Gold Coin Packing Machine

Professional Manufacturer in China

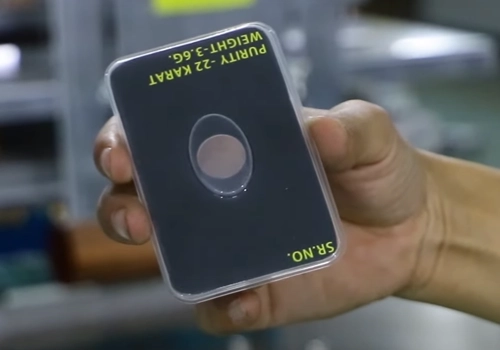

Gold coin packaging is the last important process in the sale of gold coins and bars, and the gold coin packaging machine plays a big role in this link. It not only displays supplier information and product specifications clearly, but also prevents wear and tear during transportation.

In the production and processing industries such as gold, silver coins and bars, the protective panel of the machine can reduce the safety hazards of employees during operation. The fully automatic machine greatly increases the production and reduces labor input.

SuperbMelt is committed to precious metal processing. In the production of gold coins and gold bars, we have a professional production line experience and equipment research and development team.

| Model | SPB-8KWRS |

| Power | 8KW |

| Oscillation Tube | 7T69RB |

| Max Pressure | 750kg |

| Electrode Stroke | 150mm |

| Electrode Size | 250*350mm |

| Stress Mode | Pneumatic |

| Input Voltage | 50/60HZ Ac380 3P |

| Frequency | 27.12MHZ |

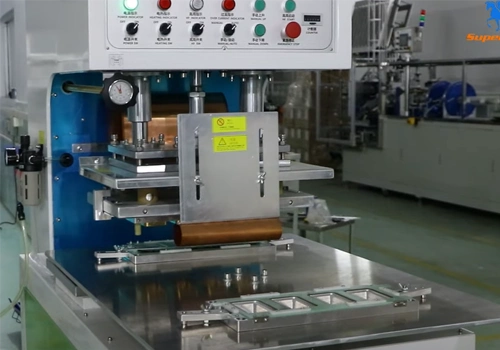

SuperbMelt Gold Coin Packaging Machine adopts high frequency heat sealing technology. First put the gold coin into the packaging mold, then heat and fuse, so that the two sides of plastic or one side of plastic and one side of cardboard are tightly bonded together. The two sides of the cardboard will first be coated with glue of materials such as pvc, so that the two are integrated.

Single and Double Operation Possible

Double-station can realize multi-employee operation, improve work efficiency, and manual turntable can ensure accurate position.

Equipped with Safety Protection

Gold coin packing machine is equipped with a high-sensitivity device to prevent sparks, it can effectively protect the gold coin packaging mold.

A Variety of Packaging Processes

One machine can realize a variety of packaging processes, and can do welding or edge tearing according to the customer’s packaging design.

It can also be changed to a pressurized cylinder to make a synchronous edge trimming process.

100 Degree High Temperature Welding

Machine-printed packaging is stronger than hand-bonded packaging, preventing collisions and friction during transportation and sales. At the same time keep the gold coins and nuggets beautiful.

Mass Production

The design of two lower molds can speed up the welding, and put the material at the same time of the compression mold, which can save more time and realize mass production.

Perfect Packaging Effect

Equipped with a high-temperature precision welding table, the welding package products are smooth and flat.

The SuperbMelt Gold Coin Packaging Machine is specially designed for gold coins and gold ingots, and can be customized in different sizes and packaging styles, such as double-sided blister sealing packaging, blister hanging card sealing packaging, blister cover heat sealing packaging for double-sided paper card holders.

The shape and packaging materials of gold coins can also accept diversified, round, square, irregular and other shapes of gold coins, and can be welded with pvc, cardboard, plastic and genuine leather materials.

One machine has two sets of down molds, which can realize mass production and greatly improve work efficiency.

Accepts a wide variety of packaging styles and coin shapes, including square, round, irregular, etc.

The finished product is perfect, and the packaging is welded firmly.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Gold Coin Packing Machine

Any Question About SuperbMelt Gold Coin Packing Machine

Guide of Gold Coin Packing Machine

How to Use the Coin Packing Machine

- Check the Connection

Three phase line connect to the power, one connect to the air compressor and make sure the parameter between 0.3-0.4.

- Turn on Power

Power switch on,turn on heat and high frequency switch when doing welding for pvc material,then select manul or auto for your work need.

- Adjust the Temperature and Cooling Time

The temperature can be adjusted according to the material, for PVC,90-100 more or less, cooling time can set 3s.

- Start Welding

Set the material to the down mold,Place gold coins or gold nuggets, then put another layer of material, then turn the turntable for automatic welding.

Type of High Frequency Coin Packaging Machines

In addition to gold coin packaging, our machine can accept non-standard customization. If you need to do other types of packaging such as electronic products, stationery, daily necessities, etc., just only need to replace the mold.

Automatic Turntable High Frequency Coin Packaging Machine

This machine is an automatic turntable packing machine with 3 working stations. It suitable for small products can achieve 300 times per hour. It is equipped with 3 molds, and each mold has 3 packaging positions, so it can produce 300 times per hour. so for this machine it can finsh 900-1000pcs per hour.

It is very suitable for medium and large factories, and the design of automation can improve work efficiency and increase production.

Manual Turntable High Frequency Coin Packaging Machine

The working principle is the same as the circular machine, but the operation method is different. This one needs to manually rotate the turntable, and then carry out packaging and welding. There are 2 working stations, which is more suitable for small gold coin processing factories. The feeding speed of employees determines the output of the machine.

FAQ Guide of Gold Coin Packing Machine

- What is a gold coin packing machine used for?

- What types of coins can it handle?

- What is the production capacity?

- Does it support automatic coin feeding?

- Can it pack coins in different types of packaging?

- How accurate is the coin counting and packaging?

- Is the machine easy to operate and maintain?

- What is the power supply requirement?

- Can the machine handle multiple coin sizes at the same time?

- Can the machine be integrated into an existing production line?

What is a gold coin packing machine used for?

A gold coin packing machine is used to automatically package coins, ensuring efficiency, consistency, and protection during storage or shipment. It can handle various types of coins, such as gold, silver, or commemorative coins, and can package them into rolls, capsules, boxes, or other protective containers. This automation reduces manual labor, improves production speed, and minimizes errors in counting and handling.

What types of coins can it handle?

The SuperbMelt Gold Coin Packing Machine is designed to handle a wide variety of coins, accommodating different shapes and sizes. It works efficiently with round, square, and even irregular-shaped coins, making it versatile for gold, silver, and other precious metal coins. Its adaptable molds and fully automated system ensure that each coin is securely packaged, preserving its quality while supporting mass production.

What is the production capacity?

The SuperbMelt Gold Coin Packing Machine features dual down molds, enabling simultaneous packaging and significantly boosting productivity. It is designed for high-speed, continuous operation, allowing for mass production of gold, silver, and other precious metal coins. The fully automated system reduces labor input while maintaining consistent quality, making it ideal for large-scale coin packaging operations.

Does it support automatic coin feeding?

Yes, the SuperbMelt Gold Coin Packing Machine supports automatic coin feeding. Coins are loaded into the machine and conveyed to the packaging station without manual intervention, ensuring smooth, continuous operation. This automation reduces labor, minimizes handling errors, and improves overall production efficiency.

Can it pack coins in different types of packaging?

Yes, the SuperbMelt Gold Coin Packing Machine can handle a variety of packaging types. It accommodates different coin shapes—round, square, or irregular—and can apply various packaging styles, ensuring that each coin or bar is securely sealed and presented professionally. This flexibility makes it suitable for diverse production needs and market requirements.

How accurate is the coin counting and packaging?

The SuperbMelt Gold Coin Packing Machine ensures high accuracy in both counting and packaging. Its automated system precisely counts each coin before packaging, minimizing errors and reducing waste. Combined with firm sealing and consistent alignment, it guarantees that every package meets strict quality standards.

Is the machine easy to operate and maintain?

Yes, the SuperbMelt Gold Coin Packing Machine is designed for user-friendly operation and low-maintenance use. Its intuitive control panel allows operators to set parameters and monitor the packaging process easily, while the machine’s modular design simplifies cleaning, adjustments, and part replacement, reducing downtime and ensuring long-term reliability.

What is the power supply requirement?

The SuperbMelt Gold Coin Packing Machine typically requires a standard industrial power supply, usually AC 220V/50Hz or AC 110V/60Hz, depending on the model and regional specifications. It is designed to operate efficiently within these voltage ranges to ensure stable performance and consistent packaging quality.

Can the machine handle multiple coin sizes at the same time?

Yes, the SuperbMelt Gold Coin Packing Machine is designed to handle multiple coin sizes simultaneously. It can accommodate round, square, and irregularly shaped coins, allowing manufacturers to package different denominations or designs in one production line without changing setups, which greatly improves efficiency and reduces downtime.

Can the machine be integrated into an existing production line?

Yes, the SuperbMelt Gold Coin Packing Machine can be seamlessly integrated into an existing production line. Its compact design, automated feeding system, and adjustable settings allow it to work alongside other processing equipment, such as coin stamping, polishing, or quality inspection machines, ensuring a smooth, continuous workflow while boosting overall production efficiency.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited