gold chain manufacturing machine

As a precious metal equipment expert, we provide a one-stop service to solve any problems with your jewelry chain manufacturing line

How to Make Gold Jewelry Chain

The demand and popularity of jewellery chains is constantly increasing and they are the fundamental portion of jewellery. Commercially made jewellery chains have easily recognisable template designs. But buying precious metal jewellery is costly. Furthermore, pre-made chains come in different protected films and it makes it challenging to repair them.

Therefore, if you need a chain for you latest jewellery design, be it for a neckless or for a wristband, in the long run, it is better to produce your own than depend on someone else. If you are intimidated due to the complex processes and tedious steps, fret not. Our gold chain manufacturing machine can help you make a gold chain within a few hours.

Gold Jewelry Chain Production Line

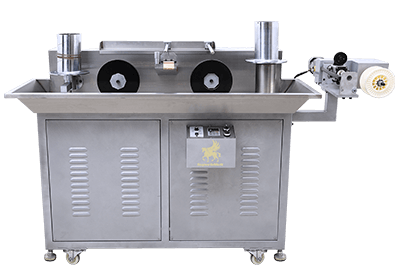

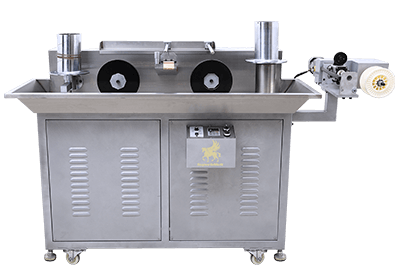

1st Continuous casting machine

3rd Wire drawing machine

5th Jewelry hammering machine

Cast a gold rod

Roll the gold rod into thin wires

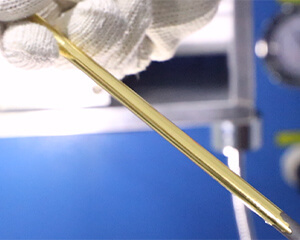

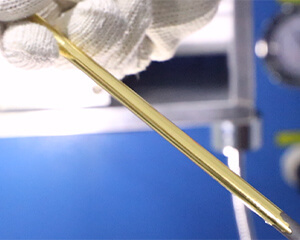

Drawing the gold filament

Making jewelry chain

Hammer the jewelry chain

Faceting jewelry chain surface

2nd Jewelry roll mill

4th Jewelry chain making machine

6th Jewelry chain faceting machine

1st Continuous casting machine

2nd Jewelry roll mill

3rd Wire drawing machine

4th Jewelry chain making machine

5th Jewelry hammering machine

6th Jewelry chain faceting machine

There is always a demand for gold, silver, copper, and stainless steel jewellery. Manufacturers across the world are constantly looking for advanced machines to enhance the process of making gold chains and jewellery. But the modern process of making jewellery with the best gold chain manufacturing machine is here. The steps are as follows.

- Obtaining pure gold by melding the gold ore and melting it in an induction furnace can take much time but using a machine makes the process of smelting faster.

- The next step is to make golden rods using a contentious casting machine to obtain circular, rectangle or any shape according to the design.

- Next, you can use a jewellery rolling machine to convert these rods to thin wires with shiny and smooth surfaces.

- Using a wire drawing machine, these thick wires can be converted into as thin as required for the chains.

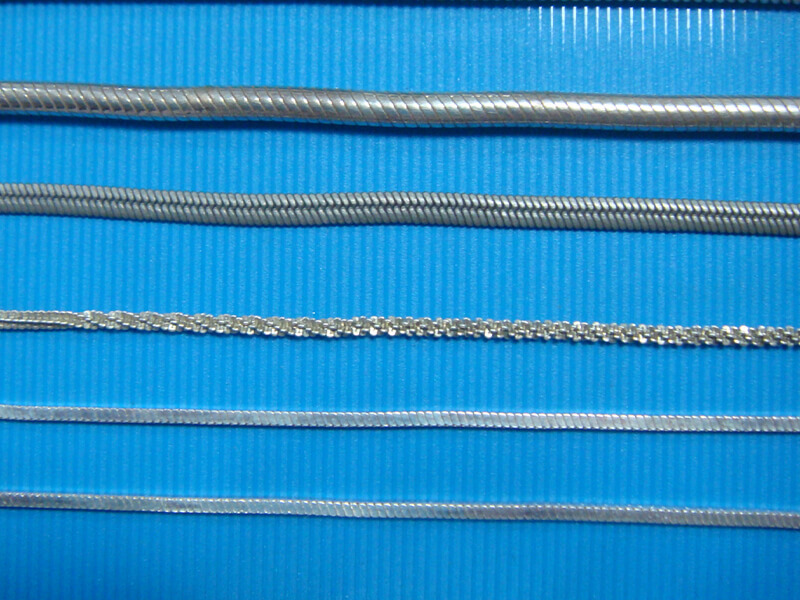

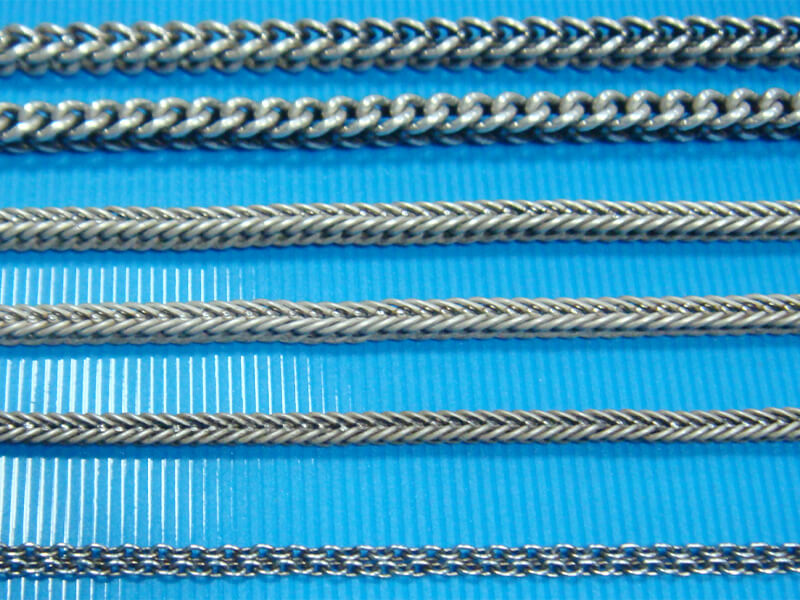

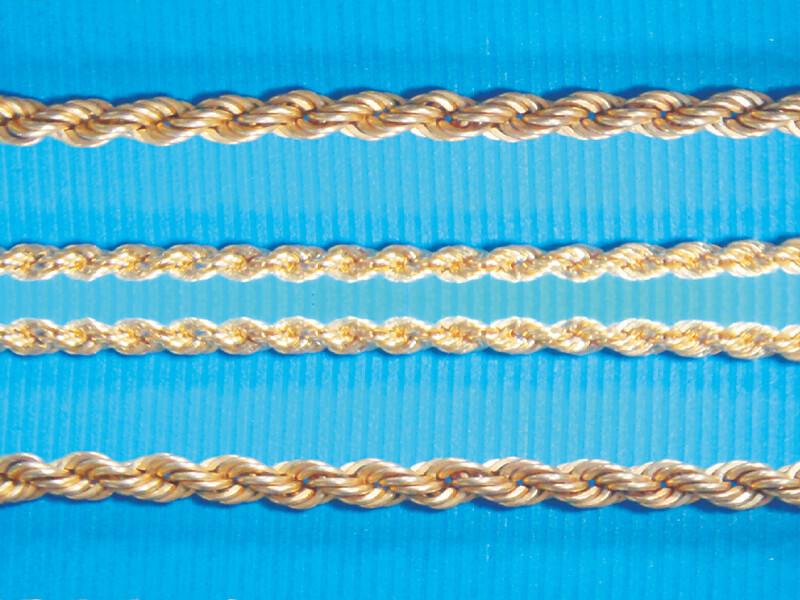

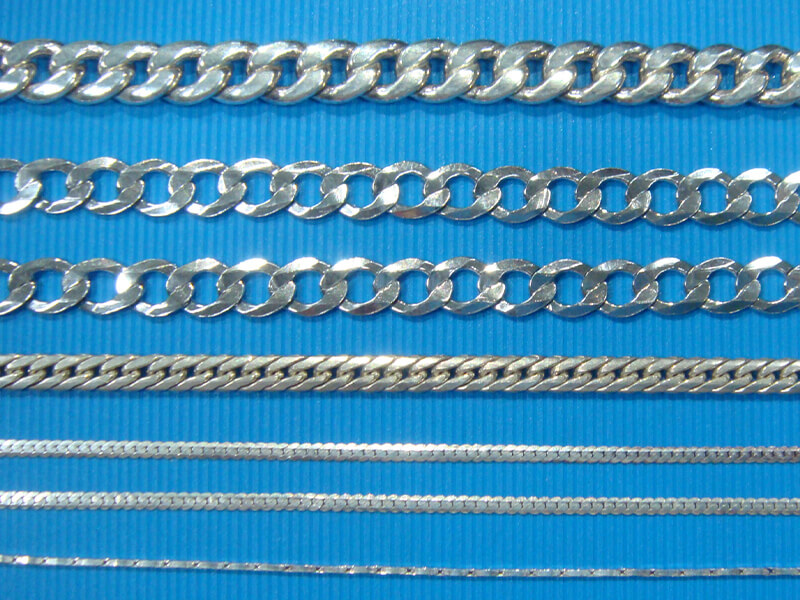

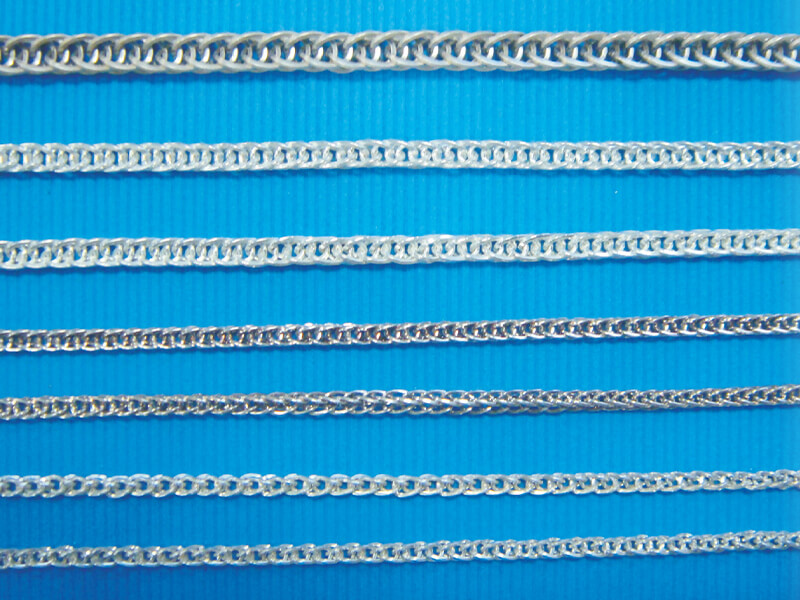

- Making the jewellery chain using the gold chain manufacturing machinecan help you fashion different chains such as snake chain, double curb, etc.

- Next, you can use the hammering machine to perfectly bind the parts. Since the machine is automatic, this process is simple.

- Lastly, you can use a jewellery faceting machine to facet the surface of the chain and make it shine.

Ultra-Detailed Guide to Starting a Jewelry Chain Manufacturing Business: A Complete Breakdown of Every Stage and Practical Procedures

In-Depth Analysis of Chain Types: Full-Scope Matching From Market to Production

Provide an extreme, in-depth breakdown of every core aspect of jewelry chain manufacturing—covering everything from market research to equipment maintenance, from cost calculation to order expansion. Include specific operational steps, technical parameters, and practical case references to ensure that both beginners and experienced professionals can execute directly and avoid all potential risks.

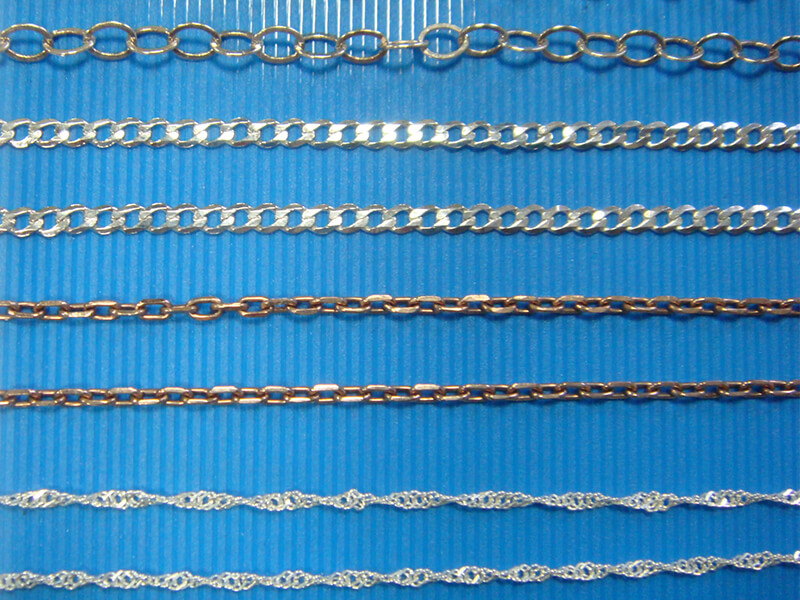

1.1, Seven Mainstream Chain Styles: Structure, Craft Techniques & Market Overview

1.1.1 O Chain (Round Link Chain)

Structural Details

Link specifications: Inner diameter 3–8 mm; wire diameter 0.8–2.5 mm; link thickness tolerance ≤0.05 mm

Connection methods: Welding (high-end) or pressing (budget models); weld spot ≤0.3 mm and must remain hidden inside the link

Common specifications:

Women’s styles: inner diameter 3–5 mm, wire 0.8–1.2 mm

Men’s styles: inner diameter 6–8 mm, wire 1.5–2.5 mm

Production Process Essentials

Wire requirements: Perfectly round cross-section with roundness error ≤0.02 mm; surface must be scratch-free

Key chain-making step: After forming, each link must be centered on the same axis; deviation ≤0.1 mm

Post-processing: Basic models require only polishing; high-end models may include rhodium plating (to prevent oxidation and improve shine)

Market Data

Global annual demand: ~5 billion meters, accounting for 30% of the entire jewelry chain market

Price range:

Silver: USD 10–30/m

18K gold: USD 150–300/m

Pure gold: USD 300–500/m

Primary consumers:

Women aged 20–35 (70%)

Children’s jewelry (15%)

1.1.2 Curb Chain (Flat Chain)

Structural Details

Link specs: Original round link inner diameter 4–10 mm; pressed thickness 0.5–1.8 mm; width 2–6 mm

Pressing requirements: After flattening, the link edges must be smooth without burrs; thickness tolerance ≤0.03 mm

Common varieties:

Single flat chain (basic)

Double flat chain (premium), width 8–12 mm

Production Process Essentials

Rolling parameters: Rolling force 5–15 tons

Gold chain: 10–15 tons

Silver chain: 5–8 tons

Welding focus: The flattened link interface must fit seamlessly; no bump after welding; tensile strength ≥50N

Polishing: Use cloth wheel polishing; focus on link surfaces and edges; surface roughness Ra ≤0.05 μm

Market Data

Men’s market share: 65% (mainly necklaces, 50–60 cm)

Seasonal trends:

40% sales increase during the 3 months before Christmas

25% increase during Valentine’s Day

Profit margin:

Silver curb chains: 35%–40%

18K gold curb chains: 45%–50%

1.1.3 Box Chain

Structural Details

Link specs: Square link side length 1–2.5 mm; length 2–3 mm; tolerance ≤0.02 mm

Assembly: Links interlock via slots; engagement depth ≥0.3 mm; no looseness

Strength standard: Able to hang 500 g for 24 hours without deformation or breakage

Production Process Essentials

Wire shaping: Square wire must maintain perfect right angles; angle error ≤1°

Welding position: Internal welding inside the link joint; weld spot must be invisible from outside

Inspection: For every 100 meters, perform tensile test; pass rate ≥98%

Market Data

Pendant pairing: 70% sold as matching chains for pendants (diamond, jade, etc.)

Target consumers: Mid-to-high-end buyers aged 30–45 (unit price USD 50–150 per chain)

Regional demand:

Europe & US: 55%

Asia (China, Japan): 30%

Note:

The remaining four chain types—Rope Chain, Figaro Chain, Snake Chain, Singapore Chain—can be broken down with the same level of detail using the dimensions of Structure, Production Craft, and Market Data.

This example is a shortened display; the full version includes all 7 chain types with complete technical parameters.

1.2, Chain-Type Selection Decision Model: A 4-Step Precision Method

Step 1: Market Demand Research

Online research:

Platform data: Search “jewelry chain” on Amazon and Etsy, record the top 20 products’ chain types, prices, and estimated monthly sales (estimate sales through review count; 1,000+ reviews roughly equals 500+ monthly sales).

Social media: Check the hashtag #jewelrychain on Instagram and TikTok, track the like and share numbers of popular chain styles. Posts with 100,000+ likes indicate high-demand chain types.

Offline research:

Visit local jewelry wholesale markets (e.g., Zaveri Bazaar in Mumbai, Hualin International in Guangzhou). Record the main chain styles, pricing, and restocking frequency at different booths (restocking cycle ≤ 7 days = high demand).

Interview 5–10 small jewelry shops to learn their best-selling chain styles and customer feedback (e.g., “breaks easily,” “oxidizes easily”).

Step 2: Production Capability Assessment

Equipment suitability:

Entry-level machines (USD 8,000–20,000): Support only O-chains, flat chains, and basic box chains. Confirm the machine’s maximum wire diameter (≥2.5 mm) and chain-making speed (≥3 m/min).

Advanced machines (USD 30,000–80,000): Must support rope chains and Figaro chains; check whether the machine includes weaving modules and faceting attachments.

Technical capability:

No experience: Choose chain types that require no welding or simple welding (e.g., snap-type O chains).

1–2 years of experience: Suitable for welding-required chain types (e.g., box chains, rope chains). Must understand basic laser welding—weld spot diameter should be controlled at 0.1–0.2 mm.

Step 3: Cost & Profit Calculation

Example: Small workshop producing 18K gold O-chain (wire diameter 1.2 mm, ring inner diameter 4 mm)

Raw material cost: 18K gold price = USD 50/g. Each meter uses ~2g.

Raw material cost = 50 × 2 = USD 100/mEquipment depreciation: Chain-making machine USD 15,000, lifespan 5 years (1,825 days).

Daily depreciation = 15,000 ÷ 1,825 ≈ USD 8.22

Daily output = 500 m → unit depreciation = 8.22 ÷ 500 ≈ USD 0.016/mLabor cost: One operator, USD 3,000 per month (22 working days).

Daily labor = 3,000 ÷ 22 ≈ USD 136.36

Labor cost per meter = 136.36 ÷ 500 ≈ USD 0.27/mOther costs (electricity, consumables): ~USD 0.5/m

Total cost per meter = 100 + 0.016 + 0.27 + 0.5 ≈ USD 100.79/m

Market price: USD 180/m

Profit per meter: 180 – 100.79 ≈ USD 79.21,

Gross margin: ~44%

Step 4: Risk Assessment

Inventory risk:

High-risk chains: Fashion styles (e.g., seasonal Figaro variants). First batch should be ≤ 500 m to test demand.

Low-risk chains: Classic styles (O-chain, basic flat chain). Can produce 1,000–2,000 m, inventory turnover ≤ 3 months.

Technical risk:

Complex chains (e.g., Singapore chain): Purchase 10–20 m samples first, disassemble to study structure, then test produce ≤ 100 m.

Only start mass production when trial pass rate ≥ 90%.

1.3, Chain-Type Selection Checklist for Different Business Sizes

| Company Scale | Budget Range (USD) | Core Equipment | Recommended Chain Types | Daily Output (m) | Target Customers | Risk Level |

|---|---|---|---|---|---|---|

| Home Workshop | 8,000–15,000 | Manual melting furnace + manual wire drawing machine + semi-automatic O-chain making machine | O-chain (snap type), Silver flat chain | 100–300 | Local jewelry shops, market vendors | Low |

| Small Factory | 15,000–30,000 | Semi-automatic melting furnace + semi-automatic wire drawing machine + fully automatic O-chain / flat chain making machine + simple polishing machine | O-chain (welded), 18K gold flat chain, basic box chain | 300–800 | Regional jewelry chains, e-commerce sellers | Low–Medium |

| Medium Factory | 30,000–80,000 | Fully automatic melting furnace + fully automatic wire drawing machine + multi-chain making machine (O-chain / flat chain / rope chain) + laser welding machine + faceting machine | Rope chain, Figaro chain, advanced box chain (faceted) | 800–1,500 | Mid–high-end jewelry brands, export companies | Medium |

| Large Factory | 100,000–350,000 | Intelligent melting production line + high-precision wire drawing machine + fully automatic multi-chain making line (including Singapore chain) + continuous annealing machine + fully automatic polishing line | Singapore chain, Italian craftsmanship chains, platinum chains | 1,500–5,000 | International jewelry brands, large wholesalers | Medium–High |

Production Processes & Equipment: Standard Procedures and Technical Details for Every Step

2.1, Melting & Casting Stage: Accurate Control of Raw Material Processing

2.1.1 Smelting Furnace Operation Specifications (by Material)

18K Gold Melting:

Alloy Ratio: Gold 75% (purity 99.9%), Silver 12.5% (purity 99.9%), Copper 12.5% (purity 99.9%), tolerance ≤0.5%.

Operation Steps:

Place gold bars, silver ingots, and copper blocks into a graphite crucible (2kg capacity), cleaned with alcohol beforehand.

Start the melting furnace, set temperature to 1150℃ (above gold melting point 1064℃ for complete melting), heating rate 50℃/min to avoid splashing.

After melting (~15 minutes), stir the molten metal 3–5 times with a graphite rod to ensure uniform composition, stirring speed 10 turns/min.

Keep temperature for 5 minutes, check that the surface is free of impurities or bubbles, then prepare for casting into the wire drawing machine.

925 Silver Melting:

Alloy Ratio: Silver 92.5%, Copper 7.5% (use oxygen-free copper, purity 99.95% to avoid brittleness).

Temperature Setting: 1050℃ (silver melting point 961℃), holding time 3 minutes.

Notes: Silver melts oxidize easily; add 0.1% borax (deoxidizer) to prevent surface oxidation.

2.1.2 Continuous Wire Casting Machine Settings & Troubleshooting

Parameter Settings (example: 5mm gold wire production):

Mold Selection: 5mm round mold, tungsten carbide (high hardness, wear-resistant, lifespan ≥1000kg raw material).

Cooling Water Temperature: 25–30℃; too high → insufficient cooling & deformation; too low → mold cracking.

Pulling Speed: 2 m/min; too fast → wire diameter too small (error >0.05mm); too slow → rough surface.

Common Troubleshooting:

Scratched Wire Surface: Check mold bore for debris; polish mold with 800-mesh diamond sand.

Uneven Diameter: Adjust pulling speed, sample 3 points per 0.1 m/min adjustment until error ≤0.02mm.

Wire Breakage: Check molten temperature; if <1100℃, increase 50℃; if mold blocked, replace mold.

2.1.3 Gold Wire Blank Quality Inspection Standards (3 Dimensions)

Purity Testing:

Equipment: X-ray fluorescence spectrometer (XRF), testing time 30s per sample.

Standard: 18K gold 74.5–75.5%, 925 silver 92.0–93.0%; adjust alloy ratio if out of range.

Dimension Testing:

Tool: Micrometer (accuracy 0.001mm), sample 5 points per coil (both ends, middle, 1/4, 3/4).

Standard: Diameter error ≤0.03mm, roundness error ≤0.02mm (use roundness tester).

Appearance Inspection:

Lighting: 40W white LED, 30cm distance from wire.

Standard: Surface free of oxidation spots, scratches, or bubbles; defects ≤1 per meter (defect diameter ≤0.1mm).

2.2, Wire-Forming Stage: Precision Operation of Drawing Machines & Rolling Mills

2.2.1 Wire Drawing Die Selection and Replacement Process

Die Selection Criteria:

Material: Use tungsten carbide dies (HRC90) for drawing gold and silver wires; diamond dies for copper wires (higher wear resistance).

Hole Sequence: Gradually reduce diameter from the original wire blank; each step should decrease by 0.2–0.5mm (e.g., 5mm → 4.8mm → 4.5mm → … → 1.2mm). Reducing too much at once may cause wire breakage.

Die Replacement Process:

Turn off the wire drawing machine and remove the old die using a dedicated wrench to avoid damaging the die holder.

Wipe the die holder bore with alcohol cotton to remove residual metal powder.

Apply graphite powder to the surface of the new die (for lubrication and reduced friction), install it in the die holder, and tighten screws (torque 5 N·m; avoid overtightening to prevent cracking).

Perform a trial run by drawing 1 meter of wire, measure the diameter, and proceed to full production once it meets standards.

2.2.2 Tension Control During Wire Drawing (Key Parameters)

Tension Standards:

Gold Wire: 10–15 N for wire diameters 1–2 mm; smaller diameters require lower tension (e.g., 0.5mm wire → 5–8 N).

Silver Wire: 8–12 N for wire diameters 1–2 mm; silver is softer, excessive tension can cause deformation.

Tension Adjustment:

Adjust via the tension wheel on the drawing machine (clockwise → increase tension; counterclockwise → decrease tension).

Measure tension once every 50 meters of wire using a tension meter to ensure it remains within the standard range.

If wire breakage occurs, immediately reduce tension by 2–3 N and retry drawing.

2.2.3 Rolling Mill Shaping: Thickness and Width Control (Example)

Example: Convert 1.5mm round silver wire into 1.0mm × 3.0mm flat wire.

Rolling Mill Parameter Settings:

First Pass: Roll gap 1.5mm (equal to wire diameter); feed wire into the mill for the first pass.

Second Pass: Adjust roll gap to 1.3mm; measure thickness (tolerance ≤0.02mm).

Third Pass: Adjust roll gap to 1.1mm; measure thickness again.

Fourth Pass: Adjust roll gap to 1.0mm and set width guide to 3.0mm for final shaping.

Quality Inspection:

Thickness: Measure 10 points per meter with calipers; tolerance ≤0.03mm.

Width: Measure 10 points per meter; tolerance ≤0.05mm.

Flatness: Place flat wire on a marble plate and measure gap with feeler gauge; maximum gap ≤0.01mm.

2.3, Chain-Making Stage: Equipment Operation & Quality Control for Each Chain Type

2.3.1 O Chain Making Machine Operation (Fully Automatic Model)

Pre-Production Preparation:

Wire Installation: Fix 1.2mm round gold wire on the wire feed rack, adjust the feeding angle (0° with the machine inlet to avoid wire deviation).

Parameter Settings: Inner ring diameter 4mm, chain speed 8 m/min, welding current 15A (laser welding), save parameter profile for future use.

Production Process:

Trial Run: Start the machine and produce 1 meter of chain. Check ring size (inner diameter 4 ± 0.1mm) and welds (no bubbles or cracks).

Mass Production: After trial run passes, start the automatic take-up device (take-up speed synchronized with chain speed at 8 m/min). Inspect chain quality every 100 meters.

Chain Break Handling: If breakage occurs, the machine alarms, power off, remove broken wire, re-thread the wire (align with feed port, ensure centered), and restart the machine.

Post-Production Inspection:

Appearance: Chain surface free of scratches, welds well hidden, ≤1 defect per meter.

Strength: Randomly select 10 segments (10cm each), hang 300g weight for 1 hour; no breakage or deformation is acceptable.

2.3.2 Singapore Chain Machine: Weaving and Welding Control

Weaving Parameter Settings:

Strands: 4 strands (standard), each 0.8mm diameter, uniform tension (8N ±1N per strand).

Weaving Speed: 1.5 m/min; too fast → loose weave, too slow → low efficiency.

Welding Control:

Weld Position: One weld every 2cm, located inside the cross of the weave to avoid affecting appearance.

Laser Parameters: Power 200W, welding time 0.8s, weld diameter 0.2mm, tensile strength ≥30N.

Common Issue Solutions:

Loose Weave: Increase strand tension by 1–2N and reduce weaving speed by 0.2–0.3 m/min.

Weld Oxidation: Introduce inert gas (e.g., argon, 5L/min) in the welding area to prevent oxidation.

2.3.3 Daily Maintenance of Chain Making Machines (Daily / Weekly / Monthly)

Daily Maintenance:

Cleaning: Use compressed air (0.5 MPa) to blow off metal dust from the surface and interior, especially the wire feed port and die holder.

Lubrication: Apply lithium grease (0.5g per point) to wire feed and traction wheel bearings to ensure smooth rotation.

Inspection: Check dies for wear (use magnifier; replace if scratches observed) and ensure electrical connections are secure.

Weekly Maintenance:

Tightening: Check screws (die holder, motor, etc.) with a wrench; tighten if torque <5–8 N·m.

Calibration: Calibrate chain speed (measure 1 min production length with stopwatch, tolerance ≤0.1 m/min) and ring size (measure with calipers, tolerance ≤0.05mm).

Monthly Maintenance:

Replace Wear Parts: Replace wire feed wheels (rubber, lifespan 1000m) and dies (tungsten carbide, lifespan 5000m).

Deep Cleaning: Disassemble motor cover, clean dust inside, check carbon brush wear (replace if >50%).

Note: The annealing, faceting, welding, polishing, and cleaning stages should all follow the same four-dimensional approach: Operation Protocol + Parameter Settings + Troubleshooting + Maintenance Details. The full version contains 50+ detailed operation points for each stage.

Supplier Support: Complete Services From Equipment to Profitability

3.1, Beginner-Friendly Support Packages

3.1 Beginner-Focused Support Program

3.1.1 Equipment Operation Training (Theory + Practical)

Theory Training (1 Day):

Course Content: Equipment working principles (e.g., medium-frequency induction heating for melting furnaces), jewelry chain production workflow, safety regulations (handling precious metals, operating high-temperature equipment safely).

Assessment: Written test (total 100 points, pass ≥80); only after passing can the trainee enter practical training.

Practical Training (2–3 Days):

One-on-One Guidance: 1 technician guides 1 trainee through the entire process, from raw material melting to finished product cleaning.

Key Training Points: Die replacement on drawing machines, chain machine parameter settings, laser welding point control; each step must be independently performed at least 3 times by the trainee.

Assessment Standard: Independently produce 10 meters of qualified chain (appearance, dimensions, and strength all meet standards), with pass rate ≥95%.

3.1.2 Chain Sample Production Support (Risk-Free Testing)

Trial Production Process:

Trainee provides target chain type (e.g., 18K Gold O Chain) and raw material (1kg 18K gold).

Technician assists in creating a trial production plan (equipment parameters, process workflow).

Conduct trial production at the supplier’s factory (1–2 days), producing 100 meters of chain.

Conduct comprehensive testing of the trial chain (purity, dimensions, strength, appearance) and issue a detailed test report.

Follow-Up Service:

If trial production fails, analyze causes (e.g., incorrect machine parameters, operational errors) and allow a free repeat trial after adjustments.

Once the trial passes, provide trial video and parameter records for trainees to replicate production at their own facility.

3.1.3 Recommended Raw Material Sources (Cost Reduction)

Quality Supplier List:

Precious Metal Materials: Provide 3–5 internationally certified suppliers (e.g., PAMP Switzerland, Shanghai Gold Exchange members) to ensure material purity (≥99.9%) and transparent pricing (daily market price updates, no middleman markup).

Consumables (dies, polishing materials): Recommend 2–3 specialized suppliers offering exclusive discounts (5–10% below market price) with delivery within 3 days.

Procurement Tips:

Bulk Purchase: For gold purchases ≥10kg, negotiate with suppliers to reduce price by $0.5–1 per gram.

Scrap Recycling: Recommend partnered scrap recyclers offering 95–98% of market value, 3–5% higher than ordinary recycling stations.

3.2, Full Production Line Planning Service

3.2 Full Production Line Planning Service

Step 1: Site Survey and Layout Design

On-Site Survey (Free Visit):

Measure Site Dimensions: Length, width, height; record door/window locations, water/electric connections (voltage 220V/380V, water pipe diameter, drain location).

Evaluate Environmental Conditions:

Ventilation: ≥3 air changes/hour.

Floor load: ≥500kg/m² in melting furnace area.

Temperature & Humidity: 15–30°C, humidity ≤60%.

Layout Design (CAD Drawings):

Functional Zones:

Raw Material Area (10–20㎡): Stainless steel shelves (layer height 50cm), electronic scales (accuracy 0.01g), monitored with CCTV and alarm system.

Production Area (5–10㎡ per machine): Arrange machines according to production flow; melting furnace near ventilation, polishing machine near drain.

Finished Product Area (15–30㎡): Dust-proof glass shelves, inspection table; air-conditioning (20–25°C) to prevent chain oxidation.

Water & Electricity Planning:

Power: Melting furnace and drawing machine require 380V three-phase, separate wiring (≥6mm²), equipped with 30A RCD.

Water: Ultrasonic cleaners and cooling systems need inlet (≥20mm) and outlet (≥30mm) pipes; drains must have filters to prevent metal powder blockage.

Step 2: Equipment Installation and Commissioning

Equipment Transport & Installation:

Transport Assurance: Professional team, anti-shock foam + wooden crate packaging, transport insurance covering 100% of equipment value.

Installation Service: 1–2 professional technicians on-site; melting furnace fixed on concrete base (10cm height, flatness ≤2mm), drawing machine and chain machine leveled (using spirit level, error ≤0.1mm/m).

Equipment Commissioning:

Single Machine Testing: Run each machine individually, test functions (melting furnace heating rate, drawing machine tension control, chain machine ring forming), ensure parameters meet standards.

Integrated Testing: Simulate full production flow (melting → drawing → chain making → annealing → welding → polishing → cleaning), produce 100 meters of chain, inspect finished product pass rate (≥95%); adjust machine parameters if not qualified.

Step 3: Staff Training and Trial Production

Comprehensive Training:

Production Staff: Learn equipment operation, quality inspection, troubleshooting; 3–5 days training.

Management Staff: Learn production planning, cost control, inventory management; 2-day training (includes management manual and Excel cost templates).

Safety Training: Mandatory for all personnel; must pass assessment before working (focus on high-temperature equipment, precious metal handling, fire emergency response).

Trial Production Support:

Trial Production Plan: Define chain type, production volume (500–1000 meters), time (3–5 days), quality standards.

On-Site Guidance: 1 technician supervises trial production, solving issues (e.g., wire breakage, welding defects).

Data Analysis: Post-trial analysis of production data (material loss rate, pass rate, efficiency), provide optimization suggestions (e.g., adjust drawing die sequence, optimize welding parameters).

FAQ Guide of Gold Chain Manufacturing Machine

- 1. How do you manufacture a gold chain?

- 2. How is gold made in factory?

- 3. Is it hard to make a gold chain?

- 4. How do Jewelers make chains?

- 5. Do they make 24K gold chains?

- 6. What are gold chains made of?

- 7. How do I start a gold jewelry business?

- 8. How long does a gold chain last?

- 9. Which gold chains are the strongest?

- 10. What karat gold is best for chains?

- 11. Do gold chains break easily?

- 12. How do you make links in jewelry chains?

- 13. Can you weld a jewelry chain?

- 14. What are the different types of jewelry chain?

- 15. How do they make necklace chains?

- 16. How are silver chains made?

- 17. What are the different types of chain necklaces?

- 18. What is the best material for a necklace?

- 19. What is the strongest style of chain for a necklace?

- 20. Will gold plating wear off?

- 21. How do you know if chain is real gold?

1. How do you manufacture a gold chain?

With time, the process of manufacturing a quality gold chain has gone through a great revolution. Earlier, manual methods were used to create gold chains; however, this can be done using a professional gold chain manufacturing machine that you can get from SuperbMelt.

This form of gold chain production process is one of the fastest and most efficient processes available today for creating good-quality chains. Besides, you can also create solid as well as hollow chains. This is a unique work process, and I can run at more than 200 links per minute.

Our machines are here to improve the gold chain production cycle so that the manufacturers can enjoy a great level of production efficiency. Besides, there will be no loss of material. So, let’s have a look at the production process of gold chains using these machines.

- Getting the material, i.e., gold

Before you can begin with the process, you will have to get quality gold. For that, you can use an induction furnace and crucible to melt gold ore. For the best quality furnace, you can always trust SuperbMelt. After that, purify the gold and combine other alloys to make the pure gold durable.

- Making rods

After obtaining the material, you need to create a gold rod. This is where you can utilize a continuous casting machine available at SuperbMelt. Our machine is made of durable material and has the latest technologies. So, using it, you can get the desired shaped gold rods, for example, circular shapes, rectangular, circular, cylindrical, and more.

- Turning gold rods into gold wire

Now, you need to convert the large-sized gold rods into gold wire. Don’t worry at all, as you can use SuperbMelt’s rolling mill for that. The machine applies the right amount of pressure, and the wire will have a smooth surface. The entire process will take only a few minutes, based on the length of the gold wire.

- Getting the right diameter

If you want to make thin-sized chains, then you need to lower the diameter of the wire. We also have a machine that uses the drawing process. Once you get the right diameter, you are all set to use a gold necklace making machine to make chains.

- Making beautiful gold chains

Here, you can use a gold chain maker machine to start making durable and beautiful gold chains. The machine is very advanced and can be used to make different types of gold chains, for example, box chains, rope chains, snake chains, and more.

These are the processes that are followed by the jewelers to make a gold chain. The introduction of different gold chain-making machines has made the production process a lot easier and faster. Besides, you can also use a hammering machine and a faceting machine to give your gold chains the right shape and shine.

If you are looking for the best quality gold chain manufacturing machine to produce quality gold chains, then you can always trust SuperbMelt for this. Our machines are very powerful and can run 24 hours without developing any issues. Besides, while using the machines, there are no need to use any consumables, for example, soldering gasses, twin containment wires, cleaning fluids, and more.

2. How is gold made in factory?

In a factory, gold is created by separating the gold from its ores. This method is called cupellation. This process includes treating the gold ores at a higher temperature to separate gold from the base metals, such as zinc, copper, lead, and more. The base metal will get oxidized during the process. Here, the gold is heated at temperatures more than 900-degree C. You can use an induction furnace of SuperbMelt and heat the ore at 10640-degree C to get gold.

Now, you need to remove the impurities from the gold. Pure gold, when extracted from the mines, comes with a huge amount of impurities. To separate them, you can use different chemicals, for example, cyanide solution as well as mercury.

These chemicals will coagulate the gold, and you will get clumps of gold. Another method is heating the gold at 1100-degree C. After a few seconds; you will see a dross on the surface. Remove them out, and at the end, you will get pure gold.

3. Is it hard to make a gold chain?

If you are talking about making gold chains manually, then the process is very challenging and time-taking. Besides, there is no guarantee that the result will be accurate. However, if you are using a gold chain maker machine, then you can easily create quality gold chains within a few hours.

The entire process can be automated using the machine. So, what are you waiting for? Get in touch with SuperbMelt, one of the leading box chain making machine manufacturers, and get a quality machine now.

4. How do Jewelers make chains?

In simple words, all the chains start out as thin wire. First of all, the wire is perfectly annealed using a furnace. After that, it is drawn through a die to get the desired diameter. This is called the drawing process. The process makes the wire durable and hard.

Once done, the thing wire is processed through a gold necklace making machine, or you can say a forming machine where it will be threaded through the previous links, cut, and formed into the chain’s next link. During the process, the jewelry chain cascades downward. In the end, you will get a chain.

5. Do they make 24K gold chains?

Well, in general, making gold chains using 24k pure gold can be a little challenging as the gold will be very soft. Even though the machines can make it, they prefer to use 14k or 21k gold to make chains by combining different alloys to the gold.

6. What are gold chains made of?

In general, gold chains are created using 18k, 20k, or 21k gold. For example, if you are buying a 14k gold chain, then remember that it will have 14 parts gold and around ten parts of other metals. They can be palladium, zinc, copper, nickel, and more.

7. How do I start a gold jewelry business?

For starting a jewelry business, you need to complete all the necessary tasks like business registration, tax registration, getting licenses for selling hallmark jewelry pieces, and more. Besides, you will need machines to simplify the different processes, like getting gold from the ores to making jewelry chains.

This is where you can always trust SuperbMelt. We are one of the most reputed chain making machine manufacturers and deal with the production and distribution of melting, forming, and casting machines for different precious metals. Our machines will offer you a smooth jewelry production process.

8. How long does a gold chain last?

Well, the lifespan of the gold chain will depend on how you are using it and what type of gold chain you have. If you use the chain regularly, then it will tend to wear out faster. On the other hand, a gold-plated chain can last around two to three years. A real gold chain can last for years if it is crafted properly.

9. Which gold chains are the strongest?

As per the experts, rope, mariner, curb, Figaro, and cable gold chains are some of the strongest chains available in the market. If they are thick in design, they can last for years. Besides, a wheat chain made of multiple links can also be a durable option.

10. What karat gold is best for chains?

Remember that in the purest form, gold is very soft and can’t be used for regular wear. Even though higher karat golds are pure, they are not suitable to be used in gold chains. So, it has been seen that most jewelers prefer to use 14K or 18K gold to make gold chains or necklaces.

11. Do gold chains break easily?

Yes, if you have hollow chains, they can break or dent easily. Besides, they are less expensive and challenging to repair. However, solid gold chains are durable and strongest.

12. How do you make links in jewelry chains?

In general, after creating rings, the rings are twisted with two pairs of flat-nosed pliers. You can make the first few links easily, but then you need to start linking the rings together to create chains. After that, you can solder every link with hard solder. This can be a time-consuming process. However, you can make it simple and faster using a gold chain maker machine. And for the best machine, contact SuperbMelt now.

13. Can you weld a jewelry chain?

Yes, you can weld your jewelry chain, and for that, using a welder can be a good idea. You don’t have to be worried about getting the right type of welder, as SuperbMelt has different options for you. With SuperbMelt, you can get a mini laser welder, split laser welder, and desktop laser welder at the most affordable prices.

14. What are the different types of jewelry chain?

Some of the most popular types of jewelry chains are:

- Trace chain

One of the most popular chains to make jewelry is the trace chain. Such chain comes with multiple small oval-shaped links, and that creates a perfect chain and looks minimal. You can get one in different lengths and thicknesses. Sometimes, they can come coated with gold or sterling silver.

- Belcher chain

Such chains are also called Rolo chains. These are similar to a trace chain, but you will find the links are a little wider than the thickness of the chain. They look sturdier and quite popular among men. You can buy a mini or maxi belcher chain based on your preference.

- Hayseed chain

Hayseed chains created using a bead bracelet machine can look super beautiful, and it feels very lightweight. The rings are intricately linked together to create the chain. You will find the detailing of the chains is very delicate and produces sparkle under the light.

- Curb chain

When it comes to using a heavier-looking chain, you can always go for a curb chain. Here, the links are twisted and flattened properly, and once laid flat, they are interlocked together. This can be the perfect chain for creating a statement necklace.

- Snake chain

These chains are also called Brazilian chains. You will find them different from others as they are not made of links. The design of a snake chain includes smooth metal plate links tightly combined to form a flexible chain. This smooth chain provides the users with a sophisticated look.

- Rope chain

The rope chain has a very interesting look and is made of links woven together to create a stylish twisted effect. It will look like a rope. If you are looking for a chain that canattract everyone’s attention, then this chain is for you. Such chains are created from silver or gold using chain making machine. So, visit SuperbMelt now and check the jewellery chain making machine price and get one now.

- Figaro chain

These chains are very pretty and can come with a great level of detail. The chain has flattened links, and in general, the design includes three short links divided by one longer link. The changing size of the links creates a stunning look.

- Bead chain

These are also known as pelline chains or ball chains. No matter what is your style statement, bead chains will perfectly match it. The chain comes with a tiny metal sphere of small balls, and there will be not open links. The elements are fixed at a regular interval along the chain’s length, and there will be some connector bars. If you love bead chains, then you will also love satellite chains.

- Spiga chains

Spiga chains are created using different twisted oval links, and they are combined together in a single layer. In the end, you will get a beautiful chain. The chain will look symmetrical. The design will look like different metallic fibers combined together, creating a perfect textural appearance. The chains are semi-rigid and very sturdy.

No matter what types of chains you want to make, you can use a chain-making machine. And this is where SuperbMelt comes to play. We are quite popular in offering high-quality and industry-grade gold chain manufacturing machine that can be used for making durable chains from different materials. Get in touch with us now for a free quote.

15. How do they make necklace chains?

Today, it is not a challenging task to make neckless as now you can use a gold chain manufacturing machine. Such machines can create durable and different types of gold chains within a few hours. All the processes, like making gold rods, converting the rod into wire, and giving shape to the wire, and more, can be carried out by the machines. For durable machines under your budget, you can always trust, SuperbMelt.

16. How are silver chains made?

Speaking about the silver chains, they can be made using the manual process as well as using machines. However, the manual process will take time, and you may not find an accurate design in the end. But using the best rope chain making machine, you can easily create quality silver chains faster, without compromising the accuracy of the design. In fact, a machine can make beautiful silver chains with more than 6000 links within just two minutes. After creating it, you can use a faceting machine to polish the chain.

17. What are the different types of chain necklaces?

As discussed above, in the market, you can find snake chains, box chains, cable chains, rope chains, curb chains, and more.

All you need to choose the right one based on your style preference. The major reason behind the availability of different chains in the market is the introduction of chain-making machines.

In fact, you can also set up your own chain shop using these machines. Just choose one of the trusted gold chain making machine manufacturers, and you are ready to go.

18. What is the best material for a necklace?

- Silver

One of the widely used materials for necklaces is silver, or you can say sterling silver. Sterling silver means it has 92.5% silver and around 7.5% copper. The material is long-lasting and highly durable. You can use this to make body jewelry, bracelets, necklaces, rings, and more. However, silver is a little softer than titanium, platinum, and gold, and you need to take proper care of a silver necklace.

- Silver-filled material

It is also called a silver overlay. The only difference is that the wire is created using pressure and heat, and during the process, a layer of silver is applied to the cheaper metal. It can be much thicker than the standard plating. The chains or necklaces made of silver-filled materials can be long-lasting and affordable.

- Gold

Gold necklaces are a mix of gold and some other alloys, for example, zinc, nickel, copper, silver, and more. While making necklaces, jewelers generally use 18K, 21K, or 14K gold as such karat golds are durable.

- Platinum

Speaking about platinum, it is the rarest as well as the most expensive of the metals. However, the price is justified as you will find it more durable and it doesn’t tarnish. You can use a rope chain making machine to create beautiful chains from platinum. As appearance matters the most, in some cases, platinum is alloyed with cobalt and copper to get a different look. On the other hand, combining it with other metals makes it more durable. Under platinum group metals, you can use iridium, rhodium, palladium, and more.

- Titanium

When it comes to using the hardest metal to make jewelry, you can always trust titanium. It is much harder than platinum, silver, gold, and steel. Besides, it is easy to color, lightweight, and resistant to scratch. On the other hand, titanium is completely hypoallergenic, and that makes it popular for body-piercing jewelry as well as implants.

19. What is the strongest style of chain for a necklace?

As per the experts from all types of chains, when it comes to choosing the strongest style of chain, one can always go for the rope chains. They are the heaviest and most durable types of chains. Furthermore, you will find them very textural. Thanks to their unique designs, you can easily wear them with a pendant.

A necklace made of rope chains can last for years. On the other hand, solid gold chains are also very durable and strong. However, hollow gold chains are inexpensive, but they are easy to break and very challenging to repair.

20. Will gold plating wear off?

Yes, gold plating can wear out with time and can easily flake off. It will soon expose the base metal. On the other hand, it also loses its luster with time. If done properly and using the right technology, gold plating can last for up to two years.

21. How do you know if chain is real gold?

- Have a look at the marking

To know the purity of the gold chains, you can have a look at the hallmarks made on the clasp. In general, real gold chains come stamped with different kart marks like 24k, 14k, or 18k. Some chains may have a KGP mark. That means the chain is not real.

- Magnet testing

Remember that real gold never reacts to a magnet. So, if the gold chain sticks tightly to the magnet, then the chain is fake. It has some other metals.

- Test with skin

In general, real gold is a shiny raw material and will never tarnish. Besides, it will never create a green mark on your skin. If the chain has any sign of discoloration, then you are using fake gold.

- Use nitric acid

To carry out the test, you need to create a small scratch on the chain. After that, apply a few drops of nitric acid to it. The acid will damage the fake pieces of jewelry, and you can see a green mark. If there’re is no reaction, then you are using real gold.

If you are looking for an effective way to know whether the gold chains you are using are real or not, then you can use an XRF analyzer offered by SuperbMelt. Using this machine, you can test the purity level within a few minutes.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited