Jewelry Faceting Machine

Superbmelt provide a one-stop service to solve any problems with your jewelry chain manufacturing line

The Superbmelt jewelry faceting machine is the universal help for self-alignment that is combined within the vertical as well as the horizontal head machines. It is quite simple and versatile in terms of its operations, and it produces greater work with a huge amount of profitability.

For longer life and interchangeable parts, they are built rigidly as this machine generally comes equipped with the additional motor being fixed with the main divider in terms of assembly with a separately adjustable speed controller for the rotational speed within the ring or the bracelet that lies under the protection of jewelry faceting machine. In order to cut the designs on every kind of jewelry named bangles, or rings, or even pendants, they can be crafted accordingly.

- Each time when you are cutting the stone, the repeated actions are thereby producing a similar effect here.

- You need not have to get the wheel reinvented for cutting out a round brilliancy. There is always the kind of referral point that can easily help you in guiding towards the cutting nature with the help of Superbmelt jewelry faceting machine.

- You will still be having a working machine in almost one year or even a decade, and more is what it means that these machines are reliable.

- If you are taking care of it in the best way, most of these machines will have a longer life, and reliability also includes the preciseness over the life of the machine with every included accessory that it has.

- You can easily cut out a stone here while comparing the machine’s beings about the greater challenges here in terms of speed. The machine is quite accurate here to help you in cutting out the perfect stone.

- Superbmelt jewelry faceting machine can help create the straightened faces on the rock along with holding it in the hands that are quite hard here.

- Cost is also among the deciding factors in addition to that of accuracy and speed. The amount of money that you will be paying will be the determining factor here.

- The production capacity is generally at number 5 making it highly reliable and the most cost-effective solution that is available easily.

| Model | SPB-2CSCM |

| Item | Parameter |

| Max. Chain Diameter | 12mm |

| Speed | 24000rpm |

| Voltage | 220V/380V 50Hz |

| Size | 70x85x150 cm |

| Weight | 500kg |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Jewelry Chain Making Line Solution

Any Question About SuperbMelt Jewelry Chain Making Line Solution

Complete Guide to Jewelry Chain Faceting Machines: From Principles to Model Selection

Introduction: Why Do Chains Need Faceting (Cutting/Engraving)?

In the jewelry industry, chains are not merely accessories that connect pendants; they are also key carriers of design aesthetics and perceived value. Faceting—also known as engraving or cutting—is the critical process that elevates a chain’s appearance and quality. Chain faceting refers to cutting precise planes, textures, or grooves onto the surface of chain links using specialized equipment, giving the chain a renewed visual effect and tactile quality. Its necessity and core value are reflected across multiple dimensions and have a profound impact on a jewelry brand’s market competitiveness.

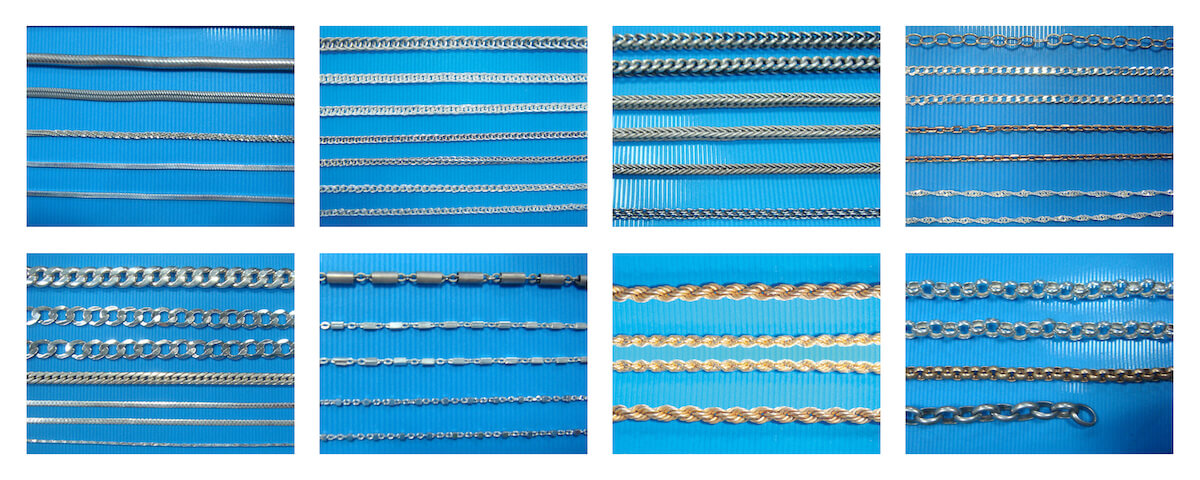

From an aesthetic standpoint, un-faceted chains typically have smooth or single-curvature surfaces with plain luster and limited visual depth, making them less eye-catching. After faceting, multiple reflective surfaces are formed on each link, creating multi-angle light refraction and sparkle. For example, classic side chains processed with diamond-cut faceting become significantly more three-dimensional and noticeably more brilliant under natural light compared to ordinary polished chains. Whip chains, when engraved with interlaced patterns, display a refined and vintage texture that complements various jewelry styles.

From a market-value perspective, faceting significantly increases the added value of a chain. Chains of the same material and thickness generally sell for 30%–50% more after precise faceting. This is because faceting adds production cost while also meeting consumer demand for high-quality, personalized jewelry. In the high-end jewelry sector, customized faceted chains have become an important tool for differentiation, helping brands establish strong identity through unique pattern designs.

Additionally, the faceting process improves practicality and durability. Well-designed facets can reduce the visibility of minor scratches, helping the chain maintain its shine during daily wear. Certain faceted textures can even increase surface friction, preventing links from loosening or slipping and enhancing wearing stability. Whether for mass-market fashion jewelry or high-end luxury pieces, faceting has become a core process for elevating chain quality and expanding consumer appeal.

What Is a Jewelry Chain Faceting Machine?

A Jewelry Chain Faceting Machine is a specialized piece of jewelry-processing equipment designed for performing precise cutting and polishing on the surface of chain links to create predetermined facets and patterns. It integrates core functions such as mechanical transmission, precision positioning, and cutting/polishing, and can carry out standardized or customized faceting on chains made from different materials (gold, silver, K gold, stainless steel, etc.) and different structures (side chains, cross chains, wheat chains, etc.). It is an indispensable key device in modern jewelry chain production.

The core working principle of a chain faceting machine is to use a power system to drive the cutting tool at high speed, while a clamping mechanism secures the chain and controls its feeding speed and motion path, allowing the tool to cut the surface of the chain links according to preset angles, depths, and patterns. The main components of the equipment include the power source (motor), cutting tools, clamping system, positioning device, and control system. Some high-end models are also equipped with automated monitoring modules to maintain real-time control over faceting accuracy.

Compared with traditional manual faceting, a professional faceting machine completely eliminates the problems of low efficiency, poor accuracy, and insufficient consistency associated with handwork. Manual faceting relies on the craftsman’s experience and technique, which is not only time-consuming and labor-intensive, but also makes it difficult to ensure that every chain and every individual link in mass production has precisely the same faceting effect. A chain faceting machine, however, achieves micron-level cutting precision through mechanical control, ensuring product standardization while greatly improving production efficiency—reducing work that once required hours of manual labor to just a few minutes.

Depending on production needs, chain faceting machines vary greatly in size and capabilities—from compact tabletop manual models suitable for DIY workshops, to fully automated CNC production lines for medium and large factories. But their core mission remains the same: to provide precise and efficient faceting, giving chains exquisite surface effects and enhancing the quality and value of jewelry products.

Types of Chain Faceting Machines

Jewelry chain faceting machines can be classified into several categories based on key features such as their level of automation and the number of spindles. Different types of equipment vary significantly in operating methods, processing efficiency, and application scenarios, making them suitable for production needs of different scales.

3.1, Manual Chain Faceting Machine

A manual faceting machine is the most basic type of faceting equipment, featuring a simple structure and relying entirely on manual operation. Its core characteristic is “full-process manual control.” These machines are typically compact, mostly in a tabletop design, lightweight, and easy to move. They are mainly composed of a hand-operated lever, a simple clamping platform, a fixed cutting tool, and a workbench. During operation, the worker must manually move the lever to control the chain’s feeding speed and cutting direction, while visually adjusting the faceting angle to complete the cutting process.

Its advantages include low cost and a low entry barrier, with equipment prices usually only a few thousand yuan, making it suitable for beginners with limited budgets or DIY hobbyists. The simple structure results in a low failure rate and almost negligible maintenance costs. However, the limitations are also very clear: processing efficiency is extremely low, with only 1–2 meters of chain processed per hour, making it unsuitable for mass production. Faceting precision relies entirely on the operator’s experience and skill level, leading to poor product consistency and common issues such as uneven facet depth or angle deviations. Long-term operation is also physically demanding and easily causes worker fatigue.

Manual faceting machines are mainly suitable for DIY studios, home workshops, or small-batch custom processing, and are only appropriate for lower-priced chains with minimal precision requirements.

3.2, Semi-Automatic Faceting Machine

A semi-automatic faceting machine is a transitional model between manual and fully automatic machines, with the core feature of “partial process automation with manual intervention for key operations.” The machine is equipped with a motor-driven cutting system and an automatic feeding device, allowing the cutting tool to operate at high speed while the chain is fed at a uniform rate, reducing manual labor. At the same time, it retains manual adjustment for facet angles, tool replacement, and chain positioning calibration, balancing automation efficiency with manual control flexibility.

The advantages of this type of machine lie in its high cost-performance ratio, combining efficiency and precision. Its processing efficiency is 3–5 times higher than that of manual machines, capable of handling 5–10 meters of chain per hour, with faceting precision errors controlled within 0.1mm, meeting the quality requirements of small to medium batch production. The operating difficulty is moderate, and workers can operate it after short-term training without needing specialized technical skills.

The limitations include restricted capability for processing complex patterns, making it unable to achieve high-precision custom faceting. In batch production, a certain number of operators are still required, so labor costs are higher compared to fully automatic machines.

Semi-automatic faceting machines are the mainstream choice for small jewelry factories, suitable for scenarios with moderate precision requirements and limited production scale. They can process common chain types such as side chains and cross chains.

3.3, CNC / Fully Automatic Faceting Machine

The fully automatic CNC faceting machine is the most technologically advanced and highly automated high-end model, with the core feature of “computer-programmed, fully automated processing.” Equipped with a professional CNC control system, the machine allows presetting processing parameters on a computer (such as facet angles, depths, patterns, feed speed, etc.). Once the program is input, the machine can automatically complete the entire workflow—including chain loading, positioning, cutting, polishing, and unloading—without manual intervention. Some high-end models also support 3D simulation processing, allowing the faceting effect to be previewed in advance and reducing trial-and-error costs.

Its advantages are remarkable:

Extremely high processing precision, with facet errors controlled within 0.01mm, capable of producing intricate and complex faceting patterns, such as diamond grids and spiral textures.

Impressive processing efficiency, able to handle 20–50 meters of chain per hour, and capable of 24-hour continuous operation, significantly improving production efficiency.

Excellent product consistency, ensuring that each chain link in batch production has identical faceting, meeting high-end market quality standards.

Flexible customization, as facet styles can be quickly switched by simply adjusting program parameters, supporting multi-variety, small-batch production.

The main limitations are high equipment costs—a high-end CNC faceting machine typically costs $42,000–$196,000 requiring a substantial initial investment. It also demands highly skilled operators, including professional CNC programmers and maintenance personnel. Maintenance costs are high, with core components such as precision motors and cutting tools being expensive to replace.

Fully automatic CNC faceting machines are mainly suited for medium to large jewelry factories, high-end custom brands, and OEM/ODM manufacturers.

3.4, Single-Spindle vs. Multi-Spindle

In addition to classification by automation level, jewelry chain faceting machines can also be categorized based on the number of spindles. The number of spindles directly determines the machine’s processing efficiency and the number of chains that can be processed simultaneously, making it a key factor affecting production capacity.

- Single-Spindle Faceting Machine: This type of machine has only one cutting spindle and can process only one chain at a time. It features a simple structure, stable operation, and easy setup, with more precise control over faceting accuracy. It is suitable for processing single high-precision chains. Its limitation lies in low processing efficiency, making it unsuitable for large-scale mass production. Single-spindle machines are commonly found in manual, semi-automatic models, and some high-end custom fully automatic models, and are ideal for small-batch, high-precision production scenarios.

- Multi-Spindle Faceting Machine: These machines are equipped with two or more cutting spindles. Common models have 2–6 spindles, while some large-scale machines can have 8–12 spindles, allowing multiple chains to be processed simultaneously. The main advantage is a multiple-fold increase in processing efficiency—for example, a 6-spindle machine can achieve six times the efficiency of a single-spindle machine—significantly reducing per-unit processing time and cost. Multi-spindle machines are suitable for large-scale standardized production, particularly for medium to large factories and OEM/ODM manufacturers with bulk orders. Their limitations include large size, high cost, and more complex setup. If one spindle malfunctions, it may affect overall production progress. High stability and synchronization are required; otherwise, inconsistencies in the faceting effect across multiple chains may occur.

Key Factors When Choosing a Chain Faceting Machine

When choosing a jewelry chain faceting machine, it is essential to consider your production needs, product positioning, and budget. Focus on the following seven key parameters, as they directly determine the machine’s processing quality, production efficiency, and long-term operating costs, making them critical factors in the selection decision.

4.1, Cutting Precision

Cutting precision is the core performance indicator of a faceting machine, directly determining the fineness and consistency of the chain’s facets. It is typically measured by facet angle deviation, depth error, and surface roughness. For high-end jewelry chains, the facet angle deviation should be controlled within ±0.1°, depth error within 0.01 mm, and surface roughness Ra ≤ 0.8 μm to ensure smooth, evenly reflective chain surfaces and avoid burrs or scratches.

When selecting a machine, prioritize the specified precision parameters and request sample processing from the manufacturer. Inspect the facet flatness and angle consistency under magnification. The positioning system (e.g., linear encoders, servo motors) directly affects precision stability. Machines equipped with high-precision servo motors and closed-loop control systems maintain accuracy over long-term use. High-precision machines are essential for luxury jewelry brands or customized products, while lower-cost chain production can tolerate slightly higher deviations, but errors should still be within 0.1 mm.

4.2, Cutting Speed & Efficiency

Processing speed, usually measured in meters per hour (m/h), is a key indicator of a machine’s production capacity, directly affecting order delivery times and production costs. Different types of machines vary significantly: manual machines process about 1–2 m/h, semi-automatic machines 5–10 m/h, fully automatic single-spindle machines 20–30 m/h, and multi-spindle automatic machines 50–100 m/h.

When selecting a machine, consider your order volume and delivery schedule. Small workshops or low-volume production do not require high-speed machines, avoiding wasted capacity. Medium to large factories or bulk orders require high-speed multi-spindle machines to increase output and reduce unit costs. Also, consider the “effective processing time”—actual production time after deducting tool changes, setup, loading, and unloading. Some machines may have high nominal speeds but low actual efficiency due to long auxiliary times.

4.3, Compatibility with Chain Types

Jewelry chains vary widely in structure, material, and diameter, including types like flat chains, cross chains, corn chains, and pearl chains, with materials such as gold, silver, and stainless steel, and diameters from 0.3 mm to 3 mm. Machine compatibility determines production flexibility.

High-quality faceting machines should support a wide range of chain types through adjustable clamping fixtures, cutting angles, and speeds. When selecting a machine, clearly communicate your core product range to the manufacturer (e.g., thin K-gold chains vs. thick stainless steel chains) and request a demonstration. Some specialized machines have narrow compatibility; for a diverse product line, choose a versatile multi-functional machine. If focused on a single chain type, a dedicated machine may offer higher efficiency and precision.

4.4, Tooling Options

The cutting tool is the core execution component in faceting. Tool material, type, and adaptability directly affect facet quality and tool life. Common materials include carbide, diamond-coated tools, and natural diamond tools. Carbide tools are cost-effective and suitable for ordinary metal chains. Diamond tools offer high hardness and wear resistance, ideal for hard materials (stainless steel, 18K gold) and high-precision faceting.

When selecting a machine, check the supported tool types and specifications, including compatibility with different angles (30°, 45°, 60°) and shapes (flat, round, groove). Consider tool replacement convenience and procurement costs; some niche machines require custom tools from the manufacturer, increasing long-term maintenance costs. Machines with widely available, standardized tools are preferable.

4.5, Clamping System

The clamping system secures the chain to prevent slippage during processing, directly affecting facet precision and surface quality. A high-quality clamping system should provide uniform clamping force to avoid chain deformation, smooth contact surfaces with soft pads (rubber, felt) to prevent scratches, flexible adjustments for different diameters and structures, and a wide clamping range covering the manufacturer’s main products.

During selection, test stability by lightly pulling the chain after clamping and observing any movement. Transparent protective covers allow monitoring during processing. Automatic clamping systems are more stable and efficient but costlier, recommended for mass production. Manual clamping may suffice for small-scale production to reduce equipment costs.

4.6, Control System

The control system is the “brain” of the faceting machine, determining operational convenience, processing flexibility, and precision stability. Manual machines rely on mechanical controls. Semi-automatic machines have simple CNC panels to adjust basic parameters like speed and feed. Fully automatic CNC machines use professional systems (e.g., Mitsubishi, Siemens), supporting programming, simulation, and parameter storage.

When selecting a machine, consider operator skill and production requirements. Small workshops or beginner operators may prefer simple mechanical or basic CNC systems. Medium to large factories and custom production require advanced CNC systems with G-code programming, graphical interfaces, and multiple parameter storage for quick switching between products. Stability and reliability are critical—choose reputable brands with solid after-sales support to avoid production interruptions.

4.7, Machine Stability & Build Quality

Machine stability and build quality directly impact long-term reliability and precision retention, often overlooked but crucial. The frame material, structural design, and assembly determine stability. High-quality machines use high-strength cast iron or welded steel frames, low center of gravity, and vibration resistance, ensuring minimal vibration during processing. Precision assembly with tight tolerances reduces noise and prevents loosening or deformation over time.

When selecting a machine, inspect frame materials and weld quality, and run the machine to check vibration and noise levels (≤75 dB is ideal). Evaluate key components such as motors, bearings, and guides—machines using reputable brands have longer lifespans and lower failure rates. Protective features, like fully enclosed shields, prevent debris from scattering, protect operators, and maintain a clean workshop environment.

Chain Faceting Effects Comparison

Different faceting techniques and equipment can produce distinct chain facet effects, matching various jewelry design styles and market positioning. Below is a comparison of mainstream facet effects in the market, along with their suitable applications, helping businesses choose the appropriate processing method based on product positioning:

Diamond Facet: Multiple diamond-shaped planes are cut on the chain links, one of the most classic facet styles. Features include multiple reflective surfaces and strong three-dimensionality, producing a dazzling sparkle under light. Suitable for precious metal chains like gold and K-gold, often used for main chains of high-end necklaces and bracelets. Manual, semi-automatic, and fully automatic machines can achieve this effect. Fully automatic machines produce more regular diamond angles, ideal for batch production.

Straight-Line Facet: Parallel straight lines are cut on the sides of the chain links, either longitudinal or transverse. Characteristics are simplicity, elegance, and smooth lines, fitting minimalist or modern jewelry styles. Common on flat chains, box chains, and other basic chain types. Processing difficulty is low, achievable with manual machines, making it suitable for small workshops and affordable jewelry production.

Spiral Facet: Continuous spiral patterns are cut on the chain surface, offering a unique, dynamic style. Suitable for personalized, fashionable jewelry, often used by niche brands or for customized products. This requires high precision and advanced control systems, achievable only with fully automatic CNC machines, as manual and semi-automatic machines cannot ensure continuous and uniform spiral patterns.

Grid Facet: A grid pattern formed by alternating diamond or square facets, creating a complex, premium texture with strong surface layering. Common in high-end luxury jewelry. Requires high-precision, multi-spindle, fully automatic machines. Processing is time-consuming and costly, suitable for flagship products of luxury jewelry brands.

Matte Facet: Using special tools (e.g., grinding wheels, sandblasting tools) to create a fine matte texture instead of a traditional smooth surface. Features include understated matte finish and warm tactile feel, effectively concealing minor scratches from daily wear. Suitable for vintage or light-luxury jewelry, common on silver or stainless steel chains. Processing difficulty is moderate; semi-automatic machines with dedicated matte tools can achieve it, while fully automatic machines can control the uniformity of matte granules for batch production requiring high consistency.

Groove Facet: Shallow or deep grooves are cut along the edges or surface of the chain links, such as single or double grooves, enhancing three-dimensionality and design appeal. It can also create a “slimming” visual effect, making thick chains appear lighter. Suitable for various chain materials and styles, requiring precise control of groove depth and width. Achievable with semi-automatic or fully automatic machines, ideal for regular product lines of mid-range jewelry brands.

How to Match a Machine with Your Business Size

Different scales of jewelry enterprises have vastly different production needs, budgets, and product positioning. Selecting a chain faceting machine must be “tailor-made” to avoid underutilization or overloading. Below is a detailed selection guide for different enterprise scales, with precise recommendations based on production scenarios and core requirements:

6.1 DIY / Small Workshops

Enterprise Characteristics: Extremely small production scale, usually home-based or operated by 1–2 people, focusing on small custom orders or handmade jewelry. Budget is limited (usually under RMB 10,000 / ≈ USD 1,400). Product positioning is low-cost or niche custom, with low output requirements but some flexibility needed.

Core Needs: Low cost, easy to operate, small footprint, capable of basic faceting, no batch production required.

Selection Recommendations: Prefer manual faceting machines, ideally desktop mini models:

Equipment cost: RMB 3,000–8,000 (≈ USD 420–1,120), within budget.

Compact size: ≤50cm×30cm×40cm, can be placed on a desk.

Equipped with basic tools (straight-line and simple diamond cutters) for straight or simple diamond facets.

Flexible clamping system: suitable for chains 0.5–2mm in diameter (e.g., silver or thin K-gold chains).

No complex installation, ready to use out of the box, simple manual, no professional training required.

Pitfalls to Avoid: Do not select used semi-automatic or fully automatic machines, as they have high maintenance costs, complex operation, and may have precision loss. Avoid machines with unnecessary functions (e.g., manual machines with multiple tool positions or CNC panels), which add cost without value.

6.2 Small Jewelry Chain Factories

Enterprise Characteristics: Fixed production space (50–200㎡), 5–20 employees, producing small-to-medium batches (50–200 meters/day), targeting mid-market (mall counters, e-commerce jewelry brands). Moderate budget: RMB 50,000–200,000 (≈ USD 7,000–28,000). Requires balance between quality and efficiency.

Core Needs: Moderate production efficiency, stable faceting precision, product adaptability, reduced labor costs.

Selection Recommendations: Prefer semi-automatic faceting machines; 1–2 machines can form a small production line:

Production efficiency: 5–15 m/h, meeting daily output requirements.

Faceting precision: 0.05–0.1mm error, capable of diamond, straight-line, and groove facets.

Adaptability: Swappable fixtures and tools for 0.3–3mm chains, including flat, box, and corn chains.

Ease of operation: Simple CNC panel for preset parameters (speed, facet depth); workers can operate independently after 1–2 days training.

Durability: Core components (motor, rails) from well-known domestic brands; MTBF ≥5,000 hours.

Upgrade Option: For occasional custom orders, add 1 small fully automatic CNC machine (budget RMB 100,000–150,000 / ≈ USD 14,000–21,000) to handle high-precision customized orders while the main line uses semi-automatic machines for batch production.

6.3 Medium-to-Large Factories

Enterprise Characteristics: Large scale (≥200㎡ workshop), 20–100 employees, daily output 200–1,000 m, covering mid-to-high-end markets, some export overseas. High precision, efficiency, and stability required. Budget: RMB 200,000–1,000,000 (≈ USD 28,000–140,000). Need standardized large-scale production with fast product model switching.

Core Needs: High efficiency, ultra-high faceting precision, multi-product adaptability, 24-hour continuous operation, reduced unit cost, meeting large order and fast delivery requirements.

Selection Recommendations: Prefer multi-spindle fully automatic CNC machines, with 3–6 production lines:

Production efficiency: Multi-spindle (4–6 spindles) 30–60 m/h per machine; multiple lines satisfy daily output; unit processing time 1–2 min/m.

Faceting precision: ≤0.01mm error, supports spiral/grid facets; surface roughness Ra ≤0.4μm.

Automation: Automatic feeding, unloading, tool change; CCD visual inspection for quality control.

Control system: Mitsubishi or Siemens high-end CNC; supports G-code, 3D simulation; stores >100 parameter sets; product switching ≤10 min.

Stability: High-strength cast iron body, vibration-resistant, noise ≤70dB, water cooling, 24h operation, MTBF ≥10,000 h.

Support Recommendations: Integrate automated logistics (conveyors) connecting forming, faceting, polishing, and plating for fully automated production. Employ 1–2 maintenance specialists for stable operation.

6.4 OEM / ODM Factories

Enterprise Characteristics: Mainly brand subcontracting (international or top domestic jewelry brands), handling diverse orders (batch + custom), requiring high precision, consistent faceting, rapid response, flexible production, strict cost and delivery control. Budget: unlimited, scalable with order volume.

Core Needs: Extreme faceting precision, full product coverage, rapid order response, traceable production process, meeting strict brand standards.

Selection Recommendations: Combination of multi-spindle fully automatic CNC machines + high-end custom machines:

Main equipment: 4–8 spindle fully automatic CNC machines (imported or high-end domestic), 50–80 m/h, faceting error ≤0.005mm, ISO9001/SGS certified.

Custom equipment: 1–2 high-end CNC machines supporting special tools (natural diamond cutters) and complex 3D or brand-specific facets.

Smart features: Industrial IoT for real-time production monitoring (quantity, precision, machine status) for full traceability.

Flexible production: Fast switching between products (<5 min), supporting multi-product, small-batch OEM/ODM production.

After-sales service: 24/7 on-site support; core components warranty ≥3 years.

Cost control: Bulk procurement discounts, long-term maintenance contracts, optimized scheduling for ≥90% equipment utilization to reduce unit cost.

FAQ Guide of Jewelry Faceting Machine

- 1. What is a jewelry chain cut faceting machine?

- 2. Application field of SuperbMelt jewelry chain faceting machine?

- 3. What are the safety features of jewelry chain faceting machines?

- 4. Do operating SuperbMelt jewelry chain faceting machine require special training?

- 5. How to produce jewelry chains nowadays?

- 6. How does the SuperbMelt jewelry chain faceting machine work?

- 7. How long does it take to facet a gemstone?

- 8. What does faceting mean?

- 9. What does a faceting machine do?

- 10. What materials can the SuperbMelt jewelry chain faceting machine be used for?

- 11. How do you clean a jewelry chain faceting machine?

- 12. How durable is a jewelry chain faceting machine?

- 13. What machines are used to make jewelry chains?

- 14. Does a jewelry chain lose gold when cutting facets? How to collect this gold?

- 15. How to choose the best jewelry chain faceting machine manufacturer?

1. What is a jewelry chain cut faceting machine?

For years, humans have been using different tools and technologies for marking, cutting, forming, cleaning, welding, and engraving jewelry. Now, jewelers have moved from depending on the traditional hand tools to advanced faceting equipment. This machine has brought a great revolution in the field of making gold chains. Using this machine, you can attain more efficient, precise, customized, and accurate cuts.

When you have the best jewelry chain faceting machine, you can easily carry out different processes, such as creating accurate lines, lapping, plain cuts, chamfers cut, and more. All you need to program the device based on your finishing or cutting requirements, and you are ready to go. These machines are quite popular among jewelers to give a stunning decoration to gold as well as the silver chain. As a result, they attract more customers to buy jewelry pieces.

If you want to buy a good quality machine under your budget, then it is time to contact SuperbMelt. Our machines are manufactured under expert guidance and have superior quality components. What’s more? In order to meet the unique quality requirements of different buyers, all the machines are tested under multiple quality-control tests. Talking about some amazing features of this machine. The list includes:

- Smooth finishing

- Quality and reliable performance

- Impressive strength

- Creates stunning designs

- Less maintenance and better service life, and more.

2. Application field of SuperbMelt jewelry chain faceting machine?

Most of the jewelers are now using the best faceting machines to carry out different tasks such as polishing, lapping, and more. For example, you can use this to attain the desired level of shininess in the jewelry created using different base materials, for example, brass. Polishing and lapping using a faceting machine can provide you with a good cosmetic surface for a high-quality fold plating process.

What’s more? Sometimes, you may need to create bevels on the chain to make it appear more beautiful. For this, you can also use a faceting machine. Such a machine can easily create multi bevels designs around the edge of the chain for a unique shape.

Apart from all these things, you can use this to create plain cuts, straight or customized lines, chamfer cuts, and more.

3. What are the safety features of jewelry chain faceting machines?

Anyone working around or with the machinery needs to always remain alert towards the possible dangers at all times. With time, machines are getting more complicated and high-tech. After all, you are now witnessing Industry 4.0. So, to keep the process of jewelry making safe, you need to buy a machine with maximum safety features.

Choose a chain faceting machine with a speed adjustment feature so that you can attain the desired speed for cutting and polishing. Besides, it is advisable to buy a machine that has a robust and completely sealed structure to keep yourself protected from the machine’s moving parts.

What’s more? Some machines come with motors that adopt step-less speed modulation technology. For accurate cutting of gold chain, go for a faceting machine with such a feature. Some gold chain-making machines have an automatic cooling system. A machine equipped with such a system can perform 24×7, and you don’t have to worry about the overheating issue.

4. Do operating SuperbMelt jewelry chain faceting machine require special training?

SuperbMelt is one of the trusted and reputed manufacturers as well as suppliers of different types of chain-making machines. We offer a casting machine, roll mill, drawing machine, jewelry chain making machine, hammering machine, and jewelry faceting machine.

We are committed to supplying highly reliable and effective machines that are designed with superior quality raw materials and advanced technology. All our machines are known for their amazing features, for example, noise-free operation, high operation, amazing level of precision, perfection, long machine life, and rugged design.

Speaking about the usability of the machine, even though our chain faceting machine comes equipped with the latest technology, you will not find them complex to use. One can use the machine without going through any special training.

Our quality machines are perfect for every business dealing with the jewelry industry. Most of the machines are designed to carry out the process automatically so that you can enjoy a perfect product. They meet the required industrial quality requirements and are safe to use. To know more about our automatic faceting machine to get a free quote, you can visit our official site and contact our executives.

5. How to produce jewelry chains nowadays?

During ancient times, manual processes were used to make jewelry chains. But those were very time taking processes, and creating a chain with a simple design, it can take months. Well, things have now changed, and now you can make chains with complex designs within a few hours or days using jewelry chain-making machines, including chain faceting machine. Let’s talk about today’s jewelry chain-making process.

- Getting pure gold

Before you can start the chains-making process, you need to obtain pure gold with the desired level of purity. But how to do that? You can use a furnace or crucible to meld gold. Gold ores are melted to get gold. SuperbMelt suggests using an induction furnace and a quality graphite crucible for this process. Once done, you need to purify the gold and make gold bars or rods, to begin with, the jewelry chains making process.

- Making gold rod

The next step is to make a gold rod from the gold bar or gold. Here, most jewelers use a continuous casting machine of SuperbMelt. We have manufactured this machine using the latest technologies, durable materials, and you can make gold rods with the desired shape. You can go for a circular shape, rectangular, cylindrical, and more shapes using this single machine.

- Making thin wire from the rods

As you can use gold rods to make chains, you need to create thin wires from that gold rod. This is where you can use our high-quality rolling mill. Fed the rod into the machine, and it will convert that into a thin wire. It creates accurate pressure, and you will get gold wire with a shiny mirror effect and a smooth surface.

- Lowering the wire diameter

Now, you need to further process the wire to create a thin wire. Instead of using any manual method, you can use a jewelry chain drawing process to get this done faster. Once you obtain the desired diameter, you can use that to make chains.

- Making chains

Nowadays, jewelers use a chain-making machine to make chains from different materials. For example, SuperbMelt’s chain-making equipment. This is quite versatile, and you can make different types of chains, such as snake chains, box chains, rope chains, and more, using this single machine. This machine can also be used to make double chains, and anchor chains.

You have successfully made a jewelry chain. Well, the process doesn’t end here. You need to make sure the chain is in the right shape. If not, then use a jewelry hammering machine to perfectly bind the gold parts for a perfect shape. It is very easy to use the machine. All you need to configure it, and the hammering machine will carry out the process automatically. Once done, you can use a chain faceting machine to cut the chain and get perfect shininess.

By using all these machines, you can make durable gold chains faster and without making any errors. Besides, you will enjoy the freedom of creating chains of any design. But for maximum benefits and features, you should buy a high-quality machine, and this is where SuperbMelt comes to play. Be it a continuous casting machine or a chain faceting machine, SuperbMelt has everything for you.

6. How does the SuperbMelt jewelry chain faceting machine work?

To understand the working principle of a jewelry chain faceting machine, let’s understand how does a normal faceting machine work. In general, every faceting machine comes with two important components.

One is the grinding wheel or a lap, and another one is mast or head assembly. Now talking about the process, a rough piece of gemstone or a chain is carefully attached to the head section.

Through rotation, angle, and adjustments of the head height, the object is gradually lowered into contact with the wheel until the facet has been ground. SuperbMelt’s faceting machine follows the same working process while working with a gold or silver chain.

7. How long does it take to facet a gemstone?

Well, this will depend on the size and design of the gemstone. However, in general, to facet a simple round gemstone, the process can take one to 2 hours. If you are faceting an ovals styles gemstone, the process may take around one to two and half hours. As per the experts, a medium sort of stone can take up to eight hours. Some other stones, such as sapphires, can take more time as such gemstones are very hard.

8. What does faceting mean?

In simple words, faceting means removing excess parts from an object without affecting the original shape of the product. Using the faceting method, you can create lines, cuts, and patterns on the object.

9. What does a faceting machine do?

The primary purpose of a faceting machine is to facet and polish the gemstone or jewelry chain at the same time. This way, you will save time as well as efforts that are required to polishing laps and inter-changing grinding on the single-wheel design.

10. What materials can the SuperbMelt jewelry chain faceting machine be used for?

SuperbMelt’s jewelry chain faceting machine can be used for the materials that you normally utilize to make jewelry chains. Speaking about some common materials that the machine can process are:

- Gold

It is a fact that more than 60 percent of gold is utilized to make jewelry. But the quality of the gold that generally use to make jewellery is not 100 percent pure. Why? It is very soft, and the hardness level of 100 percent pure gold is around 2.5 to 3 on the Mohs Hardness Scale. That’s why jewelers use 14K, 18K, 16K, or 21K gold to make gold chains. Various alloys are combined with gold to make it durable. However, SuperbMelt’s faceting machine can easily process all these types of gold.

- Silver

The machine can also use for a silver chain. Silver is a well-known metal, but jewelers don’t use 100 percent pure silver as this is very soft. In fact, it is softer than platinum and gold. So, jewelers normally add around 7 to 8 percent copper to enhance its hardness, brightness, and luster. That’s why the maximum purity level of silver is 92.5 percent, and it is generally called 925 silver.

- Copper

Copper is made into brass and bronze. In this case, the proportion of copper and the presence of other metals will determine how it will look. Compared to other metals such as gold or silver, copper is a little durable and can last for years. Our machine can be used to cut and polish copper-made chains.

- Platinum

Another common material that SuperbMelt’s faceting machine can process is platinum. Platinum is very durable, and it doesn’t tarnish. Don’t think that our machine can’t process it as this material is very dense. Equipped with advanced technologies, our face cutting machine can handle different metals. If you are looking for one of the best faceting machines, SuperbMelt has the best model for you.

11. How do you clean a jewelry chain faceting machine?

As all the bearings are properly lubricated and sealed, you don’t have to worry about the oiling of the bearing on SuperbMelt’s faceting machine. Now, talking about the cleaning of the machine, you need to clean it very often as such machines are built to precision, and you want to maintain that level. To clean the machine, you can use a dental brush or a soft-bristled paintbrush. The major areas on the machine that you should clean are the index gear and hard-to-reach sports on the faceting head and the base.

To clean the index gear, utilize a dental brush and carefully brush in between the teeth. Make sure that there is no swarf in gear. After that, use a small paintbrush and clean out all the loose particles.

Some parts, like the splash pan on a faceting machine, are easily removable. So, you can remove that and properly rinse it out, then put it back in place.

12. How durable is a jewelry chain faceting machine?

Well, a good faceting machine should be durable enough to process both silver and gold chains. Besides, you need to make sure that every time you cut the chain; you are getting the same effect. You don’t have to set the machine every time you want to cut a fine line. When it comes to buying a durable machine, you trust the machine available at SuperbMelt.

Our machine is made of high-quality metal and can keep functioning for years without developing any issues. Have a look at the faceting machines for sale and place your order now. For more information about our machines, please feel free to contact our experts anytime you want.

13. What machines are used to make jewelry chains?

Nowadays, most of the jewelers use advanced machines to make stunning jewelry pieces. For example, a jewelry faceting machine. Well, the jewelry-making process also involves some other machines. Let’s have a look at those machines.

- Continuous casting machine

The first machine that is used in the process is a continuous casting machine. This particular machine is used to cast melted gold into a rod. SuperbMelt’s machine comes with a gas insert melting protection technology to produce accurate as well as automate temperature control during the process.

- Jewelry roll mill

Once a gold rod is created, you need to convert that into thing wires. This is where you can use a jewelry roll mill machine offered by SuperbMelt. The machine can effectively roll the rods and offers you a thin wire.

- Wire drawing machine

SuperbMelt’s wire drawing machine can be used to create thin wire from a thick wire under the drawing process. You can easily get the desired standard of gold wire to produce the jewelry.

- Jewelry chain making machine

Once you are done with the wire making, you can use this machine to make a jewelry chain. All you need to insert the wire into SuperbMelt’s jewelry chain-making machine, and the machine will carry out the task. This single machine can handle cutting, welding, winding, and other important processes to make durable gold or silver chains.

- Jewelry hammering machine

After making the chain, you need to make sure that the chain is in the desired shape. If not, then you can attain the shape using our hammering machine. Insert the chain into the machine and attain the targeted shape within a few hours.

- Jewelry chain faceting machine

A chain faceting machine is used to attain a perfect finishing. Using this, you can get a good quality mirror finish lapping, lines, stars, accurate chamfers cut, plain cut, and more.

If you are looking for a reliable platform to buy all these machines, including a facet cutting machine under your budget, then don’t think much and get in touch with SuperbMelt now.

14. Does a jewelry chain lose gold when cutting facets? How to collect this gold?

Well, during the chain-making process, the gold chains lose gold. The road is processed to create a chain, and during the process, you may lose gold. This is quite common if you are using a manual method to make chains. In general, thin the jewelry casting process, the portion of unused casting can be more than the finished product.

To collect the unused gold or gold dust, you can simply clean the table on which you are making, and then you need to separate the gold dust from other things, like dust. However, if you are using a gold-making machine, you may not lose gold when cutting facets.

The machine used an advanced software program to offer you an accurate cutting process, preventing loss of gold. Besides, some machine comes with built-in gold particles collecting unit. If you want to buy the best faceting machine, then it is advisable to get in touch with SuperbMelt now. Check out our faceting machines for sale offer to get one at a discounted price.

15. How to choose the best jewelry chain faceting machine manufacturer?

Buying a jewelry faceting machine means you are making a huge investment, and for that, you need to make sure that you are buying it for a reputed manufacturer and supplier. So, how to choose the best manufacturer. Here are some factors that you should consider.

- Experience of the manufacturer

Before choosing a manufacturer, always check their experience in the industry because only a highly experienced manufacturer can offer you quality jewelry faceting machine supported by a robust R&D.

- Technical support offered by the manufacturer

Make sure that the company offers great technical support. These machines can develop technical issues while functioning. You should resolve them as soon as possible. A manufacture with a robust technical support team can help you in that, and you can enjoy an uninterrupted production process.

- Don’t forget to check the reputation of the brand

Before making your purchase, you prefer to check the reputation of the company in the industry. But how to check it? Well, you can go through the review posted online by the clients who have used their machines. However, you can always trust SuperbMelt to buy a good quality automatic faceting machine. The company is an AAA accredited company, and we follow a strict machine manufacturing procedure to make durable machines.

- Always pay attention to details

You need to make sure that the machine can provide the users with accurate perfection, long service life, high operation, utmost precision, and more. Besides, you should also consider some other features, like noise-free operation and rugged design. Well, SuperbMelt’s automatic faceting machine is created using solid metals, and it meets the necessary industrial quality standards.

Keep all these things in your mind, and you will be able to choose the best jewelry faceting machine manufacturer to buy the machine.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited