Jewellery Laser Welding Machine

SuperbMelt jewelry laser welding machine uses advanced welding technology to improve the quality of jewelry repair.

SuperbMelt Jewellery Laser Welding Machine utilizes high-precision, fast laser technology to repair rings, bracelets, necklaces, and other gold and silver jewelry, preserving the original appearance and quality of the jewelry.

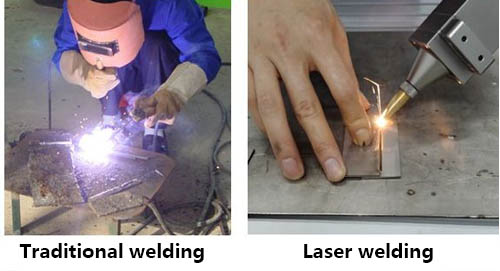

- Compared to traditional flame jewelry repair, laser repair offers higher precision when restoring complex jewelry pieces.

- Laser jewelry repair does not require welding materials; it directly melts the material for welding, reducing material usage while ensuring quality.

- Jewelry welded with laser technology exhibits high strength at the weld points, maintaining the original appearance and quality of the jewelry, whereas traditional repair methods often result in rough welds, affecting the appearance and strength of the jewelry.

- Jewellery Laser Welding Machine can operate continuously for 24 hours, significantly increasing factory production efficiency.

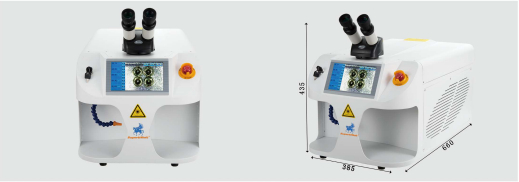

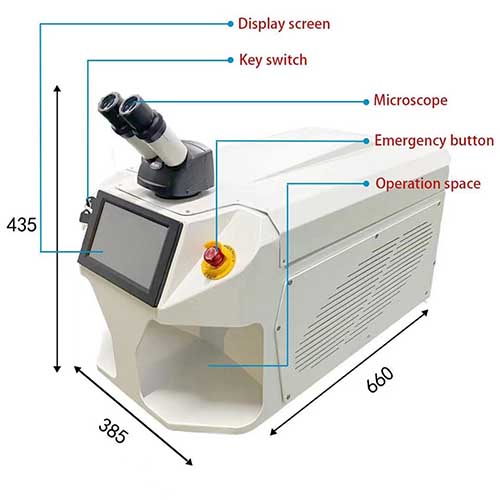

SuperbMelt Jewellery Laser Welding Machine is an advanced jewelry processing equipment. Its compact desktop design makes it an ideal choice for small jewelry shops, DIY jewelry makers, and other users.

| Model | SPB-150WB |

| Wavelength | 1064nm |

| Max output power | 150W |

| Max pulse energy | 80J |

| Pump source | Single lamp |

| Pulse width | 0.1-20ms |

| Pulse frequency | ≤50Hz |

| Aiming and positioning | Microscope + camera system |

| Application | Welding and repairing various precious metal trinkets |

| Host power consumption | ≤5KW |

| Electricity demand | AC220V±5%/50Hz |

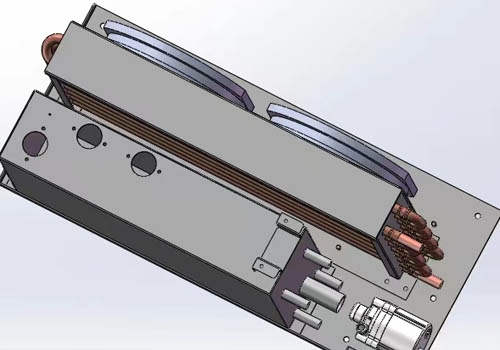

| Cooling system | Water cooling + air cooling |

| Dimension | 660x385x435mm |

| Weight | 49kg |

- 1.The high-performance laser power supply developed by our company ensures high single pulse energy, low power consumption, and minimal thermal impact, making the welding process cool to the touch.

- 2.The welding process does not require filler material, offering high welding speed, reliable joints, minimal workpiece deformation, and aesthetically pleasing results.

- 3.This equipment can weld materials such as gold, silver, platinum, titanium and its alloys, and nickel bands. It is suitable for precision welding of small, heat-sensitive parts in jewelry, dental repairs, watch springs, integrated circuit leads, and various other applications. It is ideal for use in industries such as optoelectronics, electronics, communications, machinery, automotive, military, and gold jewelry.

- 4.The ceramic laser cavity uses products from internationally renowned manufacturers, ensuring high reliability and performance of the equipment.

- 5.The unique YAG crystal cooling method improves beam quality and extends the lifespan of the xenon lamp, reducing operational costs.

- 6.The machine is equipped with a water cooler, which helps cool the laser main unit during operation, ensuring more precise temperature control.

- Jewelry

Repair and manufacture of precious metal jewelry such as gold, silver, platinum, and titanium, including rings, bracelets, necklaces, and more.

Repair broken or worn jewelry to maintain its appearance and value.

- Dental Repairs

Used in the dental field for repairing dentures, such as filling holes and repairing crowns.

- Watchmaking and Repair

Precision welding of watch parts such as balance springs and other small components to ensure the accuracy and functionality of the watch.

- Integrated Circuits and Electronic Components

Welding of integrated circuit leads and other electronic components, suitable for manufacturing and repairing electronic devices.

- Optoelectronic Devices

Welding of precision parts in optoelectronic devices, applicable to optical communication and optical sensors.

- Machinery and Automotive

Used for welding mechanical parts and automotive components, especially small and precise parts.

- Military

Welding of small precision parts in military equipment to enhance the reliability and performance of the equipment.

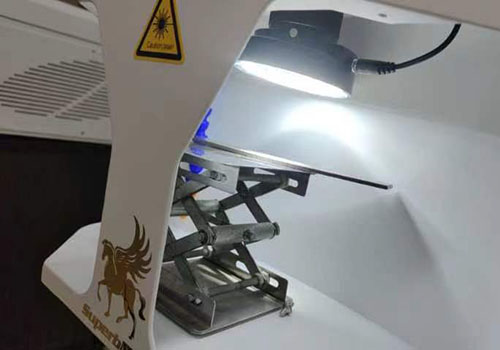

The laser optical microscope is used to magnify the welding materials, enabling precise welding.

The external water tank cools down the main unit of the welding machine, making its temperature control accurate and the welding tight.

the laser beam generates a high-energy density spot at the focal point. The heat generated at this spot is sufficient to melt the welding material and form a weld seam, resulting in better welding performance.

SuperbMelt Jewellery Laser Welding Machine Multi-language Support

This device supports multi-language operation. Let us know the language you need, and we can customize the settings to make your operation simpler and more efficient.

Why SuperbMelt Jewellery Laser Welding Machine

Any Question About SuperbMelt Jewellery Laser Welding Machine

Here's What Our Satisfied Customers Have to Say

SuperbMelt Jewellery Laser Welding Machine FAQ

By using lasers’ high thermal energy and targeted welding technology, the Jewellery Laser Welding Machine uses laser deposition welding. The workpiece melts to produce a certain weld pool by adjusting variables including laser pulse width, energy, peak power, and repetition frequency. The surface heat is transmitted inside. It is extensively employed in the production of gold and silver jewelry as well as in the welding of micro and tiny components because of its special benefits.

Yes, using proper techniques and equipment to create and repair welded jewelry is generally safe. The strength, precision, and aesthetic advantages of laser welding make it the preferred method for making and repairing fine jewelry. When purchasing or repairing welded jewelry, it is crucial to choose a reputable jeweler who uses SuperbMelt professional-grade equipment and follows best practices.

While both welding and soldering have their places in jewelry making and repair, welding, particularly laser welding, offers several advantages in terms of strength, precision, and aesthetics. It is especially preferred for high-end, intricate jewelry pieces. However, for simpler repairs and cost-effective solutions, soldering remains a practical choice.

Normal Welding: Offers strong welds for structural and industrial uses, ideal for larger-scale applications with less precise requirements. Although it may cause greater heat distortion and necessitates post-weld finishing, it is economical and adaptable.

Laser welding :is the best option for sensitive, high-precision applications where excellent connection quality and low heat distortion are essential. Although it costs more and calls for certain tools and knowledge, it provides unparalleled accuracy and visual attractiveness.

Conventional welding techniques sometimes result in a harsh process with bigger weld areas and seams that need extensive post-processing. The method of laser welding is more sophisticated than ordinary welding. The gaps produced by laser welding are almost nonexistent. Furthermore, laser welding is much quicker than traditional welding and doesn’t need to be finished aesthetically afterwards. In addition, laser welding emits no radiation, making it safe for human use.

Laser welding in jewelry is designed to join precious metals with unparalleled precision, strength, and aesthetic quality. It is particularly suitable for creating and repairing intricate and delicate jewelry, ensuring minimal thermal distortion and preserving the jewelry’s integrity. The clean, invisible seams produced by laser welding enhance the overall appearance of the jewelry, making it the preferred method for high-end and custom designs. By choosing laser welding, jewelers can ensure their pieces are both beautiful and durable, meeting the high standards expected in the fine jewelry industry.

High Precision: Complex Work: Laser Welding Laser welding is perfect for intricate and delicate jewelry designs because it can be used to create work that is quite exact and detailed.

Small pieces: It is possible to successfully weld tiny pieces without causing harm to the surroundings.

Reduced Deformation: The concentrated laser beam produces a very narrow Heat Affected Zone (HAZ), which lowers the possibility of thermal deformation and harm to jewelry’s heat-sensitive components.

Reduces the possibility of harm coming to gemstones and other delicate materials put in jewelry by protecting it

Robust and Long-Lasting Joints:

Strengthening: Produces robust, long-lasting joints that can tolerate normal wear and strain.

Consistent Quality: Generates minimally defective, consistently high-quality welds.

Beautiful, Spotless Surface:

minimal Post-Processing: This method creates smooth, clean welds that usually need minimal post-processing, saving time and preserving the jewelry’s aesthetic appeal.

Invisible Seams: Laser welds often have very few visible seams or discolorations and are of excellent aesthetic quality.

Material Flexibility:

Large Variety of Metals: Able to fuse a broad variety of jewelry-grade precious metals, such as titanium, platinum, silver, and gold.

Compatibility of materials: The capacity to fuse disparate metals together, offering versatility in jewelry creation and maintenance.

Process without contact:

Decreased deterioration Jewelry wear is decreased by laser welding since it is a non-contact procedure.

precise control: Offers exact control over the parameters of the welding process, guaranteeing excellent outcomes without causing harm to jewelry.

1. Tungsten Inert Gas Welding, or TIG welding:

accuracy: Offers excellent control and accuracy; appropriate for certain jewelry-making tasks, but often falls short of laser welding in terms of precision.

Better heat control than some other conventional techniques; nonetheless, its heat-affected zone is bigger than that of laser welding.

2. Micro welding: Precision: Involves small-scale welding methods, often with the use of specialized tools designed for intricate tasks.

Applications: Suitable for bespoke work and repairs of very delicate jewelry.

3. Conventional welding: Still extensively used for simple repairs and attaching components when creating jewelry.

Heat and accuracy: Laser welding is less suited for delicate or detailed work than other methods since it has a bigger heat-affected zone and less precision.

In brief

Because of its excellent structural and aesthetic outcomes, low heat impacts, and great accuracy, laser welding is the primary method utilized for jewelry. Other welding techniques, such TIG, micro, and conventional welding, are also used, but because of their shortcomings in accuracy and heat control, they are often less appropriate for complex or expensive jewelry.

For dealing with gold, laser welding is a great technique because of its accuracy, low heat impact, robust joints, and smooth finish. It ensures excellent quality and longevity and is extensively used in the jewelry business for both producing and repairing gold jewelry.

- precious metals: gold, silver, platinum, and palladium.

- Common metals: stainless steel, carbon steel, aluminum, titanium, copper, brass.

- Alloys: nickel alloys, cobalt alloys, superalloys.

- Specialty metals: magnesium, tungsten, molybdenum, and dissimilar metals.

The SuperbMelt laser welding process encompasses material selection and cleaning, machine calibration and fixture setup, the laser welding operation (including laser generation, welding, and real-time monitoring), and post-welding inspection and cleaning. This process offers high precision, fast speed, excellent quality, and wide applicability, making it ideal for jewelry manufacturing, electronic components, medical devices, as well as automotive and aerospace industries.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

How to Smelt Platinum: The History of Platinum Smelting

Introduction

The Jewellery Laser Welding Machine represents a breakthrough in modern jewelry repair and manufacturing. Unlike traditional flame welding, which often causes rough joints, material waste, and deformation, laser welding offers high precision, clean welds, and strong durability. By using a focused laser beam, the machine melts and fuses metals directly, eliminating the need for filler materials while maintaining the original beauty of jewelry pieces.

Compact in design yet powerful in function, this machine is suitable for small jewelry workshops, DIY jewelers, and large factories. Its ability to run continuously for 24 hours makes it highly efficient, while its versatility allows applications across jewelry, dental, watchmaking, electronics, and even military industries.

Key Features

- High-Performance Laser Power Supply – Provides strong single-pulse energy with low power consumption and minimal thermal impact, ensuring precise and stable welding.

- No Filler Material Required – The process directly melts the base metal, reducing material waste while achieving fast, reliable, and aesthetically smooth welds.

- Multi-Material Compatibility – Capable of welding gold, silver, platinum, titanium, nickel alloys, and more, making it suitable for diverse jewelry and industrial applications.

- Durable Ceramic Laser Cavity – Built with components from globally recognized manufacturers, ensuring long service life and consistent performance.

- Advanced Cooling System – Equipped with a unique YAG crystal cooling method and water cooler to maintain stable operation, extend lamp life, and lower operating costs.

- 24-Hour Continuous Operation – Designed for non-stop production, improving efficiency in jewelry manufacturing and repair.

- Laser Optical Microscope – Provides magnified views of welding areas, enabling extreme precision on small and delicate parts.

- Multi-Language Support – Customizable interface for easier operation worldwide.

Technical Advantages

High Precision & Minimal Heat Effect – The focused laser beam generates a high-energy density spot, creating clean, accurate welds with almost no thermal deformation.

Strong & Aesthetic Welds – The weld seam is smooth, firm, and nearly invisible, preserving the jewelry’s original appearance and strength.

Efficient & Cost-Saving – No filler material is needed, reducing material costs while achieving faster welding compared to traditional flame repair.

Stable & Reliable Performance – Ceramic laser cavity and optimized YAG crystal cooling ensure consistent beam quality and extend component lifespan.

Versatility Across Industries – Suitable for jewelry, dental, watchmaking, electronics, optoelectronics, automotive, and even military applications.

Continuous Operation Capability – Can run 24/7 with stable temperature control from the water cooling system, ensuring high productivity.

User-Friendly Operation – Integrated microscope and multi-language interface simplify precision welding tasks for jewelers and technicians.

Applications

Jewelry Repair & Manufacturing

Ideal for welding rings, bracelets, necklaces, and other gold, silver, platinum, or titanium jewelry.

Repairs broken or worn jewelry while maintaining its appearance and value.

Dental Repairs

Used for repairing dentures, crowns, and other dental components with precision and minimal thermal impact.

Watchmaking & Repair

Enables accurate welding of delicate watch parts, such as balance springs, ensuring both functionality and longevity.

Electronics & Integrated Circuits

Suitable for welding IC leads and other miniature components in electronic devices, ensuring reliable electrical performance.

Optoelectronic Devices

Supports precision welding in optical communication systems and sensor components requiring high accuracy.

Machinery & Automotive

Effective for welding small mechanical or automotive components, especially those requiring precision and durability.

Military Applications

Applied in the repair and manufacturing of small, high-precision military equipment parts, improving reliability and performance.

Working Principle

The SuperbMelt Jewellery Laser Welding Machine works by generating a high-energy laser beam that is focused into a very small spot using precision optics. When this concentrated beam hits the surface of the jewelry or component, the localized heat is strong enough to instantly melt the material at the focal point, creating a weld seam without the need for filler materials.

The built-in laser optical microscope magnifies the welding area, ensuring precise positioning and accurate operation. A ceramic laser cavity and advanced YAG crystal cooling system help maintain stable beam quality and extend the lifespan of the xenon lamp.

To prevent overheating, the machine is equipped with an external water cooling system that regulates the temperature of the laser unit, ensuring continuous, stable, and efficient operation. This combination of concentrated energy, advanced cooling, and precision control allows the machine to achieve strong, clean, and visually seamless welds, even on small and heat-sensitive parts.

Benefits Over Traditional Welding

The SuperbMelt Jewellery Laser Welding Machine offers several advantages compared to traditional flame or arc welding methods:

Higher Precision – The laser beam allows for extremely fine and accurate welds, ideal for delicate jewelry pieces and complex designs.

No Filler Material Required – Unlike traditional methods, laser welding directly melts the base material, reducing material waste and cost.

Minimal Heat Impact – The localized laser spot prevents heat from spreading to surrounding areas, avoiding deformation or damage to sensitive components.

Stronger Welds – The weld points created by laser technology have higher strength and durability compared to conventional repair methods.

Improved Aesthetics – Laser welds are smooth and nearly invisible, maintaining the original appearance and quality of jewelry.

Continuous Operation – Capable of 24-hour operation, the machine enhances production efficiency for both workshops and factories.

Versatility – Suitable not only for jewelry repair but also for applications in dental work, watchmaking, electronics, and precision industries.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited