Gold Wire Drawing Machine

Precision Wire Drawing Machine helps users to produce jewelry made of gold, silver, and alloys through wire drawing.

SuperbMelt Gold Wire Drawing Machine aids jewelry manufacturers and craft processors in producing gold, silver, K gold, alloy, and other metal wires with diameters ranging from 0.3 to 8 millimeters, used for creating jewelry such as rings, necklaces, bracelets, earrings, and crafts. This wire drawing machine not only addresses production issues in the jewelry industry but also finds applications in various manufacturing sectors including telecommunications, automotive, construction, and metal component and product manufacturing.

- Speed: The machine can draw metal wires with diameters ranging from 0.3 to 8mm and lengths from 0 to 15m per minute.

- Coiling: Equipped with coiling function to increase drawing pressure and facilitate material collection.

- Features: The product is equipped with a spray cooling system to reduce material temperature, minimize wire damage, and features automatic shutdown and material shortage shutdown functions to reduce manual intervention during production.

For further inquiries about the wire drawing machine, please contact SuperbMelt for customized solutions!

| Model number | SPB- |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 7.5 kw |

| Applicable metal | Gold, silver, copper, K gold, tin, etc. |

| Outgoing line speed | 0-15M/Min |

| Maximum cable diameter | 8mm |

| Minimum cable diameter | 0.3mm |

| Pulling direction | unidirectional |

| Dimension | 1860*1500*1850mm |

| Weight | 1600 kg |

| Additional features | Winding |

- High efficiency, capable of drawing up to 15 meters per minute at the fastest.

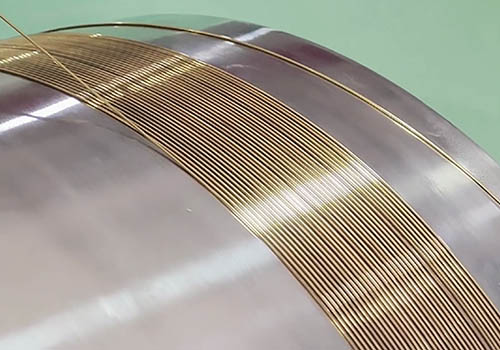

- High precision, servo-driven precision wire arrangement, preventing abrasion between wires.

- Intelligent control, PLC control system, easy and user-friendly operation.

- Automated production, featuring automatic shutdown and material shortage shutdown functions.

- Spray cooling system, reducing material and wire eye temperature to minimize wire damage.

- Coiling function, with automatic coiling capability, facilitating material collection and retrieval.

- Versatile Compatibility: Compatible with a wide range of materials including gold, silver, copper, and alloys, catering to diverse manufacturing needs.

- Enhanced Safety: Equipped with safety features such as overload protection and emergency stop buttons, ensuring operator safety during operation.

- Energy Efficiency: Utilizes energy-efficient components and design principles, minimizing energy consumption and operational costs.

- Maintenance-Friendly: Designed for easy maintenance and servicing, reducing downtime and maintenance costs in the long run.

- Customizable Options: Provides customizable options such as wire diameter settings and speed adjustments, allowing users to tailor the machine’s performance to specific production requirements.

- Jewelry manufacturing is the process of turning raw materials like gold, silver, and alloys into jewelry pieces like necklaces, bracelets, rings, and earrings.

- Manufacturing of Metal Parts: Involved in the creation of metal components for mechanical, electrical, and automotive applications.

- Telecommunication Sector: Employed in the production of metal wires, cables, and communication apparatus.

- Used in the construction industry to produce building supplies including metal pipes and wire mesh.

- Manufacturing of Art and Crafts: Used in the creation of several metal sculptures and ornaments.

- Manufacturing of Medical Equipment: Metal components for medical equipment and instruments are produced here.

- precise Instrument Manufacturing: Involves creating metal components for a range of equipment and precise instruments.

Why SuperbMelt Gold Wire Drawing Machine

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Any Question About SuperbMelt Gold Wire Drawing Machine

Any Question About SuperbMelt Automatic wire drawing machine

The Ultimate Guide to Gold Wire Drawing for Jewelry Manufacturing: Precision, Efficiency & Craftsmanship with SuperbMelt

In the luxury jewelry manufacturing industry, gold wire is the “invisible cornerstone” of exquisite pieces. From delicate pendant chains to intricate ring settings, every detail relies on the precision, consistency, and surface quality of the wire. However, many jewelry manufacturers face pain points such as unstable wire diameter, high precious metal loss, poor surface finish, and low production efficiency during the wire drawing process—issues that directly affect product quality, cost control, and market competitiveness.

SuperbMelt Gold Wire Drawing Machine is engineered to solve these core challenges. Designed specifically for jewelry production needs, it can process gold, silver, K-gold, alloys, and other metals into wires with diameters ranging from 0.3 to 8mm, providing a stable and efficient wire drawing solution for jewelry manufacturers and craft studios. This comprehensive guide will take you through every key link of jewelry-grade gold wire drawing—from the role of gold wire in jewelry manufacturing to raw material selection, precision control, cooling protection, and post-process connection—helping you master the core logic of high-quality wire drawing and maximize the value of precious metals.

The Role and Value of Gold Wire in Jewelry Manufacturing

Gold wire is not just a raw material for jewelry; it is the “building block” that determines the structural stability, aesthetic effect, and processability of the final product. Its quality directly affects every subsequent process from chain making to inlaying.

1.1, Gold Wire: The “Source Material” of Jewelry Structure

Nearly all core components of jewelry rely on the consistency of wire materials, and any deviation in wire quality will lead to defective products:

- Chains: Whether it’s box chains, rope chains, or cable chains, the uniformity of wire diameter directly determines the consistency of link size and spacing. Uneven wire will result in loose or tight links, affecting the chain’s flexibility and appearance.

- Rings & Earrings: The wire used for ring bands and earring frames requires strict consistency in hardness and diameter. Deviations will cause the ring to be out of round or the earring to be unbalanced, reducing wearing comfort.

- Setting Claws: The fine wire used for diamond or gemstone setting must have precise diameter and high straightness. Even a tiny deviation can lead to unstable setting, risking gemstone loss.

SuperbMelt Gold Wire Drawing Machine ensures that the wire diameter tolerance is controlled within a high-precision range through servo-driven precise wire arrangement, laying a solid foundation for subsequent jewelry processing.

1.2, How Wire Precision Affects Finished Jewelry Quality

Wire diameter fluctuation is the biggest hidden danger in jewelry production, and its impact runs through the entire manufacturing process:

- Chain Making: If the wire diameter is too thick, the links will be difficult to interlock, and the chain will be stiff; if it’s too thin, the links will be weak and easy to break. SuperbMelt’s high-precision wire drawing ensures a diameter tolerance of ±0.01mm, ensuring smooth chain making.

- Welding: Uneven wire diameter will cause uneven heating during laser or micro-spot welding, leading to weak welds or even welding failure. Precise wire ensures uniform welding contact surfaces, improving weld strength (up to 95% of the base metal strength).

- Weaving: For intricate woven jewelry (such as filigree work), consistent wire diameter and flexibility are essential. Deviations will cause uneven weaving density, affecting the aesthetic effect of the finished product.

1.3, Why Jewelry-Grade Wire Drawing Differs from Industrial Wire Drawing

Jewelry-grade wire drawing focuses on “precision, low loss, and high surface quality,” which is fundamentally different from industrial wire drawing that prioritizes large output and low cost:

- Precious Metal Cost Control: Gold, silver, and K-gold are high-value materials. Even a 1% increase in recovery rate can save a lot of costs. SuperbMelt’s wire drawing machine minimizes metal loss through precise tension control and spray cooling, ensuring a high recovery rate.

- Surface Quality Requirements: Jewelry wire requires a smooth, scratch-free surface (surface roughness Ra ≤ 0.05μm) to avoid affecting subsequent plating and polishing. Industrial wire drawing allows for slight surface defects, which are unacceptable in jewelry production.

- Material Performance Protection: Jewelry wire needs to maintain appropriate flexibility and hardness. Excessive heating or improper tension during drawing will damage the metal structure, making the wire brittle or too soft. SuperbMelt’s intelligent temperature and tension control ensures the original performance of precious metals is preserved.

Raw Material Selection and Wire Diameter Planning

Scientific raw material selection and reasonable wire diameter planning are the prerequisites for efficient and high-quality wire drawing. They directly determine the process difficulty, production efficiency, and final application scenario of the wire.

2.1, Precious Metal Types Suitable for Wire Drawing

Different precious metals and alloys have unique physical properties, which affect their adaptability to wire drawing. SuperbMelt Gold Wire Drawing Machine is compatible with a variety of materials, covering all mainstream precious metals used in jewelry manufacturing:

- Gold: Pure gold (24K) is soft and has good ductility, but it is easy to deform during drawing. It requires low tension and slow speed. K-gold (14K, 18K) has higher hardness due to alloying elements (such as copper, silver), making it suitable for making high-strength wires (e.g., for setting claws and chain links).

- Silver & 925 Sterling Silver: Silver has excellent ductility and conductivity, and its wire drawing is relatively easy. However, silver is prone to oxidation, so it is necessary to pay attention to anti-oxidation protection during the drawing process. 925 sterling silver (alloyed with 7.5% copper) has higher hardness than pure silver, making it suitable for mass-produced jewelry chains and accessories.

- Alloys: Common jewelry alloys (such as palladium-gold alloy, platinum alloy) have high hardness and corrosion resistance, but their ductility is relatively poor. They require precise control of drawing speed and temperature (relying on SuperbMelt’s spray cooling system) to avoid wire breakage.

- Stainless Steel: Often used in fashion jewelry, stainless steel has high hardness and wear resistance. SuperbMelt’s industrial-grade motor and high-precision molds can handle its wire drawing needs, producing wires suitable for bold statement jewelry.

2.2, Planning Logic for Initial and Target Wire Diameters

The choice between multi-pass drawing and single-pass drawing depends on the difference between the initial wire diameter and the target wire diameter, as well as the material properties:

- Single-Pass Drawing: Suitable for small diameter differences (e.g., initial diameter 2.0mm → target diameter 1.5mm) and soft materials (such as pure gold, pure silver). It has the advantages of high efficiency and low energy consumption. SuperbMelt’s machine can complete single-pass drawing stably with its high-precision tension control.

- Multi-Pass Drawing: Necessary for large diameter differences (e.g., initial diameter 8.0mm → target diameter 0.3mm) and hard materials (such as stainless steel, platinum alloy). Each pass of drawing reduces the diameter by a certain ratio (usually 10-20%) and requires intermediate annealing (to eliminate metal fatigue) to avoid wire breakage. SuperbMelt’s PLC control system can store multi-pass drawing parameters, realizing automatic parameter switching and ensuring process stability.

Key planning principle: Avoid excessive diameter reduction in a single pass, which will cause excessive metal stress, leading to wire breakage, surface scratches, or internal cracks. SuperbMelt’s customizable speed and tension settings allow for precise matching of different drawing passes and material requirements.

2.3, Typical Applications of Different Wire Diameters in Jewelry

Wire diameter directly determines the application scenario of the wire. The 0.3-8mm diameter range covered by SuperbMelt’s machine can meet almost all jewelry production needs:

- 3–0.6mm (Fine Wire): Suitable for delicate pendant chains, filigree weaving, and fine setting claws. For example, 0.3mm wire is used for ultra-thin snake chains, and 0.5mm wire is used for the setting claws of small gemstones. This range of wire requires the highest drawing precision to avoid breakage during weaving and setting.

- 8–2.0mm (Medium Wire): The most widely used range in jewelry production, suitable for necklaces, bracelets, ring bands, and earrings. For example, 1.0mm wire is used for standard cable chains, 1.5mm wire is used for medium-sized curb chains, and 2.0mm wire is used for thick ring bands. SuperbMelt’s machine can stably produce wires in this range with high efficiency (up to 15 meters per minute), meeting mass production needs.

- 5mm and Above (Thick Wire): Used for jewelry structural parts and accessories, such as bracelet buckles, necklace clasps, and large ring frames. Thick wire requires high drawing force and stable cooling. SuperbMelt’s powerful motor and spray cooling system ensure uniform diameter and no surface defects of thick wire.

Wire Drawing Precision Control and Surface Quality Management

Precision and surface quality are the core indicators of jewelry-grade wire. Strict control of these two aspects requires the coordination of mold precision, process parameters, and quality inspection.

3.1, Drawing Mold Precision and Wire Roundness Control

The drawing mold is the core component that determines wire diameter precision and roundness. The relationship between mold hole tolerance and wire out-of-roundness is direct:

- Mold Hole Tolerance: High-precision molds (mold hole tolerance ≤ ±0.005mm) are required for jewelry-grade wire drawing. SuperbMelt uses diamond molds (with high hardness and wear resistance) to ensure that the mold hole size remains stable during long-term production, avoiding diameter fluctuations caused by mold wear.

- Wire Out-of-Roundness: Out-of-round wire (deviation between maximum and minimum diameters > 0.01mm) will cause uneven stress during subsequent processes (such as chain making and welding). SuperbMelt’s machine ensures that the wire out-of-roundness is controlled within 0.005mm through precise mold alignment and stable tension control, ensuring the wire is perfectly round.

Maintenance tip: Regularly clean the mold hole to remove metal residues, which can cause surface scratches on the wire. SuperbMelt’s machine is designed for easy maintenance, allowing quick mold disassembly and cleaning.

3.2, Balance Between Drawing Speed and Tension

The balance of drawing speed and tension is crucial to avoid wire breakage and scratches. Excessive speed or improper tension will directly affect product quality:

- Problems Caused by Excessive Speed: High speed will increase the friction between the wire and the mold, generating excessive heat (leading to metal softening and diameter expansion) and increasing the risk of wire breakage. It may also cause uneven wire arrangement during coiling, resulting in surface scratches. SuperbMelt’s machine has a stepless speed regulation function (0-15 meters per minute), allowing operators to adjust the speed according to the material and diameter (e.g., 3-5 meters per minute for fine wire, 10-15 meters per minute for thick wire).

- Tension Control Key Points: Too high tension will stretch the wire, reducing its diameter beyond the tolerance range; too low tension will cause the wire to slip in the mold, resulting in uneven diameter and surface defects. SuperbMelt’s servo-driven tension control system automatically adjusts the tension according to the drawing speed and material, ensuring stable tension throughout the process.

3.3, Impact of Surface Finish on Subsequent Processes

The surface finish of the wire directly determines the success rate of subsequent processes such as welding, inlaying, and plating. Jewelry-grade wire must meet strict surface requirements:

- Welding Requirements: The wire surface must be free of oil, oxide layers, and scratches. Contaminants will block the welding contact, leading to weak welds or pores. SuperbMelt’s wire drawing machine ensures a clean surface by matching with pre-drawing cleaning processes and avoiding scratches during drawing.

- Inlay Requirements: Smooth wire surface ensures tight fit between the setting claws and gemstones. Scratches or burrs on the wire surface will cause gaps, affecting the stability of the inlay.

- Plating Requirements: Uneven surface finish will cause uneven plating (e.g., thick in some areas and thin in others), affecting the color and durability of the plating layer. The high surface finish (Ra ≤ 0.05μm) of wire produced by SuperbMelt’s machine ensures uniform plating and a bright finish.

Cooling System and Precious Metal Protection Mechanism

Heat generation during the wire drawing process is inevitable. Effective cooling and protection mechanisms can prevent metal performance degradation and reduce precious metal loss, which is crucial for cost control and product quality.

4.1, Sources of Heat Generation During Wire Drawing

The heat generated during wire drawing mainly comes from two aspects:

- Frictional Heat: Generated by the friction between the wire and the inner wall of the mold hole during drawing. The smaller the mold hole and the higher the speed, the greater the frictional heat.

- Metal Plastic Deformation Heat: When the wire is drawn, the metal molecular structure is rearranged (plastic deformation), which releases a lot of heat. Hard materials (such as stainless steel) require greater deformation force, generating more heat than soft materials.

Excessive heat will cause the wire to soften (leading to diameter expansion and shape deformation) and accelerate mold wear, increasing production costs.

Impact of Spray Cooling on Wire Performance

SuperbMelt Gold Wire Drawing Machine is equipped with a professional spray cooling system, which plays a key role in protecting wire performance:

- Prevent Overheating Softening: The spray system sprays cooling liquid evenly on the wire and mold, quickly taking away heat and keeping the wire temperature within the safe range (≤ 80°C). This ensures that the wire maintains stable hardness and diameter during drawing.

- Avoid Metal Fatigue: Excessive heat will cause metal fatigue (internal stress accumulation), making the wire brittle and easy to break during subsequent processes. Cooling in time eliminates internal stress, ensuring the wire’s flexibility and durability.

- Protect Mold and Reduce Wear: Cooling the mold reduces thermal expansion and contraction, extending the service life of the diamond mold (up to 10,000 hours of use), reducing mold replacement costs.

How to Reduce Precious Metal Loss and Microcracks

Precious metal loss and microcracks during drawing are mainly caused by improper temperature control and tension. SuperbMelt’s machine achieves effective control through multiple mechanisms:

- Temperature Control for High Recovery Rate: Precise temperature control (via spray cooling) avoids metal oxidation (which causes surface loss) and reduces the generation of metal shavings during drawing. The machine’s metal recovery rate can reach more than 99.5%, significantly reducing precious metal waste.

- Stable Tension to Prevent Microcracks: Excessive tension will cause microcracks in the wire (invisible to the naked eye but affecting the wire’s strength). The servo-driven tension control system maintains stable tension, avoiding microcracks caused by uneven stress.

- Smooth Wire Arrangement to Avoid Scratches: The machine’s servo-driven precise wire arrangement ensures that the wire is neatly coiled without mutual friction, avoiding surface scratches (which cause metal loss when polished later).

Automatic Coiling and Continuous Production Efficiency

Automatic coiling and continuous production are the keys to improving production efficiency and ensuring batch consistency. They reduce manual intervention, avoid human errors, and meet the mass production needs of jewelry manufacturers.

5.1, The Role of Automatic Coiling in Jewelry Production

SuperbMelt’s Gold Wire Drawing Machine is equipped with an automatic coiling function, which plays an important role in the entire production process:

- Stable Tension and Prevent Wire Damage: Automatic coiling maintains consistent tension with the drawing process, avoiding wire stretching or kinking caused by manual coiling. The precise wire arrangement function prevents mutual abrasion between wires, ensuring the surface quality of the coiled wire.

- Facilitate Material Collection and Subsequent Use: The coiled wire is neat and compact, easy to store and transport. When used in subsequent processes (such as chain making), it can be directly loaded into the chain making machine, reducing the time for wire arrangement and improving production efficiency.

- Improve Production Safety: Automatic coiling reduces the need for manual operation near the drawing area, avoiding potential safety hazards (such as hand being scratched by the wire or touching the high-temperature mold).

How Continuous Drawing Improves Batch Consistency

Continuous drawing (without frequent shutdowns for wire replacement) is the guarantee of batch consistency. SuperbMelt’s machine achieves continuous production through multiple designs:

- Reduce Manual Intervention: The machine is equipped with automatic shutdown and material shortage shutdown functions. When the raw material is exhausted, it automatically shuts down to avoid idling or defective products caused by lack of material. This reduces the need for manual monitoring, ensuring that the drawing parameters (speed, tension, temperature) remain stable throughout the batch production process.

- Minimize Wire Diameter Error: Frequent shutdowns and startups will cause fluctuations in drawing tension and speed, leading to differences in wire diameter between batches (or within the same batch). Continuous drawing ensures that the wire diameter error of the entire batch is controlled within ±0.01mm, meeting the consistency requirements of mass-produced jewelry.

Safety Protection and Automatic Shutdown Mechanism

The safety protection mechanism of the wire drawing machine not only protects the operator but also plays a key role in protecting precious metals:

- Wire Breakage Shutdown: When the wire breaks (due to unexpected factors such as material defects), the machine immediately shuts down to avoid idling of the drawing and coiling systems, which could cause damage to the mold or generate unnecessary metal waste.

- Material Shortage Shutdown: When the raw material wire is about to be exhausted, the machine automatically detects and shuts down, ensuring that the last section of the wire is also drawn with stable parameters, avoiding defective products caused by insufficient material tension.

- Overload Protection and Emergency Stop: The machine is equipped with overload protection (to avoid motor damage caused by excessive load) and an emergency stop button (for immediate shutdown in case of emergencies). These functions ensure the safety of operators and the stability of the production process, indirectly reducing precious metal loss caused by accidents.

How Wire Connects to Subsequent Jewelry Processes

The ultimate value of wire drawing lies in its connection with subsequent processes. The wire’s parameters (diameter, hardness, surface quality) must be accurately matched with subsequent processes (such as chain making, inlaying, and welding) to form a stable and replicable production process.

6.1 Matching Relationship Between Gold Wire and Chain Making Machine

Different types of chains have strict requirements on wire diameter tolerance. The wire produced by SuperbMelt’s machine can perfectly match various chain making machines:

- Box Chains: Require high wire roundness and diameter consistency (tolerance ≤ ±0.01mm) to ensure that the square links are neat and tightly connected. The high-precision wire produced by SuperbMelt’s machine avoids loose or skewed links.

- Rope Chains: Require the wire to have appropriate hardness and flexibility. The wire’s hardness can be adjusted by controlling the drawing speed and annealing process (coordinated with SuperbMelt’s machine parameters), ensuring that the rope chain has good twistability and shape retention.

- Cable Chains: The most common chain type, which requires stable wire diameter to ensure uniform link spacing. SuperbMelt’s machine can produce wires with consistent diameter in large batches, meeting the mass production needs of cable chains.

How Drawing Parameters Serve Different Jewelry Designs

Different jewelry designs require wires with different hardness (hard wire vs. soft wire), which can be achieved by adjusting drawing parameters:

- Hard Wire: Suitable for structural parts that require high strength (such as bracelet buckles, necklace clasps, and setting claws). It is produced by increasing the drawing speed and reducing the number of annealing passes (to retain metal hardness). SuperbMelt’s PLC control system can store hard wire drawing parameters for quick recall.

- Soft Wire: Suitable for woven jewelry, curved ring bands, and delicate pendants. It is produced by reducing the drawing speed and increasing intermediate annealing passes (to eliminate internal stress and increase flexibility). The machine’s adjustable speed and cooling parameters allow precise control of wire hardness.

Process Connection Logic from Wire Drawing to Finished Jewelry

To establish a stable and replicable jewelry production process, the following connection logic must be followed from wire drawing to finished products:

- Parameter Matching: According to the jewelry design (style, size, function), determine the wire diameter, hardness, and surface finish requirements, and set corresponding drawing parameters (speed, tension, cooling intensity) on SuperbMelt’s machine.

- Pre-Process Inspection: After wire drawing, inspect the wire’s diameter, roundness, and surface quality. Only qualified wire can enter the next process (avoiding subsequent process defects caused by unqualified wire).

- Process Coordination: Coordinate the speed of wire drawing with subsequent processes (such as chain making, welding). For example, the coiled wire from the wire drawing machine can be directly loaded into the automatic chain making machine, realizing seamless connection between processes and improving production efficiency.

- Parameter Iteration: According to the feedback from subsequent processes (such as welding success rate, chain flexibility), adjust the drawing parameters appropriately to optimize the entire production process. SuperbMelt’s machine’s parameter storage and recall function facilitates process iteration and optimization.

Why Choose SuperbMelt Gold Wire Drawing Machine for Jewelry Manufacturing?

In the competitive jewelry manufacturing industry, the quality of wire drawing directly affects the core competitiveness of products. SuperbMelt Gold Wire Drawing Machine stands out with its targeted design for jewelry production needs, bringing multiple advantages to manufacturers:

- High Precision & Consistency: Servo-driven precise wire arrangement and diamond molds ensure wire diameter tolerance ≤ ±0.01mm and out-of-roundness ≤ 0.005mm, meeting the strict requirements of jewelry-grade wire.

- Multi-Material Compatibility: Compatible with gold, silver, K-gold, alloys, stainless steel, and other materials, covering all mainstream precious metals used in jewelry production.

- Efficient & Automated Production: Maximum drawing speed of 15 meters per minute, automatic coiling, and automatic shutdown functions reduce manual intervention, improving production efficiency and batch consistency.

- Comprehensive Protection Mechanisms: Spray cooling system, stable tension control, and multiple safety protections (overload, emergency stop, wire breakage shutdown) reduce precious metal loss and ensure production safety.

- User-Friendly & Easy Maintenance: PLC intelligent control system with an intuitive touchscreen interface, easy parameter setting, and tool-free mold disassembly, reducing the threshold for operator use and maintenance costs.

- Customizable Solutions: Supports customization of wire diameter settings, speed adjustments, and other parameters to meet the personalized production needs of different jewelry manufacturers (such as small-batch custom studios and large-scale production factories).

Ready to Upgrade Your Jewelry Wire Drawing Process?

High-quality wire is the foundation of exquisite jewelry. SuperbMelt Gold Wire Drawing Machine helps you master the core of jewelry-grade wire drawing, solving pain points such as unstable precision, high metal loss, and low efficiency. Whether you are a small custom jewelry studio, a medium-sized chain manufacturer, or a large-scale luxury jewelry factory, SuperbMelt can provide customized wire drawing solutions to meet your production needs.

Want to know how to match the most suitable wire drawing parameters for your jewelry products? Need to calculate the ROI of upgrading the wire drawing machine? Contact SuperbMelt experts today! We will provide you with one-on-one professional consulting services, share product samples and process solutions, and help you take the first step toward efficient, high-quality, and low-cost jewelry production.

FAQ Guide of Gold Wire Drawing Machine

- 1. What is the process of drawing gold wire?

- 2. What is the use of wire drawing machine?

- 3. What is the raw material for wire drawing?

- 4. How does a gold wire drawing machine work?

- 5. What is a gold wire drawing machine?

- 6. What are the main components of a gold wire drawing machine?

- 7. What sizes of gold wire can be drawn using this machine?

- 8. What is the purpose of using a gold wire drawing machine?

- 9. What are the advantages of using a gold wire drawing machine?

- 10. Can other metals besides gold be drawn using this machine?

- 11. How fast can a gold wire drawing machine produce wire?

- 12. Is the drawn gold wire suitable for jewelry making?

- 13. What safety measures should be observed when operating a gold wire drawing machine?

- 14. How can I maintain a gold wire drawing machine for optimal performance?

- 15. Can a gold wire drawing machine be customized to meet specific requirements?

1. What is the process of drawing gold wire?

Melting gold into ingots is the initial stage in the preparation of gold ingots. After that, these ingots are rolled into long rods or strips with the appropriate diameter.

Annealing: After that, the gold rods or strips are annealed to make them softer. As a result, they are simpler to work with and more pliable while sketching.

Drawing: A sequence of dies with progressively decreasing diameters is used to feed the annealed gold rods. The gold rod is compressed in each die, lengthening and decreasing in diameter. Until the gold wire reaches the required diameter, this operation is repeated several times.

Intermediate Annealing: To keep the gold wire ductile and keep it from getting too brittle, it may be annealed again on occasion.

Final Drawing: To obtain the exact diameter needed for the application, the gold wire is drawn through one last set of dies.

Finishing: To improve its look and get rid of any surface flaws, the gold wire is usually cleaned and polished when it reaches the required diameter.

2. What is the use of wire drawing machine?

- Production of Wires: A wire drawing machine is primarily used to generate wires made of various materials, including alloys, steel, copper, and aluminum. Numerous products, such as electrical wiring, cables, springs, nails, screws, mesh, and fence, employ these wires.

- Jewelry Making: To create fine wires of precious metals like gold, silver, platinum, and their alloys, wire drawing machines are widely employed in the jewelry business. Jewelers then use these wires to construct elaborate designs for jewelry such as bracelets, necklaces, earrings, and rings.

- Metalworking: Wire drawing machines are used in the metalworking industry to manufacture wires that are utilized in various parts and components. To generate intricate forms and structures for equipment, automobile components, building materials, and other uses, these wires are frequently subjected to further processing such as bending, cutting, and welding.

- Electronics: In order to produce the tiny wires needed to make electrical components, circuit boards, connections, and cables, wire drawing machines are essential to the electronics sector. To guarantee the best possible performance and dependability in electrical equipment, these cables need to have exact measurements and premium surfaces.

- Craftsmanship and Artistry: To create sculptures, artwork, and ornamental features, artisan and craftsmen also employ wire drawing machines. These devices generate fine wires that may be formed and worked into complex patterns, giving visual interest to a variety of artistic endeavors.

3. What is the raw material for wire drawing?

- Steel: Because of its strength, resilience, and adaptability, steel is one of the materials most frequently utilized in wire drawing. It is used to make wires for many different uses, including as equipment, construction, automobiles, and home goods.

- Copper: Because of its exceptional conductivity and resistance to corrosion, copper is frequently utilized in electrical wiring and conductor applications. Power transmission, electronics, telecommunications, and electrical systems all depend on copper cables.

- Aluminum: Aluminum wires are ideal for applications where weight reduction and electrical conductivity are crucial, such as power distribution, electrical wiring, and aircraft, since they are lightweight, corrosion-resistant, and have strong electrical conductivity.

- Alloys: To get certain qualities like increased strength, resistance to corrosion, or visual appeal, wire drawing also makes use of a variety of metal alloys, such as bronze (copper-tin alloy) and brass (copper-zinc alloy). These alloys are used in the maritime, automotive, decorative arts, and jewelry-making sectors.

- Precious Metals: Fine wires used in jewelry-making, luxury items, and high-end electronics are produced by wire drawing using precious metals such as gold, silver, platinum, and their alloys. These metals are prized for their elegance, scarcity, and ability to withstand tarnish.

- Other Metals: In specialist sectors like aerospace, medical, and military, other metals including nickel, titanium, and tungsten may also be utilized as raw materials for wire drawing, depending on the particular needs of the application.

4. How does a gold wire drawing machine work?

In order to reduce a gold wire’s diameter while extending its length, a gold wire drawing machine works by dragging the wire through a succession of successively smaller dies. While cooling systems guard against overheating, tension control devices guarantee constant pulling. After processing, a longer, thinner wire that may be used for a variety of applications

5. What is a gold wire drawing machine?

A gold wire drawing machine is a specialized piece of equipment used to pull a gold wire through a series of dies to reduce its diameter and increase its length.

6.What are the main components of a gold wire drawing machine?

The main components include a wire feeding mechanism, drawing dies, tension control system, cooling system, and a take-up spool.

7. What sizes of gold wire can be drawn using this machine?

Gold wires with diameters ranging from 0.3mm to 8mm can typically be drawn using a gold wire drawing machine.

8. What is the purpose of using a gold wire drawing machine?

The primary purpose is to produce thinner and longer gold wires suitable for various applications, including jewelry making and electronics.

9. What are the advantages of using a gold wire drawing machine?

Some advantages include high efficiency, precision, automated operation, and the ability to produce wires with consistent quality.

10. Can other metals besides gold be drawn using this machine?

Yes, besides gold, this machine can also be used to draw wires from other metals such as silver, copper, and alloys.

11. How fast can a gold wire drawing machine produce wire?

The production speed varies depending on factors like wire diameter, machine capacity, and operational settings, but it can typically produce up to 100 meters per minute.

12. Is the drawn gold wire suitable for jewelry making?

Yes, the drawn gold wire is commonly used in jewelry making to create various types of jewelry such as rings, necklaces, bracelets, and earrings.

13. What safety measures should be observed when operating a gold wire drawing machine?

Operators should follow safety protocols regarding machine operation, maintenance, and handling of materials to prevent accidents and ensure a safe working environment.

14. How can I maintain a gold wire drawing machine for optimal performance?

Regular maintenance tasks include cleaning, lubricating moving parts, checking tension control systems, and inspecting dies for wear and tear.

15. Can a gold wire drawing machine be customized to meet specific requirements?

Yes, manufacturers often offer customization options to tailor the machine’s specifications and features according to the user’s needs.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited