Coin Reeding Machine

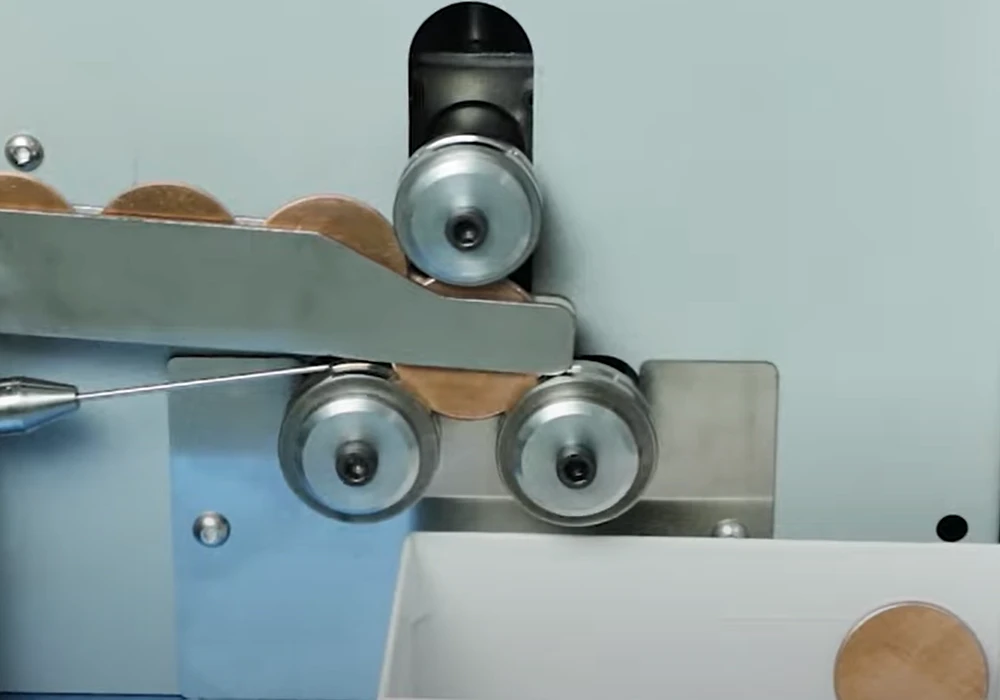

A semi-automatic coin reeding machine suitable for small-scale mints, which can be used not only for coins but also for medals.

SuperbMelt Coin Reeding Machine is a semi-automatic edge finishing machine designed for round coin and medal blanks, specifically developed for small and medium-scale minting and medal production lines. It supports interchangeable molds with a maximum diameter of 40mm, allowing users to process various coin and medal sizes within a single mold.

The machine features a manual feeding system with a production speed of 0–12 pieces per minute, enabling precise control and making it an ideal choice for trial minting and small-batch production.

With its lightweight design (50kg) and compact size, it is easy to install and operate even in limited spaces. Reliable and flexible in performance, this machine ensures smooth and precise edge finishing for coins and medals, providing professional-grade results for mints, jewelry manufacturers, and custom medal producers.

| Machine Type | Auto Coin rimming machine | Semi-auto Coin rimming machine |

| Model | SPB-ARM80 | SPB-CER3 |

| Voltage | AC220V/50HZ | AC220V/50HZ |

| Power | 1.5kw | 0.4kw |

| Mold diameter | Ф300mm | Ф40mm |

| Product size | Customize three coin sizes in one mold | customizable |

| Molding speed | 80-100 pcs/min adjustable | 0-12 pcs/min adjustable |

| Feeding method | Auto feeding | manual feeding |

| Weight | 100kg | 50kg |

| Size | L1350× W670× H720 mm | L600× W560× H450 mm |

- Precisely Targeted Application Scenarios: A semi-automatic edge finishing machine specifically designed for round coin and medal blanks. It accurately matches the production needs of small and medium-scale mints and medal production lines, while also being suitable for jewelry manufacturers engaged in custom commemorative coins and personalized medal processing.

- Flexible and Interchangeable Mold System: Supports interchangeable molds with a maximum adaptable diameter of 40mm. A single set of molds can handle the processing of various sizes of coins and medals, eliminating the need to configure separate molds for different dimensions.

- Controllable and Efficient Feeding Method: Equipped with a manual feeding system, the production speed can be flexibly adjusted within the range of 0–12 pieces per minute, allowing precise control of the production rhythm according to processing requirements.

- Compact and Lightweight Design: With a total weight of only 50kg and a compact size, it has low requirements for installation space. It can be easily installed and flexibly placed even in small workshops or studios.

- Stable and Reliable Performance: The machine operates stably with high precision in edge processing, enabling smooth and accurate edge finishing (such as reeding) for coins and medals, ensuring the continuity of the processing process.

- Strong Adaptability, Cost Reduction and Efficiency Improvement: The interchangeable mold design significantly reduces production investment in multi-specification products. There is no need to purchase molds repeatedly, making it particularly suitable for multi-variety and small-batch production and effectively controlling production costs.

- Precise Control, Suitable for Trial Production and Small Batches: The combination of manual feeding and adjustable speed design allows precise control over the processing of each blank, resulting in a low scrap rate. It is an ideal choice for trial production, sample making and small-batch custom production, perfectly matching the needs of customized processing.

- Easy Installation, Flexible Deployment: The lightweight and compact design lowers the site threshold. No complex installation and commissioning procedures are required, saving space occupation costs. The machine can be flexibly adjusted in position according to the production layout.

- Wide Application Range, High Professionalism: It is not only suitable for small and medium-scale mints, but also can meet the professional needs of jewelry manufacturers, personalized medal customizers and other enterprises for the edge finishing of commemorative coins and medals. The processing effect reaches a professional level, improving product quality and added value.

- Simple Operation, Quick Start: The machine has a simple structure and clear operation logic. No professional and technical personnel are needed to quickly master the operation skills, reducing personnel training costs and ensuring efficient production.

Semi-auto Coin Rimming Machine Features

The semi-automatic machine is small and compact, can be used on the desktop, does not take up space.

The mold can be customized, which can realize the edge production of various shapes.

Has good effect, smooth and curved, and the quality of the finished coin press will be higher.

Why SuperbMelt 1-2kg Mini Gold Melting Furnace

Any Question About SuperbMelt Mini Gold Melting Furnace

Unlocking Coin Rimming Technology: A Standardized Guide for Modern Coin Minting

Introduction of mining of platinum

In the modern minting industry, the coin rimming process holds a pivotal role, being a key step in ensuring coin quality and anti-counterfeiting performance. From everyday circulating currency to collectible commemorative coins, rimming plays an indispensable role.

From a quality perspective, the rimming process directly affects the coin’s appearance and durability. By precisely controlling the pressure, speed, and die parameters, the coin edges can be made smooth and uniform, free of burrs and cracks, enhancing overall aesthetics. Proper rimming also strengthens the edges, reducing wear and damage over prolonged circulation, extending the coin’s lifespan.

In terms of anti-counterfeiting, the rimming process is crucial. With the advancement of counterfeiting techniques, the minting industry must continually innovate anti-counterfeiting measures. Unique rimming designs—such as special lettering, patterns, or serrations—make counterfeiting more difficult and costly, effectively curbing the circulation of fake coins and maintaining monetary authority and financial stability. For example, China’s fifth series of 1-yuan coins uses advanced rimming techniques to enhance anti-counterfeiting and ensure proper circulation.

This guide aims to provide the modern minting industry with a comprehensive, scientific, and standardized set of coin rimming operation norms and technical requirements. It helps minting enterprises improve production efficiency and product quality while reducing costs and scrap rates. At the same time, it promotes overall technological advancement in the industry and strengthens collaboration, ensuring consistency and comparability of rimming quality across different mints, guiding the industry toward more standardized and professional development.

Overview of Coin Rimming Process

2.1, Definition and Function

Coin rimming refers to processing the edge of a coin during minting using specialized machinery and dies, forming specific shapes, patterns, or inscriptions. This step is crucial in coin production and circulation.

From an anti-counterfeiting perspective, rimming provides a unique advantage. As counterfeiting techniques evolve, traditional anti-counterfeiting measures often fall short, while complex rimming acts as a strong deterrent. Rolling fine serrations, unique text, or intricate patterns along the coin edge is difficult to replicate, greatly increasing counterfeiting difficulty and cost. Some Chinese commemorative coins feature micro-lettering or complex serrations on the edge, effectively discouraging counterfeiters and protecting currency authority.

Edge protection is another critical function. Coins inevitably experience friction and collisions during circulation. Without rimming, the surface patterns and inscriptions would wear quickly. Rimming forms a protective barrier, minimizing damage to the coin face and extending its lifespan. For instance, the 1-yuan coin’s edge rimming effectively preserves the floral pattern and text over long-term circulation.

Rimming also enhances visual appeal. Various edge designs, such as plain serrations, continuous serrations, interrupted serrations, or rimming with decorative text and patterns, add artistic value. Commemorative coins often use unique rimming to integrate cultural elements, elevating both cultural and artistic significance.

2.2, Common Types of Rimming

Plain Serrations: Cylindrical smooth edge with perpendicular gear-like serrations. Simple to produce, suitable for mass circulation coins, providing grip and basic anti-counterfeiting.

Continuous Serrations: Uninterrupted vertical serrations. Offers higher precision and better anti-counterfeiting, often used on high-value commemorative coins.

Interrupted Serrations: Serrations with smooth gaps in between. Creates unique visual effects and increases recognition, requiring more complex equipment and higher anti-counterfeiting.

Continuous Oblique Serrations: Serrations angled relative to the coin axis. Technically demanding, enhancing anti-counterfeiting, suitable for high-denomination coins or special commemoratives.

Edge Lettering with Serrations: Combines text and serrations for double anti-counterfeiting and decorative purposes, increasing information and aesthetic appeal.

Grooved Lettering (Security Edge): A central groove cut along the edge, separating the coin into layers with text or designs, significantly raising counterfeiting difficulty, used for high-value or high-security coins.

Preparatory Work

3.1, Equipment and Tools Selection

The core equipment is the rimming machine. Key parameters include:

Pressure control precision: Pressure must be stable to ensure clear and uniform edges. Too low leads to incomplete rimming; too high causes deformation or cracking. Advanced machines use high-precision sensors and closed-loop control.

Speed adjustment range: Low speed suits intricate designs; high speed suits mass production. Machines must accommodate various speeds for different coin types.

Die compatibility: Easy installation and replacement of dies, with accurate positioning and protection during operation.

Auxiliary tools include feeding devices, die cleaning tools, and quality inspection instruments. Proper handling ensures accuracy, efficiency, and consistent rimming quality.

3.2, Blank Quality Requirements

Material: Must meet strict standards. Circulation coins often use stainless steel or copper alloys; commemoratives may use precious metals. Impurities or improper composition can lead to deformation or cracks.

Dimensional accuracy: Diameter and thickness must be within tight tolerances to ensure uniform edge thickness and pattern clarity.

Surface condition: Smooth, defect-free surfaces are required. Scratches or pits can be magnified during rimming, affecting aesthetics and anti-counterfeiting.

Standardized Process Flow

(a) Feeding and Positioning

Automated feeding devices transport blanks to the rimming station. Sensors ensure accurate placement, and precise mechanical, pneumatic, or electromagnetic positioning aligns the blank with the rimming machine’s rotation center.

(b) Rimming Operation

Wheel startup and adjustment: Adjust wheel speed and pressure based on material and design requirements.

Rimming process: Rotating wheels move axially along the edge, uniformly imprinting the pattern. Sensors monitor speed, pressure, and temperature, with automatic adjustments for anomalies.

(c) Quality Inspection

Dimension check: Using laser or image-based measurement to ensure edge thickness and diameter meet standards.

Pattern clarity check: Visual inspection systems evaluate edge pattern sharpness.

Surface defect detection: Visual, eddy-current, and ultrasonic tests detect scratches, cracks, pits, or internal flaws.

5. Key Technical Control Points

(a) Die Design and Maintenance

Design principles: Match coin shape and edge pattern; use CAD for precision.

Dimensional accuracy: Critical for uniform edges; tolerances must be tightly controlled.

Material selection: High-strength, wear-resistant materials like alloy steel or carbide.

Maintenance: Clean daily, inspect wear, repair or replace when necessary.

Replacement cycles: Based on production frequency and coin type; replace dies when wear or deformation is severe.

(b) Process Parameter Optimization

Rimming pressure: Adjust based on material hardness and thickness.

Rimming speed: Balance quality and efficiency; lower speeds for detailed coins, higher speeds for mass production.

Temperature control: Friction generates heat; use cooling systems to maintain stability.

Quality Control and Problem Solving

(a) Common Issues

Edge cracks: Caused by material defects or improper pressure/speed.

Pattern blur: Due to worn dies, insufficient pressure, high speed, or dirty blanks.

Uneven thickness: Caused by blank variability or machine misalignment.

(b) Solutions and Prevention

Control blank material and internal stress.

Adjust pressure, speed, and conduct trial runs.

Maintain dies and machines; replace when worn.

Monitor and inspect blanks and finished coins in real time.

Conclusion

This guide systematically covers key aspects of modern coin rimming, from equipment and blank preparation to standardized workflow, technical control, quality assurance, safety, environmental measures, and future development. Strict adherence ensures:

Quality improvement: Reduces edge cracks, pattern blur, and uneven thickness; produces coins with precise dimensions and clear patterns.

Efficiency enhancement: Standardized operations and advanced equipment increase automation, stability, and productivity while reducing costs.

By applying this guide, mints can innovate, train personnel, and elevate the overall level of the industry, contributing to financial stability and economic development.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited