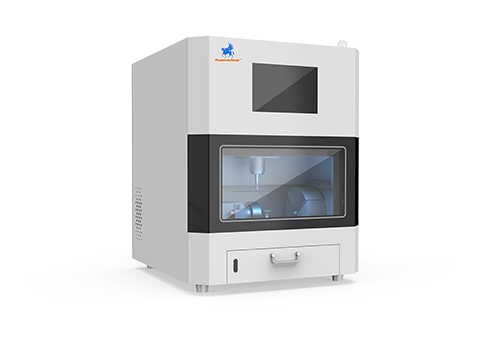

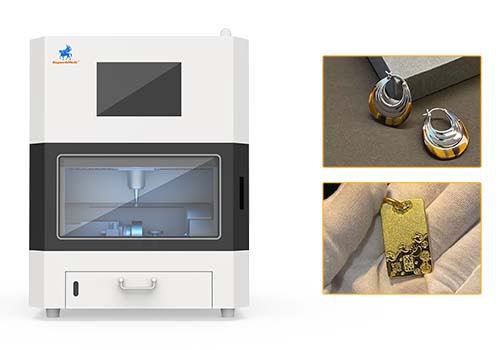

Silver CNC Machine

SuperbMelt is a leading CNC machine manufacturer in China, specializing in silver jewelry processing. We help jewelers complete precise CNC machining for rings, pendants, bracelets, and other types of jewelry.

SuperbMelt Silver CNC Machine is a precision-engineered system developed exclusively for crafting fine silver jewelry and silverware. Designed to handle the unique softness and ductility of silver, this machine ensures clean, smooth cuts and flawless engravings without damaging delicate surfaces.

Its 4-axis intelligent control system allows for both flat and 3D engraving, enabling jewelers to produce detailed textures, artistic reliefs, high-gloss finishes, and intricate filigree designs commonly found in premium silver jewelry.

Unlike traditional machines, the SuperbMelt Silver CNC Machine features a closed-loop metal recovery system that captures up to 99.9% of silver dust and shavings, reducing material loss and maximizing profit. The built-in oil and water spray nozzles help collect every particle of silver efficiently during processing.

Compact yet powerful, this machine is ideal for silver ring, pendant, bracelet, and custom silverware production, offering unmatched precision, low maintenance, and superior recovery — a must-have for modern silver jewelry workshops and studios.

| Model | SPB-CNF418 |

| X/Y/Z Travel | 147 / 118 / 85 mm |

| X/Y/Z Positioning Accuracy | 0.01 / 0.01 / 0.01 mm |

| A-axis Positioning Accuracy | 0.01° |

| X/Y/Z Repeatability | 0.01 / 0.01 / 0.01 mm |

| A-axis Repeatability | 0.01° |

| A-axis Rotation Angle | 360° |

| Spindle Power | 2.4 kW |

| Spindle Type | Tool-changing Electric Spindle |

| Max Spindle Speed | 0–60000 rpm/min |

| Spindle Cooling Method | Professional Coolant |

| Engraving Tool Holder | Quick-change Fixture |

| Transmission / Linear Guide | Grinding Ball Screw / Taiwan Original Silver Guide Rail |

| Drive System | Closed-loop Servo |

| Working Voltage | 220V / 50Hz |

| Machine Enclosure Type | Fully Enclosed, Waterproof & Dustproof |

| Air Source Pressure | 0.55 MPa |

| Overall Dimensions | 630 × 590 × 760 mm |

| Weight | ≈130 kg |

| Material | Aerospace Aluminum + Sheet Metal |

| Total Machine Power | 4 kW |

| Software | SuperbMelt Jingdiao 9.6 |

Optimized for Soft Metals

Specifically calibrated spindle speed and cutting pressure ensure smooth engraving and shaping of soft silver materials without deformation or tool marks.Ultra-Fine Surface Finishing

Delivers mirror-polished results on silver jewelry—perfect for producing high-end rings, pendants, and bracelets with bright, reflective surfaces.Anti-Oxidation System

Built-in mist cooling and lubrication reduce heat generation, preventing silver from discoloration or oxidation during engraving and cutting.High-Precision 4-Axis Control

Supports both flat and 3D silver jewelry designs, allowing for intricate engraving, texture creation, filigree patterns, and deep relief sculpting.99.9% Silver Recovery Rate

Equipped with a closed-loop silver dust recovery system and oil/water spray gun to collect fine silver particles—minimizing material loss and maximizing profit.Compact Desktop Design

Mini-sized body fits perfectly in jewelry studios or silver workshops, offering industrial-grade performance with minimal space requirements.Automatic Tool Change System

No manual adjustments needed—switches tools automatically to handle different silverworking processes efficiently and precisely.Built-in Jewelry Design Library

Preloaded with silver jewelry templates (rings, pendants, bangles) to simplify production and speed up design-to-output workflow.

Why SuperbMelt Silver CNC Machine

Any Question About SuperbMelt Silver CNC Machine

SuperbMelt Silver CNC Machine: Practical Guide for Silver Processing

Silver Material Characteristics and Technical Adaptation of Silver CNC Machines

1.1, Core Processing Characteristics of Silver (Compared to Gold and Platinum)

Silver, as a commonly used precious metal, has processing characteristics that differ significantly from gold and platinum, which directly determines the technical selection of a Silver CNC Machine:

Hardness and ductility: Pure silver (999 silver) has a hardness of about 2.5 HV, is extremely ductile, but prone to deformation. Sterling silver (925 silver) contains 7.5% copper, increasing hardness to 3.5–4 HV, still lower than gold (2.5–3 HV) and platinum (4–4.5 HV). During machining, the spindle speed must be controlled to avoid material “stretch deformation,” usually keeping it between 8,000–12,000 rpm (gold/platinum can go up to 15,000 rpm).

Thermal conductivity and melting point: Silver’s thermal conductivity (429 W/(m·K)) is much higher than gold (317 W/(m·K)) and platinum (71.6 W/(m·K)), making it prone to local heat buildup during processing, which can cause surface oxidation (forming black Ag₂O) or precision deviations. A specialized cooling system is required (e.g., oil mist cooling; avoid water cooling, which accelerates silver oxidation).

Surface finish requirements: Silver products often demand higher “mirror effect” and scratch-free surfaces (e.g., silver tableware, pendant jewelry). CNC tools must use high-hardness tungsten carbide cutters (HRC ≥ 65) or diamond-coated tools to avoid burrs from tool wear.

1.2, Core Technical Adaptation Points for Silver CNC Machines

To match silver’s characteristics, Silver CNC Machines should have these dedicated configurations:

Adjustable spindle system: Supports 5,000–15,000 rpm stepless adjustment. For pure silver: 8,000–10,000 rpm; for 925 silver: 10,000–12,000 rpm, balancing processing efficiency and material stability.

Low-friction fixtures: Use soft alloys (e.g., brass coating) or silicone non-slip clamps to prevent deformation, especially for thin silver sheets (e.g., bookmarks, thin jewelry).

Oxidation-protected machining chamber: Some high-end models have inert gas (argon) filled chambers, isolating air during processing to reduce surface oxidation and minimize post-polishing workload (traditional processing may cause 1–2% additional material loss).

Dedicated silver scrap recovery system: Silver’s density (10.5 g/cm³) is lower than gold (19.3 g/cm³), making silver filings prone to floating. Upgrade the recovery funnel’s vacuum suction (≥-0.08 MPa) with fine mesh (≤0.1 mm) to prevent loss and ensure ≥99.5% recovery.

CNC Machining Solutions for Different Silver Products

2.1 Silver Jewelry (Rings, Necklaces, Earrings)

Silver jewelry is the core application of Silver CNC Machines, requiring solutions for fine patterns and lightweight structures:

Common processes and parameters:

3D silver rings: Use a 4-axis CNC with A-axis rotation 0–360°. Use φ1–2 mm ball-end mills at 50–80 mm/min to ensure smooth inner ring curvature (tolerance ≤0.02 mm).

Hollow silver pendants: For 925 silver thin sheets (0.8–1.2 mm), use φ0.5 mm end mills with “layered cutting” (0.2 mm per layer) to prevent deformation.

Special functions: Support “small pattern repair” mode, compensating tool wear (0.005 mm per 5 pieces) to ensure consistent patterning, e.g., brushed textures or dot patterns.

2.2 Silver Tableware and Utensils (Bowls, Teacups, Goblets)

Silver tableware often involves large dimensions + curved surfaces, challenging overall precision and scratch-free surfaces:

Technical adaptation: Use CNC with ≥300×200×150 mm travel and extended spindle (≥100 mm) for inner walls. Employ spiral toolpaths to reduce tool direction changes and minimize surface marks.

Cooling and cleaning: For large surfaces, upgrade to ring-shaped oil mist cooling and high-pressure air gun (0.6 MPa) to blow away filings and prevent scratches.

2.3 Silver Decorative Items and Cultural Products (Commemorative Coins, Relief Figurines)

Silver decorative items often include high relief and complex patterns:

Depth processing optimization: Use “layered milling + depth detection.” Every 0.5 mm depth, CNC automatically checks deviation (≤0.01 mm) to compensate for silver’s elastic deformation.

Pattern fidelity improvement: Built-in “silver pattern compensation algorithm” pre-shrinks designs by 0.1–0.2% to counteract material rebound after machining.

Solutions for Silver CNC Machining Challenges

3.1 Challenge 1: Deformation and Precision Deviation

Symptoms: Thin pure silver may warp (e.g., bookmarks’ edges raise 0.5–1 mm). Sterling silver utensil inner walls may exceed 0.03 mm deviation.

Solutions:

Optimized fixtures: Multi-point clamping (e.g., 6-point silicone press feet, adjustable pressure 0.1–0.3 MPa).

Processing order adjustment: First process non-load-bearing areas (edges), then core structures (bottom) to reduce stress concentration.

3.2 Challenge 2: Oxidation and Surface Finish

Symptoms: Black oxide layer forms during machining; roughness Ra >0.8 μm.

Solutions:

Oxidation protection: Fill machining chamber with argon (5–10 L/min) or add silver anti-oxidant (e.g., 0.5% benzotriazole) to coolant.

Tool and parameter matching: For mirror finish, use φ3–5 mm diamond-coated tools, spindle 12,000 rpm, feed 30–50 mm/min. Achieves Ra ≤0.2 μm without secondary polishing.

3.3 Challenge 3: Low Silver Scrap Recovery

Symptoms: Fine silver filings float, recovery only 98–99%, leading to 100–200 g loss per 10 kg silver processed (~$70–140).

Solutions:

Dedicated recovery device: Triple filtration system — vacuum suction (-0.09 MPa), fine mesh (0.05 mm), electrostatic adsorption (5,000 V), achieving >99.7% recovery.

Filings classification: Different channels for different particle sizes to prevent clogging.

Silver CNC Machine Selection Guide for Practitioners

4.1, Small Silver Jewelry Workshops (1–5 kg/month)

- Needs: Low cost, small footprint, easy operation; mainly rings and earrings.

- Recommendation: Desktop 4-axis CNC (travel 200×150×100 mm, footprint ≤0.5 m²).

- Essential features: Non-programming silver design library (≥1,000 templates), auto tool break detection, basic scrap recovery (≥99%).

- Parameters: Spindle 5,000–12,000 rpm, positioning accuracy ±0.01 mm.

4.2, Medium Silver Factories (10–50 kg/month)

- Needs: High-efficiency batch production, multi-product adaptation (jewelry + tableware), high recovery.

- Recommendation: Vertical 4- or 5-axis CNC (travel 300×250×200 mm), dual workstation for alternating machining.

- Essential features: Oxidation-protected chamber, dedicated fixtures for utensils, triple scrap recovery, MES system to track silver loss.

- Parameters: Spindle 8,000–15,000 rpm, repeat positioning ±0.005 mm, ≥500 silver rings/day.

4.3, High-End Custom Silver Studios

- Needs: High precision, personalized design, smooth hand-finishing integration.

- Recommendation: High-precision 4-axis CNC with manual micro-adjustment; supports importing hand-drawn designs (CAD/AI).

- Essential features: Depth compensation for subsequent hand-finishing, adjustable surface finish mode (e.g., leave 0.1 mm for polishing), fast small-batch changeover (≤10 min).

FAQ Guide of Silver CNC Machine

- 1. How is metal loss minimized during processing?

- 2. What types of finishing can the CNC machine perform?

- 3. What is the difference between 3-axis and 4-axis CNC machines?

- 4. What jewelry pieces can be made using the Silver CNC Machine?

- 5. How accurate is the SuperbMelt CNC Machine for jewelry?

- 6. Can I produce 3D relief or texture patterns on silver surfaces?

- 7. What tools or cutters are used for silver engraving?

- 8. Does the machine support multiple jewelry materials besides silver?

- 9. What design files can the machine read?

- 10. Does the machine support engraving text, logos, or serial numbers on silver pieces?

1. How is metal loss minimized during processing?

SuperbMelt machines feature an integrated metal recovery system, collecting fine metal dust and chips with a recovery rate of up to 99.7–99.9%, greatly reducing material loss.

2. What types of finishing can the CNC machine perform?

It can complete engraving, texturing, polishing, drilling, bright cutting, and 3D relief carving, as well as special finishes like matte brushing and glitter effects.

3. What is the difference between 3-axis and 4-axis CNC machines?

A 3-axis CNC machine can move the tool along X, Y, and Z axes — ideal for flat or simple designs.

A 4-axis CNC machine, like SuperbMelt’s model, adds rotation, enabling 3D engraving, stone seat carving, side cutting, and more complex jewelry designs.

4. What jewelry pieces can be made using the Silver CNC Machine?

The 4-axis CNC allows simultaneous movement in X, Y, Z, and rotation axes. This enables complex carving — such as curved surfaces, deep engravings, or stone seat settings — which are difficult for traditional 3-axis systems. It’s perfect for advanced silver jewelry designs.

5. How accurate is the SuperbMelt CNC Machine for jewelry?

It offers micron-level precision, ensuring that even delicate silver filigree, engraving lines, and micro-textures are reproduced flawlessly.

6. Can I produce 3D relief or texture patterns on silver surfaces?

Absolutely. The 4-axis motion allows detailed 3D relief engraving, texture brushing, and artistic carving on silver pendants, cufflinks, and bracelets. It’s ideal for creating custom 5G/3D jewelry finishes

7. What tools or cutters are used for silver engraving?

SuperbMelt machines support diamond tools, carbide cutters, and micro-end mills, which are optimized for silver’s softness. Automatic tool changers select the correct cutter for each stage — rough cutting, fine engraving, or high-gloss polishing.

8. Does the machine support multiple jewelry materials besides silver?

Yes. While it’s optimized for silver, it also works perfectly with gold, platinum, K-gold, copper, and brass. You can adjust feed rates and spindle speeds to match the hardness and ductility of different metals.

9. What design files can the machine read?

It supports standard jewelry file formats such as STL, DXF, OBJ, and NC, compatible with CAD/CAM software like RhinoGold, MatrixGold, and JewelCAD. Users can also directly use SuperbMelt’s built-in library for quick production.

10. Does the machine support engraving text, logos, or serial numbers on silver pieces?

Yes. You can easily engrave custom names, branding marks, or serial codes on jewelry using the built-in vector engraving module — ideal for personalized or limited-edition silver jewelry.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited