XRF Gold Analyzer

The most popular SuperbMelt XRF Precious Metal Analyzer on the market

The best analyser for analysing and testing metal elements is the SuperbMelt XRF Gold Analyzer (model XR3800). It can be used to examine 72 metals including solid/liquid/metal powders such as 7 copper, zinc, platinum, palladium, platinum niobium and gold.

The SuperbMelt XRF gold tester provides fast, accurate and non-destructive analysis of metals. the XRF precious metal analyser’s built-in and user-friendly software makes it simple to use in the pawn industry, refineries, gold mines, laboratory analysis and other metal applications.

A wide variety of j-metal items, including jewellery chains, rings, gold bars, liquids, powders and mineral rocks, can be tested with this machine. This XRF gold analyser performs qualitative analysis in less than 30 seconds.

We can take your orders and enquiries at SuperbMelt. If you want the best and most affordable precious metal analyser, contact us.

| Model | SPB-XR 3800 |

| Analysis Range | ppm to 99.99% |

| Accuracy | 0.03% |

| Sample Form | Solid, powder, liquid |

| Tube Voltage | 5KV ~ 50KV |

| High Voltage Power Supply | 0 ~ 50KV |

| Camera | HD camera |

| Filters | Selectable customized switches |

| Detector Type | Si-pin (Amptek, USA) |

| Resolution | 145 + 5 ev |

| Multichannel Analyzer | Digital multichannel |

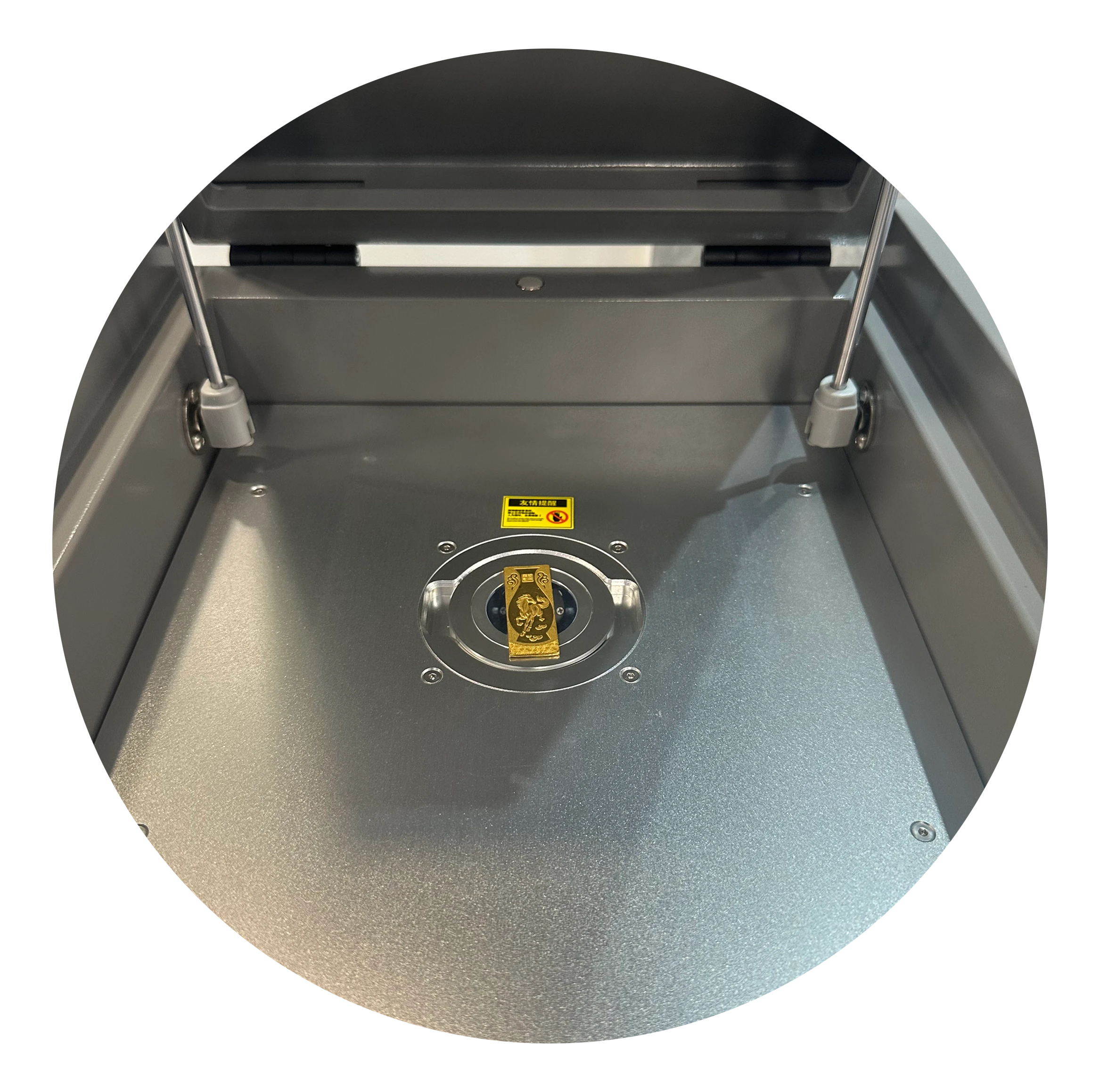

| Sample Chamber Size | 310 * 270 * 80 (mm) |

| Test Time | 3sec ~ 60sec |

| Measuring Element | 72 elements from sodium (Na) to uranium (U) except (Na、Mg、Al、Si、P、S、Cl Ar、K、Ca)light elements |

| Analysis Software | Qualitative and quantitative analysis software |

| External Dimensions | 460 * 390 * 360 (mm) |

| Weight | 38Kg |

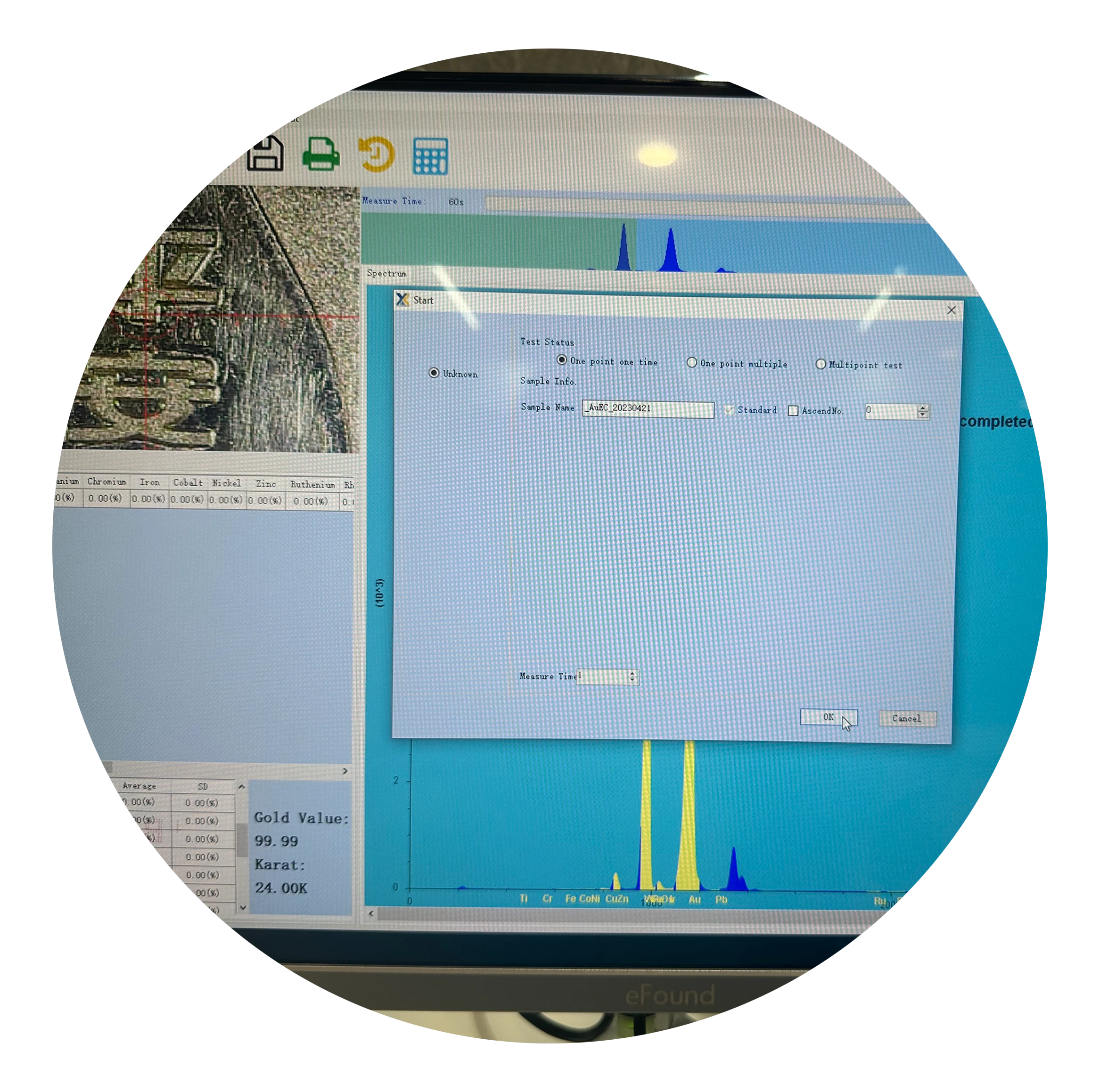

- Completely Intelligent Analysis: The operator just needs to put the samples on the measurement window and click “measurement start” to get result.

- Only one sample is needed for calibration, reducing operation steps and making operation easier

- High Accurate: Analysis results close to fire assay result.

- Rapid Analysis: Only takes several seconds for qualitative analysis, and 1 to 2 minutes for quantitative analysis.

- Superbmelt XRF precious metal analyzer is used for the analysis, detection of elements present in metals, and testing thickness of metal coatings.

- The XRF gold tester by Superbmelt is able to detect elements such as gold, silver, platinum, palladium, iron, copper, nickel, zinc, rhodium, iridium, chromium, and so on.

- The systems software is based on Microsoft Windows which makes it easy to use. By pressing the start button, analysis begins. This means that there is no need for standard samples for calibration.

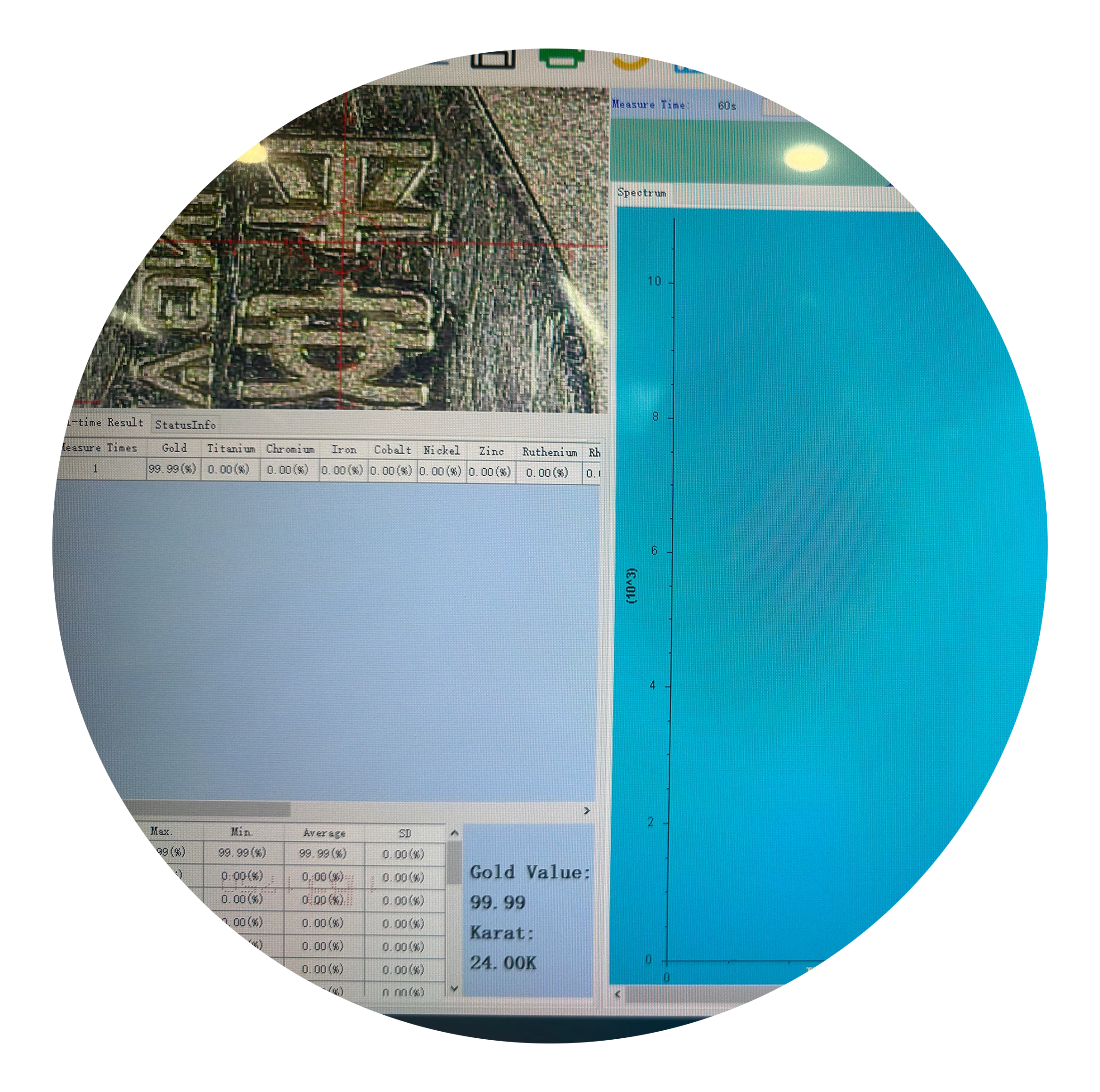

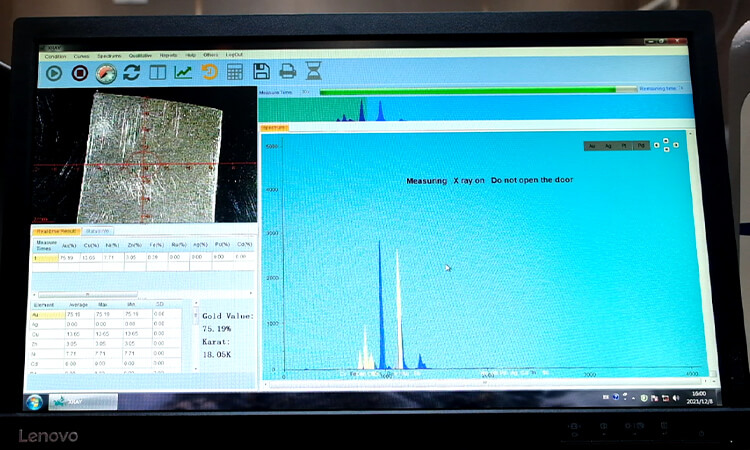

- After analysis, the Superbmelt XRF precious metal analyzer can display over 25 elements at the same time on the high-resolution screen.

- The process of analysis is fast, it usually takes 1 to 120 seconds. This helps you to save cost and time during precious metal analysis,

- On average, the Superbmelt XRF metal analyzer has an analytical tolerance of 0.01%-0.3%.

- The excited source is a low power x-ray tube that reduces the chances of precious metal damage during testing and analysis.

- Superbmelt precious metal analyzer for sale is compact in size with a total dimension of 45*30*20cm and weighs only 23kg.

- Superbmelt gold tester performs testing and analysis accurately, the result of testing is close to fire assay.

- Superbmelt XRF precious metal analyzer has a power supply mode of 220V 50Hz or 110V 60Hz that can easily be charged with vehicle power supply and battery.

- Superbmelt XRF gold tester is used in jewellery production and sales, government agencies, banks, research and development, etc.

XRF Precious Metal Analyzer

Placement

Place the metal to be tested on top of the instrument table

Click to Start

Waiting for the heavy metal analyser to start testing

End of Test

To check the metal purity content at the end of the test, check the table at the bottom of this page

Why SuperbMelt XRF Precious Metal Analyzer

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Tester For Gold

SuperbMelt metal analyzers are produced by a company that offers a comprehensive selection of cutting-edge tools for precise and trustworthy analysis of a variety of precious and base metals.

Our analysts use cutting-edge methods including atomic absorption spectroscopy (AAS) and X-ray fluorescence (XRF) to swiftly and accurately identify and quantify elements in a variety of sample types, from alloys and jewelry to mining and environmental materials.

Our metal analyzers are trusted by professionals across a range of industries, including jewelry manufacture, mining, refining, and recycling, because to their high accuracy, quick analysis times, and user-friendly software. SuperbMelt is the ideal solution for your needs in metal analysis, whether you’re looking for a benchtop or handheld analyzer.

| Model Number | Name | Type | Comments |

| XR1200 | Benchtop Gold Analyzer | Benchtop | Measure five elements of gold, silver, platinum, palladium and copper to an accuracy of 1 in 1,000 |

| XR2800 | Benchtop Gold Analyzer | Benchtop | 17 elements can be measured with an accuracy of 5 parts per million to 1 part per thousand |

| XR5000 | Handheld XRF Analyzer | Handheld | Analysis of metal elements up to 12-92 and testing of stainless steel grades and accuracy |

| XR5800 | Handheld XRF Analyzer | Handheld | Stainless steel grades can be tested for elemental content and accuracy, and 72 elements, with an accuracy of 5 parts per million |

How to identify the purity of gold and silver?

The SuperbMelt XRF SPB-XR 3800 model can be used to measure the purity of gold or silver if you don’t know how to do it yourself.

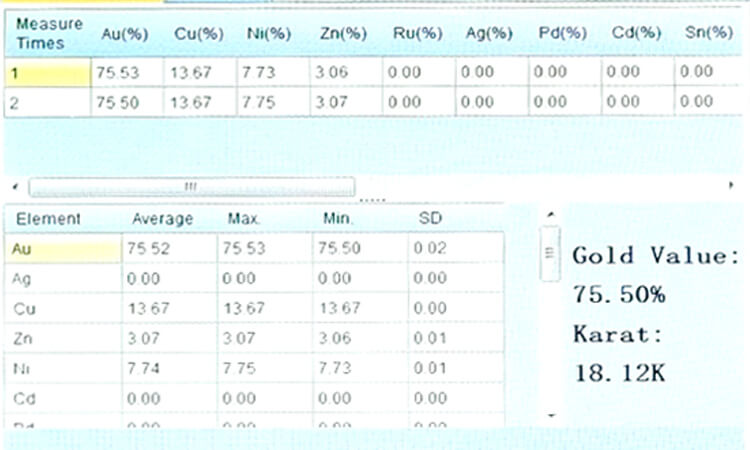

You can see the following table once you’ve completed the measurement.

To verify your gold and silver, adhere to the production conditions listed in the table. Purity Of course, SuperbMelt also offers other models of metal detectors for gold.

| Material | Karat | Millesimal fineness | Percentage |

| Gold | 24K | 999.9 | 99.99% |

| Gold | 22K | 916.7 | 91.67% |

| Gold | 18K | 750 | 75% |

| Gold | 14K | 583.3 | 58.33% |

| Gold | 10K | 416.7 | 41.67% |

| Silver | 999 | 999 | 99.9% |

| Silver | 958 | 958 | 95.8% |

| Silver | 925 | 925 | 92.5% |

| Silver | 900 | 900 | 90% |

| Silver | 835 | 835 | 83.5% |

| Silver | 800 | 800 | 80% |

How Do Customers Evaluate Our Products?

More SuperbMelt Metal Testers For You To Choose From

Any Question About SuperbMelt XRF Precious Metal Analyzer

XRF Gold Analyzer Guide for the Jewelry Industry

In the jewelry and precious metals industry, the accuracy of metal composition and purity directly determines product value, transaction trust, and brand reputation. Whether it’s a jewelry retailer verifying the 18K gold content of a ring, a recycler assessing the purity of scrap gold, or a manufacturer conducting incoming material inspection for gold bars, traditional testing methods (such as fire assay) often face pain points like long testing cycles, destructive sampling, complex operations, and high professional thresholds. These issues not only reduce transaction efficiency but also increase operational risks—for example, damaging high-value finished jewelry during testing or making wrong valuation decisions due to inaccurate results.

SuperbMelt XRF Gold Analyzer (model XR3800), based on advanced X-ray Fluorescence (XRF) technology, provides a professional solution to these industry challenges. As the best analyzer for metal element testing, it supports non-destructive analysis of 72 metals (including gold, silver, platinum, palladium, copper, zinc, etc.) and is compatible with solid, liquid, and powder samples. With fast testing speed (qualitative analysis in less than 30 seconds), high accuracy (results close to fire assay), and fully intelligent operation, it has become an indispensable tool in jewelry retail, recycling, pawnbroking, manufacturing, and refining. This comprehensive guide will take you through every key link of XRF gold analyzers—from working principles and detectable materials to industry applications, performance indicators, and equipment selection—helping you master efficient and reliable precious metal testing solutions and enhance the core competitiveness of your business.

Working Principle of an XRF Gold Analyzer

To understand the value of XRF gold analyzers in the jewelry industry, it is first necessary to clarify their core working principle—X-ray Fluorescence (XRF) technology. Unlike traditional destructive testing methods, XRF technology achieves non-destructive, rapid, and accurate element analysis through physical processes, which is perfectly aligned with the high-value and precision requirements of the jewelry industry.

1.1, Basics of X-ray Fluorescence (XRF) Technology

The working principle of SuperbMelt XRF Gold Analyzer (XR3800) is based on the X-ray fluorescence effect: when the low-power X-ray tube (the excited source of the equipment) emits X-rays to irradiate the precious metal sample, the atoms in the sample will absorb the energy of the X-rays, causing the inner-shell electrons to transition to an excited state. When the excited electrons return to the ground state, they will release characteristic X-rays with specific energy. The equipment’s detector captures these characteristic X-rays, and through the built-in intelligent software (based on Microsoft Windows system), it analyzes the energy and intensity of the X-rays to determine the types and content of elements in the sample.

Key advantage: The low-power X-ray tube of the SuperbMelt XR3800 not only ensures sufficient excitation energy for element detection but also minimizes the risk of damage to precious metals during testing—completely avoiding the sample damage problem that plagues traditional testing methods.

1.2, Why Non-Destructive Testing Is Essential for Jewelry

For the jewelry industry, non-destructive testing is not a “value-added option” but a “basic requirement.” The core reasons are as follows:

- Protecting High-Value Products: Most jewelry products (such as inlaid rings, delicate necklaces, and limited-edition gold coins) are high-value finished products. Destructive testing (such as cutting samples for fire assay) will directly damage the product’s integrity, reducing its value or even making it unsellable. SuperbMelt XRF Gold Analyzer can complete testing without damaging the sample’s appearance or structure, maximizing the protection of product value.

- Meeting Transaction Transparency Needs: In jewelry retail, recycling, and pawn transactions, customers often require on-site, visual testing. Non-destructive testing allows the tester to operate in front of the customer, displaying the analysis results in real time. This enhances transaction transparency, eliminates customer doubts about “sample replacement” or “damage to the product,” and builds trust between the two parties.

- Adapting to Diversified Sample Forms: Jewelry products have diverse forms—solid finished products (rings, chains), semi-finished materials (gold bars, silver sheets), and even raw materials (metal powders, mineral ores). Non-destructive testing can adapt to various sample forms without special sample processing, improving testing efficiency.

1.3, Differences in Testing Solid, Liquid, and Powder Samples

SuperbMelt XRF Gold Analyzer (XR3800) has strong compatibility and can handle solid, liquid, and powder samples common in the jewelry and precious metal industry. The testing methods and key points for different sample forms are slightly different, but the core advantages of fast, accurate, and non-destructive remain unchanged:

- Solid Samples: The most common sample form in the jewelry industry, including finished jewelry (rings, chains, bracelets), gold bars, silver coins, and scrap gold. Testing only requires placing the sample on the measurement window of the equipment and clicking “measurement start”—the intelligent software will automatically complete the analysis. For irregularly shaped solid samples (such as twisted chains), the equipment’s high-sensitivity detector can still accurately capture characteristic X-rays, ensuring analysis accuracy.

- Liquid Samples: Common in jewelry manufacturing auxiliary materials (such as electroplating solutions, metal refining solutions). When testing liquid samples, a special sample container (provided with the equipment) is required to hold the liquid and place it on the measurement window. The equipment can quickly analyze the element content in the liquid, helping manufacturers control the quality of the production process (such as ensuring the concentration of gold ions in the electroplating solution).

- Powder Samples: Including metal powder raw materials, mineral ores (gold ore, silver ore), and scrap metal powder. For powder samples, it is necessary to ensure that the powder is evenly spread in the sample container to avoid uneven sample thickness affecting the analysis results. SuperbMelt XR3800’s software algorithm has been optimized for powder samples, which can automatically correct the influence of sample density and thickness, ensuring accurate results.

Detectable Materials and Application Scope

SuperbMelt XRF Gold Analyzer (XR3800) is known for its wide material compatibility, covering almost all common precious metals, base metals, and their alloys in the jewelry industry. It can not only test finished jewelry but also adapt to raw materials, auxiliary materials, and even cross-industry samples, with an extremely wide application scope.

2.1, Precious Metals Analysis: Gold, Silver, Platinum, Palladium, and Alloys

The core application of the equipment in the jewelry industry is the analysis of precious metals and their alloys. It can accurately detect 72 metals, including key precious metals and common alloy elements:

- Main Precious Metals: Gold (Au), silver (Ag), platinum (Pt), palladium (Pd), rhodium (Rh), iridium (Ir), etc.—covering all precious metals used in jewelry manufacturing. For example, it can accurately measure the gold content in 14K, 18K, 22K, and 24K gold jewelry, with an analytical tolerance of only 0.01%-0.3%.

- Alloy Elements: Common alloy elements in precious metal jewelry, such as copper (Cu), nickel (Ni), zinc (Zn), iron (Fe), chromium (Cr), etc. Taking 18K gold as an example, the equipment can not only detect the gold content but also analyze the content of copper, silver, and other alloy elements, helping manufacturers ensure the consistency of alloy composition and product quality.

- Key Advantage: The equipment can display more than 25 elements at the same time on the high-resolution screen after analysis, allowing users to grasp the full element composition of the sample at a glance—avoiding the risk of “hidden element” affecting product quality or value.

2.2, Jewelry Products: Chains, Rings, Bars, Coins, and Finished Pieces

For various finished and semi-finished jewelry products, SuperbMelt XR3800 can achieve fast and accurate testing without damage:

- Finished Jewelry: Rings (inlaid, plain), chains (hollow, solid), bracelets, earrings, pendants, etc. Whether it is a small inlaid ring (with a testing area of only a few square millimeters) or a large gold bracelet, the equipment can complete testing in a short time—qualitative analysis in less than 30 seconds, and quantitative analysis in 1-2 minutes.

- Semi-Finished Materials: Gold bars, silver sheets, platinum wires, and other raw materials used in jewelry manufacturing. Manufacturers can use the equipment for incoming material inspection to ensure that the purity of the raw materials meets the production requirements, avoiding quality problems in the subsequent production process.

- Scrap Jewelry: Scrap gold, old silver jewelry, and other materials in the recycling process. The equipment can quickly assess the purity of the scrap, helping recyclers accurately value the materials and avoid losses caused by misjudgment of purity.

2.3, Beyond Jewelry: Powders, Mineral Ores, and Industrial Metals

The application scope of SuperbMelt XRF Gold Analyzer is not limited to the jewelry industry. It can also be used in cross-industry fields that require metal element analysis, expanding the value of the equipment:

- Metal Powders: Precious metal powder (gold powder, silver powder) used in jewelry inlay, and base metal powder (copper powder, zinc powder) used in alloy manufacturing. The equipment can analyze the purity and impurity content of the powder, ensuring the quality of the raw materials.

- Mineral Ores: Gold ore, silver ore, platinum ore, etc. In the mining and mineral processing industry, the equipment can quickly analyze the grade of precious metals in the ore, helping mining enterprises evaluate the value of mineral resources and optimize the mineral processing process.

- Industrial Metals: Base metals and alloys used in industrial production (such as stainless steel, brass, aluminum alloys). The equipment can be used for quality control in industrial production, such as detecting the element content of metal parts to ensure their performance meets the requirements.

Typical Jewelry Industry Applications

With its fast, accurate, non-destructive, and easy-to-operate advantages, SuperbMelt XRF Gold Analyzer (XR3800) has been widely used in various links of the jewelry industry chain, from retail terminals to manufacturing and refining, becoming a “trust guarantee” for each transaction and production link.

3.1, Jewelry Retail and Recycling: Fast Purity and Karat Verification

In jewelry retail stores and recycling centers, the speed and accuracy of testing directly affect customer experience and transaction efficiency. SuperbMelt XR3800 perfectly solves the pain points of traditional testing in these scenarios:

- Jewelry Retail: When customers buy gold, silver, or platinum jewelry, they often have doubts about the purity of the product. The store staff can use the equipment to conduct on-site testing—placing the jewelry on the measurement window, clicking the start button, and getting the purity result in 30 seconds. The intuitive display of the result (such as “18K Gold, Au 75.02%”) enhances customer trust and promotes transaction closure.

- Jewelry Recycling: Recycling centers need to quickly value a large number of scrap jewelry every day. The equipment can quickly analyze the purity of each piece of scrap, avoiding the long cycle of fire assay (which usually takes several hours to several days). For example, a recycler can test 50 pieces of scrap gold in 1 hour with the XR3800, greatly improving recycling efficiency and cash flow turnover.

3.2, Pawn Shops and Precious Metal Trading: On-Site Authentication

Pawn shops and precious metal trading companies have strict requirements for the authenticity and purity of collateral/transacted goods—false authentication will lead to huge economic losses. SuperbMelt XR3800 has become their core authentication tool:

- Pawn Shop Authentication: When customers pawn gold bars, silver coins, or high-value jewelry, pawnbrokers need to complete authentication on the spot. The equipment’s non-destructive testing ensures that the collateral is not damaged, and the fast testing speed (within 1 minute) allows the pawn process to be completed quickly. At the same time, the high accuracy (results close to fire assay) avoids the risk of accepting fake or low-purity collateral.

- Precious Metal Trading: In bulk trading of gold bars, silver ingots, and other precious metals, both parties need a neutral and accurate testing result to determine the transaction price. SuperbMelt XR3800 can be used as a third-party testing tool (recognized by many industry institutions) to provide objective element analysis results, ensuring the fairness and transparency of the transaction.

3.3, Manufacturing and Refineries: Incoming Material Inspection and Quality Control

In jewelry manufacturing and precious metal refining, quality control throughout the process is crucial to ensuring product consistency and meeting industry standards. SuperbMelt XR3800 plays an important role in incoming material inspection, in-process control, and finished product inspection:

- Incoming Material Inspection: When manufacturers purchase gold bars, silver sheets, or alloy materials, they use the equipment to test the purity and element composition of the incoming materials. If the materials do not meet the production requirements, they can be returned in time, avoiding the waste of subsequent production costs.

- In-Process Control: During the alloy smelting process, the equipment can quickly test the alloy composition to ensure that the content of each element is within the set range. For example, when smelting 18K gold, the equipment can test the gold content in real time, helping workers adjust the proportion of raw materials in a timely manner.

- Finished Product Inspection: Before the finished jewelry leaves the factory, the equipment is used for sampling inspection to ensure that the purity and element composition of the product meet the national/industry standards. This avoids the risk of product recall due to quality problems and protects the brand reputation.

Testing Speed and Data Accuracy

Testing speed and data accuracy are the two core indicators that determine the value of an XRF gold analyzer. SuperbMelt XRF Gold Analyzer (XR3800) has reached the industry-leading level in both aspects, relying on advanced hardware configuration and intelligent software algorithms, providing users with efficient and reliable testing results.

4.1, Elemental Analysis in Under 30 Seconds

The SuperbMelt XR3800 has achieved a breakthrough in testing speed, perfectly adapting to the high-efficiency requirements of the jewelry industry:

- Qualitative Analysis in <30 Seconds: For the rapid identification of precious metal types (such as distinguishing gold from silver, or verifying whether a sample contains platinum), the equipment can complete qualitative analysis in less than 30 seconds. This is especially useful in scenarios such as pawn shops and recycling centers where a large number of samples need to be screened quickly.

- Quantitative Analysis in 1-2 Minutes: For the accurate measurement of element content (such as the gold content of 18K gold jewelry, the silver content of sterling silver), the equipment only takes 1-2 minutes to complete quantitative analysis. Compared with traditional fire assay (which takes several hours), the speed is increased by more than 100 times, greatly improving production and transaction efficiency.

- Key Advantage: The fast testing speed does not come at the cost of accuracy. The equipment’s low-power X-ray tube and high-sensitivity detector work together to ensure that sufficient characteristic X-ray signals are collected in a short time, laying the foundation for accurate analysis.

4.2, Multi-Element Detection for Accurate Valuation

The value of precious metal products is not only determined by the content of the main precious metal but also affected by the type and content of alloy elements. SuperbMelt XR3800’s multi-element detection capability ensures accurate valuation of products:

- Simultaneous Detection of 25+ Elements: The equipment can display more than 25 elements at the same time on the high-resolution screen after a single test, including the main precious metal and all alloy elements. For example, when testing a 14K gold ring, it can simultaneously display the content of gold, copper, silver, nickel, and other elements, allowing users to fully grasp the sample’s composition.

- Support for Coating Thickness Testing: In addition to element content analysis, the equipment can also test the thickness of metal coatings (such as the gold plating thickness on silver jewelry). This is crucial for jewelry manufacturers that produce plated products—ensuring that the coating thickness meets the standard and avoiding problems such as coating peeling.

- Accuracy Close to Fire Assay: The analytical tolerance of the equipment is only 0.01%-0.3%, and the test results are close to the authoritative fire assay method. This makes the equipment’s results acceptable in industry transactions, pawnbroking, and quality inspection, eliminating the need for repeated testing with traditional methods.

4.3, Software Algorithms and Measurement Consistency

The stability of test results (measurement consistency) is equally important as accuracy—especially for mass production and batch testing. SuperbMelt XR3800 ensures measurement consistency through advanced software algorithms and intelligent calibration functions:

- Intelligent Software Algorithm: The equipment’s software is based on the Microsoft Windows system, which is easy to operate and has built-in intelligent correction algorithms. It can automatically correct the influence of factors such as sample shape, density, and temperature on the test results, ensuring that the results of the same sample are consistent even in different environments.

- Simplified Calibration Process: Unlike traditional XRF analyzers that require multiple standard samples for calibration, the SuperbMelt XR3800 only needs one sample for calibration, which greatly reduces the operation steps and professional requirements for operators. Even new employees can complete calibration and testing proficiently after simple training.

- No Need for Standard Samples for Daily Use: The equipment’s software has a self-calibration function. After the initial calibration, no standard samples are needed for daily testing—just turn on the machine and use it, which further improves testing efficiency and reduces operating costs.

Equipment Selection and Operation

Choosing the right XRF gold analyzer and mastering standardized operation methods are crucial to maximizing the equipment’s value. This chapter will focus on the key points of equipment selection, operation difficulty, and daily maintenance, helping you make rational decisions based on your business needs.

5.1, Benchtop vs Portable XRF Analyzers

The XRF gold analyzers on the market are mainly divided into benchtop and portable types. SuperbMelt provides both types of products, and you can choose according to your application scenario and testing needs:

- Benchtop XRF Analyzer (e.g., SuperbMelt XR3800): Suitable for fixed scenarios such as jewelry stores, pawn shops, manufacturing factories, and refineries. It has the advantages of higher accuracy, more stable performance, and larger sample testing area. The SuperbMelt XR3800 is compact in size (45*30*20cm) and weighs only 23kg, which does not take up much space—even small retail store counters can place it easily. It supports 220V 50Hz or 110V 60Hz power supply, and can also be powered by vehicle power supply or battery, making it flexible in use.

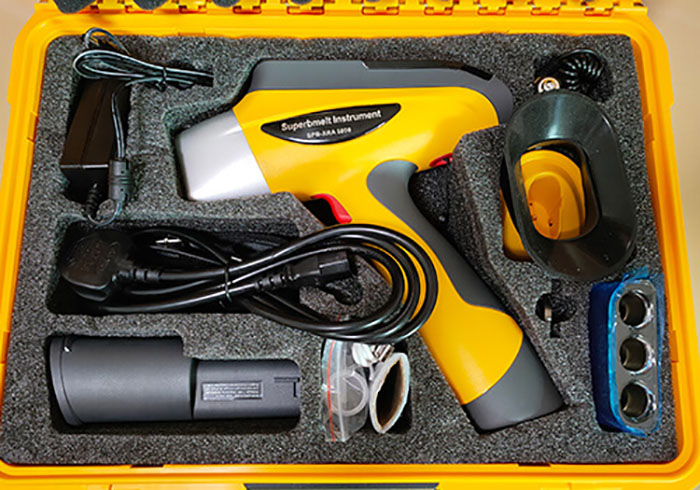

- Portable XRF Analyzer: Suitable for on-site testing scenarios such as mining areas, outdoor recycling, and on-site inspection. It has the advantages of small size, light weight, and easy carrying. SuperbMelt’s portable XRF analyzer retains the core advantages of fast, accurate, and non-destructive testing, and is equipped with a rechargeable battery, which can work continuously for 4-6 hours—perfect for users who need to move testing locations frequently.

- Selection Suggestion: If your business is mainly fixed (such as a retail store or factory), the benchtop SuperbMelt XR3800 is more suitable (higher cost performance and accuracy); if you need to conduct on-site testing frequently (such as a mobile recycling team), the portable type is the better choice.

5.2, Ease of Operation and Training Requirements

The SuperbMelt XRF Gold Analyzer is designed with “user-friendliness” as the core, minimizing the operation threshold and training costs:

- Completely Intelligent Operation: The operation process is extremely simple—operators only need to place the sample on the measurement window and click “measurement start” to get the test result. There is no need for complex parameter setting or professional knowledge of XRF technology. Even employees without professional testing experience can master it in 1-2 hours of training.

- Intuitive Software Interface: The software is based on the Microsoft Windows system, which is familiar to most operators. The test results are displayed in the form of numbers and charts, which are intuitive and easy to understand. The software also supports data storage and export (such as exporting to Excel), facilitating users to manage test records.

- Low Training Cost: SuperbMelt provides one-on-one online/offline training services for each customer. The training content includes equipment operation, calibration, daily maintenance, and common problem solving. After training, the manufacturer will also provide a detailed operation manual and video tutorials for users to review at any time.

5.3, Daily Maintenance, Calibration, and Safety Standards

Proper daily maintenance and calibration can extend the service life of the equipment and ensure the stability of test results. At the same time, complying with safety standards is the basic requirement for using XRF equipment:

- Daily Maintenance: The daily maintenance of the SuperbMelt XR3800 is simple: ① Keep the measurement window clean (wipe with a soft cloth regularly to avoid dust or stains affecting the test); ② Ensure the equipment is placed in a dry, ventilated environment (avoid moisture or high temperature); ③ Check the power supply and cable connections regularly to avoid poor contact. The equipment has a long service life (average service life of 5-8 years) and low maintenance costs.

- Calibration Requirements: The equipment only needs initial calibration (one sample is enough) before use. It is recommended to perform a calibration check every 3-6 months (using the standard sample provided by SuperbMelt) to ensure the accuracy of the test results. If the equipment is moved or used in a harsh environment, it is recommended to calibrate it again.

- Safety Standards: The SuperbMelt XR3800 complies with international X-ray safety standards. The low-power X-ray tube (emission dose far below the safety limit) and the built-in safety protection device (such as the measurement window safety interlock—X-rays are only emitted when the sample is placed correctly) ensure the safety of operators. The equipment has passed multiple international safety certifications, and users can use it with confidence.

Conclusion

In the modern jewelry and precious metals industry, where efficiency, accuracy, and trust are increasingly important, the XRF gold analyzer has become an indispensable core tool. SuperbMelt XRF Gold Analyzer (XR3800), with its advantages of fast testing speed (qualitative analysis in <30 seconds), high accuracy (results close to fire assay), non-destructive testing, easy operation, and wide material compatibility, has become the first choice of professionals in jewelry retail, recycling, pawnbroking, manufacturing, and refining.

It not only solves the pain points of traditional testing methods (slow speed, destructive testing, complex operation) but also enhances transaction transparency and trust—for example, helping retail stores gain customer trust through on-site testing, assisting manufacturers in improving quality control efficiency, and enabling recyclers to accurately value scrap materials. The compact size, flexible power supply, and low maintenance costs of the equipment also reduce the use threshold for small and medium-sized enterprises, allowing more users to enjoy the benefits of advanced XRF technology.

Choosing a SuperbMelt XRF Gold Analyzer is not just an investment in equipment, but an investment in business efficiency, brand reputation, and market competitiveness. In the future, with the continuous development of the jewelry industry, XRF technology will play an increasingly important role, and SuperbMelt will continue to provide more advanced and reliable metal analysis solutions for the industry.

Ready to Upgrade Your Precious Metal Testing Process?

SuperbMelt XRF Gold Analyzer (XR3800) is designed to meet the diverse testing needs of the jewelry and precious metals industry. Whether you are a jewelry retailer needing fast on-site verification, a recycler pursuing efficient valuation, or a manufacturer requiring strict quality control, this equipment can provide you with professional, reliable, and efficient testing solutions.

Want to know how to match the most suitable testing parameters for your products (such as finished jewelry, gold bars, or metal powders)? Need to calculate the ROI of upgrading to an XRF gold analyzer (how much time and cost can be saved compared to traditional testing)? Contact SuperbMelt experts today! We will provide one-on-one professional consulting services, share product samples and application cases, and help you take the first step towards efficient, accurate, and non-destructive precious metal testing.

FAQ about Precious Metals Analysers

- 1. What is XRF Precious Metal Testing?

- 2. How Do You Identify Precious Metals?

- 3. How To Test For White Gold?

- 4. What Are The XRF Precious Metal Analyzer On The Market?

- 5. How Accurate is XRF Analysis?

- 6. Are Your Gold Measuring Machines Accurate?

- 7. Will your X-Ray Analyzer Harm To Body Health?

- 8. What Are The Purity Ranges Of Gold Jewelry?

- 9. What Are The Benefits Of Using A Portable XRF Machine?

- 10. How To Test For Gold At Home?

1. What is XRF Precious Metal Testing?

XRF precious metal testing is a quick and accurate way to determine the concentration and presence of precious metals, as well as trace different alloying and light elements in just a few seconds. This method is perfect for detecting if gold is real or not. With an XRF gold testing machine, metal samples are bombarded with a powerful x-ray beam to determine their purity level. If you’re looking for the best XRF testing machines, check out the models available on SuperbMelt’s official website.

2. How Do You Identify Precious Metals?

XRF precious metal analyzers have become a popular method for detecting precious metals in various industries due to their accuracy and safety. While other methods such as the acid test, magnet test, and water test can be ineffective or even damaging to precious metals, XRF testing provides an efficient and non-destructive way to accurately determine the presence and concentration of precious metals. If you want to ensure the safety of your precious metals while obtaining accurate results, consider using an XRF precious metal analyzer.

3. How To Test For White Gold?

Testing for platinum is comparable to testing for other kinds of gold. Use the XRF Precious Metals Analyzer to precisely identify the metal composition of platinum using X-ray fluorescence technology. This is a simple, non-destructive test for platinum that won’t harm jewelry. XRF analyzers are frequently used in pawn shops and by professional jewelers to examine metals.

It should be noted that the rhodium plating on some platinum jewelry will have an impact on the test results. The underlying metal can be seen when the rhodium plating is worn or scraped, and the surface can be examined.

4. What Are The XRF Precious Metal Analyzer On The Market?

Various studies have demonstrated that XRF is a highly efficient and speedy method for detecting the purity of materials. This technique provides both qualitative and quantitative data about the elemental composition of metals. Additionally, precious metal analyzers are easy to operate. When it comes to purchasing an XRF gold testing machine, there are two major types available. Depending on your requirements, you can purchase one and begin testing your metals. Let’s take a closer look at these machines.

Desktop XRF Metal Analyzer: SuperbMelt offers two models in this category, namely the SBP XR 1200 and SPB XR 3200, both of which are highly efficient and user-friendly. Results can be obtained within 5 to 10 minutes. There is no need for any technical skills or knowledge to operate these machines. Simply place a small piece of the metal sample on the machine and press the start button. Within seconds, the machine will display the purity value of the metal sample on the LCD screen. These models are ideal for conducting sophisticated purity analyses on different metals. They offer a wide range of metals, better sensitivity and resolution, and are equipped with the latest technology. The machine can store the reports, and you can check them later whenever you want. They can also be used to measure coating thickness as they release powerful x-rays, making it possible to measure multiple-layer coatings faster. These models have various applications in different industries, such as petroleum, polymers, mineral beneficiation, mining, cement production, and more.

Handheld XRF Metal Analyzer: SuperbMelt’s handheld XRF gold analyzer is a popular non-destructive analytical tool. With this machine, there is no need to send metal samples to labs and wait for days to receive a report. You can determine the purity level instantly in the field. This small machine can detect various components of metals as well as alloys, including cobalt alloys, bronze zinc, silver, stainless steel, tungsten, and more. The handheld model functions by measuring secondary x-rays released by the sample metal when triggered by the primary x-ray source. Each element has a unique set of characteristic fluorescents, which the machine reads and shows you the value of different elements present in the metal. Such machines can be used in various industries, such as oil, gas, precious metal recycling, mining, construction, jewelry stores, and more. Use this gold carat analyzer machine and witness an unmatchable metal identification process. Visit SuperbMelt, check the gold XRF testing machine price, and place your order now.

5. How Accurate is XRF Analysis?

- SuperbMelt’s XRF precious metal analyzer is built with cutting-edge technologies to deliver 100 percent accurate findings. This is the simplest technique to determine the elemental makeup of alloys, the purity of precious metals, and different geochemical materials. An XRF analyzer will always produce an accurate result. There is one thing, though, that you must remember.

- The XRF testing regulations state that heavier elements will perform less accurately than lighter ones. Additionally, the accuracy level in the 1 ppm to 1000 ppm range will be a bit greater, at 0.1 percent, than the accuracy level in the range to 100 percent. Additionally, the accuracy level will change depending on the materials you are testing.

- For instance, if you compare metals and plastic, metals will have significantly higher accuracy levels. With SuperbMelt’s precious metal analyzer, you can change the response limit for a sample to increase accuracy, so you don’t need to worry about this. Modern detector types are used in our equipment. Use this instead of the conventional metal analysis techniques right away. The equipment is inexpensive.

6. Are Your Gold Measuring Machines Accurate?

There is no doubt that our machine is accurate. But it has a lot to do with the sample itself. The tester must make sure that the sample is free of plating or other chemical pickling substances. If the sample is small, you can polish it. If the sample is large, you can flatten it, or cut it, and test its parts.

7. Will your X-Ray Analyzer Harm To Body Health?

Certainly not. The X-Ray is weak and we design protecting function. If you open the chamber cover carelessly when the power is operating, the machine will switch off the X-Ray automatically.

8. What Are The Purity Ranges Of Gold Jewelry?

The 10K, 18K, 24K, and 14K purity ranges are some popular choices. Always keep in mind that the purity level of the gold will affect the strength, longevity, and malleability of the metal. For the highest level of durability, for example, you can use 10K gold. The level of gold will be lower, though. While this is pure, 24K gold is very soft. Using our XRF precious metal analyzer, you can determine the purity range of the gold jewelry.

9. What Are The Benefits Of Using A Portable XRF Machine?

The device is made to test and analyze various metals to ascertain their chemical makeup.

Any number of metals, including iridium, osmium, chromium, nickel, zinc, iron, platinum, and gold, can be tested using only this one machine.

The outcome will be available to you in approximately ten seconds.

The product is really simple to use and runs on Microsoft Windows software. Furthermore, this product can be used without standard samples being used for calibration.

A portable XRF device can be used anywhere and can run for more than 48 hours after being fully charged.

The fact that it provides you with a non-destructive metal analysis approach is the best feature.

10. How To Test For Gold At Home?

Using an XRF gold tester is among the simplest ways to assay gold at home. You can use the SuperbMelt Gold Tester’s XR5000 model to reliably and precisely ascertain the purity and makeup of gold.

Place a tiny sample of your gold in the machine’s testing area, then press the start button to operate the XR5000. The instrument will next employ X-ray fluorescence technology to determine the metal’s elemental composition, and the results will be shown on the screen in a matter of seconds.

Using an XRF gold tester is among the simplest ways to assay gold at home. You can use the SuperbMelt Gold Tester’s XR5000 model to reliably and precisely ascertain the purity and makeup of gold.

Place a tiny sample of your gold in the machine’s testing area, then press the start button to operate the XRA5000. The instrument will next employ X-ray fluorescence technology to determine the metal’s elemental composition, and the results will be shown on the screen in a matter of seconds.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited