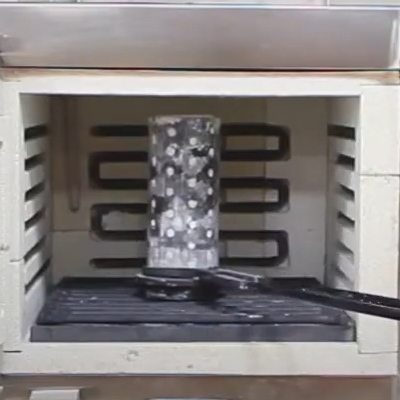

Wax burnout oven

SuperbMelt Professional Jewelry Burnout Oven

SuperbMelt Is A Professional Manufacturer Of Wax Melting Machines, Focusing On Melting Wax Flowing In Plaster Molds. A Hollow Plaster Mold Is Obtained During Jewelry Casting.

Special Design For Secondary Combustion; Re-Collect The Incomplete Combustion During The Dewaxing Process, Let It Burn Again And Fully Burn It, And Reduce The Wax Smell In The Environment As Much As Possible.

| Model number | SPB- HTF | SPB-WF2 | SPB-WF4 | SPB-WF6 | SPB-WF12 | SPB-WF18 | SPB-WF24 | SPB-WF32 | SPB-WF40 |

| Power source | 3 phase 380V, 50/60Hz | Single phase 220V | Single phase 220V | Single phase 220V | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz |

| Power | 11.5kw (9kw+2.5kw) | 2.5kw | 3kw | 4kw | 6kw | 9kw | 9kw | 12kw | 12kw |

| Capacity | 24 pcs of 4*9 inch flask | 2 pcs of 4*9 inch flask | 4 pcs of 4*9 inch flask | 6 pcs of 4*9 inch flask | 12 pcs of 4*9 inch flask | 18 pcs of 4*9 inch flask | 24 pcs of 4*9 inch flask | 32 pcs of 4*9 inch flask | 40 pcs of 4*9 inch flask |

| Operation temperature | 850℃ | 850℃ | 850℃ | 850℃ | 850℃ | 850℃ | 850℃ | 850℃ | 850℃ |

| Chamber size | 420* 550* 500 mm | 300* 150* 270 mm | 300* 300* 270 mm | 450* 300* 270 mm | 450* 300* 520 mm | 450* 300* 520mm | 570* 440* 520 mm | 580* 580* 530 mm | 700* 580* 530 mm |

| Dimension | 850* 1200* 1900 mm | 700* 400* 750 mm | 700* 550* 750 mm | 800* 550* 750 mm | 800* 550* 750 mm | 800* 720* 750 mm | 900* 720* 750 mm | 970* 840* 850 mm | 1040* 840* 850 mm |

Features of Burner Wax Burnout Oven

1. SPB- HTF is special design for two-time burning; it will re-collect those not fully burnt during dewaxing process and let them to be burnt again for full combustion, and reducing the wax flavor in the environment as much as possible.

2. Fully automatically controlled temperature, with Over-temperature protection and Break-even protection functions, to prevent furnace from losing control and getting burnt, causing fire risk.

3. Proven Intermittent power outage function, which controls the heating speed, ensures the sintering quality of gypsum mold, and improves the yield rate of castings.

4. Heating Element design layout is reasonable, temperature in furnace is uniform and air convection is good-good for the water evaporation and discharge after heating the wet work-pieces, therefore improving the lifetime of heating elements.

5. The furnace door is equipped with safety device; when the doors open, furnace will shut down automatically to ensure the safety of the operators.

6. Adopting the new high temperature resistance, lightweight materials, having good characteristics of high efficiency, energy saving, and environmentally friendly.

7. Furnace is small but the inner dimension is big and durable, easy to repair; and when replacing heating wire, there is no need to disassemble the furnace body and refractory plate.

Jewelry Wax Model Melting Furnace

A specialized piece of machinery known as a jewelry wax model melting furnace is used in the jewelry business to melt wax models that have been made in order to produce metal castings.

To form a mold that will later be filled with metal to produce the finished jewelry piece, the wax models are melted inside a furnace.The furnace is usually constructed of a heat-resistant substance, such steel or ceramic, and is intended to sustain high temperatures.

The wax is heated to the required melting temperature, which is normally between 140-170°F (60-77°C), using electric heating sources.

The furnace also contains temperature controls to guarantee that the wax melts precisely and consistently, and that it does so at the proper temperature.Wax can be poured into a mold after it has melted to produce a negative space for the metal casting.

The mold chamber is then free of the wax model and prepared for the addition of molten metal. The method of metal casting is then used to manufacture the finished jewelry item.Overall, the Jewelry Wax Model Melting Furnace is essential to the jewelry-making process because it makes it possible to melt wax models precisely and consistently to produce molds for metal casting.

Why SuperbMelt Wax Burnout Furnace

Any Question About SuperbMelt Wax Burnout Furnace

Helpful Resource For Your Reference (SuperbMelt Burnout oven expert)

More Precious Metal Processing Equipment For Your Choice

Any questions about SuperbMelt Burnout oven

About Burnout Oven FAQ

Depending on the kind of wax, different waxes have different melting points. Beeswax has a melting point of around 144-147°F (62-64°C), whereas paraffin wax has a melting point of roughly 120-160°F (49-71°C). The melting point of soy wax is around 120–125°F (49–52°C). It’s vital to remember that the wax’s melting point can also be influenced by the various chemicals and perfumes put to it.

Yes, you can melt it with microwave wax. To prevent the wax from overheating and potentially igniting a fire, it is critical to use a microwave-safe container and to melt quickly while stirring. It is also recommended to use a thermometer to keep track of the temperature of the wax and make sure it does not exceed its melting point. However, melting wax in a microwave oven is a very unsafe operation, and it is generally not recommended to use a microwave oven to melt wax.

Maintaining the caliber of your wax melts begins with cleaning the wax melting kettle. To clean a wax melting pot, follow these instructions:

Switch off the wax melting pot and let it to finish cooling. By doing this, the wax will solidify and become simpler to remove.

As much of the solidified wax as you can should be removed with a paper towel. Make care to properly dispose of the wax.

Hot water should be added to the melting pot, and it should soak for 10 to 15 minutes. This will aid in removing any leftover wax.

Scrub the pot with a non-abrasive sponge or towel. Be gentle to prevent scratching the pot’s surface.

To get rid of any soap residue, give the pot a thorough hot water rinse.

Before using the pot once more, thoroughly dry it.

To avoid a buildup of wax and other debris that might compromise the quality of your wax melts, it is crucial to clean the wax melting pot after each usage.

Wax is melted in a wax melting pot for use in manufacturing candles, soap, and wax melts, among other things. The pot normally comprises of an inner container that houses the wax and is heated by an under-the-container heating source.

The user fills the pot with the required amount of wax and adjusts the temperature before using the wax melting pot. The wax is then heated by the heating element, melting and becoming liquid. The user may pour the melted wax into molds or utilize it as they choose after it has melted.

A thermostat to maintain a steady temperature and a pouring funnel to make it simpler to pour the melted wax are additional characteristics that some wax melting pots include. Depending on the model, they may be powered by propane gas or electricity.

A machine made for melting wax models used in jewelry creation is referred to as a wax model melting pot or wax melting furnace. Wax is injected into a mold to generate the wax models, which are then used to create a mold for the finished item of jewelry. The wax model must be melted down after it has fulfilled its function in order to reuse the mold for the subsequent batch of wax models.

The wax model melting pot can melt wax rapidly and effectively since it functions essentially as a miniature furnace. Usually, it comprises of a metal pot or crucible that is heated by a gas burner or electric coil. When the wax models are put in the pot, the wax is heated until it melts and becomes liquid, allowing it to be drained out of the pot.

In order to prevent overheating, which might cause the wax to burn or degrade, the wax melting pot’s temperature must be precisely controlled. Modern wax melting pots have temperature control systems integrated into them that allow for exact temperature control, making it simple to melt the wax to the right consistency.

In conclusion, a wax model melting pot is a crucial piece of equipment for jewelry designers that employ wax models in their manufacturing process. It makes it possible for the wax to melt quickly, saving time and ensuring reliable outcomes.

When creating jewelry, a burnout furnace is used to burn out wax or other materials from a mold before casting. Any leftover wax or other materials from the mold are destroyed by the high temperatures in the burnout oven, leaving a clear space for the metal to be poured into. This procedure is crucial for ensuring that the jewelry piece’s final proportions and features are precise. In the lost-wax casting procedure, burnout ovens are frequently used in conjunction with wax model melting pots and other tools.

In particular in lost-wax casting, the burnout procedure is a vital phase. The wax model is heated to a high temperature in a burnout oven during this procedure, causing the wax to melt and evaporate and leaving behind a hollow in the sculpture’s design. The original wax model will then be recreated by pouring molten metal into this hollow. Burnout is crucial because it guarantees that there are no contaminants or moisture in the mold that might degrade the final casting’s quality. Additionally, it aids in lowering the possibility of the mold bursting or shattering during the casting process as a result of any trapped moisture or air expanding quickly.

Guide: From the user's perspective

Jewelry Manufacturers

1. From the User Perspective — Addressing the Practical Needs of Jewelry Manufacturers

1.1 Daily Precision Casting of Gold, Silver, and Copper Jewelry

Context: Jewelry manufacturers work daily with a variety of precious metals such as gold, silver, and copper, crafting intricate and delicate designs that require precision.

Role of the Wax Burnout Oven:

Ensures efficient and uniform wax elimination;

Prevents wax residue from remaining in the mold;

Reduces casting defects such as porosity and inclusions.

1.2 High Demand for Casting Accuracy and Surface Quality

Context: The jewelry industry requires extremely high standards for surface smoothness and dimensional fidelity of final products.

Value of the Wax Burnout Oven:

Equipped with precision temperature control systems and multi-stage heating programs for accurate heat ramping;

Prevents cracking or expansion during the burnout process, preserving mold integrity;

Guarantees flawless surface finish and exceptional casting precision.

1.3 A Critical Step in the Lost Wax Casting Process

Context: Wax burnout is the first and most crucial step in determining the final quality of the cast.

Key Role:

Serves as the bridge between design and casting;

Combines accurate temperature curves with low-emission design to support eco-friendly production;

An indispensable core equipment in the precision casting workflow.

2. From an Industry Application Perspective — Why the Jewelry Industry Relies on Wax Burnout Ovens

Industry Trends & Demand for High-End Customization

With more brands entering the high-end bespoke jewelry space, there is a rising need for precision in the microstructure of cast pieces.

Wax Burnout Oven Advantage:

Provides a stable and reliable burnout environment to meet increasing industry technical standards.

Efficiency and Batch Consistency

When burning out multi-cavity plaster molds in large batches, uniform furnace temperature is critical.

Wax Burnout Oven Capability:

Designed with high-capacity chambers and intelligent thermal control systems to support continuous factory-level production.

3. From a Technical Feature Standpoint — Highlighting the Value of the Equipment

Intelligent Temperature Control System:

Multi-stage programmable temperature settings;

Adjustable heating-holding-cooling cycles to suit different investment materials and wax types.

High Temperature Performance & Energy Efficiency:

Rapid heat-up to over 850°C;

Superior insulation and low energy consumption.

Safe and Eco-Friendly Design:

Equipped with high-temperature exhaust treatment systems;

Optimized internal venting reduces harmful gas emissions effectively.

Small workshop / DIY metal worker

Analysis Based on User Scenarios

1. Target Users:

Individual jewelers

Independent artists

Small jewelry studios

DIY metalworkers and craft enthusiasts

These users often work on a small scale but require high precision and professional-quality results. They typically have limited workspace and modest production volumes, so equipment must be compact and easy to operate.

2. Application Needs:

Small-batch production of precision metal pieces (gold, silver, copper, etc.)

Lost wax casting processes, often used in fine jewelry and detailed artwork

Wax burnout is a critical step in achieving clean, high-quality castings

3. Equipment Requirements:

Compact design to fit into limited studio or home workshop space

Intuitive interface for quick learning and reliable operation

Consistent and precise temperature control to ensure clean burnout

Durable build for long-term use with metals like gold, silver, and copper

Educational and research institutions

Educational and research institutions—such as art academies, metalworking departments, and industrial design labs—frequently integrate lost-wax casting processes into their curriculum and experimental research.

These institutions require a reliable Wax Burnout Oven to demonstrate the complete burnout and casting process with precision and safety. Whether for teaching metal crafts in fine arts courses or conducting mold development studies in design labs, the oven serves as an essential piece of equipment.

With programmable temperature control, clean burnout performance, and user-friendly interface, the Wax Burnout Oven allows students and researchers to gain hands-on experience in professional-grade casting techniques within a classroom or lab environment.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited