molds. There’s no need to readjust settings after each mold change—production can start immediately, significantly improving efficiency.

Why SuperbMelt Automatic Coin Making Equipment

Any Question About SuperbMelt Automatic Coin Making Equipment

Any Question About SuperbMelt Automatic Coin Making Equipment

FAQ Guide of Automatic Coin Making Equipment

- 1. What machines are used to make coins?

- 2. What materials can this machine process?

- 3. What is the production capacity of the machine?

- 4. What kind of press force does the machine use?

- 5. What coin sizes can the machine produce?

- 6. Can this machine be integrated into an existing production line?

- 7. What kind of coin surface finishes can it achieve?

- 8. Does the machine support double-sided stamping?

- 9. Can the equipment handle irregular shapes or only round coins?

- 10. How much pressure does it take to press a coin?

- 11. What is the difference between forging and coining?

- 12. Do I need to manually feed silver blanks into the press?

- 13. What is the typical size range of silver items that can be pressed?

- 14. What are the main types of coin making machines?

- 15. What is the recommended tonnage for coin making?

1. What machines are used to make coins?

- Melting Furnace

Used to melt metals such as gold, silver, copper, or alloys before casting them into blanks.

Common types: Induction melting furnace, electric resistance furnace. - Continuous Casting Machine / Ingot Casting Machine

Converts molten metal into long bars or ingots, which will be further processed into blanks. - Rolling Mill

Rolls cast bars into thin metal sheets of precise thickness.

Can be manual, electric, or hydraulic rolling mills depending on production scale. - Blanking Press / Blanking Machine

Punches out round discs (blanks) from the metal sheet.

Blanks are the raw shape of coins before stamping. - Annealing Furnace

Softens the metal blanks through heat treatment to prepare them for stamping.

Ensures metal doesn’t crack during pressing. - Cleaning and Polishing Machines

Clean and polish blanks to remove oxidation, grease, or debris before stamping.

Common types: vibratory finishing machines, centrifugal disc polishers. - Coin Press / Stamping Machine / Hydraulic Press

Uses high tonnage pressure (e.g., 20T–50T) to stamp detailed designs onto the blank.

Can be automatic or semi-automatic.

Some advanced machines combine blanking and stamping in one. - Edge Lettering or Reed Milling Machine (optional)

Used to inscribe edge text or create ridges (reeding) on the coin edge. - Inspection and Sorting Machine

Checks coins for quality, accuracy, and defects.

Automatically sorts accepted vs. rejected coins. - Packaging Machine (optional)

For batch-counting, wrapping, or sealing coins after production.

2. What materials can this machine process?

- Gold – Ideal for high-value commemorative and bullion coins.

- Silver – Common for collectible coins, medals, and currency-grade coins.

- Copper – Widely used for lower-denomination coins and custom tokens.

- Brass – A popular choice for decorative or promotional coins.

- Aluminum – Lightweight and cost-effective, often used for souvenir coins.

- Nickel – Suitable for durable and corrosion-resistant coinage.

- Platinum – For premium-grade medals or limited edition coins.

- Zinc Alloys – Used in low-cost, mass-production tokens.

3. What is the production capacity of the machine?

Automatic models:

- Can produce up to 20 coins per minute, depending on the size (typically 1g–20g) and material.

Manual or semi-automatic models:

- Typically produce 5–10 coins per minute, depending on operator speed and setup time.

Daily output estimate (for automatic models):

- Around 8,000–12,000 coins per 8-hour shift, assuming continuous operation with minimal downtime.

Factors That Affect Production Capacity:

- Coin weight and diameter

- Material hardness (e.g., gold vs. copper)

- Die change frequency

- Machine tonnage (e.g., 20T, 30T, 50T)

- Feeding system speed (manual vs. automatic)

4. What kind of press force does the machine use?

The coin making machine uses high-pressure hydraulic or servo-driven force to stamp designs onto metal blanks. The press force varies depending on the machine model and application.

Typical Press Force Range:

10 to 50 tons (10T–50T) of nominal pressing force.

Recommended Press Force by Coin Size & Material:

| Coin Type | Material | Press Force (Recommended) |

|---|---|---|

| Small coin (1–5g) | Gold/Silver | 10–20 tons |

| Medium coin (5–15g) | Gold/Silver/Copper | 20–30 tons |

| Large coin (15–30g) | Brass/Nickel/Platinum | 30–50 tons |

Why Press Force Matters:

Ensures clear and detailed engraving on both sides

Prevents incomplete stamping or metal deformation

Accommodates varying hardness of materials (e.g., silver vs. brass)

5. What coin sizes can the machine produce?

Typical Coin Size Range:

Diameter:

From 10 mm up to 50 mm

(Custom machines may support up to 60 mm or more)Thickness:

From 1 mm to 5 mm

(Adjustable based on material type and design depth)Weight:

From 1 gram to 30 grams, commonly

(Heavier coins possible with larger press models)

Customizable Coin Sizes:

Coin dimensions are fully customizable by changing the mold/die set.

The machine’s PLC system can store multiple settings for different coin sizes and shapes.

Supports:

Standard circular coins

Custom shapes (hexagonal, oval, square) with custom dies

Medals, tokens, and commemorative pieces

6. Can this machine be integrated into an existing production line?

Integration Capabilities:

Modular Design

The machine is designed with modular automation components (feeding, stamping, and discharging), making it easy to connect with upstream and downstream equipment.

PLC-Controlled System

It uses an advanced PLC control system that allows synchronization with other machines—such as melting furnaces, rolling mills, blanking lines, polishing systems, or packaging units.

Signal Interface Available

The machine can be equipped with I/O signal interfaces or communication protocols (e.g., Modbus, Ethernet) for seamless integration into smart factory setups.

Automatic Feeding & Discharging Units

Compatible with robotic arms, conveyors, or vibrating feeders to support fully automated production flow.

Common Integration Scenarios:

Upstream: Metal melting → sheet rolling → blanking

Midstream: Coin pressing/stamping (this machine)

Downstream: Edge lettering → polishing → inspection → packaging

7. What kind of coin surface finishes can it achieve?

Common Coin Surface Finishes Achieved:

Proof Finish

– Mirror-like, highly polished background with frosted design elements.

– Used for collector and commemorative coins.Brilliant Uncirculated (BU) Finish

– Bright, shiny surface with sharp details, typical for bullion coins.Matte Finish

– Soft, non-reflective surface with a subtle texture for a classic look.Satin Finish

– Smooth but less glossy than BU, providing a muted sheen.Frosted Finish

– Raised design areas have a frosted texture contrasting with polished fields.Textured or Patterned Finish

– Custom textures or patterns can be applied via specialized dies for unique aesthetics.

How Surface Finish Is Controlled:

Die engraving: Precision engraving and polishing of the dies dictate the final finish on the coin.

Metal preparation: Annealing, cleaning, and polishing blanks before pressing enhance finish quality.

Post-processing: Additional polishing, sandblasting, or coating can be applied after pressing.

8. Does the machine support double-sided stamping?

Details on Double-Sided Stamping:

The machine uses matched upper and lower dies to imprint detailed designs on both the front (obverse) and back (reverse) sides of the coin simultaneously.

Ensures precise alignment between the two sides for consistent, high-quality coins.

Supports various relief depths and intricate patterns on both faces.

Commonly used for official currency coins, commemorative coins, and collectible medals.

Benefits of Double-Sided Stamping:

Saves production time by stamping both sides in a single press cycle.

Guarantees symmetrical and balanced designs.

Reduces the risk of misalignment and rework.

9. What kind of coin surface finishes can it achieve?

The coin making machine can produce a variety of surface finishes, tailored to your design and production needs. Common finishes include:

Proof Finish — Mirror-like, highly polished background with frosted or matte design elements, ideal for collector coins.

Brilliant Uncirculated (BU) Finish — Bright and shiny surface with sharp details, typical for bullion coins.

Matte Finish — Soft, non-reflective surface with a subtle texture for a classic look.

Satin Finish — Smooth, less glossy than BU, offering a muted sheen.

Frosted Finish — Raised design areas have a frosted texture contrasting with polished fields.

Textured or Patterned Finish — Custom textures or patterns can be applied through specialized dies for unique aesthetics.

The final finish depends largely on die engraving precision, metal blank preparation (such as annealing and cleaning), and any post-press treatments like polishing or coating.

10. How much pressure does it take to press a coin?

Pressing a coin typically requires between 10 to 50 tons of pressure, depending on factors such as the coin’s size, thickness, material hardness, and the level of detail in the design.

Typical Press Force Range for Coin Pressing:

| Coin Size/Weight | Material | Recommended Pressure (Tons) |

|---|---|---|

| Small coins (1–5 grams) | Gold, Silver | 10–20 tons |

| Medium coins (5–15 g) | Silver, Copper | 20–30 tons |

| Large coins (15–30 g) | Brass, Nickel | 30–50 tons |

Why pressure matters:

Ensures crisp and detailed designs are clearly imprinted on both sides.

Prevents incomplete or uneven stamping.

Accommodates different metal hardness to avoid damage to dies and blanks.

Advanced machines can automatically adjust the pressing force based on stored parameters for each mold to optimize quality and extend die life.

11. What is the difference between forging and coining?

Forging vs. Coining: Key Differences

| Aspect | Forging | Coining |

|---|---|---|

| Definition | Shaping metal by applying compressive forces, usually at high temperatures, to form parts or tools. | A precise stamping process where metal blanks are compressed under high pressure to imprint detailed designs, typically at room temperature. |

| Purpose | To form rough or semi-finished shapes with improved strength and grain structure. | To produce finely detailed, flat or slightly raised images/designs on metal surfaces (e.g., coins, medals). |

| Process | Deforming metal using hammers, presses, or dies — often hot forging. | Compressing metal blanks between engraved dies under high pressure (cold working). |

| Material State | Often involves heating the metal to make it malleable (hot forging). | Usually done cold or at room temperature to retain metal detail and finish. |

| Typical Products | Automotive parts, tools, hardware, structural components. | Coins, medals, badges, precision parts with detailed surface designs. |

| Detail Level | Lower surface detail, focused on shape and strength. | High precision, intricate surface detail and relief. |

| Equipment Used | Forging presses, hammers, anvils. | Coining presses, hydraulic or mechanical presses with precision dies. |

Summary:

Forging is about shaping and strengthening metal parts, often at high heat, with less focus on surface detail.

Coining is a high-precision stamping process that imprints detailed designs onto metal blanks, mostly used for coins and medals.

12. Do I need to manually feed silver blanks into the press?

Feeding Options:

Automatic Feeding System:

Most modern silver press machines are equipped with motor-driven automatic feeding and discharging systems. They handle silver blanks continuously without manual intervention, improving efficiency and consistency.Manual Feeding:

Some smaller or semi-automatic machines may require manual loading of blanks, but this slows down production and increases labor costs.

Benefits of Automatic Feeding:

Reduces labor and operator fatigue

Ensures steady, precise blank placement for accurate stamping

Increases production speed and throughput

13. What is the typical size range of silver items that can be pressed?

Typical Size Range for Pressed Silver Items

Diameter:

From 10 mm up to 50 mm (custom sizes possible with specialized dies)Thickness:

From 0.5 mm to 5 mm, depending on the design and material thicknessWeight:

Generally from 1 gram to 30 grams, adaptable based on machine tonnage and mold design

Customization:

Silver press machines can be customized to handle larger or uniquely shaped items such as medallions, tokens, or jewelry tags.

Adjustments to dies and press settings allow for flexibility in size and thickness.

14. What are the main types of coin making machines?

Main Types of Coin Making Machines

Blanking Machine (Coin Blanking Press)

Cuts metal sheets into round blanks (planchets) that will be stamped into coins.

Produces uniform blanks of precise diameter and thickness.

Often the first step in coin production.

Annealing Furnace

Heats blanks to soften the metal for easier stamping and to improve metal ductility.

Coin Stamping Machine (Coin Press)

Uses matched upper and lower dies to imprint detailed designs on both sides of the coin.

Can be manual, semi-automatic, or fully automatic.

Includes hydraulic and mechanical presses.

Edge Lettering Machine (Coin Edge Press)

Imprints text, patterns, or reeding on the edge of coins for security and decoration.

Automatic Coin Making Machine

Integrates blanking, feeding, stamping, and discharging into one automated system.

Increases production speed and reduces labor costs.

Coin Inspection and Sorting Machine

Uses vision systems and sensors to inspect coins for defects and sort them by size or type.

Coin Packaging Machine

Packages finished coins into rolls, tubes, or cases for distribution.

Summary:

| Machine Type | Function | Stage in Production |

|---|---|---|

| Blanking Machine | Cut blanks from metal sheets | Initial step |

| Annealing Furnace | Soften metal blanks | Pre-stamping |

| Coin Stamping Machine | Stamp designs onto blanks | Main minting operation |

| Edge Lettering Machine | Add edge details | Post-stamping |

| Automatic Coin Making Machine | All-in-one coin production | Integrated full process |

| Inspection & Sorting Machine | Quality control & sorting | Post-production |

| Packaging Machine | Pack coins for sale | Final stage |

15. What is the recommended tonnage for coin making?

Recommended Press Tonnage for Coin Making

| Coin Size / Weight | Material Type | Recommended Tonnage (Tons) |

|---|---|---|

| Small coins (1–5 grams) | Soft metals (gold, silver) | 10–20 tons |

| Medium coins (5–15 g) | Silver, copper alloys | 20–30 tons |

| Large coins (15–30 g) | Harder metals (brass, nickel, platinum) | 30–50 tons |

Why Choose the Right Tonnage?

Sufficient pressure is needed to ensure clean, detailed stamping without defects.

Too little pressure can cause incomplete designs or poor impressions.

Excessive pressure can damage dies or cause excessive wear.

Matching tonnage to coin specifications optimizes production quality and die longevity.

Additional Notes:

For very thin or delicate coins, lower tonnage with precision control may suffice.

For coins with deep relief or intricate designs, higher tonnage may be necessary.

Many modern machines feature adjustable tonnage and pressure control for flexibility.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited