Jewellery Manufacturing Machines

SuperbMelt offers a range of product assembly line equipment (jewelry, coins, necklaces, rings)

Professional Production Line Machinery Solutions for Jewelry, Coins, and Rings

SuperbMelt offers a range of product manufacturing equipment that covers the production of various items, including jewelry, rings, necklaces, and coins.

Whether you are a gold prospector, a small to medium-sized jewelry business, or a new jewelry entrepreneur, we have professional training programs to help you address all your product manufacturing needs.

SuperbMelt specializes in jewelry manufacturing machines and coin production equipment, with highly specialized equipment and a professional training team.

Throughout the jewelry and coin industry, SuperbMelt provides top-notch production equipment and an after-sales team to assist you in bulk production.

SuperbMelt ring, necklace, coin production line equipment

Ring production line equipment

SuperbMelt employs a precise and innovative process for crafting exquisite jewelry rings. This involves the use of specialized machinery, each serving a crucial purpose in the production line:

3D Jewelry Scanner: Our 3D scanner captures intricate design details and the ring’s shape with exceptional precision. This technology ensures that even the most complex and intricate designs are accurately replicated.

3D Wax Printer: The 3D wax printer takes the digital designs and turns them into tangible wax models. This step is vital for ensuring that the design’s intricate details are accurately translated to the physical model.

Plaster Mixer: The plaster mixer is used to create a precise and durable mold for casting. It ensures that the mold material is thoroughly mixed and free of air bubbles, which is crucial for creating high-quality rings.

Wax Burner: The wax burner is essential for creating the wax models of the rings. It allows us to mold and shape the wax to form the basis for the final ring.

Casting Machine: The casting machine is where the magic happens. It’s used to pour molten metal into the plaster mold created earlier. This process allows us to transform the wax model into a stunning, solid metal ring.

These machines collectively form the backbone of our jewelry manufacturing process. They enable us to seamlessly transform digital designs into tangible, beautiful jewelry pieces, ensuring precision, accuracy, and quality at every step of the way. The result? Exquisite rings that meet the highest standards of craftsmanship and artistry.

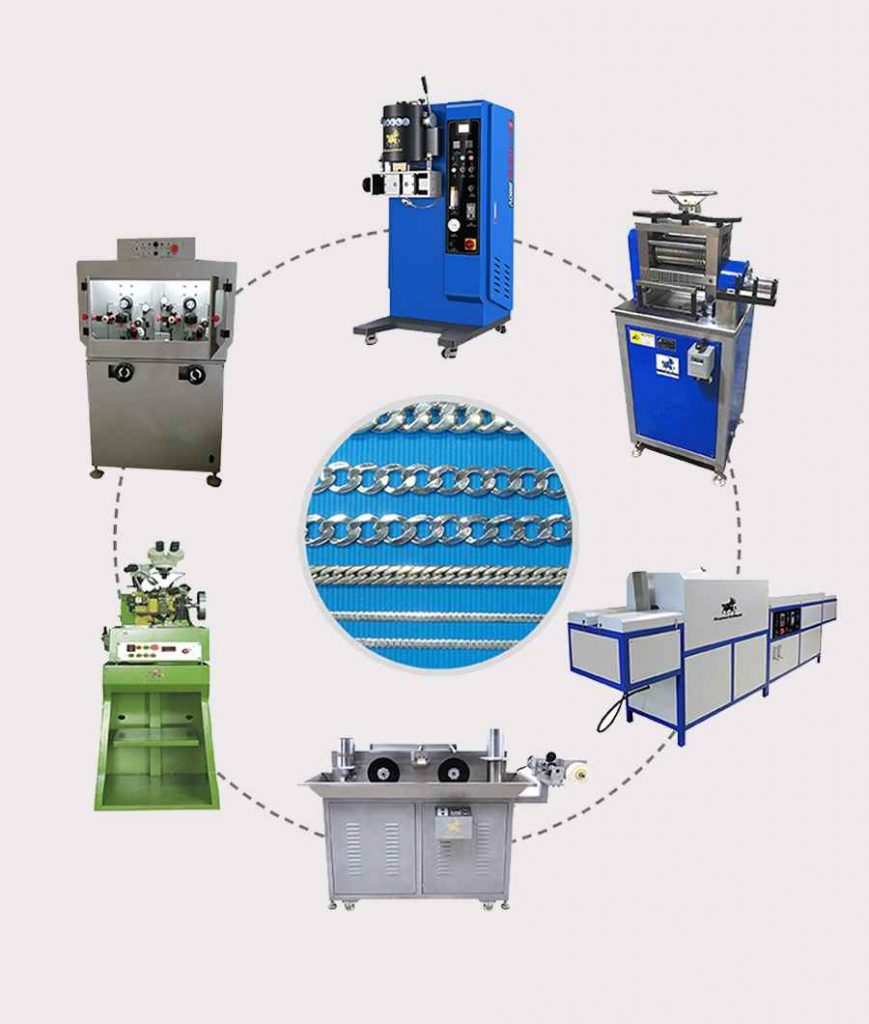

Necklace Production Line Equipment

At SuperbMelt, we employ a highly precise and innovative process to craft exquisite jewelry necklaces. This process relies on specialized machinery, with each machine playing a crucial role in our production line:

Vertical Continuous Casting Machine: The continuous casting machine is used to inject molten metal material into specific-shaped continuous casting billets for subsequent processing. It serves as the starting point for necklace manufacturing, ensuring the purity and uniformity of the metal.

Hydraulic Press: The hydraulic press is employed to compress the continuous casting billets into the desired shape and size. This step is vital to ensure the accuracy and durability of the metal portion of the necklace.

Wire Drawing Machine: The wire drawing machine is used to draw the metal billets into wires of the required diameter and texture. This is a critical component of necklace chains, demanding high precision.

Annealing Furnace: The annealing furnace is used to heat and cool metal wires, enhancing their ductility and malleability. This is crucial for bending and shaping the necklace.

Chain-Making Machine: The chain-making machine shapes the metal wires into the intricate details and structures that form the necklace chain. It’s the final step in creating the necklace, ensuring uniformity and quality.

These machines collectively form the backbone of our jewelry necklace manufacturing process. They guarantee the accuracy, durability, and aesthetics of the metal portion, resulting in high-quality jewelry necklaces. Each machine plays a critical role in different stages of manufacturing, ensuring the final product is both exquisite and long-lasting.

Coin Production Line Equipment

SuperbMelt employs a range of specialized machines, each playing a crucial role in coin manufacturing, to create stunning coins or colored coins:

Vertical Continuous Casting Machine: The continuous casting machine is used to melt high-quality metal material and inject it into molds of specific shapes, forming the foundation of the coins. This ensures that the metal part of the coin possesses outstanding quality and uniformity.

Hydraulic Press: The hydraulic press is employed to compress metal billets into the required shape and size for coins. This step is vital to ensure the accuracy and durability of the coins.

Embossing Machine or UV Printer: The embossing machine is used to add intricate designs and patterns to the surface of the coins, while the UV printer is utilized for coloring. Both contribute to giving the coins a unique appearance and character.

Annealing Furnace: The annealing furnace is used to heat the coins to increase their toughness and ductility. This is crucial to ensure that the texture and shape of the coins meet requirements.

These machines work in close coordination, forming the core of the coin manufacturing process. They guarantee the quality and accuracy of the metal part of the coins and imbue them with a distinctive appearance and value. Whether producing standard coins or colored ones, each machine plays a pivotal role at different stages of manufacturing, ensuring the final coins are both exquisite and durable.

Creating Excellence in Jewellery Manufacturing Equipment with SuperbMelt

We at SuperbMelt are experts in designing finely built jewellery making equipment. Our equipment is made to meet the wide range of requirements of the jewellery business, from making magnificent coins to creating exquisite necklaces and rings.

For the creation of necklaces, our cutting-edge machinery guarantees the highest standards of quality and accuracy. We provide a wide selection of jewellery manufacturing equipment to make necklaces that are both attractive and strong, ranging from continuous casting machines to wire drawing machines.

Rings: Exquisite precision is needed to create elaborate and personalised rings. Each ring manufactured by SuperbMelt is guaranteed to exceed the greatest levels of craftsmanship and creativity thanks to the company’s equipment, which includes 3D jewellery scanners and casting machines.

Coins: Accuracy and quality are critical while producing coins. We have the tools necessary to create genuinely remarkable standard and coloured coins, including hydraulic presses, embossing equipment, and UV printers.

Customise Your Production Line: We are aware that every jeweller has specific needs. Because of this, we give you the option to modify your production line to suit your unique requirements. If you want to create necklaces, rings, or coins, SuperbMelt has the know-how and equipment to make it happen.

Experience the difference in quality, accuracy, and personalization when you choose SuperbMelt for your jewellery making equipment. With our cutting-edge technology and unrivalled industry knowledge, take your jewellery creation to new heights.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Jewelry Crafting Guide by Type

Rings — In-Depth Manufacturing Guide (Example: Gold Ring)

Full Process and Equipment:

① Model Creation (CAD or Scanning)

Use CAD software such as Rhino, MatrixGold, or ZBrush to design the ring model, or use the SuperbMelt 3D laser scanner to scan a physical ring and generate a high-precision STL file.

② 3D Printing (Wax Pattern Formation)

Import the STL file into a 3D printer for wax model printing. Depending on precision and application, you can choose from:

4K Printer: Standard resolution (~50μm), ideal for daily wear styles;

8K Printer: High resolution (≤25μm), capable of extremely fine details, suitable for relief and micro-setting;

Wax Printer: Designed for lost-wax casting, leaves no residue after burnout, ideal for gold and platinum rings;

Resin Printer: Good for non-precious metal jewelry that will be electroplated and worn directly.

③ Burnout & Mold Creation (Investment Process)

Mount the wax ring models on a wax tree, embed them into a flask with investment powder, then place the flask into the SuperbMelt burnout furnace, gradually heating to 750~850°C to remove the wax and create a clean cavity.

④ Melting & Vacuum Casting

Melt gold in the SuperbMelt induction melting furnace (2–5 minutes), then pour the molten metal into the mold using the SuperbMelt vacuum casting machine.

⑤ Cutting & Initial Polishing

After casting, cut the individual rings from the “ring tree” using clippers, then polish using an electrolytic polishing machine to remove oxidation and brighten the surface.

⑥ Automatic Stone Setting

Use the SuperbMelt automatic stone setting machine to inlay diamonds or other gemstones precisely.

⑦ Finishing & Quality Inspection

Apply additional finishing like brushing or electroplating (gold/rhodium) as desired, clean thoroughly with an ultrasonic cleaner, and manually inspect the stone setting and polish quality.

Necklaces — Deep Process Guide (Example: K Gold Necklace)

Process & Key Equipment:

① Use a wire rolling machine to reduce precious metal to the desired wire diameter.

② Feed the wire into a chain-making machine (O-link, box chain, snake chain, etc.) to produce the chain structure.

③ To diversify the chain styles, use a faceting machine to create decorative cuts on the surface.

④ Use a multi-tank electro-polishing system to clean and finish the K gold surface.

Bracelets — Deep Process Guide (Example: Sterling Silver Bracelet)

Detailed Process & Equipment:

① Material Preparation & Forming

Use a wire drawing machine and rolling mill to reduce silver bars to the correct wire size, then shape using a forming press.

② Module Assembly & Welding

For segmented chains, use CNC stamping molds to shape links and join them with a silver soldering gun or spot welder.

③ Engraving & Surface Texturing

Use a CNC engraving machine or laser engraver to apply custom designs or inscriptions.

④ Surface Treatment & Finishing

Use magnetic polishers, tumbler machines, and hand buffing tools.

For antique-style finishes, oxidize with a surface oxidation furnace before buffing.

⑤ Electroplating & Stone Setting

Electroplate with silver or gold, and use an automatic stone setting machine to inlay zircon, crystals, etc.

Pendants — Deep Process Guide (Example: 3D Relief Pendant)

Steps:

① Design & Sculpting

Create 3D relief models using ZBrush, then print with a SuperbMelt high-precision SLA printer.

② Burnout & Casting

Invest and cast the wax model using a vacuum casting machine.

③ Detail Finishing

Use micro-grinders and needle polishing tools to refine relief edges and transitions.

④ Personalized Finishing

Apply brushed, sandblasted, or colored finishes using electroplating and texture machines.

⑤ Loop Welding & Inspection

Attach loops using a spot welder, and inspect with a digital magnifier.

Earrings — Deep Process Guide (Example: Gemstone Stud Earrings)

Step-by-Step:

① Model Design & Printing

Design the earring and setting in CAD, print with a SuperbMelt SLA wax printer.

② Casting the Main Body

Follow the standard investment → burnout → casting process.

③ Post Attachment

Cut stainless or metal wire using a wire cutting machine, and weld to the earring body with a laser welding machine.

④ Polishing & Plating

After initial polishing, apply a protective or K gold layer with an electroplating system.

⑤ Stone Setting & Packaging

Inlay gems using an automatic setting machine, then pack with a clean room packaging unit.

FAQ Guide of Jewellery Manufacturing Machines

1. What equipment do I need to start making jewelry?

Before starting jewelry making, it’s important to know what type of jewelry you plan to create, as different kinds require different machines.

Basic Jewelry Making Machines:

These machines are suitable for beginners and cover the fundamental steps in jewelry production:

Melting Furnace: The melting furnace is the first core step in jewelry making. It determines the metal’s purity, flow, and the quality of the final piece.

Casting Machine: The casting machine turns your design into a physical piece, controlling the shape, details, and overall quality of the jewelry.

Rolling Mill: The rolling mill transforms metal ingots into workable materials, essential for rings, chains, and settings.

Wire Drawing Machine: This machine converts metal into wires, which are indispensable for making chains and other jewelry components.

Annealing Furnace: The annealing furnace restores the metal’s softness and ensures smooth processing, often used in conjunction with rolling, wire drawing, and shaping.

Polishing Machine: The polishing machine gives jewelry its final shine and texture, determining the appearance and quality of the finished piece.

Specialized Jewelry Making Machines:

These machines are used for specific tasks or advanced production, often suited for bulk production or complex designs:

Chain Making Machine: Converts metal wire into finished chains and can produce various styles such as box chains, snake chains, O chains, and Rolo chains. It is essential for mass-producing necklaces and bracelets.

Wax Setting Machine: Precisely fixes gemstones, diamonds, or decorative pieces onto wax models before casting, preparing them for high-quality, consistent production—especially for complex designs.

3D Printer: Prints high-precision wax or resin models directly from design files, accurately reproducing intricate details. It allows rapid prototyping, easy design modifications, and the creation of complex structures that are difficult with traditional methods. Printed models can be used for batch casting, saving materials, reducing costs, and improving efficiency.

3D Scanner: Digitizes physical jewelry or models into high-precision 3D files, capturing every detail and dimension. It enables replication, customization, and design verification, ensuring accuracy for casting and machining. The scanned models can also be directly used for 3D printing or CAD/CAM processes, improving productivity and precision, especially for custom or complex designs.

These are just some common jewelry-making machines. There are also other machines used in jewelry production, such as laser welding machines, laser engraving machines, CNC engraving machines, and bead chain-making machines.

2. What supplies do I need to start a jewelry business?

1. Jewelry Type and Business Scale Classification

A. Small Handcrafted or Startup Workshop

Suitable for: Rings, earrings, pendants, bracelets, and other handmade or custom jewelry.

Required equipment/tools:

Basic tools: pliers, scissors, files, hammers, sandpaper, tweezers, etc.

Small melting furnace or portable casting equipment

Small polishing or grinding machine

Handcraft materials: metal sheets, silver wire, copper wire, gemstones, alloys, wax models, etc.

Safety gear: gloves, goggles, masks

Basic packaging materials: jewelry boxes, small pouches, display stands

B. Medium Workshop / Small Production Factory

Suitable for: Batch production of necklaces, rings, bracelets, and simple gemstone-set jewelry.

Required equipment/tools:

Medium melting furnace + vacuum or centrifugal casting machine

Rolling mill and wire drawing machine (for chains and metal wires)

Annealing furnace (to ensure metal ductility and smooth processing)

Medium polishing machine or vibration polishing machine

Chain making machine (for mass chain production)

Basic 3D printer (for rapid prototypes or wax models)

Wax setting machine (for batch gemstone setting)

C. Large Production Factory / Professional Jewelry Factory

Suitable for: High-end jewelry, large-scale gemstone-set jewelry, precision custom pieces, platinum or diamond jewelry.

Required equipment/tools:

Industrial melting furnace and casting machine

Automated rolling mill, wire drawing machine, and annealing furnace

Industrial polishing machine and ultrasonic cleaning machine

Fully automatic chain making machine and wax setting machine

High-precision 3D printer + 3D scanner (for complex designs or custom production)

CAD/CAM system (digital design and batch production)

Large quantities of raw materials (precious metals, gemstones, diamonds, semi-precious stones)

Packaging and quality inspection equipment

2. Other Essential Supplies (for all scales)

Safety equipment: gloves, goggles, masks, fire protection

Packaging materials: jewelry boxes, pouches, tags, instruction manuals

Design and documentation: sketchbooks, computer design software (e.g., Rhino, MatrixGold)

Sales and marketing: e-commerce accounts, website, social media, photography equipment

Summary:

Small startup workshop: Relies mainly on hand tools and small equipment, low investment, flexible customization.

Medium workshop: Requires basic mechanized equipment, suitable for small batch production.

Large factory: Needs full professional equipment and digital systems, capable of high-precision mass production.

3. What is the future of the jewelry industry?

Jewelry has always been a symbol of beauty, status, and personal expression. As consumer preferences evolve and technology advances, the industry is entering a transformative era.

The future of the jewelry industry will be shaped by digital innovation, sustainability, and personalization. Advanced technologies like 3D printing, CAD/CAM design, and CNC machines are enabling more precise, complex, and customizable pieces. Consumers increasingly demand unique, bespoke jewelry, while ethical sourcing and eco-friendly materials—such as lab-grown diamonds and recycled metals—are becoming essential.

E-commerce and digital experiences, including AR/VR virtual try-ons, will drive sales and brand engagement, especially among younger generations. Emerging materials, mixed designs, and smart jewelry features will continue to expand market possibilities. Overall, the industry is moving toward a digital, sustainable, and customer-centric future, where innovation and personalization are key to success.

4. How is AI used in the jewelry industry?

The jewelry industry is embracing the power of artificial intelligence to revolutionize design, production, and customer experiences. From creating intricate pieces to personalizing shopping, AI is reshaping every step of the process.

AI is applied in multiple areas of the jewelry industry:

Design and Prototyping: AI software generates unique designs and optimizes 3D models for both aesthetics and manufacturability.

Customization and Personalization: AI enables virtual design tools, allowing customers to personalize jewelry and receive style recommendations based on preferences.

Quality Control: Machine learning inspects jewelry for defects, ensuring high precision in gemstones, metal finishing, and craftsmanship.

Supply Chain Optimization: AI predicts demand, manages inventory, and improves sourcing efficiency, reducing waste and production delays.

Marketing and Sales: AI analyzes customer behavior to recommend products, set pricing, and enhance virtual try-on experiences for online shoppers.

Summary:

AI makes jewelry design, production, and sales smarter and more efficient, while offering highly personalized experiences for consumers and improving quality across the industry.

5. What is the most expensive metal used in jewellery making?

Platinum (Pt)

Extremely rare, dense, and durable.

Naturally white, hypoallergenic, ideal for high-end jewelry and diamond settings.

Gold (Au)

Popular for its luster, malleability, and historical value.

Price varies depending on karat (24K, 18K, 14K) and market demand.

Palladium (Pd)

Rare white metal, part of the platinum group.

Lightweight, corrosion-resistant, used in rings and white gold alloys.

Rhodium (Rh)

Very rare, silver-white metal mainly used for plating or coating white gold.

Adds reflective shine and prevents tarnish, highly valuable due to scarcity.

Iridium (Ir)

One of the rarest and densest metals, part of the platinum group.

Extremely hard and corrosion-resistant, occasionally used in high-end jewelry or alloyed with platinum.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited