Silver Smelting Kit

The most popular SuperbMelt 1-2kg silver smelting kit on the market

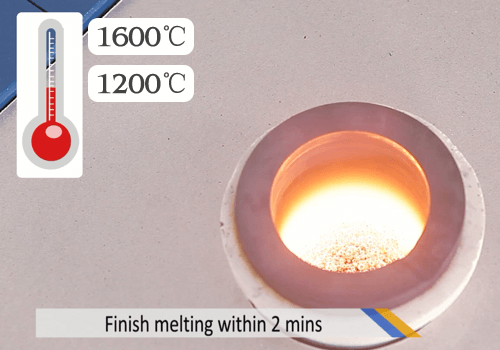

Superbmelt silver smelting kit is used for melting silver, gold, copper, brass, bronze and their alloys, measuring up to 2kg. Superbmelt home gold smelting kit has a melting temperature of 1600 degrees celsius that melts within 2 minutes.

Superbmelt silver smelting kit China has an IGBT induction heating technology that makes the melting process highly efficient and easy to use. The induction heating technology also conserves energy use.

The silver melting kit for sale by Superbmelt is applicable for use in jewellery making, precious metal mining, personalized melting, etc. Contact Superbmelt today for an affordable and high-quality mini smelting kit.

If you wanna check gold melting furnaces with bigger capacity, Please click here.

- Superbmelt silver smelting kit is suitable for melting silver, gold, copper, brass, bronze and their alloys measuring up to 2kg.

- Superbmelt silver smelting equipment has a maximum temperature of 1600 degrees celsius suitable for an efficient metal melting process.

- The melting process is carried out through induction heating. The induction heating technology ensures a fast-melting process, improve melting quality, save melting cost, etc.

- The maximum power required for melting with the Superbmelt mini silver smelter is between 3.5kw to 3.8kw.

- Superbmelt electric melting machine has a PLC control unit that automates the entire melting process. This makes the electric melting machine easy to use even for new users.

- Superbmelt silver melting equipment is designed with high-quality steel material that is resistant to high temperatures. The makes the silver smelting kit easy to maintain and gives the machine long service life.

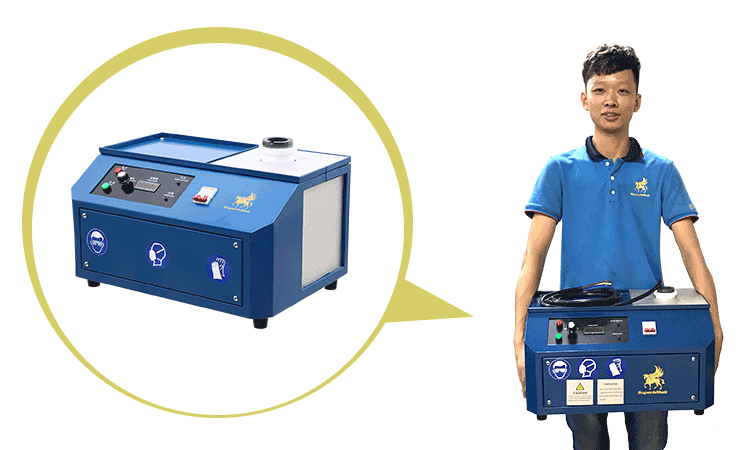

- Superbmelt silver smelting kit is compact in size. The furnace total dimension is 520*400*330mm, this takes up minimal space.

- The silver smelting equipment has a total weight of 21kg, which is convenient to transport from one location to another.

- Supermelt mini electric silver smelter has a water cooling unit that helps to regulate the furnace temperature. A regulated temperature allows you to melt continuously for long hours.

- Superbmelt silver melting furnace is efficient for melting as a result of its speed melting time. The melting time is usually 2 minutes. This allows you to melt 30kg of metals within 1 hour.

- The Superbmelt silver melting equipment is applicable in jewellery production, precious metal mining, personalized melting, etc.

- Superbmelt silver melting machine is easy to charge and the process of molten metal removal is easy. The melting furnace is equipped with a tong that allows you to easily remove hot crucibles from the melting chamber.

- The induction heating technology also prevents precious metal loss.

| Model number | SPB-DH1 | SPB-DH2 |

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm |

| Weight | 21 kg | 22 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

Graphite crucible for gold/Silver melting Furnace

Small 1-2kg gold and silver smelting machine is portable size design, light weight, easy to carry and fix.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Gold and Silver Smelting Kit

Any Question About SuperbMelt Gold and Silver Smelting Kit

Silver Smelting Kit Guide for Jewelry Makers: Fast, Efficient Melting with SuperbMelt

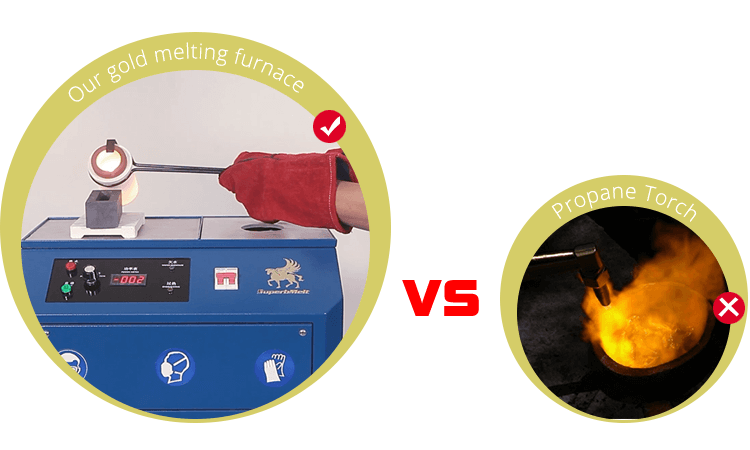

For jewelry makers, whether you’re a professional workshop owner, a small-scale refiner, or a DIY enthusiast, the melting process is the cornerstone of creating exquisite precious metal jewelry. From recycling old silver scraps into new ingots to casting personalized silver pendants and refining alloy materials, the efficiency, precision, and safety of melting directly affect production quality, cost control, and creative execution. Traditional melting tools—such as propane torches or small manual furnaces—often struggle with pain points like slow melting speed, unstable temperature control, high precious metal loss, and cumbersome operation. These issues not only reduce production efficiency but also increase the risk of material waste and even safety hazards, especially for small-batch, personalized jewelry production.

SuperbMelt Silver Smelting Kit, powered by advanced IGBT induction heating technology, provides a professional solution tailored to the needs of jewelry makers. Designed for small-batch production, it supports melting silver, gold, copper, brass, bronze, and their alloys with a maximum capacity of 2kg per batch. With ultra-fast melting speed (reaching 1600°C in just 2 minutes), energy-saving performance, and intelligent PLC control, it bridges the gap between manual tools and large industrial furnaces, making precise, efficient metal melting accessible to jewelry workshops, small refineries, and DIY jewelers. This comprehensive guide will walk you through every key aspect of silver smelting kits—from basic definitions and material compatibility to heating technology, operation safety, and industry applications—helping you master reliable small-batch metal melting solutions and elevate your jewelry making craft.

Understanding What a Silver Smelting Kit Is

Before diving into the practical applications, it’s essential to clarify what a silver smelting kit is, its core value in jewelry production, and how it differs from large industrial melting equipment. This foundational understanding will help you determine if it’s the right tool for your specific needs.

1.1, Definition and Core Purpose in Jewelry Production

A silver smelting kit is a compact, professional melting device designed for small-batch precious metal processing. Its core purpose is to heat solid metal materials (such as silver scraps, gold nuggets, copper ingots) to their melting point (up to 1600°C for SuperbMelt’s kit) and convert them into molten metal for subsequent processes like casting, ingot making, or alloying. For jewelry makers, this tool is indispensable for three key scenarios:

- Jewelry Casting Preparation: Melting precious metals into molten state to pour into molds, creating custom jewelry pieces like rings, bracelets, and pendants.

- Precious Metal Recycling: Reprocessing old, broken jewelry or production scraps into reusable ingots, reducing material waste and lowering raw material costs.

- Alloy Experimentation & Sample Testing: Blending different metals (e.g., silver with copper to make sterling silver) to create custom alloys, or testing small batches of materials to ensure quality before mass production.

SuperbMelt Silver Smelting Kit, in particular, is optimized for jewelry production’s unique needs—prioritizing compact size, easy operation, fast melting speed, and minimal metal loss to support both professional and hobbyist use.

1.2, Difference Between a Smelting Kit and Industrial Melting Furnaces

Many jewelry makers may wonder how a small smelting kit differs from large industrial melting furnaces. The key differences lie in scale, design focus, and application scenarios—making smelting kits far more suitable for small-batch jewelry production:

- Capacity & Production Scale: Industrial furnaces typically have a melting capacity of tens or hundreds of kilograms, designed for mass production. SuperbMelt Silver Smelting Kit has a 2kg per batch capacity, perfectly matched to small-batch jewelry making (e.g., producing 10-20 silver pendants at a time) or DIY projects, avoiding the waste of energy and materials caused by “overcapacity” operation.

- Size & Space Requirement: Industrial furnaces are bulky (often requiring dedicated workshops) and heavy. SuperbMelt’s kit has a compact dimension of 520*400*330mm and weighs only 21kg, making it easy to place in home studios, small workshops, or even mobile workspaces—no need for large-scale infrastructure investment.

- Operation & Cost: Industrial furnaces require professional operators and high energy consumption. SuperbMelt’s kit features PLC automatic control, allowing even new users to master it quickly. Its IGBT induction heating technology saves energy, and the overall purchase and operation costs are much lower, making it accessible to small businesses and hobbyists.

- Flexibility: Industrial furnaces are designed for fixed, large-scale production lines, making it difficult to switch between different metals or adjust processes frequently. SuperbMelt’s kit supports melting a variety of metals (silver, gold, copper, etc.) and can be quickly adjusted for different melting requirements—ideal for personalized jewelry production that requires frequent process changes.

1.3, Typical Users: Jewelry Workshops, Small Refineries, DIY Jewelers

SuperbMelt Silver Smelting Kit’s design is tailored to three core user groups in the jewelry industry, addressing their specific pain points:

- Small to Medium Jewelry Workshops: These workshops focus on custom jewelry or small-batch production. They need efficient, space-saving melting equipment to handle frequent material switching and ensure consistent melting quality. The kit’s 2kg capacity, 2-minute melting speed, and stable temperature control help them improve production efficiency while maintaining product quality.

- Small Precious Metal Refineries: Refineries that process small batches of scrap jewelry or precious metal scraps need equipment that minimizes metal loss and ensures refining precision. SuperbMelt’s IGBT induction heating technology reduces precious metal loss, and its easy operation allows for efficient processing of various scrap materials.

- DIY Jewelers & Hobbyists: For enthusiasts who create jewelry as a hobby or side business, ease of use, safety, and affordability are key. The kit’s PLC automatic control, built-in safety protections, and compact design make it easy to use at home, while its fast melting speed lets them bring creative ideas to life quickly.

Materials and Capacity Compatibility

A smelting kit’s value is largely determined by its ability to handle different metals and adapt to various production scales. SuperbMelt Silver Smelting Kit excels in material compatibility and capacity flexibility, covering most common needs of jewelry makers.

2.1, Metals Supported: Silver, Gold, Copper, Brass, Bronze, and Alloys

One of the kit’s core advantages is its wide material compatibility, supporting all major metals and alloys used in jewelry production:

- Precious Metals: Silver (including sterling silver 925), gold (24K, 18K, 14K), and their alloys. The kit’s high temperature (up to 1600°C) easily reaches the melting points of these metals (silver melts at 961.8°C, gold at 1064°C), ensuring complete melting.

- Base Metals & Alloys: Copper, brass (copper-zinc alloy), bronze (copper-tin alloy), and other common jewelry alloys. These metals are often used as base materials for plated jewelry or as alloy components to adjust the hardness and color of precious metals. The kit’s stable heating ensures uniform melting of alloys, avoiding component segregation.

Key advantage: The kit’s IGBT induction heating technology provides uniform heat distribution, ensuring that even alloys with different melting points are fully melted and mixed evenly—critical for maintaining the quality and performance of jewelry materials.

2.2, Recommended Melting Capacity (Up to 2kg) for Small-Batch Production

SuperbMelt Silver Smelting Kit is designed with a maximum melting capacity of 2kg per batch, which is optimized for small-batch jewelry production:

- Efficient Small-Batch Processing: For jewelry workshops producing 5-20 pieces per order (e.g., a batch of 10 silver rings requiring 0.5kg of silver), the 2kg capacity allows for processing 4 batches of materials in an hour (thanks to the 2-minute melting speed), balancing efficiency and material utilization.

- High Hourly Output: With a 2-minute melting cycle, the kit can melt up to 30kg of metal per hour (2kg/batch × 30 batches/hour)—far exceeding traditional manual tools (which typically melt 2-5kg per hour). This high efficiency meets the daily production needs of small jewelry workshops.

- Flexible Capacity Adjustment: While the maximum capacity is 2kg, the kit can also handle smaller batches (e.g., 0.1kg for DIY sample testing) without compromising melting efficiency or quality. This flexibility is ideal for personalized orders or alloy experimentation.

2.3, Suitability for Jewelry Casting, Recycling, and Sample Testing

The kit’s material compatibility and capacity flexibility make it suitable for three core jewelry production scenarios:

- Jewelry Casting: Before casting, the kit melts precious metals into molten state, which is then poured into molds to create jewelry blanks. The fast melting speed (2 minutes) reduces the waiting time between batches, improving casting efficiency. The uniform melting ensures that the molten metal flows smoothly into the mold, avoiding defects like air bubbles or incomplete filling.

- Precious Metal Recycling: For old, broken jewelry or production scraps (e.g., silver wire ends, gold polishing dust), the kit melts them into reusable ingots. The minimal metal loss (thanks to induction heating technology) maximizes the recovery rate of precious metals, reducing raw material costs for jewelry makers.

- Sample Testing & Alloy Experimentation: When developing new jewelry designs or testing custom alloys (e.g., adjusting the copper content in sterling silver to change its hardness), the kit’s small-batch capacity allows for low-cost experimentation. Jewelry makers can test different alloy ratios with minimal material waste, ensuring the final product meets design requirements.

Heating Technology and Melting Performance

Heating technology is the core of a smelting kit’s performance. SuperbMelt Silver Smelting Kit adopts advanced IGBT induction heating technology, which outperforms traditional heating methods (such as resistance heating or propane torches) in efficiency, temperature control, and energy saving—directly enhancing the quality and efficiency of jewelry melting.

3.1, IGBT Induction Heating and Its Advantages Over Traditional Heating

IGBT (Insulated Gate Bipolar Transistor) induction heating technology works by generating a high-frequency magnetic field through an induction coil, which induces eddy currents in the metal material, heating it from the inside out. Compared to traditional heating methods, it has four key advantages for jewelry makers:

- Faster Melting Speed: Traditional propane torches or resistance furnaces heat materials from the outside in, resulting in slow and uneven heating. Induction heating heats the metal internally, allowing SuperbMelt’s kit to reach 1600°C in just 2 minutes—melting silver or gold far faster than traditional tools (which often take 10-15 minutes per batch).

- Energy Saving: Induction heating directly heats the metal material, with almost no heat loss to the surrounding environment. The kit’s power consumption is only 3.5-3.8kW, which is 30-50% more energy-efficient than traditional resistance furnaces. This reduces long-term operation costs for jewelry workshops.

- Uniform Heating & Minimal Metal Loss: Even internal heating ensures that the metal melts completely without local overheating or underheating, avoiding oxidation and volatilization of precious metals. This minimizes metal loss—a critical advantage for high-value materials like silver and gold.

- Clean & Safe Heating: Unlike propane torches (which produce open flames and exhaust gas) or coal-fired furnaces (which generate smoke and dust), induction heating is clean and smokeless. It eliminates fire hazards and air pollution, creating a safer, healthier working environment for jewelry makers.

3.2, Fast Melting Efficiency (Up to 1600°C Within Minutes)

SuperbMelt Silver Smelting Kit’s melting efficiency is a game-changer for small-batch jewelry production, with two key performance highlights:

- Ultra-Fast Melting Speed: The kit can melt 2kg of silver or gold in just 2 minutes—far faster than traditional tools. For example, a jewelry workshop that needs to melt 10kg of silver per day can complete the task in just 40 minutes (including batch switching time), freeing up time for other production processes (e.g., casting, polishing).

- High Maximum Temperature: With a maximum temperature of 1600°C, the kit can handle not only silver and gold but also high-melting-point metals like copper (melting point 1085°C) and bronze (melting point 950-1050°C). This wide temperature range expands its application scope, allowing jewelry makers to process a variety of materials without needing multiple devices.

Key advantage: The fast melting speed does not compromise melting quality. The kit’s precise temperature control ensures that the molten metal has a stable viscosity, which is critical for smooth casting and avoiding defects in jewelry pieces.

3.3, Energy-Saving Features and Stable Temperature Control

For small jewelry workshops and DIY jewelers, energy costs and temperature stability are important considerations. SuperbMelt’s kit addresses these needs with targeted design:

- Energy-Saving IGBT Technology: As mentioned earlier, the kit’s induction heating technology is highly energy-efficient, with a power consumption of only 3.5-3.8kW. Compared to a traditional 5kW resistance furnace, it can save up to 30% of electricity costs per month—significant for long-term operation.

- Water Cooling Unit for Stable Temperature: The kit is equipped with a built-in water cooling unit that regulates the furnace temperature during long-term operation. This allows for continuous melting for hours without overheating, ensuring stable temperature control and consistent melting quality. For example, a workshop can run the kit continuously for 4-6 hours to process a large batch of scrap silver, without interruptions for cooling.

- Precise Temperature Adjustment: The PLC control unit allows users to set and adjust the melting temperature with precision (±5°C). This is critical for alloy melting—different alloys require specific temperatures to ensure uniform mixing and avoid component segregation. For example, when melting 925 sterling silver (92.5% silver + 7.5% copper), users can set the temperature to 980°C for optimal results.

Operation, Safety, and User Experience

For jewelry makers—especially those new to smelting—ease of operation and safety are non-negotiable. SuperbMelt Silver Smelting Kit is designed with user-friendliness and safety as priorities, ensuring that both professionals and beginners can use it with confidence.

4.1, Simple Operation for Beginners and Professional Jewelers

The kit’s PLC automatic control system simplifies the melting process to just a few steps, making it accessible to users of all skill levels:

- Intuitive PLC Control Panel: The kit features a user-friendly PLC control panel with clear buttons and a digital display. Users only need to: ① Place the metal material into the crucible; ② Set the target temperature (e.g., 960°C for silver); ③ Press the “Start” button. The kit will automatically complete the heating and melting process, with the digital display showing real-time temperature and progress.

- Easy for Beginners: No professional smelting experience is required. Even new users can master the operation in 10-15 minutes. SuperbMelt also provides a detailed operation manual and video tutorials, guiding users through setup, operation, and maintenance.

- Efficient Molten Metal Removal: The kit comes with a dedicated tong for safely removing hot crucibles from the melting chamber. The crucible is designed for easy pouring, allowing users to transfer molten metal to molds or ingot trays quickly and safely—reducing the risk of spills and burns.

4.2, Built-in Safety Protections (Overheat and Power Stability)

Safety is a top priority for SuperbMelt, and the kit is equipped with multiple built-in safety protections to prevent accidents:

- Overheat Protection: If the furnace temperature exceeds the safe limit (1650°C), the system will automatically shut down and trigger an alarm, preventing equipment damage and fire hazards.

- Power Stability Protection: The kit has a built-in voltage stabilizer that adapts to voltage fluctuations (110V 60Hz or 220V 50Hz). This ensures stable operation even in areas with unstable power supply, avoiding melting interruptions or quality issues caused by voltage spikes/drops.

- Water Cooling Protection: The water cooling system is equipped with a flow sensor. If the water flow is insufficient (e.g., due to a blocked pipe), the system will stop heating and alarm, preventing the furnace from overheating due to poor cooling.

- High-Temperature Resistant Material: The furnace body is made of high-quality heat-resistant steel, which can withstand long-term high-temperature operation without deformation or damage. The crucible is made of high-purity graphite, which is corrosion-resistant and compatible with all precious metals—avoiding contamination of molten metal.

4.3, Compact Design for Home Studios and Small Workshops

Space is often a constraint for small jewelry workshops and home studios. SuperbMelt Silver Smelting Kit’s compact design solves this problem:

- Small Size: With dimensions of 520*400*330mm, the kit is about the size of a small cabinet. It can be placed on a workbench or shelf, taking up minimal space—ideal for home studios or small workshops with limited area.

- Lightweight & Portable: Weighing only 21kg, the kit is easy to move and transport. For example, a DIY jeweler can easily move it from a home studio to a craft fair for on-site demonstrations, or a mobile recycling team can take it to different locations to process scrap jewelry.

- Easy Installation: No complex installation is required. Users only need to connect the kit to a power supply and a water source (for the cooling system), and it’s ready to use—no need for professional installation services or infrastructure modifications.

Jewelry Industry Application Scenarios

SuperbMelt Silver Smelting Kit’s combination of fast melting speed, small capacity, easy operation, and wide material compatibility makes it suitable for a variety of jewelry industry scenarios—from professional production to creative DIY projects.

5.1, Jewelry Making and Precious Metal Casting Preparation

In jewelry making, casting is one of the most common processes, and the smelting kit plays a key role in preparing molten metal for casting:

- Custom Jewelry Production: For small-batch custom orders (e.g., wedding rings, personalized pendants), the kit’s fast melting speed (2 minutes) allows jewelers to quickly prepare molten metal for casting, reducing lead times. The precise temperature control ensures that the molten metal flows smoothly into the mold, creating sharp, detailed jewelry pieces.

- Alloy Jewelry Making: When making alloy jewelry (e.g., 18K gold rings, sterling silver bracelets), the kit’s uniform heating ensures that the alloy components are fully mixed. For example, when making 925 sterling silver, the kit melts silver and copper at the optimal temperature, ensuring the alloy has the right hardness and luster.

- Repair & Remodeling: When repairing or remodeling old jewelry (e.g., resizing a silver ring, remaking a broken necklace), the kit melts the old jewelry into molten metal, which is then recast into the desired shape. This reduces material waste and allows jewelers to reuse precious metals from old pieces.

5.2, Precious Metal Recycling and Personalized Melting

Precious metal recycling and personalized melting are growing needs in the jewelry industry, and the kit is perfectly suited for these scenarios:

- Scrap Jewelry Recycling: Jewelry workshops often generate scrap materials (e.g., silver wire ends, gold polishing dust, broken castings). The kit melts these scraps into reusable ingots, maximizing the recovery of precious metals. The minimal metal loss (≤0.5%) ensures that jewelers don’t waste valuable materials—for example, recycling 1kg of silver scraps can yield 0.995kg of silver ingots, saving significant costs.

- Personalized DIY Projects: For DIY jewelers and hobbyists, the kit allows for creative personalized melting. For example, melting old silver coins into a custom ingot, or blending different metals to create unique alloy jewelry. The small capacity (2kg max) and easy operation make it easy to experiment with different designs and materials.

- Small-Scale Precious Metal Trading: Small precious metal dealers or collectors can use the kit to melt scrap gold/silver into standard ingots for trading. The kit’s fast melting speed and high accuracy ensure that the ingots have consistent purity and weight, meeting trading standards.

5.3, Small-Scale Mining Samples and Experimental Alloy Testing

Beyond traditional jewelry making, the kit also supports small-scale mining and alloy research scenarios:

- Small-Scale Mining Samples: For small-scale gold or silver miners, the kit can melt ore samples to test the precious metal content. This allows miners to quickly evaluate the value of ore deposits without sending samples to a professional laboratory—saving time and money.

- Experimental Alloy Testing: Jewelry designers and material researchers can use the kit to test new alloy formulas. For example, testing the effect of adding small amounts of palladium to silver to improve its durability, or creating new colored alloys for unique jewelry designs. The small-batch capacity and precise temperature control make it easy to experiment with different ratios and record results.

Conclusion: Is a Silver Smelting Kit Right for You?

If you’re a jewelry maker—whether a professional workshop owner, a small refiner, or a DIY enthusiast—who needs to process small batches of precious metals (silver, gold, copper, etc.) for casting, recycling, or alloying, a silver smelting kit is an ideal investment. SuperbMelt Silver Smelting Kit, in particular, stands out with its advanced IGBT induction heating technology, fast melting speed (2 minutes per batch), compact design, and easy operation—addressing the core pain points of traditional melting tools.

It’s the perfect solution if you: ① Need to improve small-batch melting efficiency (replacing slow manual tools); ② Want to minimize precious metal loss (critical for high-value materials); ③ Require a compact, space-saving device for home studios or small workshops; ④ Need easy-to-operate equipment (no professional experience required); ⑤ Want to process multiple metals/alloy types with one device.

Unlike large industrial furnaces, which are costly and impractical for small-scale use, or traditional manual tools, which are slow and inefficient, SuperbMelt Silver Smelting Kit bridges the gap—offering professional-level performance at an affordable price. It’s not just a tool; it’s a way to enhance your jewelry making efficiency, reduce costs, and unlock more creative possibilities.

Ready to Upgrade Your Jewelry Melting Process?

SuperbMelt Silver Smelting Kit is designed specifically for jewelry makers’ small-batch melting needs. With its 2kg capacity, 2-minute melting speed, 1600°C maximum temperature, IGBT induction heating, and PLC automatic control, it’s the reliable choice for professional workshops and DIY enthusiasts alike.

Want to know how to match the right melting parameters for your specific jewelry project (e.g., melting sterling silver for casting vs. recycling gold scraps)? Need to calculate the ROI of upgrading to a SuperbMelt smelting kit (how much time and material cost you can save)? Contact SuperbMelt experts today! We’ll provide one-on-one professional consulting services, share product samples and application cases, and help you take the first step toward efficient, precise, and safe precious metal melting.

If you need a melting furnace with larger capacity (more than 2kg per batch) for scaled-up production, please click here to explore our industrial-grade melting furnaces.

FAQ Guide of Silver Smelting Kit

Many people might have silver jewelry with various defects, such as broken bracelets and missing links in silver chains. In addition, the ease of melting silver jewelry scraps to create new jewelry designs is also a favorable aspect. This is why the demand for silver smelting kit has increased profoundly in recent times. At the same time, it is also inevitable to wonder about the best ways to melt silver at home. The following discussion helps you find answers to some of the top questions regarding the functioning and efficiency of silver melting machine.

- 1. How to Melt Silver Nowadays?

- 2. How to Melt Silver in Induction Furnace?

- 3. How to Use Silver Melting Furnace for Silver Mining?

- 4. How Silver Melting Furnace is Useful for Precious Metal DIY Enthusiasts?

- 5. How Silver Melting Furnace is Useful for Silver Mining Laboratories?

- 6. Could I get 9999 Silver from your Silver Melting Furnace?

- 7. What is the Heating Principle for Silver Melting?

- 8. Could We Use This Furnace to Melt Most Metals like Iron, Gold, Silver, Copper, and Aluminum?

- 9. Can You Melt Silver at Home?

- 10. Can You Melt Old Silver Rings to Make New Ones?

- 11. Can You Melt Silver and Gold Together?

- 12. Does This Machine Need Water Chiller?

- 13. How Do You Get Impurities Out of Gold?

- 14. How Do You Melt and Purify Silver?

- 15. How Do You Melt Silver Dust?

1. How to Melt Silver Nowadays?

Silver is easily one of the most commonly available precious metals in present times. It finds applications primarily in jewelry, albeit with prominent applications in electronics, medical supplies alongside many other industrial use cases. In the form of an abundantly available precious metal, silver gives the flexibility of working with it for various reasons. On the other hand, melting silver could be a considerably complicated task for beginners. However, it is possible to start melting silver nowadays with the right supplies, knowledge, and work skills. You can follow simple steps for melting silver at home.

It is easy to have a silver melting furnace at home with the right selection. First of all, you should start with a foundry crucible, which is basically a container used in metal production. In addition, you should also get heavy-duty crucible tongs for handling the higher crucible temperatures. Another requirement for melting silver at home is a graphite stir rod. The graphite stir rod is essential for stirring the molten silver alongside ensuring that it melts completely before casting.

The most important requirement for melting silver is the silver melting furnace. The furnace is a suitable pick for individuals interested in working with silver melting frequently, especially with large amounts. Finally, you should also ensure to get safety equipment such as industrial-grade goggles, aprons, face shields, or gloves. Once you have procured all the items required for silver melting, you could just place the silver products in the crucible and put the crucible on or in the furnace. That’s it! You could have your own apparatus for melting silver at home.

2. How to Melt Silver in Induction Furnace?

When you are trying to find the right silver melting machine price, you could come across induction furnaces as one of the top choices. Most important of all, it is important to remember that the right furnace has profound implications for the process. Even with the availability of different options on the market presently, only a few alternatives could offer the ease and control which you could find with induction furnaces. Interestingly, you don’t need any genius IQ for understanding the working of an induction furnace.

The working of the induction gold melting furnace could show exactly how to use it for melting silver. Basically, the power supply to the induction furnace helps in generating a high-frequency current. The high-frequency current then passes through a water-cooled copper coil, thereby resulting in high-frequency magnetic flux. Subsequently, the magnetic flux passes around the silicon carbide crucibles holding the silver precipitate.

At this point, you can witness how the induction furnace helps in melting silver. The temperature of the silicon carbide crucibles increases due to the high resistance. As a result, conduction heat transfer starts between the crucible and silver precipitate, thereby increasing the temperature of the silver precipitate. The silver precipitate would start melting once it reaches the melting point.

3. How to Use Silver Melting Furnace for Silver Mining?

The mining industry easily comes as one of the top entries in the energy-intensive manufacturing sectors. As of now, furnaces continue to be the most commonly used instruments across various mining companies for successfully smelting gold or silver. A new era of furnace designs has led to the arrival of electric and induction silver smelting machine.

The new furnace designs have the capability of saving energy with smelting processes in comparison to traditional furnace designs. So, what are the possible ways in which silver melting furnaces could help with silver mining? Here are some of the important value advantages you can obtain from a silver melting furnace for silver melting.

The first advantage of using a modern silver smelting machine for sale would be energy conservation. Induction furnaces leverage non-contact heating method, which offers considerably higher energy efficiency. At the same time, reduced wastage of energy also implies considerable savings in the total energy consumed for melting metals.

Silver mining could benefit productively with a furnace that offers a higher melt rate. As a result, the mining site could carry out various batch melts in a short course of time.

Another profound value proposition of smelting furnaces for silver mining is the cleaner and effective method for heat production. Heating of metals within short time periods alongside the lack of need for startup time or warm-up and cool-down cycle make them more efficient for silver mining.

4. How Silver Melting Furnace is Useful for Precious Metal DIY Enthusiasts?

DIY enthusiasts also look forward to many applications of a small silver smelting machine without any doubts. DIY arts and crafts with silver become a lot easier with a melting furnace at your disposal. All you need is the proper knowledge of best practices and essential requirements for melting silver at home. Once you are ready with the required information and equipment, DIY silver melting could help you create interesting pieces of art and jewelry.

The best way to get suitable value from a small silver smelting furnace at home for silver DIY enthusiasts is through the development of casts or molds. With the cast or mold, you could easily find some interesting ways to shape up molten silver into attractive products. DIY enthusiasts should understand the important implications associated with creating a mold or cast. First of all, you should note that it is possible to create casts and molds from materials such as clay, wood, ceramic and specific alloys. Even if they are an inexpensive part of supplies in silver melting, they have critical importance for any silver DIY enthusiast.

Carve or shape the desired material according to the desired detail and relevant size. If you are trying to use clay or ceramic, then you must fire the mold to temperatures more than 1000 degrees Fahrenheit. After melting the silver, you must pour molten silver into the mold immediately. Make sure that you are carefully slow and gentle while pouring the molten silver so that you don’t spill silver. It is important that the silver reaches all angles of the shape you have created in the mold. At the same time, the silver must be distributed uniformly in all parts of the mold.

5. How Silver Melting Furnace is Useful for Silver Mining Laboratories?

One of the notable requirements of silver mining laboratories in a large or small silver smelting machine would be continuity. Silver mining laboratories would require prolific and continuous melting of silver for different applications. Starting from research on quality of silver jewelry to the study on effectiveness of new designs, silver mining laboratories have a lot on their hands. With the help of a portable electric silver melting furnace, you could experience many promising benefits. Now, it is inevitable to wonder about the benefits of precious metal melting furnaces for silver mining laboratories.

The foremost benefit of a portable furnace is the ease of portability. The advantage of a compact size helps in easier transportation and maintenance of the furnace.

Electric metal melting furnaces are also exceptionally favorable choices for melting gold, copper, bronze, brass, silver, and their alloys.

The higher efficiency of new furnace designs with water cooling units alongside reduced concerns of overheating give another plausible reason. No matter how many hours you have to work in your laboratory, the electric or induction silver melting machine could be a top pick for you.

Most important of all, a small silver melting furnace designed for safety ensures that all the melting happens in a closed chamber. As a result, you can also be safe from exposure to molten silver during your work in the laboratory.

6. Could I get 9999 Silver from your Silver Melting Furnace?

No. Another common question that emerges with respect to the effectiveness of a silver smelting kit refers to authenticity. There are many factors that come into play for defining the quality of silver generated from melting furnaces. For example, the technology advantage works profoundly in favor of the Superbmelt crucible melting pot. The benefits of induction heating technology with the Superbmelt silver melting machine give the assurance of quality of the silver. The melting furnace works effectively by preventing the loss of silver, which is observed commonly in the traditional melting process.

Most important of all, you have the flexibility of choosing from different types of crucibles for melting silver. The Superbmelt crucible melting pot helps you choose graphite crucibles or the ones made of silicon carbide according to needs. With the help of induction heating technology, you can have consistent texture in the molten silver. At the same time, the Superbmelt crucible silver melting pot also works on restricting the concerns of oxidation, shrinkage, and porosity in metals after the casting process. As a result, you can have the assurance of highest quality of silver with an induction heating furnace.

7. What is the Heating Principle for Silver Melting?

The basic principle related to the working of an induction gold melting furnace or silver melting pot focuses on a higher voltage electrical source. The high voltage of electrical supply flowing through the primary coil helps in generating higher current and low voltage in the metals. Basically, the whole melting process works on the concept of induction, i.e., transferring heat energy to metals without any contact. The concept of induction heating for melting silver is considerably simple and has changed the ways in which silver and gold are used in different applications.

For the case of a silver melting furnace, induction heating principle has promising benefits with higher responsiveness of silver. Interestingly, silver features the highest electronic conductivity among other elements. At the same time, silver also features the highest thermal conductivity among metals. With the help of induction furnaces, users could heat silver to high temperatures without actually applying heat. The use of induction heating helps in improving efficiency of silver melting. Furthermore, it also helps in avoiding the negative impacts on environment due to pollution.

8. Could We Use This Furnace to Melt Most Metals like Iron, Gold, Silver, Copper, and Aluminum?

The introduction of advanced silver and gold melting furnace manufacturers has led to profound benefits for melting metals. The arrival of modern melting furnaces and equipment advancements has facilitated plausible replacements for the manual process. In comparison to traditional processes, you could now depend on the Superbmelt crucible melting pot for melting your desired metals.

Most important of all, you could be able to melt metals such as iron, aluminum, gold, silver, and copper within a matter of minutes. The flexibility for melting any type of metal gives prolific advantages for any user. You have multiple options for a melting furnace, such as an electric or induction gold melting furnace. Electric and induction furnaces by Superbmelt could give you adequate flexibility in melting gold, copper, silver, aluminum, platinum, and many other metals.

9. Can You Melt Silver at Home?

Yes, you could easily melt silver at home with trivial silver melting machine price. At a low cost, you could find an excellent quality melting pot for melting silver and gold. When you choose the right melting point, you have the job half done already. First of all, you need to start by taking note of the melting point of silver. This will help you find a suitable melting pot that can reach the desired temperature. An induction melting pot that could bear the impact of higher heat levels would be the ideal choice for melting silver at home.

Most important of all, you also need to review the melting capacity of the pot. You need to check the size of the melting pot on the grounds of applications for which you need to melt silver at home. Furthermore, it is also important to check the induction heating machine for its specifications properly. Once you have selected the right melting pot for silver, you could easily melt silver at home with few simple steps.

10. Can You Melt Old Silver Rings to Make New Ones?

One of the prominent applications of induction or electric silver melting furnace refers to recycling old jewelry. It is easy to melt jewelry scraps into new jewelry with comparatively lower costs. The induction heating technology in modern melting pots could help in melting silver while ensuring consistency. Silver has the ideal properties suited for induction furnaces and offers ease of melting without any complications.

Collect all the items you want to melt down like your old silver rings. Some of the other items which you can choose for melting silver to make new jewelry include coins, cutlery, and decorative items. All you have to do is place the old silver items in the crucible of the melting pot. Now, heat the furnace to a temperature beyond the melting point of silver and make sure that you monitor the temperature of the furnace. It is equally important to ensure that you remove the silver only after it has melted completely.

After the silver melts, use your graphite stir rod for skimming the slag from the top of the molten silver. Slag generally comes in the form of impurities and other materials which have come out of silver during melting. Once you have removed the impurities from the molten silver, you can pour down the molten silver into new casts. If you have readymade or custom-built molds, then you could get silver jewelry effortlessly without additional costs.

11. Can You Melt Silver and Gold Together?

When you are looking for silver or gold smelting equipment, you may come across the need to melt silver and gold together. It is definitely possible to melt silver and gold together when you have the right idea of melting temperature. The resulting alloy from melting gold and silver together is known as Electrum.

As a matter of fact, Electrum offers improved strength, malleability, and flexibility. The interesting fact about Electrum is that it is available in naturally occurring forms in certain cases. In the natural state, Electrum could include elements of platinum, copper, and other metals.

Melting silver and gold together would lead to a product that determines color on the basis of amount of gold and silver in the mix. Silver can be responsible for lightening the properties of gold. So, the addition of more silver in the mix would lead to a whiter appearance. In some cases, adding copper in the mix helps in adding hues such as rose gold for a better aesthetic appearance.

12. Does This Machine Need Water Chiller?

No, you don’t need a water chiller for this silver melting machine for sale. First of all, the use of induction heating technology ensures that the melting pot stays within desired temperature limits. At the same time, the system features a unique and highly productive water cooling system.

As a result, you don’t have to worry about continuous operations of the machine for hours. Generally, water chillers are required for silver and gold melting equipment due to staggeringly high temperatures required for melting metals. Additionally, you could also get the functionality of monitoring the temperature of the unit constantly.

Therefore, you could easily identify any concerns about overheating. Another important feature of the machine which takes away the need for a water chiller is the PLC control system. With everything configured according to your specifications, you could achieve better efficiency in controlling the melting process and associated conditions.

13. How Do You Get Impurities Out of Gold?

In the case of commercial or portable gold melting equipment, you could find that melting gold would burn off majority of the impurities in the furnace itself. Gold is generally extracted from the mines and comes with various impurities, such as traces of metals. The purification of gold primarily involves the addition of chemicals such as mercury or cyanide. On the other hand, addition of such chemicals could lead to coagulation, thereby developing clumps. So, you could opt for a favorable alternative to this process of removing impurities from gold.

Try putting gold in a silver melting machine and heat it to the melting point of gold for a few minutes. You could see the slag forming at the top of the molten metal. Carefully remove the slag from the top of the molten metal and stir the gold properly after every cleaning. Continue repeating all the steps in the process until you find that there is no slag formation.

14. How Do You Melt and Purify Silver?

You could easily choose the Superbmelt crucible melting pot for melting silver without too much effort. The arrival of advanced melting machines gives prolific advantages in speed of melting silver. At the same time, users also have concerns about purity of silver from a silver smelting machine.

You could try out the DIY measures of skimming off the slag before adding molten silver to the molds. On the other hand, the crucible melting pot will not give you any special refining functionality. So, you may need an additional refining mechanism for purifying silver after melting.

15. How Do You Melt Silver Dust?

Melting silver is definitely easier with a small silver melting machine featuring advanced and innovative functionalities. However, you could come up with certain setbacks along the way if some factors go out of the way. This is where you should come to terms with silver dust melting. There are many possible technologies that you could use for melting silver dust.

For example, an electric silver melting furnace, a coal furnace, or a gas torch could be some proven alternatives. However, melting silver dust is different from regular silver melting. You need to have a flux with the silver dust before melting while ensuring the crucible is pre-heated sufficiently.

Conclusion

The choice of a good silver melting kit is more important than you think. A crucible melting machine is not preferred only for the advantages of improved productivity but also for ease of use. Modern melting equipment requires minimal maintenance while also facilitating better opportunities for melting different types of metals.

The availability of melting machines could also present favorable reasons for melting silver at home or in laboratories. Most important of all, the use of advanced technology such as induction heating could deliver prolific value advantages. Find more about silver melting equipment available at the best prices right now!

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited