Sheet Rolling Machine Manufacturer

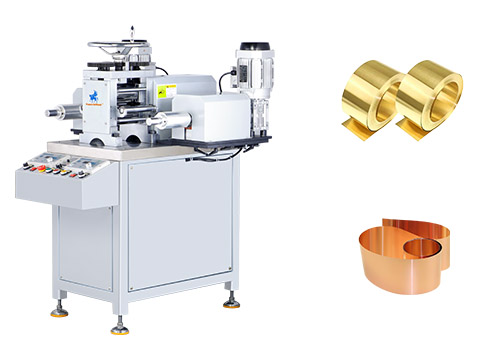

SuperbMelt Rolling Mill Manufacturer: One-Stop Solution for Metal Processing Issues

SuperbMelt Sheet Rolling Machine Manufacturer help clients customize rolling mills with special requirements such as online thickness measurement, coiling, and correction functions. These features enable clients to meet complex metal processing needs.

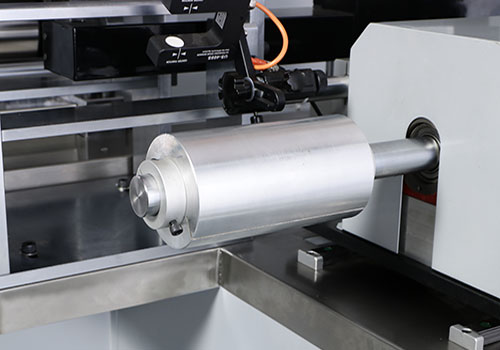

- Coiling: Provides tension during the rolling process, ensuring that the material is rolled more uniformly, and the resulting material is coiled neatly rather than scattered, saving collection time.

- Correction: Prevents material misalignment, which can cause issues with coiling and layer displacement.

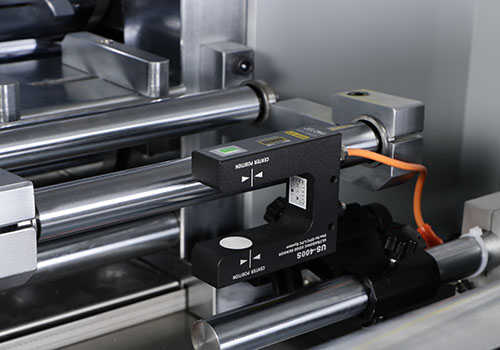

- Thickness Measurement: Thickness is measured during the rolling process, reducing the need for manual measurements.

- Jewelry Manufacturing: This sector of the economy benefits immensely from accurate rolling mills, which enable it to create exquisite jewelry in metals such as gold, silver, and platinum with superior finishes and uniform thickness.

- Electronic & Electrical Components: Rolling mills are used to make metal sheets and strips with exact measurements for electronic components, such as terminals and connections.

- Automotive Industry: Applied to the production of precise-sized metal parts such as brackets, shims, and ornamental trimmings.

- The aerospace industry uses precision rolling mills to fabricate parts for airplanes and spacecraft that need materials with precise mechanical qualities and tolerances.

- Coinage: High accuracy in metal thickness is required because rolling mills are used to create metal sheets from which coins are stamped.

- Medical Devices: Required for the manufacturing of surgical tools and biomedical implants, where surface quality and material consistency are critical.

- Use in construction and architecture: Metal sheets and strips that are made for ornamental elements, structural components that need to be highly resistant to rust, and building materials.

- Crafts & Metal Art: Rolling mills are used by artists and artisans to create distinctive textures and patterns on metal for both artwork and practical goods.

| Model number | SPB-YP-12PZQ | SPB- | SPB- |

| Power supply | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 9 kw | 11 kw | 22 kw |

| Applicable Products | Platinum, gold, silver, copper, K gold and their alloys | Platinum, gold, silver, copper, K gold and their alloys | Platinum, gold, silver, copper, K gold and their alloys |

| Rolled size | 60mm | Within 150mm | Within 300mm |

| Sheet thickness | 25mm- 0.5mm | 1-0.03mm | 30-0.3mm |

| Roller diameter | 150*210mm | Large shaft 180*250/small shaft 60*250 | 220*400mm |

| Dimension | 1130*775*1400mm | 1830*2100*1700mm | 2030*2800*2200mm |

| Weight | 980KG | 1800KG | 2400KG |

- Straightening Capability: This function prevents material misalignment during coiling, avoiding the overlapping and misplacement of layers. It ensures that the material feeds through the mill in a precise alignment, significantly reducing waste and improving product consistency.

- Automatic Cleaning: Equipped with a roller wiping system, the machine automatically cleans the rolling mill rollers, maintaining a flawless surface on the rollers to prevent any damage to the finished product. This helps in achieving a high-quality finish on the metal sheets without defects.

- High Precision: The mill produces extremely flat and uniform thickness products with a tight tolerance of ±0.005 mm. This precision is crucial for applications requiring exact dimensions and contributes significantly to reducing material waste.

- High Hardness Rollers: The rollers are made of materials reaching a hardness level of HRC60-62. This high hardness extends the lifespan of the rollers, reduces maintenance needs, and supports the processing of tougher metals without deforming the rollers.

- Dual-Side Coiling: By allowing coiling on both sides, the machine greatly enhances production efficiency, and the accuracy and straightness of the finished products. This feature is especially beneficial in high-volume production settings, ensuring faster processing times and consistent product quality.

- Real-Time Thickness Display: The mill provides real-time display of the rolling thickness, which offers a reference for the rolling process and reduces the need for frequent manual measurements. This feature helps in maintaining consistent product quality and reduces production errors.

- Adjustable Tension Control: The use of a highly sensitive adjustable magnetic powder clutch to control the tension prevents the material from breaking due to excessive pulling forces. This adjustability is crucial for handling different types of materials and thicknesses, ensuring smooth and continuous production without interruptions.

Equipped with a rewinding function, ensuring product straightness and dimensional stability

Alignment device to prevent sheet displacement causing uneven pressing thickness

PLC Thickness Gauge: The online thickness measurement function allows for real-time monitoring of sheet thickness

Why SuperbMelt Sheet Rolling Machine Manufacturer

Any Question About SuperbMelt Sheet Rolling Machine Manufacturer

About SuperbMelt Sheet Rolling Machine Manufacturer Guide

What is the function of the sheet collecting function of the sheet rolling machine?

Enhanced Production Efficiency:

By eliminating the need for manual intervention and enabling continuous operation, automatic take-up increases efficiency.

Quality Control:

By minimizing possible damage or contamination that may happen during manual handling, automatic recoiling helps preserve the final product’s flatness and cleanliness.

Space Saving:

Compared to manual operations, automatic recoiling systems often take up less room, freeing up important workspace space.

Enhanced Safety:

It lowers the likelihood of workplace injuries by reducing the frequency of direct worker-machine interaction.

Stable and Repeatable Product Dimensions:

Automatic recoilers can preserve consistent roll-up according to predetermined settings, guaranteeing stability and repeatability in product dimensions.

What is the function of the deflection correction function of the rolling mill?

Prevents Material Shift: Throughout the rolling process, the material is kept correctly aligned thanks to the straightening system’s ability to automatically detect and modify the position of the material feed. This keeps the content from straying from its intended course.

Enhances Product Quality: Straightening helps prevent problems like uneven thickness or jagged edges by making sure the material travels through the rollers consistently, which improves the overall quality of the final product.

Minimizes Material Waste: Proper straightening of the material feed position helps reduce waste from material shift, which results in fewer rejections and less reprocessing and lowers production costs.

Boosts Production Efficiency: By minimizing machine downtime and adjustment delays brought on by material transitions, straightening helps the production line run more smoothly and continuously.

Adapts to Different Materials: The versatility and flexibility of modern straightening systems are increased by their ability to handle materials with varying widths and thicknesses.

What is The Difference between Double Head Rolling Machine and Ordinary Electric Rolling Mill?

Guarantees Product Consistency: This feature assists in making sure that the finished product satisfies exact requirements by continually checking the thickness of the material being processed. This is important for applications where quality and functionality depend on homogeneous thickness.

Boosts Efficiency: By enabling instantaneous rolling process modifications, real-time thickness assessment eliminates the need for human inspections and corrections. Production may be greatly accelerated, and downtime can be decreased.

Improves Material Usage: Precise control over material thickness can result in a more economical use of resources by cutting down on waste and possibly even lowering expenses.

Quality Control: To maintain standards of quality and adhere to industry requirements, it is essential to discover deviations from the intended thickness early in the process by continuous monitoring.

Feedback for Process Optimization: By enhancing the mill’s overall performance and rolling settings, the data gathered from thickness measurements may be utilized to increase output quality and yield.

About Rolling Machine Manufacturer FAQ

- 1. What are rolling mills mainly used for? What metals are they suitable for?

- 2. What’s the difference between SuperbMelt’s electric rolling mills and manual rolling mills?

- 3. What are the advantages of a double-head rolling mill?

- 4. What types of metal wire can a wire rolling mill produce?

- 5. What is the maximum feed thickness and minimum output thickness for rolling mills?

- 6. How does SuperbMelt ensure rolling precision?

- 7. Is the equipment noisy? Can it run continuously?

- 8. Can you customize roller textures or rolling dimensions?

- 9. Is the rolling mill safe to operate? Does it have an emergency stop function?

- 10. Is the rolling mill suitable for hard metals like platinum?

- 11. What maintenance is required for the equipment?

- 12. Can the rolling mill be used with other machines?

- 13. What is the warranty period, and what after-sales services are offered?

- 14. Can beginners operate the machine? Is professional training required?

- 15. Can the rollers be replaced if damaged?

- 16. Can the same machine process different metals?

1. What are rolling mills mainly used for? What metals are they suitable for?

Rolling mills are primarily used in metalworking to reduce the thickness of metal stock, flatten it, and shape it into desired forms such as sheets, wires, bars, or strips. They work by passing the metal between one or more pairs of rolls that compress and elongate it.

Main Uses of Rolling Mills:

Metal Thickness Reduction

Flattening ingots or cast billets into sheets or strips.

Wire and Bar Forming

Creating round, square, or custom-shaped wire and bars for jewelry or industrial use.

Surface Finishing

Producing smooth or patterned finishes (e.g., matte, mirror, or textured).

Precise Sizing and Tolerance Control

Especially important in electronics, watchmaking, and coin minting.

Goldsmith and Jewelry Applications

Forming gold/silver sheets and wires for ring shanks, bangles, pendants, etc.

Types of Metals Suitable for Rolling Mills:

Rolling mills are suitable for both precious metals and non-precious metals, including:

Precious Metals

Gold – Soft and easy to roll; often used in jewelry-making.

Silver – Similar to gold, ideal for thin sheets and wires.

Platinum – Requires more force but still workable with precision rolling mills.

Palladium – Softer than platinum, can be rolled for fine jewelry.

Non-Precious Metals

Copper – Very malleable, widely used in electrical and artistic applications.

Brass – Common in decorative and functional components.

Aluminum – Lightweight; used in industrial and consumer products.

Nickel – Harder; used in coinage and industrial parts.

Steel/Stainless Steel – Needs heavy-duty rolling mills due to hardness.

Summary Table

| Metal Type | Workability in Rolling Mill | Common Uses |

|---|---|---|

| Gold | Very easy | Jewelry sheets, wires |

| Silver | Very easy | Jewelry, silverware |

| Platinum | Moderate | Fine jewelry, dental parts |

| Copper | Very easy | Electrical parts, arts |

| Brass | Easy | Hardware, decorative trim |

| Aluminum | Easy | Foils, casings, panels |

| Nickel | Moderate to hard | Coins, battery components |

| Steel | Hard | Industrial sheets, machine parts |

2. What’s the difference between SuperbMelt’s electric rolling mills and manual rolling mills?

1. Power & Operation

| Feature | Electric Rolling Mill | Manual Rolling Mill |

|---|---|---|

| Operation | Powered by an electric motor | Operated by hand crank |

| Effort Required | Minimal manual effort | Requires physical strength |

| Speed | Faster and consistent | Slower and user-dependent |

2. Productivity & Efficiency

| Feature | Electric Rolling Mill | Manual Rolling Mill |

|---|---|---|

| Throughput | High — suitable for continuous or large-batch work | Low — best for small-scale tasks |

| Precision Control | Electric models often offer better thickness control | Control depends on user’s skill |

| Time Efficiency | Saves time in repetitive operations | Time-consuming for larger jobs |

| Feature | Electric Rolling Mill | Manual Rolling Mill |

|---|---|---|

| Best For | Medium to large jewelry workshops, professional metalworkers | Hobbyists, small studios, beginners |

| Material Types | Handles thicker, harder metals more easily | Better for thinner, softer metals |

| Recommended Use | High-volume wire and sheet production | Occasional forming or texturing |

3. What are the advantages of a double-head rolling mill?

A double-head rolling mill combines flat and wire rolling functions into one compact machine, saving space and cost. It allows jewelers to quickly switch between rolling metal sheets and shaping wires, boosting efficiency and workflow. Suitable for materials like gold, silver, copper, and platinum, it delivers precise, consistent results ideal for both hobbyists and professional workshops. This versatile and cost-effective tool is perfect for those seeking to improve productivity without investing in multiple machines.

4. What types of metal wire can a wire rolling mill produce?

A wire rolling mill can produce various types of metal wire, including round, square, and flat shapes. It works with metals such as gold, silver, copper, platinum, and their alloys, making it ideal for crafting jewelry chains, ring wires, and other fine metal components. This versatility allows jewelers to create customized wire profiles suited to different design and functional needs.

5. What is the maximum feed thickness and minimum output thickness for rolling mills?

The maximum feed thickness and minimum output thickness of rolling mills vary by model. For example, SuperbMelt electric rolling mills typically support a maximum feed thickness of up to 5mm and can roll metal down to a minimum thickness of about 0.2mm. Specific capabilities depend on the machine’s design and intended use, so it’s best to refer to the product specifications for precise details.

6. How does SuperbMelt ensure rolling precision?

SuperbMelt ensures rolling precision by using high-hardness tool steel rollers that are precisely ground for smooth and even surfaces. The machines are equipped with fine-tuning screw systems that allow accurate adjustment of roller gaps, ensuring consistent thickness and flatness without surface waviness. This combination of durable materials and precise mechanical control guarantees high-quality, uniform metal rolling suitable for delicate jewelry manufacturing.

7. Is the equipment noisy? Can it run continuously?

SuperbMelt rolling mills are designed with low-noise motors to minimize operational sound. They support continuous, long-duration use without overheating, making them suitable for factory and workshop environments that require stable, around-the-clock production.

8. Can you customize roller textures or rolling dimensions?

Yes, SuperbMelt offers customization options for roller textures and rolling dimensions. Customers can request special roller patterns such as wave, sandblast, or embossing textures, as well as non-standard rolling sizes to meet specific metal processing needs.

9. Is the rolling mill safe to operate? Does it have an emergency stop function?

ChatGPT 说:

Yes, SuperbMelt rolling mills are designed with safety in mind. They come equipped with emergency stop buttons, protective guards, and overload protection systems to ensure operator safety during use.

10. Is the rolling mill suitable for hard metals like platinum?

Yes, SuperbMelt rolling mills, especially the high-tonnage electric models, are suitable for rolling hard metals such as platinum and palladium. For these applications, it’s recommended to choose reinforced rollers and higher-power motors to handle the increased hardness effectively.

11. What maintenance is required for the equipment?

Regular maintenance for the rolling mill includes daily cleaning of metal debris from the roller surfaces, periodic lubrication of moving parts, and routine inspection of the motor and transmission components to prevent wear and rust. Proper maintenance ensures smooth operation and extends the machine’s service life.

12. Can the rolling mill be used with other machines?

ChatGPT 说:

Yes, the rolling mill can be integrated with other equipment such as annealing furnaces, wire drawing machines, and cutting tools to form a complete metal processing production line, enhancing overall workflow efficiency.

13. What is the warranty period, and what after-sales services are offered?

SuperbMelt offers a 2-year warranty on its rolling mills, which is one year longer than the industry standard. This extended warranty reflects the company’s commitment to product quality and customer satisfaction.

After-Sales Services:

24-Hour Support: SuperbMelt provides prompt assistance, with responses to inquiries and issues typically within 24 hours. Superb Electromachinery Co., Limited

Free Replacement of Faulty Parts: Any malfunctioning spare parts covered under warranty will be replaced and shipped via express courier within 24 hours at no additional cost. Superb Electromachinery Co., Limited

Remote Technical Assistance: The company offers remote support through live chat, illustrative images, or real-time videos to address installation, operation, and maintenance queries. Superb Electromachinery Co., Limited

This comprehensive after-sales support ensures that customers receive timely assistance, minimizing downtime and maintaining the efficiency of their operations.

14. Can beginners operate the machine? Is professional training required?

Yes, beginners can operate SuperbMelt rolling mills with ease. The machines are designed with user-friendly controls and come with detailed operation manuals and instructional videos. Additionally, SuperbMelt offers remote video training and real-time support to help new users quickly learn how to use the equipment safely and efficiently. While professional training is not strictly required, it is recommended to ensure optimal operation and maintenance.

15. Can the rollers be replaced if damaged?

Yes, the rollers on SuperbMelt rolling mills are designed to be replaceable. They feature a modular construction that allows users to easily remove and swap out damaged or worn rollers. This design helps extend the machine’s lifespan and allows for upgrades or customization with different roller types or textures as needed.

16. Can the same machine process different metals?

Yes, the same rolling mill can process different metals such as gold, silver, platinum, copper, and their alloys. However, it is recommended to thoroughly clean the rollers between processing different metals to avoid cross-contamination and maintain the quality and appearance of each metal. Proper cleaning helps prevent any unwanted reactions or discoloration caused by metal residues.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited