2kg Melting Furnace

The most popular SuperbMelt 1-2kg gold and silver melting furnace on the market

SuperbMelt 2kg melting furnace can melt up to 2kg of metals in a single operation. It is suitable for melting silver, gold, copper, aluminum, brass, bronze, and their alloys.

The furnace is available in two models: SPB-DH1 and SPB-DH2, designed to meet specific needs. Equipped with an induction heating system, the furnace not only saves time and costs but also enhances the efficiency of the production line.

This electric melting furnace is versatile and applicable in various fields, including jewelry making, scrap recycling, laboratory research, and personal use.

At SuperbMelt, our dedicated research team continuously develops innovative technologies to meet market demands and fulfill customer needs. We provide a wide range of machines to customers worldwide, catering to their unique melting and casting requirements.

For those looking for furnaces with larger capacities, please click here for more information.

If you wanna check metal melting furnaces with bigger capacity, Please click here.

- Superbmelt 2kg gold melting furnace is suitable for melting metals such as gold, silver, aluminium, copper, brass, bronze, and their alloys.

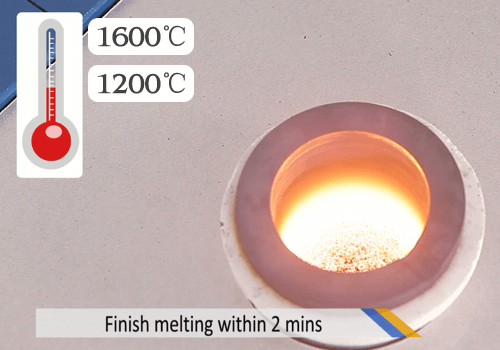

- You can melt up to 2kg of metal within 2 minutes, and 30kg of metal within 1 hour.

- The 2kg electric melting furnace allows you to melt continuously for 24 hours due to the presence of the water cooling unit. The water cooling unit prevents overheating of the metal melting furnace.

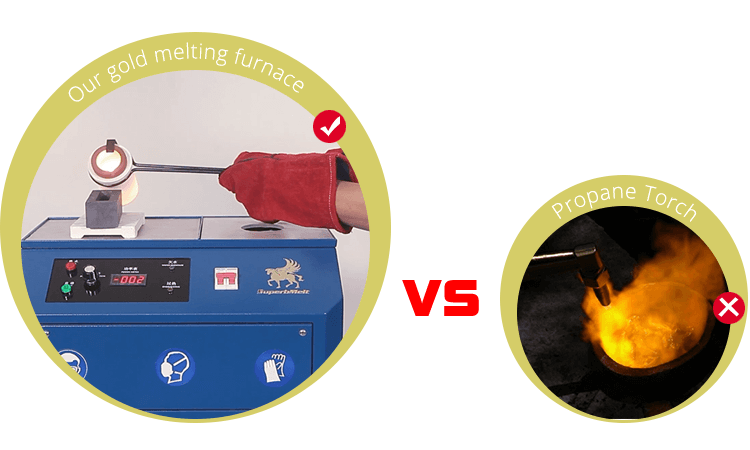

- Superbmelt metal melting furnace has an IGBT induction heating technology that ensures molten metal consistency, conserves energy use and saves melting time.

- Superbmelt home furnace for melting metals has a PLC control system which makes it easy to use.

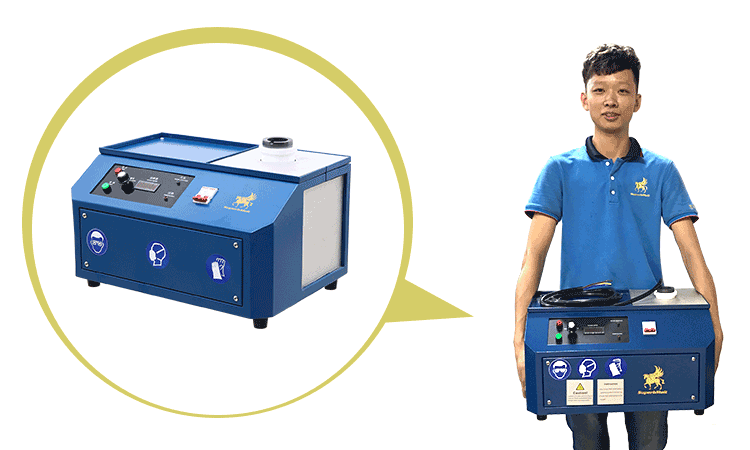

- Our 2kg gold melting furnace is a compact design with a dimension of 520*400*330mm and a total weight of 21kg to 22kg, this means you don’t require much space for your small melting furnace and it is easy to transport.

- Superbmelt electric melting furnace is suitable for use in jewellery industries, metal scrap recycling, gold mining, gold recovery plant, laboratory research, personal melting, etc.

- Superbmelt small metal melting furnace is safe for both the operator and the environment. The melting chamber of the 2kg gold melting furnace is enclosed to prevent molten metal spillage and escape of melting temperature.

- There is no release of toxic gases, smoke or noise when melting with Superbmelt electric melting furnace.

- You can use readily available crucibles such as graphite and silicon carbide crucibles to melt in your metal melting furnace. The graphite and silicon carbide crucibles are available at Superbmelt Electromachinery Co. Limited.

- Superbmelt small metal melting furnace is highly efficient for melting. Items cast are usually free of shrinkage, oxidation and porosity.

- Superbmelt 2kg electric melting furnace has a maximum temperature of 1600 degree celsius.

- The maximum power required for melting in the gold melting furnace is between 3.5kw and 3.8kw. Therefore, you don’t need to incur extra cost for melting and you can save up to 50% on energy.

- The 2kg melting furnace comes with an installation video and tutorial guide. This makes the operating process easy for you, even as a first time user.

- Superbmelt 2kg gold melting furnace prevents precious metal loss compared to the traditional melting process.

| Model number | SPB-DH1 | SPB-DH2 |

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm |

| Weight | 21 kg | 22 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

Graphite crucible for gold/Silver melting Furnace

Small 1-2kg gold and silver smelting pot is portable size design, light weight, easy to carry and fix.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Induction 2kg Melting Furnace

Any Question About SuperbMelt 2kg Melting Furnace

2kg Melting Furnace – Professional Buyer & Production Guide

The 2kg melting furnace has become a core equipment in small – batch metal processing fields such as jewelry manufacturing, precious metal recycling, and material experimentation. With its balanced capacity, high – precision performance, and flexible applicability, it perfectly solves the production pain points of small – scale enterprises and professional institutions. This guide will comprehensively analyze who the 2kg melting furnace is suitable for, its core performance advantages, and its application value in different scenarios, helping you make scientific purchasing decisions and optimize production processes.

Introduction of mining of platinum

The 2kg melting furnace is positioned as “small – batch, high – precision, and multi – scenario” equipment. It is not a universal device, but it can maximize the input – output ratio for specific user groups. The following are the core applicable groups and their demand matching logic:

1.1, Early Platinum Mining

- Core Business: Producing gold chains, silver pendants, K – gold rings, and other small – sized jewelry, with daily output ranging from 5 to 20kg of finished products.

- Pain Points to Solve: Limited workshop space (usually 10 – 50 square meters), difficulty in carrying large – capacity furnaces; small batch orders (often 1 – 5kg per order), requiring flexible switching between different metals (gold, silver, platinum); high requirements for metal purity, avoiding excessive material waste during melting.

- Why 2kg Capacity is Suitable: The 2kg melting furnace can meet the material demand of 1 – 2 batches of small orders at a time, without causing raw material backlog. Its compact size (generally 60cm×50cm×80cm) can be placed in a corner of the workshop, saving space. Meanwhile, it can quickly switch between different metals, reducing the time cost of material replacement and cleaning.

1.2, Modern Platinum Mining Techniques

- Core Business: Recycling and remelting old jewelry, scrap precious metal components, and used electronic gold – plated materials, with daily recycling volume of 3 – 10kg.

- Pain Points to Solve: The recycled materials are mixed, requiring small – batch melting and purification; the purity of the recycled metals needs to be controlled to ensure the quality of remolded products; the production scale is small, and large – capacity furnaces are not cost – effective.

- Why 2kg Capacity is Suitable: The 2kg melting furnace can separately melt different types of recycled materials, avoiding cross – contamination between metals. Its small – batch melting mode facilitates precise control of the purification process, and the melted metal can be directly cast into small ingots (2kg each), which is convenient for storage and subsequent processing. The equipment investment is low (usually 3,000 – 8,000 US dollars), and the investment recovery period is generally within 6 months.

1.3, Business value and investment market

- Core Business: Conducting metal material research, such as alloy formula experimentation, melting point testing, and metal performance analysis, with each experiment requiring 0.5 – 2kg of metal samples.

- Pain Points to Solve: High requirements for temperature control accuracy to ensure the repeatability of experimental data; need to adapt to various metal materials (including high – melting – point metals such as platinum and palladium); small sample volume, requiring no excessive waste of experimental materials.

- Why 2kg Capacity is Suitable: The 2kg melting furnace has high temperature control precision (usually ±1℃), which can accurately simulate the melting environment required by experiments. The 2kg capacity can meet the sample demand of multiple groups of experiments, avoiding material waste while ensuring experimental efficiency. It is easy to operate and can be operated by laboratory personnel without professional smelting technicians.

1.4, Platinum is more ductile than gold and sliver

- Core Business: Creating custom – made metal crafts, such as copper sculptures, silver ornaments, and hand – forged iron art, with small production batches (usually 1 – 3 pieces per order) and diverse metal types.

- Pain Points to Solve: Need to flexibly adjust the melting amount according to customer orders; the crafts have high requirements for metal texture, avoiding oxidation and impurities during melting; limited funds and space, requiring cost – effective and compact equipment.

- Why 2kg Capacity is Suitable: The 2kg melting furnace can realize “on – demand melting” for custom orders, reducing inventory of raw materials. Its closed melting environment can reduce metal oxidation, ensuring the texture of crafts. The equipment has low energy consumption (usually 3 – 6kW) and low daily operating costs, which is suitable for small – scale handmade workshops.

1.5, Platinum is more ductile than gold and sliver

- Core Business: Producing metal components such as electronic contacts, connectors, and small – sized metal shells, requiring melting of copper, silver, and their alloys.

- Pain Points to Solve: The components have high requirements for metal density and uniformity, requiring stable melting processes; small batch production, needing to quickly switch between different component raw materials.

- Why 2kg Capacity is Suitable: The stable temperature control and uniform melting effect of the 2kg melting furnace can ensure the density and uniformity of metal materials, reducing the defective rate of electronic components. The 2kg capacity matches the small – batch production rhythm of electronic components, and the fast melting speed (generally 15 – 30 minutes per batch) can shorten the production cycle.

What are the platinum melting furnaces on the market nowadays

The 2kg melting furnace’s market competitiveness lies in its balanced and excellent core performance. The following three aspects are the key indicators that buyers must focus on, directly determining production efficiency, product quality, and long – term use costs.

2.1, Vacuum electroslag platinum melting induction furnace

- Optimal Batch Adaptation: The 2kg single melting capacity is perfectly aligned with the order volume of small – scale manufacturers (1 – 5kg per batch). It can complete the melting of a single small order at one time without splitting or merging batches, avoiding the problem of metal composition changes caused by multiple melting of the same batch of materials. For example, a jewelry workshop producing 18K gold rings can melt 2kg of 18K gold alloy at one time, which is exactly the raw material demand for 50 – 80 rings.

- High Production Efficiency: Compared with smaller – capacity furnaces (1kg or less), the 2kg melting furnace reduces the number of melting cycles. Taking gold melting as an example, a 1kg furnace needs 2 – 3 cycles to complete a 2kg order, while a 2kg furnace can finish it in one cycle, saving 50% of the melting time. Compared with larger – capacity furnaces (5kg or more), it has a shorter heating time (the 2kg furnace takes 15 – 30 minutes to melt gold, while the 5kg furnace takes 30 – 50 minutes) and lower energy waste.

- Low Raw Material Backlog: Small – scale enterprises often face the problem of limited capital turnover. The 2kg melting furnace does not require a large amount of raw material reserve for each melting, reducing the capital occupation of raw materials. At the same time, it can quickly respond to urgent orders, improving customer satisfaction.

2.2, step 1: Casting bullion

- Precision Temperature Control: High – quality 2kg melting furnaces usually have a temperature control range of 200 – 2000℃, with a temperature control accuracy of ±1℃, which can precisely match the melting points of different metals (gold: 1064℃, silver: 961℃, copper: 1085℃, platinum: 1768℃). The built – in digital temperature controller can display the real – time temperature and support temperature setting and storage, ensuring the consistency of melting parameters for each batch. Some high – end models are equipped with PID automatic temperature adjustment technology, which can automatically compensate for temperature fluctuations and avoid metal overheating or incomplete melting.

- Reasonable Power Configuration: The power of mainstream 2kg melting furnaces is usually 3 – 6kW, which can balance heating speed and energy consumption. A 4 – 5kW furnace can heat 2kg of gold from room temperature to 1100℃ (melting and heat preservation temperature) in 20 – 25 minutes, meeting the needs of continuous production. Meanwhile, the power is compatible with the common 220V or 380V power supply in workshops, without the need for special power transformation, reducing the cost of supporting facilities.

- Stable Heat Preservation Performance: The furnace body is usually made of high – density refractory materials (such as alumina fiber), which has excellent heat insulation performance, reducing heat loss during melting. After reaching the set temperature, the heat preservation power consumption can be reduced by 30% – 40% compared with the heating stage, saving long – term energy costs. At the same time, stable heat preservation can avoid metal oxidation caused by temperature changes and ensure the purity of molten metal.

2.3, Platinum resistance furnaces

- High – Quality Crucible Options:

- Graphite Crucibles: The most commonly used type for 2kg melting furnaces, with high temperature resistance (up to 2000℃) and good thermal conductivity. It is suitable for melting gold, silver, copper, and their alloys. The service life of a high – density graphite crucible can reach 50 – 100 melting cycles, and the cost per use is low.

- Quartz Crucibles: Suitable for melting high – purity metals and alloys with high melting points (such as platinum and palladium). It has good chemical stability and will not react with molten metal, ensuring the purity of the metal. However, its service life is relatively short (20 – 50 cycles) and the cost is higher than that of graphite crucibles.

- Ceramic Crucibles: Cost – effective, suitable for melting non – precious metals such as copper and aluminum. It has good corrosion resistance but poor thermal shock resistance, so it should avoid rapid heating and cooling.

- Strong Process Compatibility: The 2kg melting furnace is not only limited to simple metal melting but also can be matched with different processes to meet diverse production needs:

- Alloy Preparation: It can accurately mix different metals in proportion and melt them to prepare customized alloys (such as 18K gold, sterling silver, and copper – nickel alloys). The uniform temperature field ensures the uniform composition of the alloy.

- Casting Connection: It can be directly matched with small casting molds or continuous casting machines. The molten metal can be directly cast into gold bars, wire blanks, or small – sized workpieces, realizing the integration of melting and casting and improving production efficiency.

- Metal Purification: By controlling the melting temperature and holding time, impurities in the metal can be precipitated, improving the purity of the metal (the purity of recycled gold can be increased from 90% to 99.9% after melting and purification).

Why equipment is needed to melt platinum

3.1 Core Use Value: Cost, Efficiency, and Quality Improvement

- Cost Reduction: Firstly, it reduces raw material waste. The precise melting control reduces metal oxidation and splashing, with a material loss rate of only 1% – 2%, which is 3 – 5 percentage points lower than that of low – precision small furnaces. Secondly, it saves energy costs. The small capacity and efficient insulation design make its energy consumption per kilogram of metal 20% – 30% lower than that of large – capacity furnaces. Finally, it reduces labor costs. The automatic temperature control and simple operation realize “one – person operation”, eliminating the need for professional smelting technicians.

- Efficiency Enhancement: It shortens the production cycle. The fast heating speed (15 – 30 minutes per batch) and flexible batch switching enable small – scale enterprises to quickly respond to orders. For example, a jewelry workshop can complete the melting and casting of a batch of custom rings in 1 hour, which is 50% faster than the traditional gas melting method. It also simplifies the production process. The 2kg melting furnace can be seamlessly connected with subsequent equipment (such as wire drawing machines and casting machines), forming a compact production line and reducing the time for material transfer and handling.

- Quality Upgrade: The high – precision temperature control ensures the uniform composition and stable performance of the molten metal, improving the qualification rate of finished products. For example, in the production of electronic contacts, the density of silver melted by a high – precision 2kg furnace is more uniform, and the conductivity of the contacts is increased by 10% – 15% compared with that of metal melted by ordinary furnaces. The closed melting environment reduces metal pollution, ensuring that the product meets relevant industry standards (such as SGS precious metal purity certification).

3.2 Scenario Differences: Application Characteristics in Different Industries

| Industry | Application Focus | Process Key Points | Core Value Embodiment |

|---|---|---|---|

| Jewelry Manufacturing | Melting of precious metals (gold, silver, platinum) and alloy preparation | Strictly control the melting temperature to avoid alloy component segregation; use argon protection to prevent metal oxidation; match with continuous casting machines for one – stop production of wire blanks | Ensure the purity and luster of jewelry raw materials; realize flexible switching between different K – gold and silver alloy formulas to meet diverse product designs |

| Precious Metal Recycling | Purification and remelting of mixed recycled materials | Separate melting of different types of metals; extend heat preservation time to precipitate impurities; cast into standard ingots for easy storage and detection | Improve the purity of recycled metals (up to 99.9% or more); realize the “turning waste into treasure” of scrap materials with low cost |

| Material Laboratory | Metal melting for experiments, alloy formula testing, and melting point verification | Ultra – high temperature control accuracy (±0.5℃ for high – end models); compatibility with special metals (titanium, nickel, etc.); accurate recording of temperature – time curves | Ensure the repeatability and accuracy of experimental data; support the R&D of new materials with small sample volume |

| Handicraft Making | Custom melting of copper, silver, and other metals, matching with manual casting | Flexible adjustment of melting amount according to the size of handicrafts; use of small – sized crucibles for easy pouring; simple operation for non – professional operators | Meet the personalized production needs of handicrafts; reduce the threshold for handmade metal crafts and improve production efficiency |

| Electronic Component Production | Melting of copper, silver, and their alloys for small – sized component casting | Strict control of metal impurity content (impurity content ≤0.01%); ensure the density and uniformity of molten metal to meet the performance requirements of electronic components | Improve the conductivity and service life of electronic components; reduce the defective rate of small – sized precision components |

3.3 Notes for Cross – Scenario Use

- Crucible Replacement: Different metals have different chemical properties and temperatures, so it is necessary to replace the corresponding crucible. For example, when switching from melting gold (using a graphite crucible) to melting platinum (using a quartz crucible), it is necessary to thoroughly clean the furnace chamber to avoid cross – contamination between crucible materials.

- Parameter Adjustment: For different metals, it is necessary to preset the corresponding melting temperature and heat preservation time. For example, the melting temperature of gold is 1064℃, and the heat preservation time is 5 – 10 minutes; while the melting temperature of platinum is 1768℃, and the heat preservation time needs to be extended to 15 – 20 minutes to ensure complete melting. High – end models have built – in material parameter presets, which can avoid operational errors.

1. Can you melt gold with induction?

Yes, you can melt gold using induction heating. Induction melting is an efficient and precise method for heating and melting metals, including gold. It works by generating an electromagnetic field through an induction coil, which induces electrical currents (eddy currents) in the metal. These currents cause the metal to heat up due to its electrical resistance, ultimately leading to melting.

Key Advantages of Induction Melting for Gold:

- Efficiency: Induction melting heats the metal directly, reducing energy loss.

- Precision: It allows precise temperature control, ensuring optimal melting conditions for gold without overheating.

- Clean Process: Induction melting does not produce open flames, making it a cleaner and safer method.

- Speed: Gold can be melted in minutes, saving time in production or crafting processes.

This method is widely used in industries like jewelry making, metal recycling, and laboratory research due to its effectiveness and reliability.

2. How hot can a melting furnace get?

The maximum temperature a melting furnace can achieve depends on its type and the technology used. Here’s a general overview:

Induction Melting Furnaces: Typically, induction furnaces can reach temperatures of up to 2,800°C (5,072°F). These furnaces are ideal for melting high-temperature metals like steel, platinum, and titanium.

Electric Resistance Furnaces: These can generally achieve temperatures of about 1,200°C to 1,800°C (2,192°F to 3,272°F). They are suitable for metals like gold, silver, aluminum, and copper.

Gas-Fired Furnaces: Commonly used for melting metals like iron and bronze, these furnaces can reach temperatures of around 1,600°C to 2,000°C (2,912°F to 3,632°F).

Crucible Furnaces: Designed for melting non-ferrous metals, crucible furnaces often operate at a maximum temperature of 1,100°C to 1,500°C (2,012°F to 2,732°F).

Each type of furnace is optimized for specific applications and materials, and the choice depends on the melting point of the metal and the production requirements. For gold and silver, furnaces typically operate within a range of 1,000°C to 1,200°C (1,832°F to 2,192°F), which is sufficient for these metals.

3. What metals Cannot be heated by induction?

Induction heating relies on electromagnetic induction to generate heat within a conductive material. Therefore, metals that cannot be effectively heated by induction typically fall into these categories:

Non-Conductive Metals:

- Metals with very low electrical conductivity, such as lead or tin, are challenging to heat effectively because induction heating depends on creating eddy currents within the material.

Non-Magnetic Metals:

- Non-magnetic materials like copper and aluminum can still be heated by induction but require higher power and take longer compared to ferrous (magnetic) metals.

Non-Metallic Materials:

- Materials such as ceramics, plastics, and glass are entirely unsuitable for induction heating unless they are coated or embedded with a conductive material.

Metals with Low Permeability:

- Metals with low magnetic permeability, such as austenitic stainless steels, are harder to heat with standard induction methods, though specialized systems can overcome this limitation.

In summary, while induction heating is highly efficient for most conductive metals, those with poor conductivity, low magnetic permeability, or a low melting point may require alternative heating methods for optimal results.

4. Can I melt gold without flux?

Yes, you can melt gold without flux, but using flux is generally recommended for better results. Flux serves several purposes in the melting process:

Benefits of Using Flux:

- Removes Impurities: Flux helps to separate impurities from the gold, resulting in purer molten metal.

- Prevents Oxidation: It creates a protective layer over the gold, minimizing oxidation during melting.

- Improves Flow: Flux ensures smoother pouring by reducing viscosity and improving the flow of the molten gold.

Challenges Without Flux:

- Without flux, impurities may remain in the gold, affecting its quality.

- Oxidation can occur, leading to discoloration or imperfections in the final product.

- The melting process might be less efficient, particularly for scrap gold or gold with alloyed metals.

When Melting Without Flux:

If you choose to melt gold without flux:

- Use clean, pure gold to minimize impurities.

- Employ a controlled environment with minimal oxygen exposure to reduce oxidation.

- Use high-quality equipment like an induction melting furnace for precise temperature control.

While it’s possible to melt gold without flux, incorporating it can significantly enhance the process, especially when dealing with impure gold or refining tasks.

5. Is the 2kg melting furnace energy-efficient?

Yes, the induction heating system ensures high energy efficiency and lower operational costs.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited