Graphite Mold for Silver

As a top graphite molds supplier, Superbmelt provides various molds for silver casting

Graphite mold for silver can be used to hold molten silver, gold or any other precious metals into shapes. Graphite mold for silver is made up of 99.9% of silver and ash content that is less than 0.1%. This composition of material ensures that precious metal is not contaminated.

Graphite mold for silver has a wide application; used for holding molten gold, silver or other precious metals. It can be used for testing or ingot casting.

The mold for silver has an excellent thermal stability for fast cooling and it has a proper corrosion resistance to acid and alkali. The graphite mold has good thermal conductivity properties which highly shortens casting time and saves energy. The graphite mold keeps its original natural graphite physical and chemical properties.

There are also graphite molds for silver that are designed for making several bars at the same time for fast and quality casting.

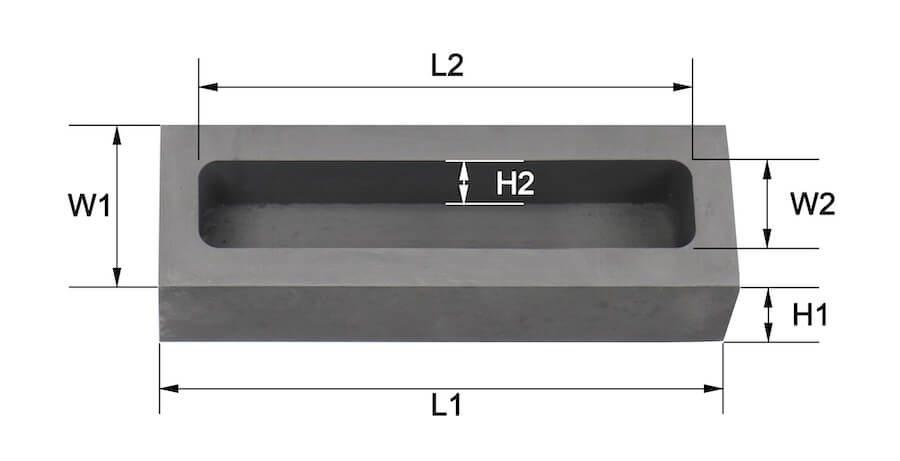

| Description | Model | Size | |||||

| L1 | W1 | H1 | L2 | W2 | H2 | ||

| 100g graphite ingot mold | G.GI.Y0100 | 55 | 40 | 20 | 35 | 20 | 10 |

| 200g graphite ingot mold | G.GI.Y0200 | 70 | 45 | 20 | / | / | / |

| 250g graphite ingot mold | G.GI.Y0250 | 67 | 50 | 26 | 47 | 25 | 16 |

| 300g graphite ingot mold | G.GI.Y0300 | 70 | 57 | 20 | / | / | / |

| 400g graphite ingot mold | G.GI.Y0400 | 75 | 67 | 20 | / | / | / |

| 500g graphite ingot mold | G.GI.Y0500 | 70 | 67 | 26 | 50 | 47 | 16 |

| 1kg graphite ingot mold | G.GI.Y1000 | 135 | 42 | 32 | 115 | 22 | 22 |

| 2kg graphite ingot mold | G.GI.Y2000 | 160 | 48 | 38 | 140 | 28 | 28 |

| 3kg graphite ingot mold | G.GI.Y3000 | 175 | 52 | 42 | 155 | 32 | 32 |

- Graphite mold for silver is commonly used in aluminium, gold, silver casting because of its best quality for intricate mold design and high volume runs.

- Graphite mold for silver is extremely stable, it does not twist or crack when molten metal is poured into the mold. The mold does not deteriorate even when used constantly. The life expectancy of a graphite mold for silver is relatively short.

- The graphite mold for silver has an excellent thermal conductivity considering the sudden heat and cold conditions; oxidation resistance and high corrosion resistance. It is the best mold for refining purposes.

- All metals cast with the graphite mold for silver are always pure as they are not exposed to impurities and contamination in the mold.

- The smooth cavity finish allows for easy removal of cast metals and is non sticky once cooled.

- Superbmelt graphite mold for silver is made from only fine graphite particle structure with high graphitization degree. That makes the mold to have a dense structure ( the dense structure of the graphite mold for silver makes the mold to be less porous); a fine surface and a low rate of heat deformity; a high mechanical strength (tensile strength of graphite mold increases with the increasing temperature compared to other materials).

- Superbmelt graphite mold for silver has an excellent thermal shock resistance, therefore can be used in any process; thermal conductivity and good oxidation resistance.

- In order to prevent metal casting that is removed from the mold from sticking to the mold surface, the material (graphite) has a good adhesion to the solidified metal. This is achieved by low wetting of the mold by liquid metal.

- The graphite mold for silver is self lubricating. The low friction between the mold surface and the solidified metal ensures that the casting is easily removed without cracks and minimizes the thickness of the defective skin.

- Graphite mold for silver casting is easy to process with graphite. Through milling, grinding, turning, the surface finish, complex shape mold with tight tolerances are available. The finishing of the inner mold surface is made to reduce the wet and friction of cast material.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Graphite Mold for Silver

As a professional graphite mold manufacturer, it is our responsibility to provide you with the highest quality graphite mold

High Quality

Any Question About SuperbMelt Graphite Mold for Silver

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

Graphite Molds for Silver Casting: Complete Guide for Jewelers & Refiners

In precious metal processing—whether it’s a small jewelry workshop casting custom silver pieces, a refinery producing standard silver bars, or an assay lab preparing test samples—casting quality directly determines product value. Contaminated silver, rough surface finishes, or inefficient batch production can lead to significant economic losses. Among the key tools for silver casting, graphite molds stand out as irreplaceable due to their unique material properties. They solve core pain points like metal contamination, slow cooling, and poor casting consistency that plague traditional molds (such as metal or ceramic molds).

This guide is tailored for jewelry makers, precious metal refiners, assay lab technicians, and scrap metal recycling professionals. It systematically covers everything you need to know about graphite molds for silver casting: from basic principles and core advantages to selection criteria, correct usage, and production line integration. By the end, you’ll be able to choose the right graphite mold and use it efficiently to produce high-purity, high-quality silver castings.

Understanding Graphite Molds for Silver Casting

1.1, What a Graphite Mold Is and How It Works

1.2, Why Graphite Is Used for Precious Metals

- Ultra-High Purity (99.9%) & Low Ash Content (<0.1%): High-quality graphite molds for silver casting are made of 99.9% pure graphite with ash content less than 0.1%. This ultra-high purity ensures that the mold does not release impurities (such as metal oxides or other contaminants) during the high-temperature casting process—critical for protecting the purity of precious metals. Even trace contamination can reduce the value of silver bars or jewelry, making this property non-negotiable for precious metal processing.

- Chemically Non-Reactive Behavior: Graphite is chemically stable and does not react with molten silver, gold, or common casting fluxes at high temperatures. This non-reactive nature prevents chemical contamination of the metal, ensuring that the cast silver retains its original purity and properties. In contrast, metal molds may react with molten silver, forming alloy impurities on the casting surface.

- Excellent Thermal Stability: Graphite can withstand extreme temperatures (up to 3000°C in inert environments) without melting or deforming, making it ideal for repeated contact with molten silver (which melts at ~962°C). This thermal stability ensures the mold maintains its shape and dimensional accuracy over multiple casting cycles.

1.3, Common Jewelry and Refining Applications

- Jewelry Workshops: Used to cast silver blanks for rings, bracelets, necklaces, and other custom jewelry. Small single-cavity or multi-cavity molds are preferred for small-batch, personalized production, ensuring consistent shape and quality of jewelry components.

- Bullion Casting: Refineries and bullion manufacturers use graphite molds to produce standard silver bars (100g, 500g, 1kg, or larger) and round ingots. Multi-cavity molds are essential here for batch production, improving output efficiency while maintaining uniform bar weight and dimensions.

- Assay Labs: Used to prepare small silver test buttons or samples for purity analysis. The high purity of graphite molds ensures that the test samples are not contaminated, guaranteeing accurate assay results.

- Scrap Refining: Scrap metal recycling facilities use graphite molds to cast molten silver (recovered from electronic waste, old jewelry, or industrial scrap) into reusable ingots or bars, facilitating storage and subsequent processing.

- Custom Logo Casting: Specialized graphite molds with engraved logos or patterns are used to produce branded silver bars (e.g., for collectors or corporate gifts), adding value to the final product.

Choosing the Right Mold for Your Silver Production

2.1, Single-Cavity vs Multi-Cavity Molds

- Single-Cavity Molds: Designed with one cavity, ideal for small-batch production, custom jewelry casting, or test sample preparation. Advantages include simple structure, easy operation, and low initial cost. They are perfect for small jewelry workshops or labs that focus on personalized or low-volume output (e.g., casting 1-5 silver pieces per cycle).

- Multi-Cavity Molds: Equipped with 2-10 (or more) identical cavities, designed for high-volume batch production. For example, a 6-cavity mold can cast 6 silver bars in a single pouring, significantly increasing production speed and consistency. They are essential for refineries, large jewelry factories, or scrap recycling facilities that need to process large quantities of silver. While multi-cavity molds have a higher initial cost, they reduce unit production costs and improve efficiency over time.

2.2, Mold Sizes and Bar Weight Options

- Target Product Weight: Choose a mold whose cavity volume matches the weight of the silver casting you need to produce. For example, if you primarily make 500g silver bars, select a 500g-specific mold—this ensures accurate weight control and avoids wasting silver on over-pouring or under-filling.

- Melting Equipment Capacity: Ensure the mold size is compatible with your melting furnace and crucible. For example, a small 1kg induction furnace may not produce enough molten silver to fill a 5kg multi-cavity mold, while a large 10kg furnace paired with a 100g single-cavity mold will waste energy and time.

2.3, Matching Mold Shape to Your Business Needs

- Rectangular Bars: The most common shape for silver bullion, easy to stack, store, and transport. Ideal for refineries, scrap recycling facilities, and bullion traders.

- Round Ingots: Popular for small silver ingots (e.g., 100g-500g) used in jewelry making or small-scale trading. Their smooth, rounded edges reduce the risk of scratches during handling.

- Test Buttons: Small, disc-shaped cavities designed for assay labs. The compact size allows for quick cooling and easy handling during purity testing.

- Custom Logo/Pattern Bars: Molds with engraved logos, brand names, or decorative patterns. Perfect for producing branded silver bars, collector’s items, or corporate gifts—adding unique value to your products.

Material Quality and Performance Factors

3.1, Graphite Purity and Ash Content

- Avoiding Metal Contamination: Low ash content means the mold contains almost no impurities (such as silica, iron, or aluminum). During high-temperature casting, these impurities would otherwise volatilize or mix with molten silver, reducing its purity and value. For example, even 0.5% ash content can lead to visible surface defects or failed purity tests in silver bars.

- Extending Mold Lifespan: High-purity graphite has a more uniform structure, making it more resistant to thermal shock and wear. Low-purity graphite, by contrast, is brittle and prone to cracking after repeated heating and cooling cycles.

3.2, Thermal Conductivity and Cooling Speed

- Faster Cooling = Higher Efficiency: High thermal conductivity allows the mold to rapidly transfer heat from molten silver to the environment, reducing cooling time. For example, a high-quality graphite mold can cool a 1kg silver bar in 5-8 minutes, while a low-quality mold (or ceramic mold) may take 15-20 minutes. This shortens the production cycle and increases daily output.

- Better Surface Finish: Fast, uniform cooling prevents the formation of air bubbles, shrinkage cracks, or rough surfaces in the silver casting. Slow cooling, by contrast, can lead to uneven solidification and visible defects that require time-consuming polishing to fix.

- Energy Savings: Faster cooling means the mold (and surrounding equipment) spends less time at high temperatures, reducing overall energy consumption. This is especially significant for large-scale production facilities with high energy costs.

3.3, Resistance to Thermal Shock and Corrosion

- Thermal Shock Resistance: The ability to withstand sudden temperature changes without cracking. High-purity graphite has excellent thermal shock resistance—even when preheated to 500°C and then cooled to room temperature, it won’t crack. Low-quality graphite, however, may split after just a few cycles, leading to mold failure and wasted silver.

- Corrosion Resistance: Graphite is naturally resistant to acids, alkalis, and most casting fluxes. This means you can clean the mold with mild acids (to remove residual silver or flux) without damaging the mold surface. It also prevents chemical reactions between the mold and molten silver, ensuring consistent casting quality over time.

How to Use a Graphite Mold Correctly

4.1, Preparing the Mold Before Pouring

- Clean the Mold: Before each use, wipe the cavity with a dry, lint-free cloth to remove any graphite dust, residual silver, or flux from previous castings. For stubborn residues, use a soft brush (do not use metal tools—they will scratch the cavity surface, leading to rough castings).

- Preheat the Mold: Preheat the mold to 200-300°C before pouring molten silver. This prevents thermal shock (sudden cooling of molten silver when it contacts a cold mold), which can cause air bubbles or cracks in the casting. Preheating also helps the molten silver flow smoothly into all parts of the cavity.

- Apply Release Agent (If Needed): For complex shapes or custom molds, a thin layer of graphite-based release agent can help with demolding. Avoid oil-based release agents—they can burn at high temperatures, releasing fumes and contaminating the silver. For most standard molds (rectangular bars, round ingots), release agents are unnecessary if the mold is clean and preheated.

4.2, Pouring Molten Silver Safely

- Ensure Proper Safety Gear: Wear heat-resistant gloves, a face shield, and a fire-resistant apron. Pour in a well-ventilated area away from flammable materials.

- Control Pouring Speed and Flow: Pour the molten silver slowly and steadily into the mold cavity. Avoid splashing or pouring too quickly—this introduces air bubbles into the metal. Tilt the mold slightly (15-30°) and pour along the cavity wall to guide the silver flow.

- Fill the Cavity Completely: Fill the cavity to the top (but not overflowing) to ensure the casting has the correct weight and shape. If the cavity is underfilled, the casting will be incomplete; overflowing wastes silver and creates messy cleanup.

4.3, Removing and Finishing the Cast Silver

- Allow Sufficient Cooling Time: Let the mold and silver casting cool naturally to at least 100°C (touchable but warm) before demolding. For 1kg silver bars, this takes 5-8 minutes; larger castings may take 10-15 minutes. Do not quench the mold in water—this causes thermal shock and cracks the mold.

- Demold Gently: Once cooled, tap the mold lightly on a hard, heat-resistant surface to loosen the casting. For tight-fitting castings, use a plastic or wooden tool to pry the edge (avoid metal tools). The casting should come out easily if the mold was clean and preheated.

- Inspect and Finish: Check the casting for surface defects (bubbles, cracks, rough spots). High-quality graphite molds produce castings with a smooth surface that only requires light polishing (if any). If defects are present, review your preheating or pouring technique—defects are usually caused by cold molds, fast pouring, or dirty cavities.

Integrating Graphite Molds into a Jewelry Production Line

5.1, Using with Induction Furnaces and Crucibles

- Matching Capacity: As mentioned earlier, align the mold size with your induction furnace and crucible capacity. For example, a 2kg induction furnace with a 2kg graphite crucible pairs perfectly with a 2kg single-cavity or 4x500g multi-cavity mold.

- Pouring Workflow: Place the preheated mold on a stable, heat-resistant surface near the induction furnace. Once the silver is fully melted (and any impurities are skimmed off), pour directly from the crucible into the mold. This minimizes the time molten silver is exposed to air, reducing oxidation.

- Flux Compatibility: If using flux to remove impurities from molten silver, choose a flux that is compatible with graphite (most standard precious metal fluxes are). Avoid excessive flux—residual flux can build up in the mold cavity over time, leading to contamination.

5.2, Improving Output with Multi-Bar Casting

- Batch Processing: Use multi-cavity molds to cast multiple identical silver bars in a single pouring. For example, a 6-cavity 1kg mold can produce 6kg of silver bars per cycle—6x more than a single-cavity mold. This reduces the number of pourings needed per day, saving time and labor.

- Consistency Control: Multi-cavity molds ensure all castings have the same weight, shape, and surface finish—critical for batch production of standard silver bars or jewelry blanks. This reduces quality control time and scrap rates.

- Parallel Workflows: Pair multi-cavity molds with multiple induction furnaces for continuous production. While one mold is cooling, another is being poured—this eliminates downtime and maximizes daily output.

5.3, Maintenance and Mold Lifespan

- Regular Cleaning: After each use, clean the mold cavity with a dry cloth or soft brush. For heavy flux buildup, soak the mold in a mild acid solution (e.g., 5% hydrochloric acid) for 10-15 minutes, then rinse with water and dry completely before reuse.

- Proper Storage: Store molds in a dry, cool, and dust-free environment. Avoid stacking heavy objects on top of molds—this can deform the cavity. For custom or delicate molds, use a protective case to prevent scratches.

- Avoid Overheating: Do not heat the mold above 800°C—excessive temperature can damage the graphite structure, reducing lifespan. Stick to the recommended preheating temperature (200-300°C).

- Inspect for Damage: Before each use, check the mold for cracks, chips, or excessive wear. If the cavity is scratched or the mold is cracked, replace it immediately—damaged molds will produce defective castings and may break during pouring, wasting silver.

Conclusion

Ready to Upgrade Your Silver Casting Workflow?

- Receive a free custom mold recommendation based on your product type and production scale;

- Request a sample of our high-quality graphite mold to test its performance;

- Get a quote for batch orders with competitive pricing and fast delivery.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited