Gold Chain Making Machine

Superbmelt provide a one-stop service to solve any problems with your jewelry chain manufacturing line

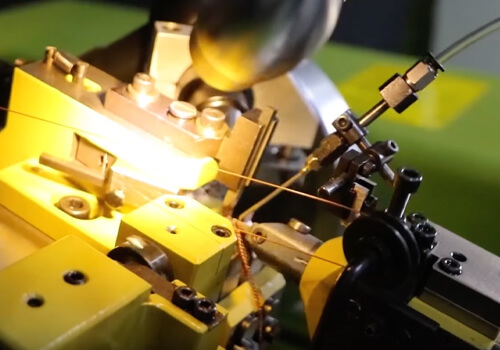

Superbmelt gold chain making machines produces chains with the basic links all same. The metal thread is spiraled before being sectioned during the creation process. One can produce a variety of different styles in certain models with the combination of programmable link torsion allowing for the creation of new chain designs as these are particularly flexible gold chain making machine.

It is an automatic machine that features higher productive capacity for single, double, triple, right and left curb chains and single multiple cable chains. The gold chain making machine has the possibility of changing from curb to cable by means of a simple quick mechanism or from right to left curb thereby facilitating the production of two chains with identical pitch that is suited to the subsequent coupling.

It is quite a versatile machine. The second air blower, the electronic speed regulator with brake, the low voltage lamp, and the chain density sensor is the endowment of this jewelry chain making machine. They are easy to operate and are responsible for the creation of gold, platinum, carat gold, silver, hard alloy chains.

- The chain can be mass produced with the help of the jewelry chain making machinesand the designs can be different.

- You can easily make thin hollow and lightweight chains.

- In different karats of golf and sterling silver is how jewelry chains are made.

- The links can be automatically welded by a laser welding torch in the updated machines.

- Different kind of shapes can be produced.

- Thin and light hollow chains can easily be made with chains of all karats of gold is mass produced.

- Chains are made pretty quickly and accurately along with saving your valuable time. It is extremely cost-effective as well as labor-effective.

- The machine is quite effective enough to produce chains of every links and shapes.

- The jewelry chain making machine allows one to produce the dual execution spirals and other kind of chains with various combinations of the long and short links on top of the combination of the linking variables and torsion.

| Model | SPB-ZC01 |

| Type | 450 high speed single, double, cross chain making machine |

| Voltage | Single phase 220v |

| Power | 200W |

| Wire size | 0.19-0.45mm |

| Speed | 450 |

| Dimension | 420*750*550mm |

| Weight | 75KG |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Gold Chain Making Machines

Any Question About SuperbMelt Gold Chain Making Machines

Gold Chain Making Guide: Six Steps for Precision Automated Gold Chain Production

In the luxury jewelry market, a high-quality chain isn’t just a “support” for pendants or bracelets—it’s a statement of craftsmanship. Consumers judge premium jewelry by the chain’s flexibility, durability, link consistency, and finish. However, traditional chain production faces pain points like uneven links, fragile welds, limited style options, and high labor costs.

SuperbMelt automatic gold chain making machines solve these challenges by integrating precision machining, automation, and advanced welding technology. This comprehensive guide will walk you through every step of high-end chain production—from raw material preparation to post-processing and custom design—while highlighting how SuperbMelt’s equipment elevates efficiency, quality, and versatility for jewelry manufacturers, studios, and custom workshops.

Core Craft Characteristics of High-End Jewelry Chains

High-end chains (used in luxury necklaces, bracelets, and pendant chains) stand out for their structural integrity, aesthetic consistency, and functional flexibility. SuperbMelt machines are engineered to produce chains that meet these strict standards

1.1, Versatile Chain Structure & Style Options

SuperbMelt machines support a wide range of chain configurations to cater to diverse market demands:

- Strand combinations: Single-strand (delicate pendant chains), double-strand (elegant bracelets), triple-strand (statement necklaces), and multi-strand (custom layered designs) chains—all achievable with quick mechanical adjustments, no need for separate equipment.

- Link movement & flexibility: Chain links are designed to rotate and twist freely, ensuring the chain drapes smoothly on the body (critical for comfort) while maintaining structural strength. Unlike cheap chains that feel stiff or break easily, SuperbMelt-produced chains balance flexibility with durability—tested to withstand 50,000+ bending cycles without link deformation or breakage.

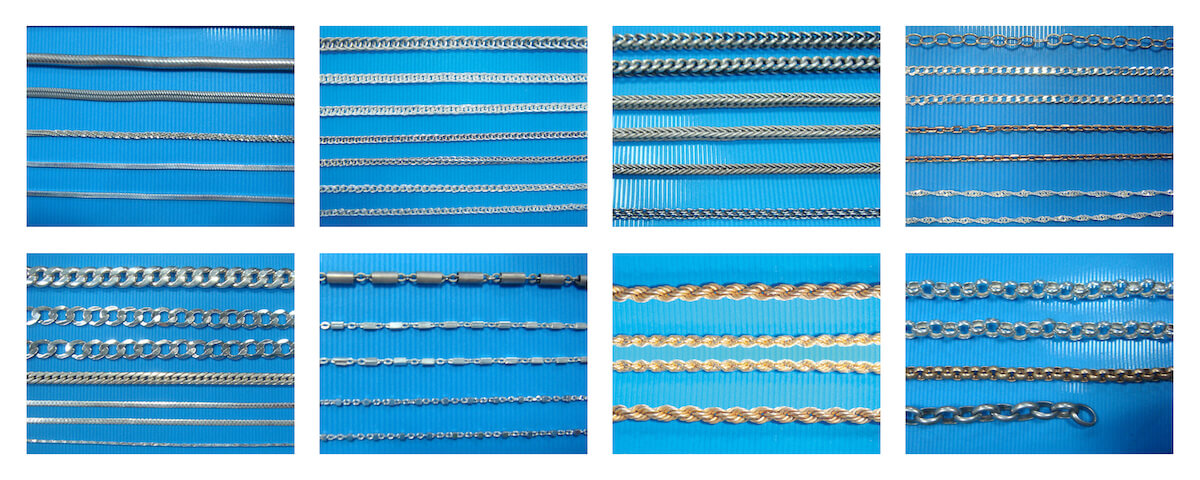

- Classic & custom styles: Specializes in high-demand styles like Curb chains (flattened, interlocking links), Cable chains (simple oval links), and custom combinations (e.g., dual-execution spirals, long-short link mixes). The machine’s programmable link torsion allows for innovative designs, making it easy to launch new styles or replicate vintage chain patterns.

1.2, Application Scope for Luxury Jewelry

The chains produced by SuperbMelt machines are ideal for:

- Necklaces: Delicate 0.2–0.5mm wire chains (for dainty pendants) to bold 1.0–1.2mm multi-strand chains (for statement pieces).

- Bracelets: Flexible single/double-strand chains (everyday wear) and sturdy triple-strand chains (designer collections).

- Pendant chains: Precision-calibrated link spacing ensures pendants sit evenly without sliding or tangling.

- High-end custom jewelry: Supports small-batch production of limited-edition chains (e.g., brand signature styles) and one-of-a-kind custom designs (e.g., personalized link patterns).

Raw Material Preparation: Lay the Foundation for High-Quality Chains

The quality of a chain starts with raw materials—SuperbMelt machines are optimized for precious metals and require specific material preparation to ensure consistent forming and durability.

2.1, Supported Metal Materials & Selection Criteria

SuperbMelt machines are compatible with all premium metals used in luxury jewelry:

- Precious metals: Gold (14K, 18K, 24K), white gold (rhodium-plated or alloyed), platinum, and 925 sterling silver. These materials require precise processing to avoid waste and maintain purity.

- Hard alloys: Tungsten carbide, titanium alloy, and stainless steel (for fashion luxury chains). These harder materials demand machines with robust torque and precision—SuperbMelt’s industrial-grade motors handle them seamlessly.

Material selection tips:

- Soft metals (24K gold, pure silver): Choose wires with slightly higher tensile strength (≥300 MPa) to prevent stretching during twisting.

- Hard metals (platinum, tungsten carbide): Opt for annealed wires to reduce brittleness and ensure smooth bending.

- Mixed-material chains (e.g., gold-plated silver): Ensure the base metal (silver) has consistent thickness to avoid plating unevenness after chain formation.

2.2, Gold Wire Specifications & Requirements

Wire diameter directly impacts chain style and functionality—SuperbMelt machines support a wide range to cover most high-end applications:

- Wire diameter range: 0.2–1.2mm (the sweet spot for luxury chains).

- 2–0.5mm: Ideal for delicate pendant chains and thin bracelets (lightweight, comfortable for daily wear).

- 6–0.9mm: Perfect for medium-weight necklaces and bracelets (balances durability and elegance).

- 0–1.2mm: Used for bold statement chains and multi-strand designs (sturdy, visually striking).

- Wire quality standards:

- Uniform diameter (tolerance ±0.01mm): Ensures consistent link size—no “thick” or “thin” sections that ruin the chain’s appearance.

- Smooth surface: Free of scratches, oxidation, or impurities (prevents defects during twisting and welding).

- Consistent hardness: Avoids uneven stretching or breaking during production—SuperbMelt recommends wires with Rockwell hardness (HRB) of 60–80 for optimal results.

2.3, Critical Preprocessing Steps (Non-Negotiable for Quality)

Raw metal wire requires four key preprocessing steps to ensure stable chain formation—SuperbMelt machines work seamlessly with preprocessed wires, and skipping these steps leads to defects (e.g., deformed links, weak welds):

Step 1: Annealing (Softening the Metal)

- Purpose: Reduces internal stress in the wire (caused by manufacturing) to improve flexibility and prevent cracking during twisting.

- Process: Heat the wire to 600–800°C (varies by metal: gold 700°C, silver 650°C, platinum 800°C) in a controlled atmosphere (to avoid oxidation) and cool slowly.

- SuperbMelt compatibility: The machine’s feeding system handles annealed wires gently, avoiding reintroducing stress.

Step 2: Cleaning (Removing Impurities)

- Purpose: Eliminates oil, dust, and oxidation from the wire surface—contaminants cause poor welding adhesion and surface defects.

- Process: Ultrasonic cleaning (15–20 minutes) with a mild detergent (pH 7–8) followed by rinsing and drying. For precious metals, use a non-abrasive cleaner to avoid scratching.

- Why it matters: Clean wires ensure laser/microspot welding penetrates evenly, creating strong, seamless welds.

Step 3: Drawing (Refining Diameter & Surface)

- Purpose: Reduces the wire to the exact target diameter (0.2–1.2mm) and creates a smooth, uniform surface.

- Process: Pull the wire through diamond dies (gradually reducing diameter) to ensure consistency. For hard metals, use multiple drawing passes with intermediate annealing.

- SuperbMelt advantage: The machine’s tension control system adapts to drawn wires of different diameters, preventing stretching or breakage during feeding.

Step 4: Precision Cutting (Preparing for Spiral Formation)

- Purpose: Cuts the drawn wire into spools of uniform length (typically 50–100kg per spool) for easy loading into the machine.

- Process: Use a precision cutter with a tolerance of ±0.5mm to avoid uneven spooling.

- Efficiency tip: SuperbMelt machines accept standard 50–100kg spools, reducing downtime from frequent spool changes.

Link Formation & Automation: Achieve Consistency at Scale

Link formation is the core of chain production—SuperbMelt’s automated system eliminates manual errors, ensuring every link is identical (a must for high-end jewelry).

3.1, Automated Spiral Formation & Link Cutting

The machine’s core workflow for link creation is fully automated, with zero manual intervention:

- Spiral formation: The preprocessed wire is fed into a precision spiral-forming module, which twists the wire into a continuous spiral (the shape of the spiral determines link style: e.g., round for Cable chains, flattened for Curb chains). The spiral’s pitch (distance between turns) is programmable via the machine’s PLC, ensuring consistent link size (tolerance ±0.02mm).

- Automatic cutting: A high-speed precision cutter slices the spiral into individual links—each link is identical in size and shape. For example, a Cable chain with 3mm links will have every link measure exactly 3mm, with no variation (unlike manual cutting, which often has ±0.1mm errors).

- Waste reduction: The automated process minimizes scrap—SuperbMelt machines achieve a 99.5% material utilization rate during link formation, critical for expensive precious metals.

3.2, Quick Style & Direction Switching (Maximize Versatility)

One of SuperbMelt’s key advantages is its ability to switch between chain styles and directions in minutes, eliminating the need for multiple machines:

- Style switching (Curb ↔ Cable): A simple quick-change mechanism allows you to switch from Curb chains (flattened links) to Cable chains (round links) in ≤15 minutes—no tools required. This is ideal for manufacturers producing multiple styles for different clients or collections.

- Direction switching (left ↔ right twist): The machine’s programmable torsion system lets you switch between left-twisted and right-twisted links, enabling the production of two chains with identical pitch (perfect for coupling into double-strand designs or matching necklace/bracelet sets).

- Multi-style compatibility: Beyond Curb and Cable chains, the machine supports custom link shapes (e.g., square, oval, rectangular) via interchangeable forming dies—simply swap the die and adjust the PLC settings to launch a new style.

3.3, Full Automation: From Feeding to Density Control

SuperbMelt machines are fully automated, covering every step from wire feeding to link assembly:

- Automatic wire feeding: A motor-driven feeder with adjustable tension (0.1–1.0N) feeds the wire into the forming module at a consistent speed (synchronized with spiral formation to avoid stretching).

- Link assembly: The cut links are automatically aligned and interlocked—no manual sorting or assembly. The machine’s vision system checks for misaligned links and rejects them (reducing defects to ≤0.3%).

- Density control: A built-in chain density sensor adjusts the link assembly speed to ensure uniform link spacing. For example, a necklace chain with 5 links per centimeter will have consistent spacing across its entire length (no “crowded” or “spaced-out” sections).

- Torsion angle adjustment: The PLC allows precise control of link torsion (0–360°), enabling custom designs like twisted Curb chains or spiral-link chains. Torsion settings are saved as recipes, so you can recall them instantly for repeat orders.

3.4, Key Advantages of Automation for High-End Production

- Consistency: Every link is identical in size, shape, and spacing—critical for luxury jewelry, where even minor variations are noticeable to consumers.

- Efficiency: The machine processes 80–120 meters of chain per hour (depending on link size), 5–10x faster than manual production. For example, a 50-meter batch of 0.5mm Cable chain takes just 30–45 minutes to produce.

- Labor savings: A single operator can manage 2–3 SuperbMelt machines, reducing labor costs by 70% compared to manual production (which requires 1 operator per machine).

- Scalability: The automated system handles both small-batch custom orders (e.g., 10 meters of a unique chain) and large-scale mass production (e.g., 1,000 meters for a retail collection) with the same consistency.

Welding & Strengthening: Ensure Durability Without Sacrificing Flexibility

Welding is the most critical step for chain durability—poor welds lead to broken chains (a nightmare for luxury brands, as they damage reputation and lead to returns). SuperbMelt uses advanced welding technology to create strong, seamless welds.

4.1, Welding Technologies: Microspot vs. Laser Welding

SuperbMelt machines offer two welding options, tailored to different metals and chain styles:

- Microspot welding: Ideal for soft metals (24K gold, pure silver) and thin wires (0.2–0.5mm). Uses a small electrical current to create a precise weld spot, avoiding heat damage to the delicate links.

- Laser welding (updated models): Perfect for hard metals (platinum, tungsten carbide), thick wires (0.6–1.2mm), and high-volume production. A fiber laser delivers concentrated heat to the link interface, creating a seamless, strong weld. The laser welding torch automatically locates the link interface (via vision system), ensuring accurate positioning even for tiny links.

4.2, Weld Quality: Strength & Aesthetics

SuperbMelt’s welding process sets high-end chains apart from cheap alternatives:

- Weld strength: The weld joint’s tensile strength reaches 95% of the base metal—meaning the chain is just as strong at the weld as it is at the link itself. For example, a 18K gold chain with laser-welded links can withstand 150–200N of tension (enough to support heavy pendants or resist pulling).

- Seamless appearance: The weld spot is nearly invisible (≤0.1mm in diameter), so the chain looks smooth and uniform—no unsightly bumps or discoloration (common with manual welding).

- Flexibility retention: Unlike over-welding (which makes links brittle), SuperbMelt’s controlled welding process preserves the link’s flexibility. Welded links can still rotate and twist freely, ensuring the chain drapes naturally.

4.3, Automated Welding Quality Control

To ensure every weld is perfect, the machine includes built-in quality control:

- Vision inspection: A camera checks each weld spot for size, position, and integrity—rejecting any links with incomplete welds or misaligned joints.

- Tension testing (optional add-on): For high-volume production, an integrated tension tester pulls every 100th link to verify strength, providing real-time data to the operator.

- Error alerts: If the machine detects a welding issue (e.g., laser power fluctuation), it stops automatically and sends an alert—preventing a batch of defective chains.

Post-Processing & Surface Finishing: Elevate Aesthetics to Luxury Standards

After welding, the chain undergoes post-processing to refine its appearance and performance—this step is what makes a “good” chain into a “luxury” chain.

5.1, Annealing & Shaping: Perfect the Chain’s Form

- Post-weld annealing: The chain is heated to 400–500°C (lower than preprocessing annealing) to relieve stress from welding and link formation. This step ensures the chain retains its shape and flexibility, even after repeated wear.

- Precision shaping: The chain is fed through a series of shaping rollers that straighten it (ensuring no kinks) and adjust link alignment. For Curb chains, the rollers flatten links to the exact desired thickness (e.g., 0.8mm for a medium-weight chain).

5.2, Cleaning: Remove Contaminants from Welding & Shaping

- Ultrasonic cleaning: The chain is placed in an ultrasonic cleaning bath (with a pH-neutral cleaning solution) to remove welding residue, oil, and metal dust. This step is critical for surface finishing—contaminants cause uneven polishing or plating.

- Rinsing & drying: The chain is rinsed with deionized water to remove cleaning solution, then dried in a heated air chamber (to avoid water spots). For precious metals, a nitrogen gas dry is available as an option to prevent oxidation.

5.3, Surface Finishing: Polishing & Plating

SuperbMelt machines work seamlessly with post-processing equipment to achieve luxury finishes:

- Precision polishing: The chain is fed into a barrel polisher or belt polisher (depending on desired finish) with abrasive media (e.g., ceramic beads for gold, steel shot for silver). Polishing removes minor surface imperfections and creates a smooth, reflective finish. For matte finishes, a specialized abrasive media is used.

- Plating (optional): For white gold or gold-plated chains, the polished chain undergoes electroplating (e.g., rhodium plating for white gold) to achieve a uniform, durable finish. The machine’s consistent link size ensures even plating thickness (no “thin” spots that wear off quickly).

- Custom finishes: The machine supports specialty finishes like brushed (using a wire brush attachment), hammered (via post-processing dies), or antiqued (via oxidation and polishing)—all of which can be integrated into the production line.

5.4, Final Quality Inspection: Meet High-End Standards

Every chain undergoes a rigorous inspection before leaving the factory—SuperbMelt’s quality control process ensures only perfect chains reach customers:

- Link spacing check: A laser measuring tool verifies link spacing is consistent (tolerance ±0.03mm) across the entire chain.

- Straightness test: The chain is laid on a precision flat surface to check for kinks or bending (rejected if deviation exceeds 0.1mm per meter).

- Weld quality inspection: A magnifying camera (100x zoom) checks every weld spot for integrity—no cracks, gaps, or discoloration.

- Tension testing: Random samples are pulled to verify weld strength (must withstand ≥120N for 14K gold chains).

- Aesthetic inspection: The chain is inspected for scratches, oxidation, or uneven finishing—only chains with flawless surfaces pass.

Advanced Customization & Production Efficiency: Balance Flexibility & Scale:Conclusion

SuperbMelt machines are designed to handle both custom orders and mass production—critical for modern jewelry businesses that need to adapt to market demands.

6.1 Advanced Customization via PLC & Electronic Speed Control

The machine’s PLC (Programmable Logic Controller) and electronic speed regulator give you full control over chain design:

- Torsion adjustment: Program link torsion (0–360°) to create custom twisted chains (e.g., a 45° twist for a unique Curb chain) or multi-twist designs (e.g., alternating 30° and 60° twists).

- Length control: Set the chain’s final length (e.g., 45cm necklaces, 18cm bracelets) with precision (±0.1cm)—the machine automatically cuts the chain to the exact length after assembly.

- Density adjustment: Adjust link density (number of links per centimeter) to create lightweight or heavyweight chains. For example, a delicate pendant chain might have 6 links per cm (lightweight), while a statement chain has 4 links per cm (heavier, more substantial).

- Recipe storage: Save custom settings (torsion, length, density, link size) as recipes—recall them instantly for repeat orders or batch production of custom designs. The machine can store up to 50 recipes, ideal for studios with multiple clients.

6.2 Quick Material & Style Switching (Minimize Downtime)

SuperbMelt machines are built for versatility, allowing you to switch between materials and styles with minimal downtime:

- Material switching: The machine’s feeding system and welding parameters are adjustable for different metals—switch from 18K gold to 925 silver in ≤30 minutes (just adjust tension, welding power, and post-processing settings).

- Style switching: As mentioned earlier, style and direction switches take ≤15 minutes—no need to reconfigure the entire machine. This is perfect for small-batch production (e.g., 50 meters of gold Cable chain, then 30 meters of silver Curb chain).

- Custom link dies: Interchangeable forming dies let you create unique link shapes (e.g., heart-shaped, star-shaped, brand-logo-shaped) for custom orders. SuperbMelt offers custom die design services—send your link design, and they’ll create a die tailored to your needs.

6.3 High Efficiency for Mass Production & Custom Orders

Whether you’re producing 1,000 meters of a best-selling chain or 10 meters of a custom design, the machine delivers efficiency and consistency:

- Mass production capabilities: The machine runs 24/7 (with automatic lubrication and heat dissipation) for high-volume orders. It processes 80–120 meters per hour, so a 1,000-meter batch takes just 8–12 hours (vs. 40–50 hours with manual production).

- Custom order efficiency: Small-batch custom orders (1–50 meters) are processed just as quickly—no setup fees or long lead times. The machine’s recipe storage means you can recall custom settings in seconds, avoiding repeated adjustments.

- Cost savings: The combination of high material utilization (99.5%), labor savings (70%), and low defect rates (≤0.3%) makes the machine extremely cost-effective. For a medium-sized manufacturer, the ROI is typically achieved within 6–12 months.

- Lightweight & hollow chain production: The machine excels at producing thin, hollow, and lightweight chains—ideal for luxury jewelry (where “lightweight comfort” is a key selling point). Hollow chains made with SuperbMelt machines are 30–40% lighter than solid chains of the same size, while maintaining durability (thanks to strong welds and precision forming).

Conclusion

In a market flooded with chain-making equipment, SuperbMelt stands out for its focus on luxury jewelry needs:

- Unmatched consistency: Every link is identical in size, shape, and spacing—critical for high-end brands that can’t afford defects.

- Versatility: Supports single/double/triple/multi-strand chains, Curb/Cable/custom styles, and all precious metals—one machine replaces multiple manual tools or specialized machines.

- Durability: Weld strength reaches 95% of the base metal, and the machine’s industrial-grade components (hardened steel forming dies, servo motors) ensure 10,000+ hours of reliable operation.

- Efficiency: 80–120 meters per hour output, 99.5% material utilization, and 70% labor savings—maximize productivity and profitability.

- Customization: PLC programming, recipe storage, and custom die support let you create unique designs that differentiate your brand.

- User-friendly: The machine’s intuitive touchscreen interface, tool-free style switching, and easy maintenance make it accessible to operators of all skill levels (no need for specialized technical training).

Ready to Elevate Your Chain Production to Luxury Standards?

High-end jewelry demands precision, consistency, and craftsmanship—and SuperbMelt automatic gold chain making machines deliver on all three. Whether you’re a small custom studio looking to expand your style offerings, a medium manufacturer scaling up production, or a luxury brand needing to maintain uncompromising quality, SuperbMelt’s equipment is engineered to meet your needs.

With its automated link formation, advanced welding, quick style switching, and cost-saving efficiency, the machine transforms chain production from a labor-intensive, error-prone process into a streamlined, high-quality operation.

Need help matching your specific production needs (chain styles, materials, volume) to the perfect SuperbMelt model? Contact our experts today—we’ll walk you through the machine’s specs, share sample chains, and help you calculate ROI for your business. Take the first step toward producing luxury chains that stand out in the market and drive customer loyalty.

FAQ Guide of Gold Chain Making Machines

- 1. How do you make a gold chain?

- 2. How do you make a 14-karat gold chain?

- 3. Is a gold chain a good investment?

- 4. How can you tell if a gold chain is real?

- 5. What karat gold is best for chains?

- 6. How is chain welded?

- 7. How can you tell 24-carat gold?

- 8. How do we make gold?

- 9. How do you make gold jewelry shiny?

- 10. How is gold jewellery made?

- 11. What machines are used to make jewelry chain?

- 12. How do they make necklace chains?

- 13. What is used for making necklace?

- 14. How are silver chains made?

- 15. What is the best material to make a necklace?

- 16. What are gold chains made of?

- 17. What is the strongest style of chain for a necklace?

- 18. What are the different types of jewelry chain?

1. How do you make a gold chain?

Earlier, gold chains were used to make by hand. As a result, to create one simple gold chain, the jewelers used to take months. However, now things have changed a lot, and thanks to advanced technologies, you can use a gold chain-making machine to create a gold chain with a complex design within a few hours. Now, let’s talk about the process of gold chain making in detail.

- Obtaining pure gold

Before making a chain, you need to get pure gold. How to get pure gold? Well, for that, you need to melt gold ore using a crucible and furnace. The experts of SuperbMelt always advise the users to use SuperbMelt’s graphite crucible and induction furnaces. Once melted, you can purify the gold and turn them into bars for making gold chains or other products.

- Creating gold rod

After getting the gold, the next step in the gold chain-making process is to create a gold rod. To make the process easier and faster, you can use the continuous casting tool from SuperbMelt. Developed using the latest technologies, these machines can cast the gold into the desired shape. Besides, you can create different shapes, for example, cylindrical, circular, rectangular, circular shapes, and more.

- Creating thin wires from the gold rod

After creating the gold rod, the rod will be processed through the rolling mill. This will transfer the rod into thin wires. The machine produces accurate pressure, and the gold wire will come up with a super smooth surface, and you can see a mirror effect on it.

- Reducing the diameter of the wire

Sometimes, you may need to create a thin-sized gold chain, and for that, you will have to convert the thick gold wire into a thin wire. For that, the drawing process is used. After getting the desired diameter, you can now use the wire to create gold jewelry chains.

- Creating jewelry chains

Not, this is the final process. Here you can use a jewellery chain-making machine to create a gold chain. Such machines are very versatile and can be used to create a different type of gold chain. For example, snake chains, rope chains, box chains, and more. What’s more? You can also create anchor chains, double chains, ad more.

Now the final product has been made. In some cases, you may need to use a hammering machine to bind the gold parts and to get a perfect shape. Just configure the machine, and the machine will automatically hammer the gold chain. After that, to enjoy the shininess, use a jewelry faceting machine.

So, using a good-quality gold chain-making machine, you can easily create different types of gold chains within a few hours. However, for better results, prefer to buy the machine from a well-known manufacturer. This is where you can always trust SuperbMelt, one of the most trusted and reliable chain-making machine manufacturers.

2. How do you make a 14-karat gold chain?

Now, it is very easy to make a 14-k gold chain, and you can even complete the chain within a few hours using a gold chain-making machine. When you have a good quality machine, the entire process can be automated. If you are looking for a perfect platform to buy a machine, then you can always trust SuperbMelt.

3. Is a gold chain a good investment?

Yes, investing in a gold chain can be a good idea as gold is a precious metal, and with time, its value may rise. However, prefer to choose a design that is evergreen so that you can use your gold chain for years without buying a new one. For example, a snake gold chain.

4. How can you tell if a gold chain is real?

There are many simple methods to tell whether the gold chain is real or not. For example, you can use an acid test. If the gold is fake, the gold chain will develop a reaction, and you can see green color on the surface. However, one of the most simple and effective ways to check the purity of the gold chain is by using an XRF gold analyzer. To get the best machine, you can always get in touch with SuperbMelt.

5. What karat gold is best for chains?

You can’t make gold chains using 24K pure gold. As per the experts, 14k, 21k, or 16k gold is good for making gold chains.

6. How is chain welded?

If you are planning to weld on a gold chain, you can do that by using a welder. For that, you can use a desktop laser welder, split laser welder, or mini laser welder. Such machines are very powerful and can complete the task within a few hours.

7. How can you tell 24-carat gold?

If you are looking for the simplest and most effective way to check the purity level of karat percentage of gold, SuperbMelt would like to suggest you use an XRF gold tester. Utilizing the most advanced XRF technology, the tool can check the purity level within 5 to 10 seconds.

8. How do we make gold?

In general, gold is made by melting the gold ore. Gold ore is melted using an induction furnace and then purified utilizing different methods. Once done, the pure gold is poured into molds to create gold jewelry or chains.

9. How do you make gold jewelry shiny?

First of all, you need to create a cleaning solution by adding dish detergent to warm water. Now, combine a few drops of ammonia and then brush the jewelry using a soft brush. Once done, you can clean the jewelry pieces using lukewarm water. After that, properly dry it using a soft towel. In the case of a gold chain, a chain faceting machine can be used to make the chain look shiny.

10. How is gold jewellery made?

Nowadays, gold jewelry pieces are made using the gold casting method, where CAD software is used to make jewelry wax models using a 3D printer. First of all, the jewelry mold is created. After that, hot wax is added to that mold. The liquid eventually cools down and takes a harder shape. Once done, it is separated from the mold, and you will get the wax vision.

After that, the investment casting method is carried out. Under this, the wax jewelry is placed in a furnace with plaster. The heat melts away the wax material, leaving the plaster cavity. Once done, you need to add molten gold inside that to create jewellery.

11. What machines are used to make jewelry chain?

Some of the most common machines that are used to make good quality jewelry chains are a gold continuous casting machine, a rolling mill, a wire drawing machine, a gold chain making machine, a chain hammer machine, and a chain faceting machine. You can easily buy all these machines at SuperbMelt under your budget.

12. How do they make necklace chains?

The process of making neckless chains is quite interesting as well as complex. However, modern technology has made it easier to create necklace chains within a few hours. There are different types of machines, including a necklace-making machine that you can use to create a metal rod, then convert the rod into a wire, and then the gold chain-making machine will turn the wire into the chain.

13. What is used for making necklace?

A gold chain-making machine is used to make a necklace. Such machines are very advanced and can create different types of patterns faster. You can create one necklace within a few hours. So, don’t think much and check the gold chain-making machine price now and get your machine. For best deals, you can get in touch with SuperbMelt.

14. How are silver chains made?

If you look at the historical data, jewelers were used to making cast loops and combine them together to create a necklace. However, due to the manual process, they used to take days or months to make a single piece of necklace. On the other hand, with a manual process, it is very challenging to solder multiple loops in one piece. So, they used the smelting process for silver rod creation.

Now, coming to the modern process, this is all about the chain-stitching process. Here, a thin silver wire is carefully processed through an automatic chain-making machine, and the machine creates the design based on the design pattern. As per the experts, one machine, in one minute, can crate silver chains with about 6000 links. Once the silver chain is made, it is polished by a chain faceting machine

15. What is the best material to make a necklace?

To make a necklace, you can use different types of materials, and the choice of material will be based on your personal choice. Some of the most common materials that you can use are:

- Silver

Most jewelers prefer to use silver as this material is soft, ductile, and malleable in nature. Besides, silver is highly reflective. On the other hand, silver material can be polished to attain the required Luminous sheen. What’s more? Compared to other materials available to make a necklace, silver is quite affordable.

- Gold

More than 50 percent of gold is used in jewellery making. The 100 percent pure gold is very soft, and on the Mohs Hardness Scale, it is rated 2.5 to 3. As pure gold is very soft and can’t be used to make chains or necklaces, jewelers used 21K, 18k, 16k, or 14k gold to make gold jewelry. Different types of alloys are used to make the gold durable. By alloying process, you create rose, yellow or white gold.

- Platinum

Another common material that is used to make the necklace is platinum. The material is silver-white, malleable, and also a highly dense precious metal. The material is super durable and will never tarnish. Besides, it is heat resistant and corrosion-resistant.

16. What are gold chains made of?

As the name suggests, gold chains are made of gold. However, the purity of the gold will vary from one chain to another. Besides, different karats of gold are used to make gold chains. For example, you can go for a 14-k gold chain that is made of 14-part gold and 10 parts of other metals. If you calculate in percentage, a 14k of gold chain can be made of around 58 percent gold, and there can be other alloys, for example, zinc, silver, copper, palladium, or nickel.

17. What is the strongest style of chain for a necklace?

Well, as per the experts, among all the available chains in the market, you will find the rope chains as the heaviest and most durable chains. Besides, they are also very textural. Due to their unique design, you can wear them with a pendant. You can use a thin or thick one based on your style preference. The modern necklace-making machine has made it much easier to produce sturdier rope neckless that can last for years.

18. What are the different types of jewelry chain?

Thanks to the introduction of the advanced gold chain-making machine, you can now buy different types of gold chains in the market that you can use based on your style statements. So, here we will discuss some of the most popular types of gold jewelry chains. Have a look.

- Puffed mariner chain

Speaking about this, this is a unique chain, and the design of the chain is greatly inspired by the nautical world. Such chains are also called as Anchor chain as it has the similar design to the gold chains that are connected to the anchors. If you are someone who loves the seas, then you can go for it.

In terms of design, it consists of multiple interlocking ovals, and there will be a bar across each oval. So, the chain comes with an intriguing and distinct appearance. These jewelry chains are available in different widths. Earlier, such chains were flat, now there are more new trends, and you can go for the puffed mariner chain. You can use them as stand-alone jewelry, or you can pair them with a beautiful pendant.

- Bead or ball chain

The chain is consisting of multiple tiny beads that are interlinked to form a chain. In terms of the design, the balls of the chains can be eighter connected very closely, or there can be small space between the balls. However, it may be noted that such chains don’t work well as a stand-alone accessory and will look perfect when you combine it with a pendant. Using a good quality automatic chain-making machine, such a chain can be developed within a few hours.

- Box chain

Such chains are made of quality and unique square links, and there will be no rounds and ovals. The square links are carefully connected to create a smooth chain. Earlier, these chains are used to make by hands, but now, most of the jewelers are using a box chain-making machine for this. Such chains are quite popular among users and can be worn by women and men. You can get them in different widths. For men, wider ones will use match perfectly. In terms of durability, box chains are very strong, and they will not break easily.

On the other hand, if one link breaks, that can be replaced without any issue. Besides, a box chain can be easily reattached without replacing any broken link or compromising the design. Based on your outfit and preference, you can pick a good length.

- Cable Chain

One of the most basic types of chains is cable chains, and they generally look like a regular iron chain. These chains have been used for years for different purposes, for example, crafting delicate and small pieces of jewelry. This common form of the chain has a series of oval links that are carefully interconnected to create functional as well as beautiful chains.

Even though such chains are not very eye-catching, you can make them look beautiful by combining them with a pendant. Such chains are very durable and sturdy as the cable chains are uncomplicated. A broken link in the cable chain is easy to fix. However, there is one thing that you should always keep in mind. The links can sometimes come part from the joined part if the chain is not perfectly developed.

- Curb Chain

The chain style is very basic, and the design is timeless. The chains are made of interconnected and uniform links. While perfectly interlocked, the links will remain flat. If you are looking for a neckless chain that looks chunky and heavy, then you can always go for a curb chain. That’s why most of the men prefer to wear this chai.

On the other hand, thinner and smaller curb chains are feminine as well as delicate. They will look beautiful when combined with a pendant. Such chains are sturdy and don’t need any special maintenance care. If you want to make a good quality curb chain at your jewelry shop faster, then you can use a gold chain-making machine offered by SuperbMelt.

- Figaro Chain

Even though the necklace will look simple, you will find them much fancier than the cable chains. The design is originated in Italy, and the chains include some alternating patterns of flattened links in different sizes. In general, the pattern of the chain is of one long link accompanied by three or, in some cases, two shorter links. The design of such chains has made them perfect to be worn by both women and men.

Such chains are a perfect sturdy choice as they are made of thick wire. Besides, they are super easy to fix. But due to the unique pattern of the chain, without replacing it, you can’t remove a broken link. Or else the entire pattern of the chain will be messed up. However, to make a Figaro chain faster, you can always use a bracelet-making machine.

- Rope Chain

When it comes to buying a beautiful chain for her or him, a rope chain can be a perfect option. Talking about the design, it includes different metal segments with the pattern twisting around to give the look of a real rope. The chai has a solid appearance and can is widely worn across the world. Most jewelers are now using a rope chain-making machine to create durable rope chains.

Rope chains are the heaviest and most durable chain types that you can use. You can wear the chain along with various pendants as they are real strings. You can always go for a thin or thick design as they will don’t come apart easily. While the larger rope chains are perfect to be worn on their own, you can use a delicate one with a pendant. As such chains have unique twisting patterns that effectively reflect lights from different angles, they always look shiny and lustrous.

- Singapore Chain

Such chains are very durable and come with a strong design that has multiple interlinked segments. When you stretch it out, it will look like a twisting open chain, and that will give it a beautiful look. That will move with a liquid touch. In general, Singapore chains are best for hold pendants as they are durable, no matter what is the width of the chain. The design is very classic can be used regularly.

- Snake chain

The chain gets its name from the snake design. If you look at the design, you will find it carrying a body of a snake, and it also moves like a snake. The chain is made of multiple small rings; they can be bands or plates and are connected tightly together to create a sleek and smooth chain. The users may not see the snake chain’s ring as they are closely knit together. They are not very textual as compared to other types of jewelry chains that you will find in the market.

Speaking more about the chains, they are quite delicate, but you can attain a stunning look by combining them with a beautiful pendant. As they all have a semi-rigid structure, the chains will not tangle easily. The best part is that they are easy to clean and maintain. You can make this your regular accessory. So, go on and get one now.

- Wheat or Spiga chain

Such chains are made up of multiple twisted oval links, and they are plaited together in a single direction. As a result, it creates a symmetrical or delicate chain. If you look at it carefully, it will look like many metallic fibers running into each other, producing a unique textural appearance. As the chain looks like the tips of wheat stalks, it is called as wheat or Spiga chain. As the chain is semi-rigid, you will find them very sturdy and durable. The look of such chains is very classic and timeless.

So, these are some of the best types of gold jewelry chains that you can find in the market. However, if you want to create something unique or make the best-quality gold chains, you can use a jewellery chain-making machine. Visit the chain-making machine price at SuperbMelt and place your order now.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited