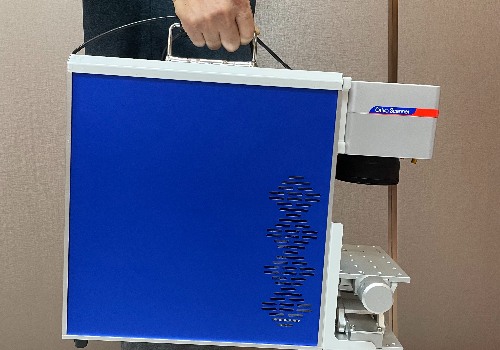

50w Laser Marking Machine

SuperbMelt 50W Laser Marking Machine is used to engrave intricate designs on metals, enhancing their aesthetic appeal. With its 50W power, this engraving machine operates faster and creates deeper engravings compared to 20W/30W models. It effectively addresses metal engraving needs.

Utilizing a 50-watt laser source, it performs detailed and precise engravings on various surfaces. This machine is commonly employed in industries such as jewelry manufacturing, manufacturing, signage, and more. With its higher wattage, it’s capable of faster and deeper engraving compared to lower-wattage machines.

The features and advantages of the SuperbMelt 50W Laser Marking Machine include:

- High Power Capability: With a 50-watt power source, it offers more substantial engraving capabilities compared to lower-wattage machines, allowing for faster and deeper engravings.

- Precision: This machine delivers detailed and precise engravings on various surfaces, ensuring high-quality results.

- Versatility: It can be used in a variety of industries, including jewelry manufacturing, general manufacturing, and signage, making it a versatile tool for different applications.

- Speed: Due to its higher power output, it completes engraving tasks more quickly, contributing to enhanced productivity.

- Durability: SuperbMelt machines are known for their reliability and long-term performance, ensuring longevity and durability.

- Easy to Operate: These machines are designed for user-friendliness, with straightforward operation, making them accessible even to those new to laser engraving.

- Precise Control: They offer precise control over the engraving process, allowing for the creation of intricate designs and patterns.

- Improved Aesthetics: The engravings achieved with this machine enhance the aesthetic quality of metal surfaces, making them more appealing.

SuperbMelt 50W Laser Marking Machine is a powerful and versatile tool that excels in precision, speed, and durability, making it an ideal choice for various industries seeking high-quality engraving solutions.

| Model Number | SPB-MFLM |

| Average Output Power | 20W/30W/50W |

| Beam Quality | M²:1.5(TEMOO mode) |

| Repeatability | 0.01mm |

| Max Line Speed | 12000mm/s |

| Min Line Width | 0.017mm |

| Power Adjustment Range | 1%-100% |

| Laser Wavelength | 1064nm |

| Total Power | ≤500W |

| Marking Range | 110mm*110mm/175mm*175mm |

| Cooling System | Air Cooled |

| Laser Repetition Rate | 20KHz-80KHz(Adjustable) |

| Equipment Working Environment | Clean or Less Dusty |

| Min Character | 0.2mm*0.2mm |

| Equipment Operating Temperature | 13℃-28℃ |

| Marking Depth | 0.01mm-1mm(Determined by material) |

| Power Requirements | AC220V/50Hz/2A |

Why SuperbMelt 50w Laser Marking Machine

Any Question About SuperbMelt 50w Laser Marking Machine

50w Laser Marking Machine Guide from the User's Perspective

Is it suitable for beginners or professional operators?

Yes, a 50W laser marking machine is suitable for both beginners and professional operators, depending on the specific needs and application.

For Beginners:

Many modern 50W machines (like SuperbMelt’s) come with user-friendly interfaces, preset parameters, and tutorials or remote guidance, making it easy for first-time users to get started quickly.For Professionals:

The high power, deeper engraving capability, and faster marking speed make it ideal for high-volume production, complex designs, or industrial-level precision required by experienced users.

In short, it’s a versatile machine that grows with the user — simple enough for new users, yet powerful enough for advanced applications.

Which users are suitable to invest in a 50W marking machine?

A 50W laser marking machine is a versatile mid-power industrial tool suitable for users who require deep engraving, high-speed marking, or processing of harder materials.

- 1. Best-Suited Industries & Applications

✓ Metalworking & Hardware Manufacturing

Typical Users: Metal fabricators, automotive part suppliers, toolmakers

Applications:

Engraving serial numbers, barcodes, or logos on steel/aluminum parts

Permanent marking on gears, valves, molds, and industrial tools

Deep engraving (0.1–0.5mm) for wear-resistant identification

✓ Jewelry & Luxury Goods

Typical Users: Jewelry workshops, watchmakers, luxury accessory brands

Applications:

Precise hallmarks, logos, or personalized text on gold/silver/platinum

Anti-counterfeiting marks on precious metals and gemstone settings

✓ Electronics & Precision Engineering

Typical Users: PCB manufacturers, microelectronics companies

Applications:

Marking circuit boards, connectors, and semiconductor components

High-contrast engravings on anodized aluminum, titanium, or ceramic

✓ Medical & Aerospace

Typical Users: Surgical instrument makers, aerospace suppliers

Applications:

FDA-compliant UDI (Unique Device Identification) markings

Traceability codes on titanium implants, surgical steel tools

- 2. Key Advantages of a 50W Machine

Deeper Engraving: Handles stainless steel, titanium, and hardened alloys better than 20W/30W lasers.

Faster Speed: 30–50% quicker than low-power lasers for batch production.

Wider Material Range: Can mark some plastics and coated materials (e.g., anodized aluminum).

- 3. Users Who Should Avoid 50W (Choose Lower Power)

Budget-limited startups: A 20W/30W machine may suffice for simple logos on softer metals.

Exclusive organic material users: For wood/leather/paper, a CO₂ laser is more cost-effective.

Ultra-fine detail requirements: For micron-level precision (e.g., microchip marking), fiber lasers >100W with galvo systems are preferable.

- 4. Investment Recommendation

A 50W fiber laser marker is ideal for small-to-medium enterprises (SMEs) needing:

Durability: Marks withstand abrasion, heat, and chemicals.

Regulatory Compliance: Meets ISO/CE standards for industrial part tracking.

ROI: Faster throughput reduces cost per mark for bulk orders.

Is the daily use cost high? What are the consumables?

1. Daily Operating Costs

| Cost Factor | Estimated Expense | Notes |

|---|---|---|

| Electricity | ~$0.5–$2/day | 50W laser uses ~1–2 kWh during 8h operation (varies by duty cycle). |

| Gas (Optional) | ~$1–$5/day (if used) | Nitrogen/compressed air for oxidation-free marking on metals. |

| Labor | Depends on wages | Minimal supervision needed for automated batch jobs. |

Total Daily Cost: ~$2–$10 (excluding labor).

Note: Far cheaper than traditional engraving (e.g., CNC) for high-volume work.

2. Main Consumables & Replacement Costs

| Consumable | Lifespan | Replacement Cost | Function |

|---|---|---|---|

| Laser Source | 50,000–100,000h | $1,500–$3,000 | Core component; rarely replaced. |

| Focus Lens | 6–12 months | $50–$200 | Ensures beam precision; scratches affect quality. |

| Protective Window | 3–6 months | $20–$100 | Prevents debris from entering the optical path. |

| Chiller Coolant | Annual refill | $30–$50 | Maintains laser temperature (if water-cooled). |

| Marking Compounds | As needed | $10–$50/bottle | Spray-on solutions for contrast enhancement (e.g., CerMark). |

Key Insight: Annual consumable costs typically total $200–$500 for moderate use.

3. Cost-Saving Tips

Preventive Maintenance: Clean lenses weekly to extend lifespan.

Batch Processing: Reduce idle time between jobs to save energy.

Use Air Assist: Compressed air is cheaper than nitrogen for most metals.

4. Comparison to Other Technologies

| Method | Daily Cost | Consumables |

|---|---|---|

| 50W Fiber Laser | $2–$10 | Lens, gas, coolant |

| CO₂ Laser | $5–$15 | Mirrors, tubes, gas |

| Mechanical Engraving | $10–$30+ | Cutting tools, lubricants |

How to choose the power size according to your needs?

1. Match Laser Power to Your Material

| Material | Recommended Power | Why? |

|---|---|---|

| Plastics/Paper/Leather | 10W–30W | Low power prevents burning; CO₂ lasers (10.6μm) are better for organics. |

| Anodized Aluminum | 20W–30W | Enough for high-contrast marks without melting. |

| Stainless Steel/Brass | 30W–50W | Balances speed and legibility for serial numbers/logos. |

| Titanium/Hardened Steel | 50W–100W | Higher power ensures deep engraving (0.2mm+). |

| Ceramics/Glass | 30W–50W (Pulsed) | Requires controlled energy to avoid cracking. |

2. Consider Your Production Needs

Low Volume/Custom Work (e.g., jewelry): 20W–30W (finer details).

Medium-High Volume (e.g., automotive parts): 50W–100W (faster throughput).

Ultra-Deep Engraving (e.g., molds): 100W+ (but costs rise significantly).

Speed Example: A 50W machine marks stainless steel 2–3× faster than a 20W model at the same depth.

3. Budget vs. Future-Proofing

| Power | Price Range | Best For | Limitations |

|---|---|---|---|

| 20W–30W | $3,000–$6,000 | Startups, thin metals | Slow on hard metals. |

| 50W | $6,000–$12,000 | SMEs, most metals | Struggles with >0.3mm depth. |

| 100W+ | $15,000+ | Heavy industry | Overkill for plastics/paper. |

Tip: A 50W fiber laser offers the best balance of cost and capability for most metal applications.

4. Technical Factors

Pulse Frequency: Higher power allows adjustable pulses (better for heat-sensitive materials).

Beam Quality (M²): Lower M² = finer marks (critical for <20μm precision).

Cooling System: Air-cooled (20W–30W) vs. water-cooled (50W+).

5. Quick Decision Flowchart

Material?

Organic (wood/leather) → CO₂ laser (30W–60W).

Metal/plastic → Fiber laser (20W–100W).

Depth Needed?

- Surface marks → 20W–30W.

0.1mm depth → 50W+.

Budget?

Under $10K → 30W–50W.

High-volume → 50W–100W.

- Example Choices:

Jewelry Studio: 30W (fine detail on silver/gold).

Auto Parts Supplier: 50W (fast, durable marks on steel).

Aerospace OEM: 100W (deep engraving on titanium).

- For hybrid needs (e.g., metal + plastic), consider dual-source lasers or prioritize your primary material. Let me know your specific use case for tailored advice!

FAQ Guide of 50w Laser Marking Machine

- 1. What materials can the 50W laser marking machine engrave on?

- 2. Is it suitable for jewelry engraving?

- 3. How deep can it engrave into metals?

- 4. What file formats are compatible with this machine?

- 5. Can it mark on curved or irregular surfaces?

- 6. What are the maintenance requirements for the machine?

- 7. What safety precautions should be taken when operating the machine?

- 8. Can it engrave images and photographs?

- 9. What is the expected lifespan of the laser source?

- 10. What software is used to control the machine?

- 11. Is training provided for using the machine?

- 12. Can it engrave serial numbers, barcodes, and QR codes?

- 13. What is the warranty coverage for the machine?

- 14. How should heat-sensitive materials be engraved?

- 15. Can the machine handle rotary engraving?

- 16. Can it engrave non-metallic materials?

- 17. What are the power requirements for the machine?

- 18. Is technical support available for the machine?

- 19. Are replacement parts available for the machine?

- 20. In which industries is the 50W laser marking machine commonly used?

1. What materials can the 50W laser marking machine engrave on?

The 50W laser marking machine can engrave on various materials, including metals (such as gold, silver, and stainless steel), plastics, ceramics, and more.

2. Is it suitable for jewelry engraving?

Yes, this machine is suitable for jewelry engraving, offering precision and high-quality results.

3. How deep can it engrave into metals?

The machine can engrave into metals to a depth that depends on the specific metal and material composition.

4. What file formats are compatible with this machine?

The machine is compatible with commonly used file formats like BMP, JPG, PNG, DXF, and PLT.

5. Can it mark on curved or irregular surfaces?

Yes, it can mark on curved or irregular surfaces with the help of specialized equipment, like rotary devices or fixtures.

6. What are the maintenance requirements for the machine?

Regular maintenance includes cleaning the lens, checking and cleaning the exhaust system, and ensuring proper ventilation.

7. What safety precautions should be taken when operating the machine?

Safety precautions involve using protective eyewear, ensuring proper ventilation, and following safe operating procedures.

8. Can it engrave images and photographs?

Yes, it can mark images and photographs, provided they are in compatible file formats.

9. What is the expected lifespan of the laser source?

The expected lifespan of the laser source can vary but typically ranges from 20,000 to 100,000 hours of use.

10. What software is used to control the machine?

The machine comes with user-friendly software for designing and controlling engravings. Common software includes EZCAD or similar programs.

11. Is training provided for using the machine?

Training is often provided by the manufacturer or supplier to ensure users can operate the machine effectively and safely.

12. Can it engrave serial numbers, barcodes, and QR codes?

Yes, the machine can engrave serial numbers, barcodes, QR codes, and other data efficiently.

13. What is the warranty coverage for the machine?

The warranty coverage varies by manufacturer and supplier but typically ranges from one to two years.

14. How should heat-sensitive materials be engraved?

Heat-sensitive materials may require lower power settings to prevent damage.

15. Can the machine handle rotary engraving?

The machine can handle rotary engraving with the addition of a rotary attachment.

16. Can it engrave non-metallic materials?

While it’s primarily designed for marking metals, it can also mark non-metallic materials like plastics and wood.

17. What are the power requirements for the machine?

The power requirements depend on the machine’s specifications but typically range from 220V to 110V.

18. Is technical support available for the machine?

Technical support is usually available to assist with troubleshooting and maintenance inquiries.

19. Are replacement parts available for the machine?

Replacement parts for the machine are generally available from the manufacturer or supplier.

20. In which industries is the 50W laser marking machine commonly used?

Industries that commonly use the 50W laser marking machine include jewelry manufacturing, electronics, automotive, medical device production, and more.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited