High Vacuum Melting Furnace

SuperbMelt China Leading Wholesale Supplier of Jewelry Smelting Equipment with Advanced Technology.

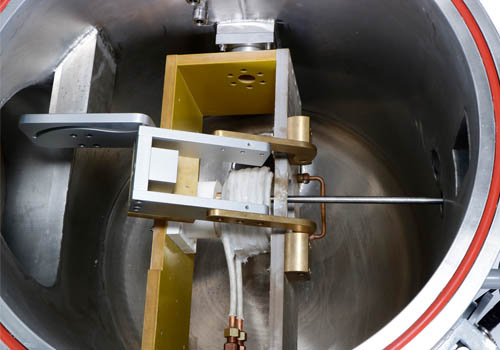

High Vacuum Melting Furnace rapidly reaches 2600°C, melting 4kg of metals like gold, silver, platinum, and palladium within three minutes. This furnace features a stirring function that ensures uniformity and bubble-free results in the melted liquid, making it the optimal choice for high-quality jewelry makers and producers of aerospace materials.

The furnace employs vacuum secondary feeding technology to prevent metal oxidation, enhancing product quality. Moreover, the High Vacuum Melting Furnace can operate continuously for 24 hours, significantly boosting production capacity.

Whether you are a high-quality jewelry manufacturer, aerospace material producer, or someone dedicated to top-notch smelting and refining, contact SuperbMelt now for a customized solution!

| Model number | SPB-HVM |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 10 kw |

| Applicable metal | Gold, Silver, Platinum, Palladium, and their alloys |

| Melting time | 3 minutes |

| Max capacity | Platinum: 4kg |

| Max temperature | 2600℃ |

| Cooling method | Water cooling |

| Dimension | 1760*720*1200mm |

| Weight | 550kg |

| Heating technology | Induction heating |

- High Density: Melts in a vacuum environment, resulting in a high-density final product.

- Anti-Oxidation: Features a vacuum secondary feeding function to prevent metal oxidation.

- Uniform Fineness: Equipped with a physical stirring function for a more uniform product fineness.

- Easy Operation: Controlled by a PLC system, ensuring simple and user-friendly operation.

- Continuous Operation: Capable of continuous loading for 24 hours, enhancing productivity.

- Safety Assurance: Multiple safety protections for worry-free and secure operation.

- Rapid Melting: Achieves quick melting at temperatures up to 2600°C.

- Optimal for High-Quality Jewelry: Ideal for jewelry makers who prioritize high-quality products.

- Bubble-Free Result: The stirring function ensures a final product free from bubbles.

- Energy-Efficient: Combines efficient melting with energy-saving features for sustainable operation.

- Jewelry Manufacturing: Perfect for creating fine jewelry made of metals including palladium, platinum, silver, and gold.

- Aerospace Industry: Used to guarantee the high purity and quality of metals in the manufacturing of aerospace products.

- Laboratory Research: Offers a melting environment at high temperatures that is appropriate for a range of metal investigations and studies.

- Production of High-Quality Alloys: This process is used to create metal alloys with a high degree of purity and quality.

- unique Metal Manufacturing: This process may be used to create a range of goods made of unique metals, including high-performance alloys.

- In these sectors, the High Vacuum Melting Furnace is a dependable melting solution that guarantees accurate and consistent quality in the finished goods.

Why SuperbMelt High Vacuum Melting Furnace

Any Question About SuperbMelt High Vacuum Melting Furnace

Any Question About SuperbMelt High Vacuum Melting Furnace

Guide to High Vacuum Melting Furnaces in Advanced Metal Materials and Precision Jewelry Casting

Introduction of mining of platinum

1.1 Core Characteristics and Growth Drivers of the Global Metal Smelting Market

Metal smelting forms the foundational support for global manufacturing. High-vacuum smelting focuses on producing “high-purity, customized, low-defect” metal materials, closely tied to high-end consumption and advanced manufacturing sectors.

- Market Segmentation and Scale: The global metal smelting market exceeds $2 trillion in scale. The high-end segment (including high-purity precious metals for jewelry and specialized industrial alloys) exhibits a Compound Annual Growth Rate (CAGR) of $8\%-11\%$. While general metal smelting (e.g., carbon steel) has low profit margins (under $10\%$), the high-end sector, such as superalloys and jewelry-grade precious metals, shows significant supply gaps and high profitability ($30\%-70\%$), with jewelry casting commanding a higher premium. The global Vacuum Induction Melting Furnace (VIM) market was valued at approximately $885$ million USD in 2023 and is projected to grow to around $1.39$ billion USD by 2032 .

- Driving Factors: Market growth is structurally driven by consumer demand upgrades in the jewelry sector (luxury, customized pieces), the expansion of high-tech industries like aerospace and semiconductors, and increasingly strict environmental policies that favor green technologies such as high-vacuum smelting.

1.2 Core Manufacturing Demands and Challenges for Molten Metal

The manufacturing requirements for high-end molten metals exceed the limits of traditional smelting, guiding the technological development of HVMF/VIM equipment.

- Purity Control: This is the paramount value of HVMF/VIM. The jewelry industry demands $\text{Au}9999$ and $\text{Ag}999$ as basic standards, with some high-end customized jewelry requiring $\text{Au}99999$ purity. Industrial metals (e.g., semiconductor targets) require purity $\ge 99.999\%$. The HVMF/VIM achieves this by operating in an extremely low-pressure environment (as low as $10^{-6} \text{ torr}$ ) to promote the volatilization and removal of impurities, effectively eliminating dissolved gases like oxygen, hydrogen, and nitrogen .

- Composition Precision and Homogeneity: K-Gold jewelry (e.g., 18K gold) requires precise ratios of gold to alloying elements like copper, silver, and palladium ($\text{Au}75\%$ in 18K gold) to ensure stable color (e.g., rose gold or white gold consistency). Industrial alloys require elemental deviation $\le 0.1 \text{wt}\%$. The electromagnetic stirring function inherent in VIM is crucial for minimizing elemental segregation during the melt and subsequent solidification process, guaranteeing compositional uniformity .

- Low Loss and Sustainability: Precious metal smelting loss must be $\le 2\%$ (with some luxury brands requiring $\le 1\%$ due to the high cost of raw materials). HVMF/VIM meets high environmental standards with low energy consumption and zero harmful emissions.

- Capacity Adaptability: The jewelry industry primarily requires small-batch, multi-cycle production (5–50 kg/batch), necessitating rapid material and specification changeovers (Gold, Silver, K-Gold). Industrial-scale production requires 50–500 kg/batch, demanding flexibility and support for continuous operation. VIM excels in controlling alloy composition in small-batch production.

What are the platinum melting furnaces on the market nowadays

Molten metals, refined and cast using HVMF/VIM, are characterized by their high purity and low defect rates, making them indispensable across high-end consumer goods and advanced manufacturing sectors.

2.1 Jewelry Industry: High Purity, Customization, and Precision Casting

The jewelry industry’s demand for HVMF/VIM technology is reflected in the extreme requirements for density, color stability, and complex form filling. In this sector, VIM technology is often implemented through Vacuum Pressure Casting (VPC) systems.

2.1.1 Core Product Categories and Smelting Requirements

| Jewelry Category | Representative Product | Core Metal Requirement | Impact of HVMF/VPC Technology |

| Gold Jewelry | Pure gold bangles, 3D hard gold pieces | Purity $\ge \text{Au}9999$; pure color consistency; high ductility | Precise vacuum control ($\ge 10^{-5} \text{ Pa}$), reducing oxidation ; ensures consistent color |

| K-Gold Jewelry | 18K rose gold rings, 14K white gold necklaces | Precise alloy ratio (e.g., $\text{Cu}20\%,\text{Au}75\%$ for rose gold); stable color; moderate hardness | Vacuum environment prevents alloy element oxidation ; guarantees color uniformity; enhances tensile strength |

| Platinum/Palladium | Platinum rings, Palladium pendants | Purity $\ge \text{Pt}950/\text{Pd}950$; soft luster; corrosion resistance | High efficiency removal of impurities (e.g., sensitizing elements like Nickel/Iron) ; ensures high surface finish |

| High-End Custom | Designer alloy pieces, wedding bands | Flexible material composition; high density (no harmful impurities); suitability for complex shapes | Supports small-batch rapid parameter change; ensures high metal density (prevents cracking during stone setting) |

2.1.2 Industry-Specific Demands: Porosity and Process Innovation

Jewelry casting is prone to porosity defects, primarily gas porosity (from dissolved gases) and shrinkage porosity (due to the $4\%-6\%$ volume reduction of gold/silver upon solidification) . High-vacuum smelting and casting are critical for overcoming these defects:

- Eliminating Gas Porosity: The VPC system vacuums the flask during casting, physically removing air and gas released from the investment mold, resulting in “pore-free castings”.

- Managing Shrinkage Porosity: High pressure is applied immediately upon pouring, which, combined with Vibration Technology , forces the liquid metal into the finest branches of the mold, ensuring excellent form filling. Vibration technology can reduce grain size by up to $50\%$ and increase the tensile strength of certain gold alloys by up to $25\%$ , improving durability and minimizing risks of hot cracking.

These technical advancements enable brands to launch premium product lines like “High-Purity Gold Jewelry” and “Nickel-Free Safe Jewelry,” enhancing product premiumization ($20\%-50\%$ price premium over standard pieces).

2.2 Other Core Industrial Applications

- Aerospace Industry: HVMF/VIM is the crucial first step in manufacturing superalloys (e.g., Inconel 718, CMSX-4) . Used in critical components like engine blades and turbine discs, these materials require extreme resistance to high temperature ($\ge 800^\circ\text{C}$ / $\ge 1800^\circ\text{C}$ heating capability) and fatigue . VIM ensures melt purity, which is essential for the success of subsequent complex processes like vacuum investment casting .

- Electronics & Semiconductor Sector: Used for manufacturing high-purity metal targets and electronic bonding wires , requiring $\ge 5\text{N}$ purity (e.g., copper, gold, aluminum) and zero oxide inclusions. The ultra-clean environment of HVMF/VIM is necessary for achieving the ultimate purification required for semiconductor miniaturization .

- Medical Sector: Used for artificial joints, dental restorations, and implantable medical device housings . HVMF/VIM efficiently removes gases (H, O) to ensure high biocompatibility and corrosion resistance, strictly controlling allergenic impurities (e.g., nickel content $\le 0.05\%$ 6).

- New Energy Sector: Used for components in power batteries and photovoltaic equipment, requiring high-purity nickel, cobalt, and silver. HVMF/VIM ensures chemical uniformity and supports reliable large-scale production.

Why equipment is needed to melt platinum

The High Vacuum Melting Furnace (VIM), which utilizes induction heating within a vacuum chamber , is a strategic asset that revolutionizes material quality and production efficiency.

3.1 Manufacturing Value: Overcoming Traditional Smelting Limitations

- Quality Innovation and Refining: The vacuum environment drastically reduces metal oxidation and impurity absorption, elevating the purity of jewelry-grade precious metals from $99.5\%$ to $\ge 99.99\%$. Furthermore, VIM employs selective refining to effectively remove deleterious low-melting-point, high-volatility trace elements (like Antimony, Tellurium, and Bismuth) , which is crucial for meeting advanced material performance requirements.

- Cost Optimization and Yield: VIM boasts high thermal efficiency ($85\%-95\%$) , significantly reducing energy consumption. Crucially, it dramatically improves material yield. Precious metal loss rates drop from $5\%-8\%$ in traditional processes to $1\%-2\%$ , reducing rework and lowering processing costs by over $30\%$. Compared to the high scrap rates (up to $40\%$) of traditional casting 7, HVMF/VIM maximizes the utilization of high-value raw materials.

- Operational Flexibility: HVMF/VIM supports small-batch, multi-cycle production (5–50 kg/batch) and quick material changeovers (1–2 hours for Gold, Silver, K-Gold) , catering perfectly to the customization demands of the jewelry industry.

3.2 Application Value: Enabling Innovation and Brand Enhancement

- Elevating the Jewelry Sector: VIM/VPC technology addresses traditional pain points like “uneven color, oxidation, and excessive impurities”. By delivering highly dense, stronger castings (up to $25\%$ higher tensile strength) , it empowers brands to launch premium, high-purity product lines.

- Foundation for Additive Manufacturing (AM): The transition to precious metal and specialty alloy 3D printing requires metal powders of extreme purity and compositional uniformity . VIM technology is the essential upstream process for preparing high-purity, inclusion-free alloy ingots before gas atomization, positioning VIM as a strategic asset for next-generation manufacturing .

- Strategic Market Access: VIM enables manufacturers to meet the stringent purity and compliance standards of regulated industries (aerospace, medical), which forms a natural entry barrier to these high-value markets.

3.3 Industrial Value: Driving Supply Chain Upgrade and Competitive Edge

- Industry Transformation and Intelligence: HVMF/VIM equipment is moving towards Intelligent Smelting (integrating AI temperature control, material traceability, and remote maintenance), driving the metal smelting industry’s shift from “labor-intensive” to “technology-intensive” .

- Building Competitive Barriers: HVMF/VIM investment is an investment in predictable ultra-high quality, low-risk operation, and continuous innovation. The extreme purity requirements enabled by VIM technology constitute a robust competitive barrier, securing long-term market advantage .

- Sustainability Strategy: The high thermal efficiency and high yield of VIM directly translate to reduced energy consumption and minimal material waste, aligning with global $\text{ESG}$ standards and offering superior sustainability metrics

FAQ Guide of High Vacuum Melting Furnace

- 1. How does vacuum help in induction melting furnace?

- 2. Why use a vacuum furnace?

- 3. What is the vacuum level of a vacuum furnace?

- 4. What is a High Vacuum Melting Furnace?

- 5. How does a High Vacuum Melting Furnace work?

- 6. What metals can be melted in a High Vacuum Melting Furnace?

- 7. What is the temperature range of a High Vacuum Melting Furnace?

- 8. What is the significance of the vacuum environment in melting processes?

- 9. How fast can a High Vacuum Melting Furnace melt metals?

- 10. What industries benefit from High Vacuum Melting Furnaces?

- 11. Is a High Vacuum Melting Furnace suitable for research applications?

- 12. Can the furnace operate continuously?

- 13. What safety features are incorporated into these furnaces?

- 14. How does the furnace prevent gas porosity in melted metals?

- 15. Can the furnace be customized for specific melting requirements?

1. How does vacuum help in induction melting furnace?

- Preventing Oxidation: The main goal of producing a vacuum atmosphere is to drastically cut down on or completely remove oxygen. The absence of oxygen in a vacuum keeps the molten metal from oxidizing. This is particularly important when melting very reactive metals like titanium.

- Lowering Contamination: The presence of airborne pollutants can be reduced with the use of vacuum. This is especially crucial when melting metals that require high purity standards and are susceptible to contaminants.

- Increasing Melting Efficiency: Heat loss from convection and conduction is decreased in a vacuum environment when there is no air present. As a result, the melting process becomes more efficient, enabling the melting of metals more quickly and uniformly.

- Improving Degassing: Vacuum makes it easier to extract gasses and other volatile components from the molten metal. This is vital for preserving the metal’s purity, particularly in uses like the creation of premium alloys where a low gas concentration is necessary.

- Avoiding Metal Splash: Since there is no air present in a vacuum, there is less chance of metal splashing while melting. As a result, the melting environment is safer and better managed.

- Controlling Vapor Pressure: Vacuum control is useful in controlling some metals’ vapor pressure, especially those with low boiling points. To stop the evaporation and loss of volatile components, this is crucial.

2. Why use a vacuum furnace?

- Preventing Oxidation: Reducing or eliminating the amount of oxygen in the heating chamber is one of the main goals of employing a vacuum furnace. This ensures that the material maintains its original qualities without developing oxides on the surface by preventing metals and alloys from oxidizing throughout the heating process.

- Preserving Purity: In applications where a high degree of material purity is necessary, vacuum furnaces are essential. The furnace produces high-purity final products by minimizing the possibility of contamination from pollutants in the atmosphere by generating a vacuum environment.

- Improving Heat Treatment: Annealing, brazing, and sintering are heat treatment procedures that are frequently carried out in vacuum furnaces. Better heat treatment outcomes may be achieved by precisely controlling temperature uniformity, quenching rates, and other crucial factors when air is absent.

- Reducing Decarburization: A vacuum furnace aids in the reduction or elimination of decarburization, which is the surface loss of carbon in processes involving the heating of carbon-containing materials. This is significant for applications where keeping the carbon content constant is essential.

- Preventing Surface Reactions: When exposed to oxygen, some materials, particularly those utilized in cutting-edge industries like electronics and aerospace, might experience unfavorable surface reactions. By creating a regulated atmosphere, vacuum furnaces stop these kinds of reactions and guarantee the material’s integrity.

- Increasing Uniformity: When it comes to temperature consistency across the heating chamber, vacuum furnaces outperform traditional furnaces. This is especially helpful in situations when exact and constant heating is necessary to get the required qualities of the material.

- Lowering the Evaporation of Contaminants: Certain substances have volatile components that evaporate at high temperatures. The material’s composition is preserved by regulating and minimizing the evaporation of these components in a vacuum environment.

- Improving Material Quality: The creation of high-quality materials with better mechanical and metallurgical qualities is aided by the clean, regulated environment found within a vacuum furnace.

3. What is the vacuum level of a vacuum furnace?

- A vacuum furnace’s vacuum level is commonly represented in measures like millitorr (mTorr), torr (mmHg), or pascal (Pa), and is measured in terms of pressure. The level of vacuum or pressure within the furnace chamber is indicated by the vacuum.

- Depending on the particular needs of the application and the furnace’s construction, vacuum levels in vacuum furnaces might change. Typical vacuum settings for various kinds of vacuum furnaces consist of

Medium Vacuum: This pressure range usually extends from 1 to 10 mTorr (millitorr) or comparable units. Mechanical vacuum pumps are used to provide a medium vacuum, which is appropriate for a variety of heat treatment procedures. - High Vacuum: 10^-3 to 10^-6 Torr is the range of high vacuum levels. Diffusion pumps and turbomolecular pumps are frequently used in addition to mechanical pumps to achieve high vacuum. For procedures like brazing and sintering that need exact control and low contamination, a high vacuum is necessary.

- Ultra-High Vacuum (UHV): Vacuums of 10^-7 Torr or less are considered ultra-high vacuums. Advanced applications, like some research projects, the production of semiconductors, and particular aerospace uses, usually demand for UHV.

4. What is a High Vacuum Melting Furnace?

A High Vacuum Melting Furnace is an advanced industrial equipment designed for melting metals under high vacuum conditions.

5. How does a High Vacuum Melting Furnace work?

It works by creating a high vacuum environment inside the furnace chamber, which helps prevent oxidation and contamination during the metal melting process.

6. What metals can be melted in a High Vacuum Melting Furnace?

High Vacuum Melting Furnaces are versatile and can melt various metals, including gold, silver, platinum, palladium, and other precious metals.

7. What is the temperature range of a High Vacuum Melting Furnace?

The temperature range typically reaches up to 2600°C, allowing for the melting of high-melting-point metals.

8. What is the significance of the vacuum environment in melting processes?

The vacuum environment prevents oxidation and contamination, ensuring high-quality and pure melted metals, particularly crucial for sensitive applications.

9. How fast can a High Vacuum Melting Furnace melt metals?

It can achieve rapid melting, typically melting 4-6kg of metal within three minutes.

10. What industries benefit from High Vacuum Melting Furnaces?

Industries such as jewelry manufacturing, aerospace, and research benefit from the precise and contamination-free melting provided by these furnaces.

11. Is a High Vacuum Melting Furnace suitable for research applications?

Yes, it is often used in research settings due to its ability to provide a controlled and ultra-clean environment for metal melting.

12. Can the furnace operate continuously?

Yes, many High Vacuum Melting Furnaces are designed for continuous 24-hour operation, enhancing production efficiency.

13. What safety features are incorporated into these furnaces?

High Vacuum Melting Furnaces often include multiple safety measures to ensure secure and reliable operation, including overpressure and short-circuit protection.

14. How does the furnace prevent gas porosity in melted metals?

The vacuum environment minimizes gas porosity by removing gases from the molten metal, resulting in high-density and quality castings.

15. Can the furnace be customized for specific melting requirements?

Yes, SuperbMelt offers customization options to tailor High Vacuum Melting Furnaces to specific user needs and applications.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited