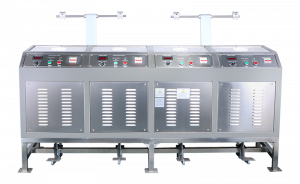

Multi Pot Melting Furnace

Simultaneously melt gold, silver and alloys with 3-pot or 4-pot independent temperature control

SuperbMelt multi pot melting furnace is designed for simultaneous melting of multiple precious metals. Available in 3-pot and 4-pot configurations, this advanced system can melt 2–10 kg per pot of gold, silver, platinum, palladium, copper, stainless steel and alloys at the same time — all in one compact machine.

Powered by a German original IGBT + CPU variable-frequency induction heating system, the furnace reaches temperatures of up to 2600°C, enabling each pot to melt different metals independently and precisely. Most metals can be fully melted in under 2 minutes, significantly improving productivity while reducing labor and energy costs.

The multi-pot design allows jewelry manufacturers and precious-metal workshops to process different metals simultaneously, making it ideal for small to medium-scale jewelry production, bullion casting, alloy preparation, assay laboratories, and R&D centers.

SuperbMelt also offers custom-built multi pot melting furnaces, including special capacities, crucible sizes, and power configurations, to match your specific production requirements.

For detailed specifications, pricing, or customization options, please contact SuperbMelt today.

| Model number | SPB-BF3 | SPB-BF4 |

| Power source | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz |

| Power | 15 kw*3 | 15 kw*4 |

| Applicable metal | Gold, Silver, Platinum, Palladium, K gold and Their alloys | Gold, Silver, Platinum, Palladium, K gold and Their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 1-10kg customized*3 | 1-10kg customized*4 |

| Max temperature | 2600℃ | 2600℃ |

| Temperature control k-type | Optional | Optional |

| Weight | 272 kg | 330 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

- Equipped with a German original IGBT+CPU variable frequency induction heating power supply, ensuring strong stability in equipment operation.

- Safety is guaranteed with built-in functions for overcurrent, overvoltage, and water shortage protection.

- Easy operation with one-key startup for melting, eliminating the need for specialized personnel;

- Simplified power structure with water and electricity separation, significantly enhancing equipment lifespan.

- Temperature can reach up to 2600°C, allowing for the melting of metals such as platinum, palladium, gold, and stainless steel.

- Jewelry and Jewelry Manufacturing Industry: Used for melting and casting precious metals such as gold, platinum, palladium, silver, etc., for the production of jewelry and ornaments.

- Metallurgy and Metal Processing Industry: Employed for smelting and melting various metals such as copper, stainless steel, etc., to meet the production requirements of metal materials.

- Education and Research Institutions: Provides a convenient and rapid smelting tool for academic research, laboratory work, and research in metal materials.

- Laboratory and Quality Inspection Industry: Utilized for sample preparation, material analysis, and metal quality testing to ensure products meet standards.

- Small and Medium-Sized Metal Processing Enterprises: Suitable for small and medium-scale metal processing enterprises, enhancing production efficiency and reducing labor costs.

Each batch melts 3 or 4 kinds of metal raw materials extremely quickly within 2 minutes, and works continuously for 24 hours, greatly improving production efficiency.

Three-furnace simultaneous smelting machine for refining 2-10 kilograms of gold, capable of melting 6-24 kilograms of metal raw materials in a single operation.

Capable of reaching a high temperature of 2600°C at any time, achieving rapid melting and enhancing production efficiency.

Why SuperbMelt Multi pot melting furnace

Any Question About SuperbMelt Three Furnace Melting Furnace

Any Question About SuperbMelt Three Furnace Melting Furnace

Multi-Pot Melting Furnace Buyer’s Guide for Jewelry & Precious Metals

Multi-pot melting furnaces allow jewelry manufacturers, precious-metal workshops, and laboratories to melt different metals at the same time, with greater speed, accuracy, and efficiency than traditional single-pot systems. For modern jewelry production, this technology is no longer optional — it is essential. In an industry where precision, speed, and metal purity directly impact profitability, outdated single-pot furnaces can no longer keep up with the demands of small-to-medium jewelry workshops, bullion casting facilities, or alloy preparation labs. This comprehensive guide will walk you through everything you need to know about multi-pot melting furnaces: why they’re a game-changer for jewelry production, how they work, how to choose between 3-pot and 4-pot configurations, the metals they can melt, and the key features that define a professional-grade system.

Why Jewelry Manufacturers Need Multi-Pot Melting Furnaces

Jewelry production relies heavily on the efficient and pure melting of precious metals like gold, silver, platinum, and palladium, as well as custom alloys. Traditional single-pot furnaces create bottlenecks that hinder productivity, compromise metal quality, and increase operational costs. Multi-pot melting furnaces address these pain points head-on, making them a must-have for modern jewelry manufacturers.

1.1, Why single-pot furnaces slow down jewelry production

Single-pot furnaces are a bottleneck for jewelry production due to their inherent limitations. First, they can only melt one type of metal or alloy at a time. This means if you need to process gold for rings, silver for bracelets, and a custom alloy for pendants in a single shift, you’ll have to melt each material sequentially — waiting for the furnace to cool down, clean the crucible, and reheat for the next metal. This downtime adds up quickly, drastically reducing daily output. Second, single-pot systems often require more manual labor: operators must monitor each melting cycle closely, switch crucibles, and adjust temperature settings repeatedly, increasing the risk of human error and further slowing down production. For small-to-medium jewelry workshops aiming to scale or meet tight order deadlines, these inefficiencies can be crippling.

1.2, How simultaneous melting of gold, silver & alloys increases output

Multi-pot melting furnaces solve the productivity problem by enabling simultaneous melting of multiple metals. Imagine melting 2–10 kg of gold in one pot, 2–10 kg of silver in another, and a custom jewelry alloy in a third — all at the same time, in one compact machine. This eliminates the sequential waiting time of single-pot systems, cutting melting cycles by up to 60% and significantly increasing daily output. For example, a jewelry workshop that previously processed 5 batches of metal per day with a single-pot furnace can process 15+ batches with a 3-pot system, all while using the same or fewer operators. The time saved on melting translates directly to more time for casting, finishing, and fulfilling orders — a critical advantage in the competitive jewelry industry. SuperbMelt’s multi-pot furnaces take this a step further: most metals are fully melted in under 2 minutes, maximizing throughput without sacrificing quality.

1.3, Why multi-pot furnaces reduce contamination between metals

Metal contamination is a costly nightmare for jewelry manufacturers. When using a single-pot furnace, residual metal from one melting cycle can mix with the next, altering the purity of precious metals and ruining batches of jewelry. Even thorough crucible cleaning doesn’t always eliminate trace contaminants, especially with soft metals like gold and silver. Multi-pot furnaces eliminate this risk by using independent crucibles for each metal. Each pot is isolated, with its own heating system and temperature control, so gold never comes into contact with silver, and alloys stay pure. This not only preserves the quality and value of precious metals but also reduces waste from contaminated batches. For jewelry manufacturers working with high-value metals like platinum or custom alloys that require precise composition, this level of contamination control is non-negotiable.

How a Multi-Pot Melting Furnace Works

Multi-pot melting furnaces leverage advanced induction heating technology to deliver fast, precise, and efficient melting of precious metals. Unlike traditional resistance heating or gas furnaces, induction heating is cleaner, more energy-efficient, and better suited for maintaining the purity of precious metals. Below is a breakdown of how these systems work, with a focus on features that matter most for jewelry production.

2.1, Independent crucible heating and temperature control

The core advantage of multi-pot furnaces lies in their independent crucible design. Each pot operates as a separate melting unit, with its own heating element, temperature sensor, and control panel. This means you can set different temperatures for different metals in the same machine: for example, 1064°C for gold, 961°C for silver, and 2600°C for platinum — all simultaneously. SuperbMelt’s multi-pot furnaces feature precise temperature control, ensuring each metal melts at its optimal temperature without overheating (which can damage metal properties or cause oxidation). The independent design also means if one pot requires maintenance or cleaning, the others can continue operating, minimizing downtime.

2.2, Induction melting technology for precious metals

Multi-pot furnaces for jewelry production use induction heating technology, which is far superior to traditional heating methods for precious metals. Induction heating works by generating an alternating magnetic field that induces eddy currents in the metal, heating it from the inside out. This process is fast (most metals melt in under 2 minutes with SuperbMelt’s systems), clean (no open flames or toxic fumes), and energy-efficient (less heat loss compared to gas or resistance heating). Crucially, induction heating minimizes contact between the metal and heating elements, reducing the risk of contamination. SuperbMelt’s multi-pot furnaces are powered by a German original IGBT + CPU variable-frequency induction heating system, which ensures strong stability in operation, consistent melting results, and long equipment lifespan.

2.3, Why 2600°C capability matters for platinum and palladium

Precious metals like platinum and palladium have extremely high melting points: platinum melts at 1768°C, and palladium at 1554°C. Many standard melting furnaces (including some single-pot induction models) can’t reach these temperatures, making them useless for processing these high-value metals. Multi-pot furnaces with a 2600°C maximum temperature capability, like SuperbMelt’s systems, solve this problem. The 2600°C capacity not only covers platinum and palladium but also allows for melting of other high-temperature metals used in jewelry components, such as stainless steel. This versatility is a major advantage for jewelry manufacturers looking to expand their product lines to include high-end platinum jewelry or durable stainless steel findings. Without this high-temperature capability, manufacturers are limited to lower-melting metals, missing out on profitable market segments.

3-Pot vs 4-Pot Melting Furnaces: Which One Do You Need?

SuperbMelt offers multi-pot melting furnaces in 3-pot and 4-pot configurations, each designed to meet different production needs. Choosing the right one depends on your daily output, the number of metals you process simultaneously, and your workshop size. Below is a detailed comparison to help you make an informed decision.

3.1, Production capacity comparison

Both 3-pot and 4-pot furnaces from SuperbMelt can melt 2–10 kg of metal per pot, so the main difference in capacity is the number of simultaneous batches. A 3-pot furnace can process 3 different metals or alloys at once, with a total potential daily output of 30–180 kg (depending on melting time and shift length). A 4-pot furnace increases this to 4 simultaneous batches, with a total potential daily output of 40–240 kg. For example, a small jewelry workshop that processes 2–3 metals per day and has a daily output of 50–100 kg will find a 3-pot furnace sufficient. A medium-sized workshop that processes 4+ metals daily and has a daily output of 100–200 kg will benefit from the extra capacity of a 4-pot system.

3.2, Typical jewelry workshop configurations

3-pot furnaces are the most common choice for small-to-medium jewelry workshops, bullion casting facilities, and assay laboratories. They offer the perfect balance of capacity and space efficiency — the compact design fits easily in most workshop layouts, making them ideal for businesses with limited floor space. Typical 3-pot configurations are used for: melting gold, silver, and a custom alloy simultaneously; or processing small batches of 3 different precious metals for custom jewelry orders. 4-pot furnaces are better suited for larger medium-sized workshops, R&D centers, or manufacturers that produce a wide range of jewelry (e.g., gold, silver, platinum, and stainless steel findings). They’re also ideal for workshops that handle high-volume orders and need to maximize throughput to meet deadlines.

3.3, How to choose based on metal types and daily output

When choosing between 3-pot and 4-pot, start by evaluating two key factors: the number of different metals/alloy you process in a single shift, and your daily output target. Here’s a step-by-step guide: 1. Count the number of unique metals/alloy you melt daily (e.g., gold, silver, platinum, custom alloy = 4 types). If you regularly process 3 or fewer, a 3-pot furnace is sufficient. If you process 4 or more, opt for a 4-pot. 2. Calculate your daily output needs. If you need to melt 100 kg or less per day, 3-pot is enough. If you need 100–240 kg per day, 4-pot is better. 3. Consider future growth. If you plan to expand your product line or increase output in the next 1–2 years, a 4-pot furnace may be a better long-term investment. SuperbMelt also offers custom-built configurations, so if your needs fall outside the standard 3-pot/4-pot options, you can get a system tailored to your exact requirements.

What Metals Can Be Melted in a Multi-Pot Furnace?

Multi-pot melting furnaces are highly versatile, capable of melting a wide range of metals used in jewelry production and related industries. SuperbMelt’s systems, with their 2600°C temperature capability and German IGBT+CPU induction system, can handle everything from common precious metals to high-temperature alloys and industrial metals used for jewelry components.

4.1, Melting gold, silver, and jewelry alloys

Gold and silver are the most common metals processed in jewelry production, and multi-pot furnaces excel at melting them efficiently. SuperbMelt’s systems can melt 2–10 kg of gold (any karat) or silver in under 2 minutes, with precise temperature control to avoid overheating and oxidation. They’re also ideal for melting custom jewelry alloys (e.g., 14K gold, 925 silver, rose gold), as the independent crucibles ensure alloy composition remains pure. Whether you’re producing mass-market silver jewelry or high-end custom gold pieces, a multi-pot furnace delivers consistent, high-quality melting results.

4.2, Melting platinum, palladium and high-temperature metals

As mentioned earlier, platinum and palladium require high melting temperatures (1768°C and 1554°C, respectively), which many standard furnaces can’t reach. SuperbMelt’s multi-pot furnaces, with their 2600°C capability, make melting these high-value metals easy and efficient. The precise temperature control ensures platinum and palladium melt evenly without losing purity, and the induction heating technology minimizes oxidation, preserving the metal’s luster and value. This makes multi-pot furnaces a must-have for jewelry manufacturers specializing in high-end platinum or palladium jewelry.

4.3, Melting copper and stainless steel for findings and components

Jewelry production isn’t just about precious metals — copper and stainless steel are widely used for findings (e.g., clasps, jump rings) and structural components. Multi-pot furnaces can easily melt these industrial metals: copper melts at 1085°C, and stainless steel at around 1450°C, both well within the 2600°C range of SuperbMelt’s systems. Melting copper and stainless steel in separate pots from precious metals eliminates contamination, ensuring your findings are durable and your precious metal batches remain pure. This versatility allows jewelry manufacturers to handle all their melting needs with one machine, reducing equipment costs and workshop clutter.

Key Features That Define a Professional Jewelry Multi-Pot Melting Furnace

Not all multi-pot melting furnaces are created equal. Professional-grade systems for jewelry production need specific features to ensure speed, precision, safety, and durability. Below are the key features to look for when choosing a multi-pot furnace, all of which are standard in SuperbMelt’s systems.

5.1, IGBT + CPU induction system and why it matters

The induction system is the heart of a multi-pot melting furnace, and a high-quality IGBT + CPU system is non-negotiable for professional use. SuperbMelt’s furnaces use a German original IGBT + CPU variable-frequency induction heating system, which offers several critical advantages: 1. Stability: The CPU controls the frequency and power output with precision, ensuring consistent melting results batch after batch. 2. Speed: IGBT technology enables fast heating, with most metals melting in under 2 minutes. 3. Energy efficiency: Variable-frequency control reduces energy consumption by adjusting power to match the melting stage, lowering operational costs. 4. Durability: German-engineered components are built to last, even under high-temperature, high-volume use. For jewelry manufacturers, this means reliable performance, fewer breakdowns, and lower maintenance costs

5.2, Safety systems for precious metal melting

Safety is paramount when melting precious metals, especially in a workshop environment. Professional multi-pot furnaces must have comprehensive safety features to protect operators, equipment, and valuable metals. SuperbMelt’s systems include built-in safety functions for overcurrent protection (prevents electrical damage), overvoltage protection (shuts down if voltage spikes), and water shortage protection (critical for cooling systems, as overheating can damage the furnace). Additionally, the simplified power structure with water and electricity separation reduces the risk of electrical hazards and significantly enhances equipment lifespan. The one-key startup function also minimizes human error, making operation safer for all staff — no specialized training required.

5.3, Customizable crucible sizes and power configurations

Every jewelry workshop has unique needs, so a one-size-fits-all furnace may not be the best fit. Professional multi-pot furnaces offer customizable options to match your specific production requirements. SuperbMelt provides custom-built multi-pot melting furnaces, including special crucible sizes (beyond the standard 2–10 kg) and power configurations. For example, if you need to melt small batches of 1 kg or large batches of 15 kg per pot, SuperbMelt can tailor the crucible size. If your workshop has specific power supply limitations, they can adjust the power configuration to match. This customization ensures you get a furnace that fits your exact needs, maximizing efficiency and return on investment.

Conclusion

In today’s fast-paced jewelry industry, efficiency, precision, and versatility are key to staying competitive. Multi-pot melting furnaces address the biggest pain points of traditional single-pot systems: slow sequential melting, metal contamination, and limited capacity. By enabling simultaneous melting of multiple precious metals and alloys, reducing contamination, and leveraging advanced induction technology, these furnaces significantly increase productivity, reduce waste, and lower operational costs. For small-to-medium jewelry workshops, bullion casting facilities, assay laboratories, and R&D centers, a multi-pot melting furnace isn’t just an upgrade — it’s a necessary investment to meet growing demand, expand product lines, and maintain the high quality that customers expect.

SuperbMelt’s multi-pot melting furnaces, with their German IGBT+CPU induction system, 2600°C high-temperature capability, independent crucible design, and customizable options, are designed specifically for the needs of jewelry manufacturers. Whether you choose a 3-pot or 4-pot configuration, you’ll get a reliable, efficient, and safe system that transforms your melting process.

FAQ Guide of Three Furnace Melting Furnace

- 1. How many types of melting furnaces are there?

- 2. What is the Three Furnace Melting Furnace?

- 3. What is the power supply requirement for the furnace?

- 4. What is the heating technology used in this furnace?

- 5. What safety features does the furnace have?

- 6. How easy is it to operate the Three Furnace Melting Furnace?

- 7. What is the maximum temperature this furnace can reach?

- 8. What metals can be melted using this furnace?

- 9. How long does it take to melt metals in this furnace?

- 10. Can the furnace be used for jewelry manufacturing?

- 11. Is specialized training required to operate the furnace?

- 12. How does the separation of water and electricity in the power structure enhance equipment lifespan?

- 13. Can the furnace be used in educational and research institutions?

- 14. What is the weight of the Three Furnace Melting Furnace?

- 15. Is the furnace suitable for small and medium-sized metal processing enterprises?

1. How many types of melting furnaces are there?

- Cupola Furnace: Foundries use this to melt cast iron.

- An induction furnace, which is frequently used in the foundry and metallurgy sectors, melts metal using electromagnetic induction.

- Arc Furnace: Used in steelmaking, this device melts metals using an electric arc.

- Crucible Furnace: Designed for small-scale operations, this furnace has a refractory crucible to hold the metal as it melts.

- Electric Resistance Furnace: This type of furnace, which is frequently used in small-scale metalworking and jewelry making, melts metal using electric resistance heating components.

- Gas-powered Furnace: Used in many industrial applications, it generates heat through the combustion of gas to melt materials.

- An oil-fired furnace produces heat by using oil as a fuel source. These furnaces are frequently used in the forging and heat-treating of metal.

- Microwave Furnace: This device uses microwave radiation to melt metal and is frequently employed in specific applications and research.

- Solar furnaces: mostly employed in research and certain commercial uses, they concentrate sunlight to reach high temperatures.

- Foundries frequently utilize tilting furnaces, which are constructed with a tilting mechanism to make pouring molten metal simple.

- The kind of metal to be melted, the volume of production, the need for energy efficiency, and particular industrial uses all influence the choice of furnace.

2. What is the Three Furnace Melting Furnace?

The Three Furnace Melting Furnace is an advanced industrial equipment designed for the simultaneous smelting of three different metals, including platinum, palladium, gold, silver, copper, and stainless steel.

3. What is the power supply requirement for the furnace?

The furnace requires a 380V three-phase power supply for optimal operation.

4. What is the heating technology used in this furnace?

The furnace utilizes German original IGBT+CPU variable frequency induction heating power supply for efficient and stable operation.

5. What safety features does the furnace have?

The furnace is equipped with overcurrent, overvoltage, and water shortage protection features to ensure a secure operational environment.

6. How easy is it to operate the Three Furnace Melting Furnace?

The furnace is designed for user-friendly operation with a one-click startup for melting, eliminating the need for specialized personnel.

7. What is the maximum temperature this furnace can reach?

The furnace can reach a maximum temperature of 2600°C.

8. What metals can be melted using this furnace?

The furnace is suitable for melting various metals, including platinum, palladium, gold, silver, copper, and stainless steel.

9. How long does it take to melt metals in this furnace?

The furnace has a rapid melting capability, completing the entire process within two minutes.

10. Can the furnace be used for jewelry manufacturing?

Yes, the Three Furnace Melting Furnace is an optimal choice for jewelry workshops and stores due to its versatility in melting precious metals.

11. Is specialized training required to operate the furnace?

No, the furnace is designed for easy operation with a one-key startup, eliminating the need for specialized personnel.

12. How does the separation of water and electricity in the power structure enhance equipment lifespan?

The separation of water and electricity in the power structure significantly improves the durability and service life of the equipment.

13. Can the furnace be used in educational and research institutions?

Yes, the furnace serves as a convenient and rapid smelting tool for academic research, laboratory work, and research in metal materials.

14. What is the weight of the Three Furnace Melting Furnace?

The furnace weighs 272 kilograms.

15. Is the furnace suitable for small and medium-sized metal processing enterprises?

Yes, the furnace is tailored for the needs of small to medium-scale metal processing enterprises, enhancing production efficiency and reducing labor costs.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited