Roll Cutting Machine

SuperbMelt gold coil and silver coil cutting machine assists jewelry manufacturers in cutting and crafting jewelry

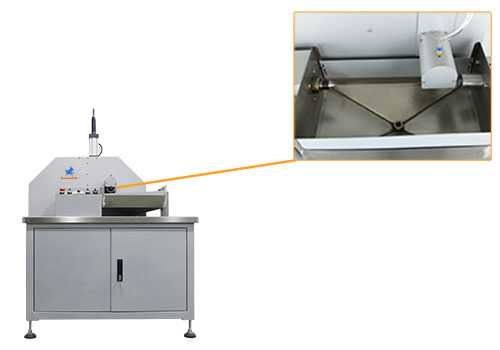

SuperbMelt Roll Cutting Machine is designed for cutting gold, silver, and alloy coil materials or tubular materials. It is used to cut pre-made semi-finished gold or silver bracelets, rings, or coils. The Roll Cutting Machine is commonly used in industries such as decorative arts, jewelry pendants, and handicrafts.

This machine features a spray cooling device to reduce the surface temperature of the saw blade, extending the tool’s lifespan. It can precisely cut materials and adjust to different widths and lengths as needed to meet various production requirements.

Utilize SuperbMelt’s Roll Cutting Machine to efficiently produce batches of bracelets and rings! Contact us immediately if you require other jewelry casting solutions!

- Smooth Cutting Edge: Equipped with tungsten steel saw blade, ensuring clean and smooth cutting edges without burrs.

- Stable Operation: Utilizes Taiwan guide rails for steady and creep-free blade movement, ensuring stable operation.

- Consistent Ring Opening: Ensures consistent ring opening with a tolerance of within ±0.03mm.

- Easy Operation: Simple operation with one-button control, easy to learn and operate.

- Spraying Cooling System: Equipped with a spraying cooling device to protect the mold and ensure efficient cooling during operation.

- Convenient Recycling: Features a funnel-type recycling tray for easy material collection and recycling.

| Model | SPA-Cir3 |

| Voltage | 220V |

| Power | 3KW |

| Pressure | 0.7MPa |

| Water consumption | 3L/H |

| Applicable metal | Gold, K gold, silver, etc. |

| Size | 700*600*1100MM |

| Weight | 71KG |

| Steam temperature | 100℃ |

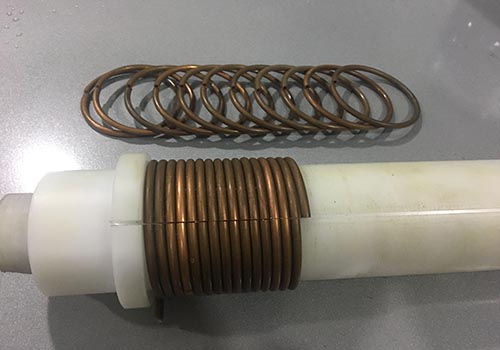

Cutting the coiled jewelry materials facilitates subsequent processing of rings or bracelets.

The spillage loading area prevents material wastage.

Easy-to-operate control panel

Why SuperbMelt Roll Cutting Machine

Any Question About SuperbMelt Roll Cutting Machine

Roll Cutting Machine Guide: From the User's Perspective

How Goldsmiths and Silversmiths Use Roll Cutting Machines to Increase Output

In the fast-paced world of jewelry manufacturing, efficiency and precision are everything. One tool that has revolutionized the way goldsmiths and silversmiths work is the Roll Cutting Machine. Designed specifically to cut gold, silver, and alloy coil or tubular materials, this machine helps streamline production while maintaining high levels of craftsmanship.

1.1, How artisans use cutting machines to mass-produce rings or bracelets

In the world of handcrafted jewelry, precision and efficiency often go hand-in-hand. While the artistry of a piece lies in its design, the ability to replicate that design consistently and quickly is equally crucial for success. This is where roll cutting machines become a vital part of modern jewelry workshops.

What Is a Roll Cutting Machine?

A roll cutting machine is an essential tool used to cut flat metal coils or tubular materials — typically gold, silver, or alloys — into predetermined shapes and sizes. These cut pieces serve as the foundation for rings, bracelets, and other jewelry components.

Unlike manual cutting tools, roll cutting machines are designed for high-precision, repeatable cuts that save time and reduce material waste.

Why Artisans Choose Roll Cutting Machines for Jewelry Making

1. Precision and Consistency

Artisans who create rings or bracelets need each unit to be identical in size and shape, especially when producing for wholesale or retail. The roll cutting machine ensures perfect repetition, maintaining quality standards across hundreds or even thousands of pieces.

2. Versatile Material Handling

Roll cutting machines can process:

Flat metal strips

Coiled alloy sheets

Tubular semi-finished pieces

This flexibility allows artisans to switch between different bracelet and ring designs quickly without changing the core equipment.

3. Spray Cooling System for Extended Blade Life

Advanced models, like the SuperbMelt Roll Cutting Machine, include spray cooling to reduce the surface heat of the saw blade. This prolongs the life of the cutting tool and ensures clean, burr-free cuts — minimizing the need for secondary polishing or reshaping.

Workflow Example: Ring Mass Production with a Roll Cutting Machine

Prepare the Coil: Artisans begin with a pre-rolled gold or silver alloy strip.

Set Dimensions: The machine is calibrated for the ring’s width and thickness.

Batch Cutting: The strip is fed into the machine, which slices it into multiple identical blanks.

Further Processing: Each blank is then rolled, formed, soldered, and polished into a finished ring.

This same process applies to bracelet production, with adjustments made for length and curve radius.

Ideal for Boutique Studios and Small-Scale Production

While mass production might sound industrial, many small jewelry studios now rely on compact roll cutting machines to scale their output. These machines bridge the gap between handmade artistry and efficient manufacturing, allowing artisans to:

Fulfill bulk orders without compromising quality

Standardize pieces for collections or custom lines

Reduce physical strain compared to manual cutting

Industries Benefiting from Roll Cutting Machines

Jewelry Designers & Studios

Handicraft Workshops

Custom Wedding Band Makers

Artisan Bracelet Brands

Conclusion

For artisans aiming to produce consistent, high-quality rings or bracelets at scale, the roll cutting machine is an invaluable investment. It preserves the handmade spirit while opening the door to larger markets and repeat business.

If you’re ready to enhance your workshop with industrial-grade precision, SuperbMelt’s Roll Cutting Machine offers the versatility and durability you need.

1.2, Reduce manual sawing and improve consistency

Artisans use cutting machines to mass-produce rings or bracelets by significantly reducing the need for manual sawing and ensuring uniformity in each piece. These machines allow for:

- Precise cutting of metal strips to exact dimensions needed for ring or bracelet blanks.

- Improved efficiency, enabling artisans to produce large batches in a fraction of the time compared to hand-cutting.

- Enhanced consistency, which is critical for creating matched sets or maintaining uniformity in serialized designs.

- Reduced fatigue, as artisans no longer need to rely heavily on hand tools, minimizing errors caused by tiredness.

Overall, cutting machines streamline the production process, allowing small workshops and individual jewelers to scale up without compromising quality.

1.3, How startup jewelry brands can use this equipment to boost production capacity and efficiency

1. Scale Production with Minimal Labor

These machines automate repetitive tasks like cutting, bending, and shaping metal strips, enabling small teams to produce large batches of ring or bracelet blanks.

Brands can fulfill more orders without hiring more artisans, keeping overhead low.

2. Ensure Consistency and Quality

Machines deliver precise, repeatable cuts and bends, ensuring each piece meets exact specs.

Uniformity is key for branding, customer satisfaction, and avoiding costly remakes.

3. Speed Up the Manufacturing Timeline

Manual sawing and bending are time-consuming. Machines cut production time by over 50%, helping startups respond quickly to customer demand or restock fast-selling designs.

4. Reduce Material Waste

Precision equipment minimizes errors and offcuts, saving costly gold, silver, or brass materials—critical for startups watching their bottom line.

5. Flexible Design Iteration

Quick setup and adjustment allow for fast prototyping and small batch runs, helping startups test new designs or seasonal collections without large commitments.

Jewelry Studio Workflow Optimization Using Roll Cutting Machines

In modern jewelry studios, optimizing workflow is key to maintaining both quality and efficiency. Roll cutting machines play a crucial role in this process. These machines enable artisans to cut precious metal sheets or wires with high precision and repeatability, significantly reducing the time spent on manual sawing or filing.

By integrating roll cutting machines into the studio workflow, jewelers can streamline repetitive tasks such as preparing blanks for rings, bangles, and pendants. The result is a more standardized output, faster production cycles, and minimized material waste.

For small studios and independent designers, the adoption of a roll cutting machine transforms batch production. It allows them to maintain consistency across pieces while scaling up output to meet customer demand. This not only enhances the professional appearance of their collections but also frees up valuable time for creative design and customization.

In short, roll cutting machines are essential tools for jewelry studios aiming to enhance productivity, reduce labor-intensive steps, and ensure a smooth, efficient production process.

2.1, Workflow redesign example: An integrated process from wire drawing, sheeting, cutting, to welding

Wire Drawing

Raw gold or silver is passed through a wire drawing machine to achieve the desired thickness for specific designs (e.g., rings, bangles, or chain links).Sheet Rolling

The drawn metal is flattened into sheets using a rolling mill. These sheets form the base material for bracelets, pendants, and more.Precision Cutting with Roll Cutting Machine

Using a roll cutting machine, the metal sheets or wires are accurately cut into uniform segments according to the design—significantly reducing the need for manual sawing. This step improves consistency and speed, especially in batch production.Forming & Bending

The cut segments can be shaped using bending machines—such as a circular bending machine—to create curved elements like ring bands or bangles.Welding or Soldering

The shaped components are welded or soldered to complete the piece. The precision of earlier steps reduces gaps and improves joint quality, simplifying the welding process.Polishing & Finishing

The completed pieces go through polishing, engraving, or plating, ready for market.

2.2, How to use roll cutting with chain cutting machines, sheeting machines, etc.

1. Roll Cutting Machine + Sheeting Machine (Rolling Mill)

Process: Start by drawing or rolling metal (gold, silver, platinum) into thin sheets using a rolling mill.

Use: Feed the uniform sheet directly into the roll cutting machine.

Outcome: You get precisely cut strips ready for further shaping into ring blanks, bracelet segments, or chain links.

2. Roll Cutting Machine + Chain Cutting Machine

Process: After cutting narrow strips with the roll cutter, those strips are passed to chain-making machines (like curb chain or cable chain machines).

Use: Ensures that each chain link is made from a consistent and cleanly cut metal strip.

Benefit: Improves chain symmetry, reduces breakage rates, and boosts chain production speed.

3. Roll Cutting Machine + Wire Drawing + Welding

Step 1: Draw thick wire into finer wire with a wire drawing machine.

Step 2: Flatten or shape it with a rolling mill, then cut into uniform pieces with the roll cutter.

Step 3: Use precision welding machines (laser or arc welders) to join components into jewelry structures (e.g., closed rings, linked chains, hinge components).

Benefits of Equipment Integration:

Reduced Manual Labor: No more hand-sawing or inconsistent cutting.

Consistency in Size: Uniform parts ensure seamless assembly.

High Output: Combined use of machines creates a semi-automated production line.

Scalable: Ideal for studios and brands looking to expand production.

2.3, Cost and time savings analysis

Introducing roll cutting machines into a jewelry workshop significantly reduces production time and labor costs. Compared to manual sawing or hand-cutting methods, roll cutting machines automate the cutting process, enabling precise and consistent cuts at a much faster rate.

Time Savings:

Manual sawing of metal sheets or wires may take several minutes per piece, especially when aiming for accuracy and uniformity.

A roll cutting machine can cut dozens of identical pieces in the same time it takes to manually saw just one or two.

For example, producing 100 ring blanks manually might take 4–5 hours. With a roll cutter, this can be reduced to less than 1 hour.

Labor Cost Reduction:

Reducing reliance on skilled manual sawing allows workshops to allocate artisans to more complex tasks such as design, setting, or finishing.

Minimizing rework due to human error lowers material wastage and scrap costs.

Material Optimization:

Consistent and straight cuts reduce metal loss.

Repeatable cutting improves metal yield and saves raw material costs over time.

ROI and Long-Term Value:

Though roll cutting machines require upfront investment, the reduction in labor hours and material loss typically leads to full ROI within a few months for medium to high-volume operations.

The increased output capacity enables studios to fulfill larger orders or diversify product lines without adding more labor.

FAQ Guide of Roll Cutting Machine

- 1. A Roll Cutting Machine is a specialized equipment used for cutting metal coil or tube materials, such as gold, silver, alloys, etc. How does a Roll Cutting Machine work?

- 2. Which industries is a Roll Cutting Machine suitable for?

- 3. What are the advantages of a Roll Cutting Machine?

- 4. How to maintain a Roll Cutting Machine?

- 5. What is the cutting speed of a Roll Cutting Machine?

- 6. What safety precautions should be taken when using a Roll Cutting Machine?

- 7. How to adjust the cutting size and shape of a Roll Cutting Machine?

1. A Roll Cutting Machine is a specialized equipment used for cutting metal coil or tube materials, such as gold, silver, alloys, etc. How does a Roll Cutting Machine work?

A Roll Cutting Machine utilizes saw blades or other cutting tools to precisely cut metal coil or tube materials to meet specific size and shape requirements.

2. Which industries is a Roll Cutting Machine suitable for?

A Roll Cutting Machine is widely used in industries such as jewelry manufacturing, craft making, decorative production, etc., for cutting metal coil or tube materials.

3. What are the advantages of a Roll Cutting Machine?

- Smooth cutting edges, high cutting precision

- Simple operation, easy to learn and use

- Fast cutting speed, high production efficiency

- Adjustable cutting size and shape as needed

- Cooling system to protect cutting tools, prolonging lifespan

4. How to maintain a Roll Cutting Machine?

- Regularly clean the surface and cutting components of the machine

- Check if the cutting tools are worn or damaged, and replace them in time

- Maintain the lubrication of the machine to ensure smooth operation

5. What is the cutting speed of a Roll Cutting Machine?

The cutting speed depends on the hardness, thickness of the material, and performance of the cutting tool. Generally, it can reach dozens or even hundreds of cuts per minute.

6. What safety precautions should be taken when using a Roll Cutting Machine?

- Wear personal protective equipment such as gloves, goggles, etc.

- Keep the machine stable during operation to avoid accidents

- Do not place hands or other objects near the cutting components to prevent injury

7. How to adjust the cutting size and shape of a Roll Cutting Machine?

By adjusting the machine settings or replacing cutting tools, different cutting size and shape requirements can be achieved.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited