Silver Casting Machine

Leading Machinery Manufacturer of Vacuum Gold and Silver Bars Casting Machine (SPB-JD1)

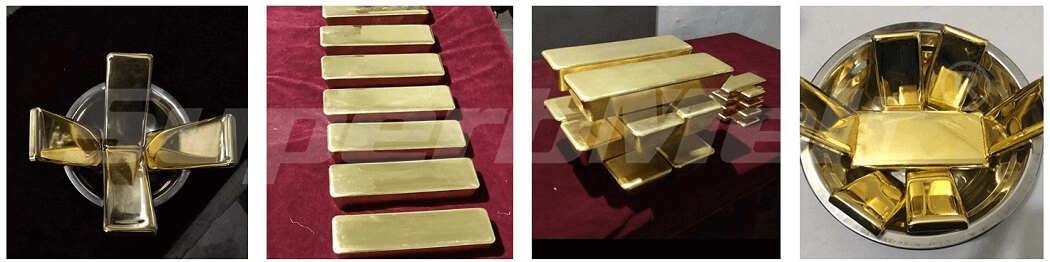

SuperbMelt silver casting machine (SPB-JD1) is designed for casting 1-2kg quality silver and gold bars. This casting machine comes with the flexibility to customize your silver and gold bar, ingot and bullion bars to any of your desired LMBA approved deal specifications.

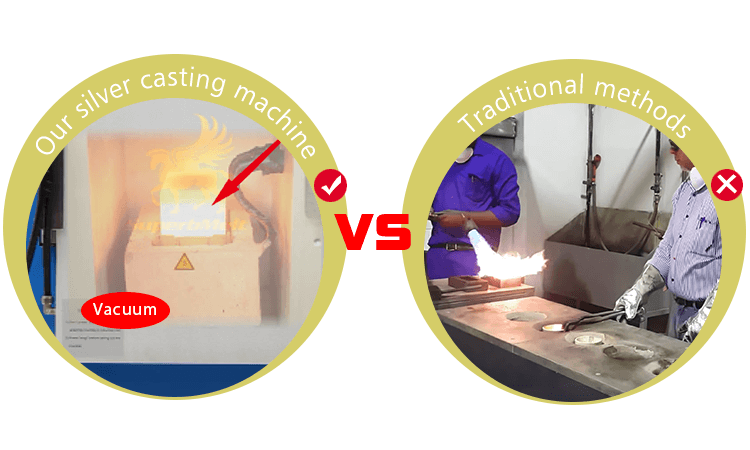

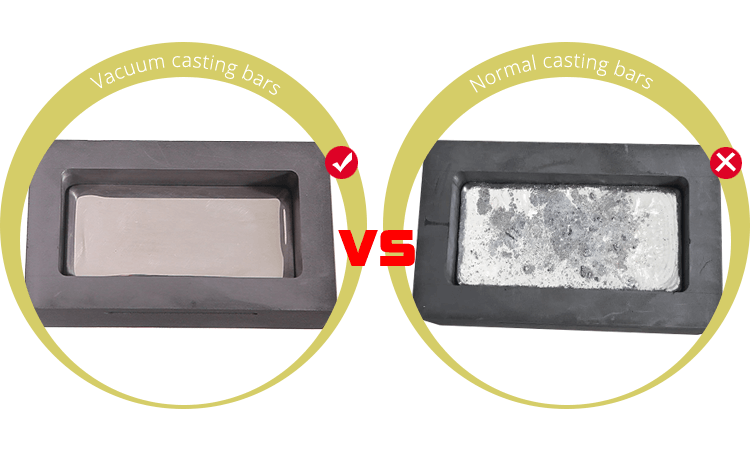

The pressurized inert gas chamber of this silver and gold bar casting machine ensures that you have a final cast with top quality and impeccable appearance by completely eliminating all forms of porosity, water waves or shrinkage in your final piece.

Compared with the traditional method. Your whole casting process will be done under vacuum. This prevents s ripples and further oxidation of your final piece. Thereby giving your product a touch of quality. With the above features the safety of your operators is better guaranteed.

Click here if you need a big capacity gold bar casting machine with higher efficiency

- Not only can you customize to your desired sizes with this SuperbMelt silver casting machine (SPB-JD1). You can also customize your gold and silver bars whose weight of 2kg and 1kg respectively

- Are you on the lookout to cutting down of your production running cost? Then this silver casting equipment is all you need.

- It comes with a very powerful induction generator capable of heating up to any of your desired melting temperature in a matter of seconds.

- With the this machine, no polluting the environment with hazardous gaseous byproduct.

- The machine is equipped with the latest green technology available in the gold industry.

- With the help of industrial chiller, ensure that the machine can be cooled in time without reducing production efficiency.

- Also, the state of the art alarm system incorporated into the design of this casting machine ensures the safety of your workers.

- System abnormalities such as system overheating or any other irregular frequencies can be easily detected.

| Model number | SPB-JD1 | SPB-JD2 | |

| Power source | Three phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz | |

| Power | 15 kw | 25 kw | |

| Applicable metal | Gold and silver | Gold or silver | |

| Max capacity | 2kg gold bar or 1kg silver bar | 2kg gold or silver | |

| Max temperature | – | 1500℃ | |

| Casting time | About 12 mins | 12 mins | |

| Casting mode | Auto and manual mode switch | Auto or manual for option | |

| Application | – | Quality bullion casting | |

| Dimension | 1000*800*1350 mm | 1000×800×1350 cm | |

| Weight | 205 kg | 225 kg | |

| Protective gas | Nitrogen or argon | Argon | |

| Vacuum pump | 63 m³/hour | 63 m³/hour | |

| Heating technology | Induction heating | Induction heating | |

| Customized mold size |

| Meet different bullion production |

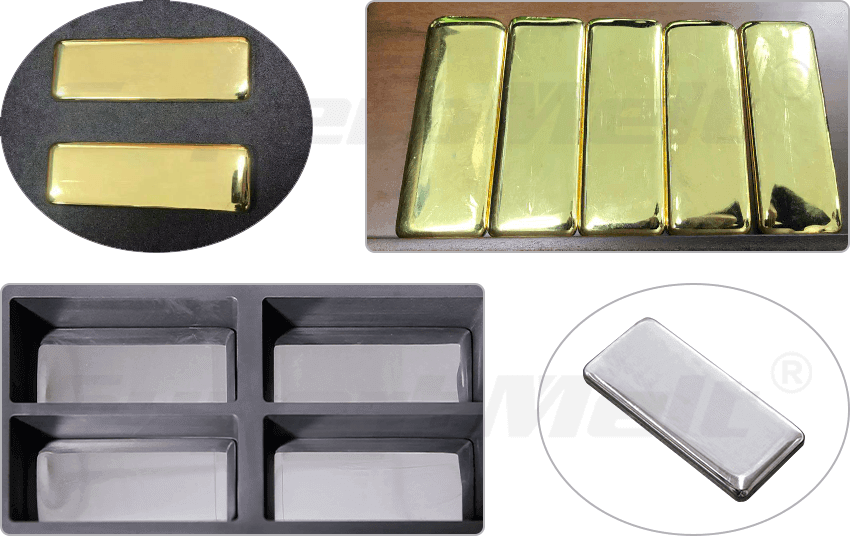

Graphite mold for gold/Silver bar casting machine

Choosing a right casting mold for gold/silver bar casting will improve the efficiency and quality of castings and save the cost of lost parts

Why SuperbMelt Vacuum Gold and Silver Casting Machine

Helpful Resource For Your Reference ( An expert about SuperbMelt vacuum gold and silver casting equipment )

More SuperbMelt Gold and Silver Casting Machines For Your Choice

Any Question About SuperbMelt Silver Casting Equipment

Complete Guide to Silver Ingots: History, Cultural Significance, Collectible Value, and Modern Casting Technology Analysis

The Historical Origins of Silver Ingots

Silver ingots, one of the most influential forms of precious metal currency in human civilization, have origins and development spanning across multiple ancient cultures. They established a foundation for global monetary systems and profoundly shaped ancient international trade and economic structures.

The earliest prototypes of silver ingots can be traced back to around 3000 BCE in Mesopotamia. The Sumerians cut natural silver pieces into fixed-weight “silver cakes,” used for intercity trade, marking the first standardized form of silver currency. This concept spread to ancient Egypt, Greece, and Rome: during Egypt’s New Kingdom (c. 1550–1070 BCE), ring-shaped silver currencies were used for royal taxation and tribute; during the Roman Republic (509–27 BCE), the “silver denarius ingots” became the Mediterranean’s dominant trading medium, recognized for their uniform weight and purity.

In China, the evolution of silver ingots has been continuous and well-documented. During the Han Dynasty (202 BCE–220 CE), round “silver cakes” were used for imperial rewards and high-value transactions. The Tang Dynasty (618–907 CE) saw the emergence of “silver sycees” (Yinding), long bar-shaped ingots weighing about 50 taels, used for taxation and military expenses. The Ming and Qing Dynasties (1368–1912 CE) marked the peak of silver ingot use, with diverse shapes such as boat-shaped, square, and weight-standard types. Each province’s ingots bore inscriptions indicating region, mint, and year, forming a nationwide monetary system that supported the “Maritime Silk Road” and extensive trade with Europe and Southeast Asia.

Following the Age of Exploration in the 16th century, silver ingots reached their global peak. Spain minted plundered American silver into “Pieces of Eight,” which circulated across Europe, Asia, and Africa, becoming the first globally accepted silver currency. In the 18th–19th centuries, the British “Standard Silver Bars” (92.5% purity) and the American “Morgan Ingots” (90% purity) emerged as key payment tools in international trade during the Industrial Revolution, elevating silver’s global monetary role to its highest point.

In ancient economies, silver ingots served dual functions—as a store of value and medium of exchange—solving the challenge of valuing goods in barter trade and facilitating large-scale commerce, taxation, and indemnity payments. The widespread circulation of silver ingots also promoted long-distance trade networks: in China, the Shanxi merchants’ “draft banks” (Piaohao) created a national financial system based on silver ingot reserves, while Europe’s Hanseatic League linked North Sea and Baltic cities through silver-based trade.

1.1, Cultural Significance of Silver Ingots

Silver ingots were not merely economic instruments—they also embodied the aesthetics, craftsmanship, and beliefs of their time, serving as tangible carriers of history and culture.

(1) Artistic Appeal in Design and Craftsmanship

The designs of silver ingots combined practicality and artistry. The iconic Chinese “sycee” from the Ming and Qing dynasties featured curved bottoms and concave tops, allowing easy stacking while symbolizing the traditional philosophy of “heaven round, earth square.” Tang dynasty silver bars were hammer-forged with smooth surfaces and fine edge textures, showcasing advanced metallurgical skills. In contrast, European silver ingots—mostly rectangular or cylindrical—were precision-cast with engraved frames and polished surfaces, blending industrial order with artistic detailing.

Craftsmanship evolved over time. Ming official mints used sand casting, leaving fine granular marks; Qing craftsmen adopted mold casting, achieving clearer inscriptions and sharper edges. European silversmiths employed pressure casting, producing denser, smoother ingots—early signs of pre-industrial technological progress.

(2) Symbolism in Inscriptions and Motifs

Inscriptions and motifs reveal rich historical and cultural information. Chinese ingots typically bore details such as “Location + Mint + Craftsman + Weight,” e.g., “Jiangxi Raozhou Mint, Zhang San, 50 taels, Guangxu Era,” providing both traceability and authenticity. Official ingots were stamped with “Ministry of Revenue” or “Customs” seals, symbolizing state authority, while privately cast ingots often featured auspicious characters like “Fu” (fortune), “Shou” (longevity), or “Ji” (luck).

Motifs carried deep cultural meanings. Chinese designs included clouds, bats, and dragons—where bats (fu) symbolized fortune and dragons represented imperial power. Some regional ingots, like Yunnan’s “Paifang-shaped” types, symbolized honesty and local commerce culture. European designs often reflected religion and monarchy: Spain’s “Pillar Ingots” depicted twin columns (the Pillars of Hercules) under a crown, while British ingots bore royal crests and crosses, embodying the union of faith and sovereignty.

Each silver ingot thus serves as a “living artifact”—a miniature record of politics, economy, craftsmanship, and aesthetics from its era.

The Collectible Value of Silver Ingots

As silver ingots disappeared from circulation, their historical rarity, cultural symbolism, and intrinsic metal value turned them into highly sought-after collectibles, bridging history, art, and investment.

2.1, Market Overview

Silver ingot prices depend on age, condition, rarity, and provenance. Below are typical reference ranges:

Ancient Chinese Ingots:

Ming official ingots (Yongle–Xuande era): $70,000–$140,000

Qing provincial ingots (e.g., Guangdong, Jiangnan Customs): $14,000–$42,000

Rare regions (e.g., Tibet, Xinjiang) or special-purpose ingots (e.g., military fund silver): up to $70,000+

Republic of China bank ingots (e.g., Bank of China, Central Bank): $2,800–$7,000

Western Ingots:

Spanish “Pillar Dollar” ingots (16th–18th century): $7,000–$21,000; rare years (e.g., 1588 Armada period): $28,000–$70,000

British standard bars (19th century): $4,200–$11,000

American Morgan ingots: $5,600–$14,000

Condition is key: pristine pieces with clear marks and minimal oxidation are worth 30–50% more than corroded ones.

2.2, Key Value Factors

Rarity: Limited survival and unique shapes (e.g., “boat-shaped” Ming ingots) or historic events (“Boxer Indemnity Ingots”) raise value sharply.

Provenance: Ingots with clear inscriptions (mint, date, craftsman) fetch 20–30% premiums over unmarked ones.

Condition: Authentic natural patina enhances value; chemically aged or restored items are discounted.

Purity and Weight: Higher purity (≥999.9‰) and heavier ingots command higher prices.

2.3, Collecting Tips and Risks

Authenticity Check:

Patina: natural silver shows smooth, warm grey tones without chemical odor.

Inscriptions: authentic fonts are neat and era-accurate; fakes show sloppy or incorrect characters.

Density Test: pure silver ≈10.5 g/cm³; deviations >0.5 g/cm³ suggest adulteration.

Craft Clues: real ancient ingots show natural casting textures; fakes often over-polished or too uniform.

Preservation:

Store in dry, cool (15–25 °C), low-humidity (<60%) conditions.

Use gloves to handle; avoid abrasive cleaning or acid solutions.

Light oxidation can be cleaned with ethanol by professionals—heavy restoration is discouraged.

Risks:

Market volatility due to silver price and collector trends.

Abundant high-quality forgeries—buy only from reputable auctions or certified dealers.

Legal risks: unearthed artifacts may be protected under heritage laws.

Modern Relevance

Silver ingots still offer valuable lessons:

Historical Insight: they document economic and trade systems, e.g., Qing customs ingots for port trade or European colonial ingots for imperial commerce.

Cultural Inheritance: their craftsmanship and motifs inspire modern jewelry and cultural products.

Financial Lessons: their stability and standardization model inform today’s bullion and investment-grade silver markets.

How Silver Ingots Are Made

Modern silver ingot casting has evolved from manual methods into automated precision manufacturing. The silver casting machine and crucible molds are central to this process—ensuring high efficiency, precision, and quality.

3.1, Crucible Molds — The Heart of Silver Casting

Crucible molds serve as the core vessels shaping molten silver. Their material and structure directly determine the ingot’s density, surface quality, and production efficiency.

| Mold Type | Material | Structure | Advantages | Applications |

|---|---|---|---|---|

| Graphite Crucible | High-purity graphite | Open/closed, polished inner wall | High heat resistance (≤1200°C), uniform heat transfer, non-reactive | Fine silver bars, small-batch casting |

| Ceramic Crucible | Alumina ceramic | Closed with injection port | High thermal stability (≤1500°C), chemical inertness | Silver alloys, high-purity bars |

| Metal Crucible | Heat-resistant steel (e.g., H13) | Detachable, coated interior | Long lifespan (≥5000 cycles), continuous casting capable | Industrial silver anodes, large-scale production |

3.2, Silver Ingot Casting Process

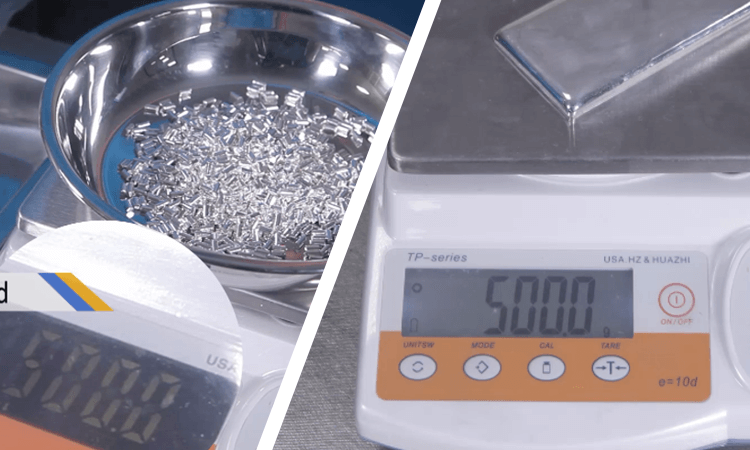

Step 1 – Preparation

Raw Materials: ≥99.9% purity silver granules or recycled silver. Impurities checked via spectrometry (Pb, Cu, Fe ≤100 ppm).

Mold Prep:

Clean with compressed air; apply 0.1 mm graphite release coating (metal molds).

Preheat molds to 200–300°C to prevent cracking and ensure uniform solidification.

Step 2 – Melting

Silver casting machines use induction heating: high-frequency electromagnetic fields generate eddy currents within the silver, heating it evenly and contact-free.

Melting range: 961.78°C (melting point) → 980–1050°C (superheat).

Electromagnetic stirring (30–60 s) removes air bubbles and ensures homogeneity.

Argon atmosphere is used for high-purity silver to prevent oxidation.

Step 3 – Pouring

Three primary methods:

Gravity Casting: cost-effective, ideal for small batches (flow rate 5–10 L/min).

Pressure Casting: hydraulic-assisted filling (0.5–2 MPa), ensuring ≥99.5% density.

Vacuum Casting: eliminates oxidation, used for LBMA-grade ingots (≥999‰ purity).

Optimized mold design prevents turbulence and air entrapment; pouring temperature kept between 980–1020°C depending on mold type.

Step 4 – Cooling and Demolding

Natural Cooling: for ≤5 kg ingots, 20–30 min.

Forced Cooling: for ≥10 kg ingots, water or air cooling (10–20 min).

Molds must cool below 100°C before demolding to prevent deformation or oxidation.

Step 5 – Post-Treatment & Inspection

Polishing: mechanical/electrolytic finishing for mirror surfaces.

Measurement: digital scales (0.001 g accuracy), dimension tolerance ±0.05%.

Purity Testing: XRF or ICP-OES analysis; only ≥999‰ can be stamped “Fine Silver.”

Stamping: engraved with serial number, purity, manufacturer (e.g., SuperbMelt), weight, and date for traceability.

Step 6 – Packaging & Storage

Finished ingots are anti-oxidized, sealed in moisture-proof films, and placed in impact-resistant boxes. High-grade products include certificates and QR-trace systems. All batches are cataloged by furnace lot number for full traceability.

FAQ Guide of Silver Ingot Casting Machine

- What purity of silver can this machine process?

- Can the machine cast other precious metals besides silver?

- What’s the typical production capacity of a silver ingot casting machine?

- Can I adjust the ingot size or shape?

- How to craft silver ingots?

- What post-processing is needed after casting?

- What type of crucible is recommended for silver melting?

- What causes air bubbles or porosity in silver ingots?

What purity of silver can this machine process?

SuperbMelt’s casting machines can refine and cast silver up to 99.99% purity, meeting investment-grade bullion standards.

Can the machine cast other precious metals besides silver?

Yes. The same system can be used for gold, copper, platinum, and palladium by changing the crucible and adjusting parameters.

What’s the typical production capacity of a silver ingot casting machine?

Depending on the model, the output ranges from 1 kg to 30 kg per batch, suitable for both small jewelry workshops and large-scale bullion manufacturers.

Can I adjust the ingot size or shape?

Yes. By changing molds, the machine can produce different ingot weights, shapes, and logos to meet custom minting needs.

How to craft silver ingots?

Crafting silver ingots involves several precise metallurgical steps to ensure purity, uniformity, and surface quality:

Material Preparation

Start with refined silver granules or scrap silver. Ensure purity above 99.9% before melting.Melting

Place the silver into a graphite or ceramic crucible and melt it using an induction melting furnace at approximately 1,000–1,100°C. Induction heating ensures fast, uniform melting without contamination.Refining (Optional)

Add fluxes such as borax to remove impurities. For investment-grade ingots, silver may be refined electrolytically before casting.Pouring into Molds

Pour the molten silver into preheated molds (graphite or steel) to avoid cracks caused by sudden cooling. Automatic casting machines ensure consistent pouring speed and weight control.Cooling & Demolding

Allow the ingot to cool gradually. Controlled cooling prevents warping and surface oxidation. Once solidified, remove the ingot from the mold carefully.Surface Treatment

Polish or buff the surface to remove oxidation and achieve a bright finish. Some ingots undergo laser engraving to add purity marks, logos, or serial numbers.Quality Inspection

Test the ingot’s weight, dimensions, and purity (using XRF or ICP analysis) to confirm it meets 999 or 999.9 standards before packaging.

What post-processing is needed after casting?

polishing, stamping, and laser engraving are done to mark purity, weight, and manufacturer identification (e.g., SuperbMelt).

What type of crucible is recommended for silver melting?

High-purity graphite crucibles are preferred for silver because they resist chemical reactions and heat stress, extending operational life.

What causes air bubbles or porosity in silver ingots?

What causes air bubbles or porosity in silver ingots?

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited