Dual Station Automatic Stone Glue Dispensing Machine

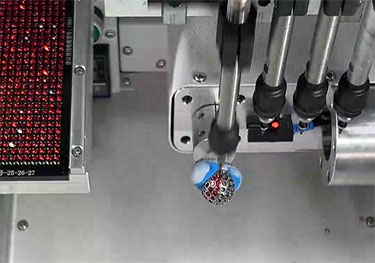

High-speed Dual Station Glue Dispenser with 4 nozzles and 1 glue head. Supports multi-color stones and complex 3D jewelry designs. Save labor, boost output.

SuperbMelt Dual Station Automatic Stone Glue Dispensing Machine is designed for simultaneous glue dispensing and rhinestone setting on jewelry pieces. Equipped with 4 suction nozzles and 1 glue dispensing head, the machine can perform 20,000–21,000 glue drops per hour and set 12,000–15,000 stones per hour. It supports multi-color and multi-size stones and allows style-based processing for enhanced flexibility.

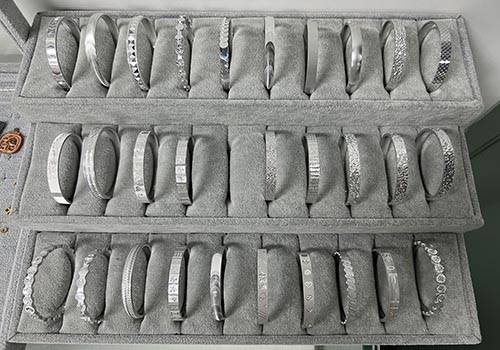

With a workflow that applies glue before placing stones, this machine is ideal for jewelry, hardware accessories, and handicrafts. It delivers stable glue output and accurate stone placement, making it highly effective for complex 3D designs. It also supports stone setting on wax models.

The Dual Station system allows for non-stop operation and performs the work of two operators at once, helping jewelry manufacturers and hardware workshops significantly increase production efficiency and reduce labor costs.

Key Features:

- Dual-Function Operation:The machine is designed to perform two tasks simultaneously—glue dispensing and stone setting. It utilizes 4 suction nozzles alongside a single glue dispensing head, ensuring efficient operation on jewelry and other items.

- High Throughput:With the ability to dispense 20,000–21,000 glue drops per hour and set 12,000–15,000 stones per hour, the machine is engineered for rapid production without compromising on precision.

- Versatile Stone Processing:It supports the handling of various stone sizes and colors and offers style-based processing, making it highly adaptable for different design requirements and complex three-dimensional patterns.

- Stable and Accurate Performance:The process—applying glue first followed by stone setting—ensures stable glue output and accurate placement of stones. This reliability is essential for intricate and delicate design work.

- Support for Wax Model Stone Setting:In addition to jewelry, the machine is also capable of processing wax models, broadening its application to include various types of products such as hardware accessories and crafts.

- Non-Stop Operation:The dual station setup supports continuous operation, essentially allowing the machine to perform the work equivalent to two operators simultaneously. This feature contributes to smoother, uninterrupted production cycles.

Advantages:

- Enhanced Production Efficiency:By automating both glue dispensing and stone setting in one system, the machine significantly increases throughput and production efficiency for jewelry manufacturers, hardware workshops, and craft producers.

- Reduced Labor Costs:The design allows for continuous operation without the need to shut down processes, thereby reducing the manpower required and cutting down on labor costs.

- Flexibility & Adaptability:The ability to handle multi-colored, multi-sized stones and execute style-specific processing makes the system suitable for a wide range of product designs and customer specifications.

- Precision in Complex Designs:Its precise and stable operation overcomes the challenges associated with complex, multi-dimensional design patterns, ensuring a consistently high-quality output.

- Streamlined Workflow:The sequential process (applying glue first, then setting stones) minimizes errors and maximizes operational speed, leading to smoother and more reliable production.

| Equipment nam | Dual Station Automatic Stone Glue Dispensing Machine |

| Equipment Model | SPB-5DZ3-2 |

| Worktable Structure | double-plane workbench and double-rotating axis working structure |

| Dispensing speed | 20000-21000/hour |

| Drilling speed | 12000-15000 grains/hour |

| Number of suction drill heads | 4 suction nozzles 1 dispensing head |

| Drill plate fixing method | ±0.02mm |

| Control system | industrial-grade five-axis motion controller |

| Main Operating System | SuperbMelt self-developed system |

| Drive system | High-end servo |

| Transmission method | High-precision Ball Screw and Linear Guide |

| Z*Y*Z/A/C effective stroke | 550*150*110mm / +150°~-90° / ±3600° |

| Power Supply | AC220V/50Hz |

| Working Air Pressure | 90psi (0.6MPa) |

| Equipment Dimensions (LWH) | 950*750*1400mm |

| Equipment Weight | Approx. 750kg |

| Rated Power | 2.5kW |

By automating both glue dispensing and stone setting in one system

The process—applying glue first followed by stone setting—ensures stable glue output and accurate placement of stones.

The system is capable of processing a wide range of colours, sizes and specific styles of treatments

Why SuperbMelt Dual Station Automatic Stone Glue Dispensing Machine

Any Question About SuperbMelt Dual Station Automatic Stone Glue Dispensing Machine

FAQ Guide of Dual Station Automatic Stone Glue Dispensing Machine

- 1. What is the Dual Station Stone Glue Dispensing Machine used for?

- 2. How many glue dots and stones can the machine apply per hour?

- 3. What types of stones and sizes are supported?

- 4. Can it work on complex or 3D jewelry designs?

- 5. Is the machine suitable for wax model stone setting?

- 6. What is the control system used?

- 7. Does it support continuous operation?

- 8. What is the positioning accuracy of the stone placement?

- 9. What industries can benefit from this machine?

- 10. What kind of glue does the machine support?

- 11. Can the machine handle custom processing needs?

1. What is the Dual Station Stone Glue Dispensing Machine used for?

The machine is designed for automated glue dispensing and stone setting on jewelry, crafts, hardware, and wax models. It improves speed and accuracy in rhinestone application processes.

2. How many glue dots and stones can the machine apply per hour?

It can dispense 20,000–21,000 glue drops and set 12,000–15,000 stones per hour, making it ideal for high-volume production.

3. What types of stones and sizes are supported?

The machine supports multi-color and multi-size rhinestones, enabling flexible design capabilities and style-specific processing.

4. Can it work on complex or 3D jewelry designs?

Yes, it is engineered to handle complex 3D patterns with precision, offering stable glue output and accurate stone positioning even on intricate surfaces.

5. Is the machine suitable for wax model stone setting?

Absolutely. The machine also supports wax mold stone embedding, expanding its applications to pre-casting processes in jewelry manufacturing.

6. What is the control system used?

The machine is equipped with an industrial-grade five-axis motion controller to ensure smooth and coordinated movement of all axes during operation.

7. Does it support continuous operation?

Yes, the dual-station design enables non-stop production, effectively replacing the workload of two operators and boosting overall efficiency.

8. What is the positioning accuracy of the stone placement?

The stone setting precision is ±0.2mm, which ensures consistent and high-quality output.

9. What industries can benefit from this machine?

This machine is ideal for jewelry manufacturers, craft producers, hardware workshops, and any business that requires high-speed, automated rhinestone application.

10. What kind of glue does the machine support?

The machine is compatible with industrial-grade adhesives commonly used in rhinestone and jewelry bonding processes.

11. Can the machine handle custom processing needs?

Yes, it supports style-based processing, allowing manufacturers to customize operations according to different product designs and customer specifications.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited