Box Chain Making Machine

Superbmelt provide a one-stop service to solve any problems with your jewelry chain manufacturing line

Superbmelt box chain making machine is designed for making box chains from thin precious metal sheets. Materials such as silver, stainless steel, gold, karat gold, platinum and so on are suitable for making jewellery chains. The jewellery chain making machine is able to make box chains with widths ranging from 0.8mm to 2.0mm.

The gold and silver chain making process is highly automated with the Superbmelt jewellery chain making machine. The process requires feeding the automatic machine with thin square metal sheets and setting the parameters. The maximum production capacity of the Superbmelt box chain making machine is 600rpm/min. The machine produces up to 500 grams of chains within an hour. The power required for operating the automatic jewellery chain machine is about 200W. The PLC control unit is user-friendly and allows users to control the speed and pressure of production. Box chains made with Superbmelt fully automatic gold chain making machine are strong, durable and not easily broken.

At Superbmelt, we provide you with top quality automatic jewelry chain making machines that are suitable for meeting your production demands. Contact Superbmelt today for all enquiries and the best box chain making machine that meets your needs.

- Superbmelt automatic chain making machine is a fast, convenient, affordable and efficient way of producing chains, especially in jewellery chain production lines.

- Superbmelt gold chain making machine is a better, faster, safer and cleaner alternative to the traditional chain making technique. The traditional technique involves using handmade tools to interlock the boxes one after the other, which can be time-consuming.

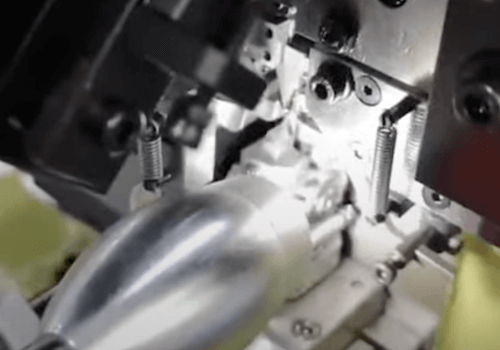

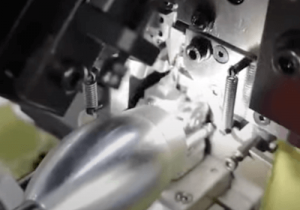

- The entire chain making process is automatic as the gold chain making machine performs cutting, bending, buckling and welding gold and silver sheet after thin sheets are fed into the automatic chain making machine.

- The width of the chains can easily be adjusted on the automatic gold chain making machine. Chain width can range from 0.8mm to 2.0 mm or above. This allows you to make a wide range of widths for customers to choose from.

- Superbmelt automatic box chain making machine has a production capacity of 600rpm/min. This is beneficial for all fast-moving jewellery chain production companies so as to meet up with demands.

- The production capacity of the Superbmelt gold chain making machine in a minute is 600rpm/min and a total of 200 and 500 grams in an hour.

- Superbmelt fully automated gold chain making machine uses metals such as gold (14K to 21K), sterling silver (7.5% copper and 92.5% silver), copper, platinum, iron, palladium, and stainless steel can be used to make long-lasting and high-quality box chains.

- At Superbmelt, we ensure our machines provide safety for users. With the automatic function, cooling unit, robust outer structure and so on, the automatic box chain making machine guarantees safety.

- The new-updated and optimized round corner folding mechanism is simple to adjust, stable in performance and reliable in operation.

- Superbmelt fully automatic gold chain making machine is made with sturdy materials which make the machine last longer. The machine is also easy to maintain through regular cleaning.

- Box chains made with Superbmelt box chain making machines have a smooth and shiny appearance and last longer because the boxes are neatly and carefully interlocked by the chain making machine.

- The power required for operating the jewellery chain making machine is 200W and single-phase voltage of 200v. This helps to save cost on energy use.

| Model | SPB-ZC04 |

| Type | Laser welding box chain making machine |

| Voltage | Single phase 220V/50HZ |

| Rated power | 400w |

| Outer diameter parameter | 0.8mm-1.5mm |

| Max. speed | 400 rpm |

| Dimension | 800*520*128mm |

| Weight | 152KG |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Box Chain Making Machine

Any Question About SuperbMelt Box Chain Making Machine

Box Chain Making — Thin-Sheet Folding Chain Process & Equipment Guide

Box Chain Structure & Advantages

1.1, How a box chain is made from thin metal sheet

The core manufacturing principle of box chains lies in transforming flat metal blanks into hollow, interlocking 4-sided “box” links—each link functioning as a self-contained structural unit. This process deviates from traditional chain-making methods (e.g., wire bending or casting) by leveraging folding to achieve geometric precision without compromising aesthetics.

Core Manufacturing Logic

Each box link originates from a small, precisely cut square or rectangular thin-metal blank. The blank undergoes a sequential forming process to create a closed or semi-closed hollow box structure, then interlocks with adjacent links to form a continuous chain. The key advantage of this method is that it eliminates visible welds on the link surface, preserving a clean, seamless appearance while ensuring structural integrity.

Step-by-Step Manufacturing Micro-Process

- Blank Preparation: Thin metal sheets are slit into strips of specified width, then cut into individual blanks with strict dimensional control. Blanks must be free of burrs or surface defects to ensure consistent folding.

- Pre-Bending: The blank is positioned in a precision die to create preliminary bends along the four edges. This step reduces material stress during subsequent folding and ensures accurate alignment of the box faces.

- Four-Edge Folding: Each edge of the pre-bent blank is folded at a 90° angle in successive stations. This progressive forming avoids metal fatigue and ensures sharp, uniform edges.

- Box Cavity Formation: The folded edges are brought together to form a hollow box cavity. The gap between opposing edges is tightly controlled to prepare for seam closure.

- Seam/Locking: The box is sealed using one of three methods—mechanical interlock (for non-precious metals), micro-welding (laser or spot welding for precious metals), or press-crimp (for seamless aesthetics). This step ensures the box retains its shape under tension.

- Interlacing with Previous Link: The newly formed box link is aligned with the last link in the continuous chain, ensuring the interlocking joint allows rotational movement.

- Final Closure/Press: A precision press applies controlled force to lock the interlink joint, eliminating gaps and ensuring smooth articulation between links.

Why the Thin-Sheet Folding Method Stands Out

- Geometric Precision: Folding creates true 90° angles, flat faces, and sharp edges—attributes that casting or wire bending cannot replicate. This precision ensures uniform link dimensions and consistent chain appearance.

- Aesthetic Consistency: No visible welds or seams on the link surface result in a clean, reflective finish. The four flat faces of each box link create multiple catch-lights, enhancing the chain’s visual appeal.

- High Repeatability: The process is easily automated, enabling mass production with minimal variation between links. This is critical for meeting the quality standards of both luxury and mass-market jewelry.

1.2, Why box chains are flexible yet robust

Box chains achieve a unique balance of flexibility (drape) and robustness (tensile strength) through their structural design and manufacturing precision—outperforming many traditional chain types in real-world applications.

Geometry-Driven Performance

The hollow box shape is the foundation of the chain’s performance:

- Torsional Stiffness: The closed 4-sided structure resists twisting, ensuring the chain maintains its shape during wear.

- Rotational Flexibility: The interlocking joint between links allows 360° rotational movement, enabling the chain to drape smoothly over curves (e.g., wrists or necks) without kinking.

This combination makes box chains ideal for daily wear—they are flexible enough to be comfortable yet rigid enough to avoid deformation.

Superior Load Distribution

Unlike welded chains, where stress concentrates at the weld joint (a common failure point), box chains distribute tension evenly around the entire perimeter of each link. Even under significant pulling force, the box structure retains its shape, reducing the risk of link failure or chain breakage. This load distribution also minimizes wear on the interlocking joints, extending the chain’s lifespan.

Thin-Sheet Folding vs. Wire Link Chains

Feature | Box Chain (Thin-Sheet Folding) | Wire-Formed Chain |

Snag Resistance | High—flat, smooth surfaces with no protruding edges | Low—rounded or irregular edges prone to catching on clothing/hair |

Reflective Surface | Excellent—four flat faces create multiple catch-lights | Moderate—rounded surfaces reflect light unevenly |

Structural Integrity | High—uniform load distribution; no weak weld points | Variable—stress concentrates at bends or welds |

Aesthetic Consistency | High—precision folding ensures uniform link dimensions | Low—wire bending often results in slight variations |

1.3, Typical Jewelry Uses

Box chains’ versatility—combined with their aesthetic and performance advantages—makes them suitable for a wide range of jewelry applications, from luxury to fast fashion.

Hand & Neck Chains

- Bracelets & Necklaces: The flat, sleek profile of box chains complements minimalist designs, while their reflective surfaces add elegance to statement pieces. They are particularly popular for “everyday wear” jewelry due to their durability and low maintenance.

- Design Flexibility: Available in various link sizes (from delicate 0.8mm to bold 2.0mm) to suit different styles—thin chains for dainty looks, thick chains for edgy or luxurious designs.

Pendants & Charms

Box chains are the preferred choice for pendant necklaces due to their low-twist design. The rigid box links prevent the pendant from spinning or flipping, keeping it centered and visible. This stability is critical for personalized jewelry (e.g., name pendants, birthstone charms) where alignment matters.

High-End Applications

Luxury jewelry brands rely on box chains crafted from precious metals (platinum, 18K gold) for their premium lines. The thin-sheet folding process meets the strict finish requirements of high-value pieces—mirror-polished surfaces, zero visible defects, and precise link alignment. These chains are often sold as standalone pieces or paired with high-end pendants.

Mass Market & Fashion Lines

For fast-fashion and mass-market brands, box chains are manufactured using silver or plated base metals (e.g., brass with gold/silver plating) via fully automated production lines. The process enables high throughput (up to 600 links per minute) at a lower cost, making box chains accessible for trendy, affordable jewelry collections.

Raw Material & Specification Requirements

The quality of box chains is directly determined by raw material specifications. Even minor deviations in thickness, hardness, or surface condition can lead to manufacturing defects (e.g., cracked edges, deformed links) or performance issues (e.g., low tensile strength). Below are the critical material requirements for successful box chain production.

2.1, Sheet Thickness & Dimensional Tolerances

Sheet thickness is a critical parameter that balances foldability, strength, and wearability. The ideal thickness range is tailored to jewelry applications, where lightweight comfort and structural integrity are equally important.

Recommended Thickness Range

- Standard Range: 0.15–0.25 mm for most jewelry box chains. This range ensures the metal is flexible enough to fold into sharp 90° angles without cracking, yet rigid enough to maintain the box shape under normal wear.

- Thickness Below 0.15 mm: Risks deformation and weak edges. Thin sheets are prone to collapsing during folding or stretching under tension, resulting in links that lose their shape or break easily.

- Thickness Above 0.25 mm: Creates challenges in folding—thicker metal requires more force, leading to uneven bends or rounded edges (instead of sharp 90° angles). The finished chain is also heavier, reducing wear comfort.

Dimensional Tolerances

Tight tolerances are non-negotiable for consistent production:

- Thickness Tolerance: ±0.01 mm. Even minor variations in sheet thickness can cause inconsistent fold angles or seam gaps between links.

- Strip Width Tolerance: ±0.02 mm. The width of the metal strip directly determines the size of the box link—variations lead to uneven link dimensions and poor interlocking.

2.2, Material Hardness & Mechanical Properties

Material hardness directly impacts the folding process and the final chain’s durability. Too soft, and the metal will crease or deform permanently; too hard, and it will crack during bending.

Optimal Hardness Range

- Typical Hardness: HV 70–120 (Vickers Hardness). This range is adjusted based on the metal alloy—softer for precious metals (e.g., 18K gold) and slightly harder for stainless steel or alloys.

- Controlled Annealing: To achieve the target hardness and ductility, metal sheets undergo controlled annealing (heating to a specific temperature, then cooling slowly). Annealing reduces internal stress in the metal, making it easier to fold without cracking while maintaining sufficient strength.

Consequences of Improper Hardness

Hardness Issue | Manufacturing Impact | Final Product Impact |

Too Soft (HV <70) | Permanent creases during folding; excessive springback | Links deform under tension; chain loses shape over time |

Too Hard (HV >120) | Cracks at fold edges; uneven bending | Brittle links prone to breaking; poor drape |

2.3, Suitable Materials

Box chains can be manufactured from a variety of metals and alloys, each selected for its aesthetic, mechanical, and cost properties.

Precious Metals

- Gold: Various karats (14K, 18K, 24K) are used. 18K gold (75% pure gold) is preferred for luxury chains due to its balance of softness (for folding) and durability. Different alloys (e.g., yellow gold, white gold, rose gold) offer color versatility.

- Silver: 999 (pure silver) or 925 (sterling silver) are common. 925 silver is more durable for daily wear, while 999 silver provides a brighter finish (ideal for high-end designs).

- Platinum: A premium choice for luxury jewelry. Platinum’s high density and corrosion resistance make it durable, but its hardness requires precise annealing to ensure foldability.

Alloys

- K-Gold Alloys: Additives (e.g., copper, nickel, palladium) are mixed with gold to adjust color and strength. For example, rose gold contains copper, while white gold uses nickel or palladium.

- Palladium Alloys: Used as a cost-effective alternative to platinum. Palladium alloys offer similar brightness and durability, with better foldability than pure platinum.

Non-Precious Metals

- Stainless Steel: Popular for fashion chains due to its low cost, corrosion resistance, and durability. Grade 316 stainless steel is preferred for jewelry as it is hypoallergenic.

Surface Pre-Treatment

Before folding, all materials undergo two critical pre-treatments:

- Degreasing: Removes oils, dirt, or contaminants from the sheet surface. Grease can cause uneven folding or poor adhesion during plating.

- Mild Pickling: Uses a dilute acid solution to remove oxide layers and surface impurities. This ensures clean fold edges and improves plating adhesion (if post-processing is required).

Box Chain Forming Process — Full Workflow

The box chain forming process is a highly automated, station-based workflow designed to transform thin metal sheets into continuous, interlocking chains. Unlike anchor chains (which use thicker metal and welding), box chain production relies on precision folding and mechanical interlocking to achieve its signature structure. Below is the complete workflow, with detailed insights into each stage.

Process Overview

Thin Sheet → Feeding & Strip Preparation → Automatic Cutting (Blank Separation) → Die & Folding Geometry Setup → Progressive 4-Side Folding → Link Formation (Seam/Locking) → Automatic Pairing & Interlinking → Finish → Post-Processing

3.1, Feeding & Strip Preparation

The feeding stage is the foundation of consistent production—any deviation in strip position or tension will lead to defective links. This stage ensures the metal strip is prepared and fed into the forming line with micron-level precision.

Feeding Mode

- Super Thin Square Strip Feeding: A precision step feed mechanism is used, equipped with tension control rollers and edge guides. The “step feed” moves the strip forward in precise increments (matching the link pitch), ensuring each blank is cut and formed at the correct position.

- Tension Control: A constant-tension system prevents the strip from stretching or wrinkling. Too much tension causes thinning; too little leads to misalignment during folding.

Strip Preparation

- Slitting: The master metal coil is slit into strips of the required width (e.g., 0.8–2.0 mm for jewelry chains) using a high-precision slitting machine.

- Deburring: The strip edges are deburred to remove sharp burrs—these can cause cracks during folding or scratch the link surface.

- Pre-Notching (Optional): For complex box designs, pre-notches are cut into the strip to guide fold alignment. This ensures the four edges of the box meet perfectly during forming.

Feed Tolerances

- Positional Accuracy: ±0.03 mm per feed step. This tolerance ensures each blank is cut to the correct length and positioned accurately in the folding die, maintaining consistent link pitch and size.

3.2, Die & Folding Geometry

Dies are the critical tooling components that determine the shape, precision, and quality of box links. Each die station is designed to perform a specific folding operation, with strict control over angles, clearances, and surface finish.

Die Function

- Progressive Forming Stations: Multiple die stations work in sequence to form the four faces of the box. For example:

- Station 1: Pre-bends the top and bottom edges to 45°.

- Station 2: Bends the top and bottom edges to 90°.

- Station 3: Pre-bends the left and right edges to 45°.

- Station 4: Bends the left and right edges to 90° and closes the seam.

- This progressive approach reduces metal stress and ensures uniform fold angles.

Critical Geometry Parameters

- Fold Angle: 90° ± 0.2°. This is the most critical parameter—any deviation will result in misshapen boxes that cannot interlock properly.

- Seam Clearance: Micro-clearances (0.01–0.03 mm) between die components ensure the folded edges meet without overlapping or gapping. Overlap causes weak seams; gaps lead to structural instability.

Die Materials & Maintenance

- Die Material: Hardened tool steel (e.g., SKD11, H13) is used for durability. The contact surfaces are polished to a mirror finish (Ra ≤0.1 µm) to prevent scratching the metal strip.

- Maintenance: Dies require regular polishing to maintain surface finish and regrinding to restore precision after prolonged use (typically every 500,000–1,000,000 cycles).

3.3, Automatic Cutting (Shearing) and Blank Separation

Automatic cutting separates the continuous metal strip into individual blanks, with precision synchronized to the feed mechanism.

Cutting Method

- High-Precision Shear/ Punch: An integrated shear or punch station cuts the strip into blanks of specified length. Shearing is preferred for thin sheets (≤0.25 mm) as it produces clean, burr-free edges.

- Synchronized Timing: The cutting action is synchronized with the feed index—each feed step is followed by a cut, ensuring the blank length is consistent (tolerance ±0.02 mm).

Quality Control

- Inline Sensors: Optical sensors inspect each blank for burrs, edge defects, or incorrect dimensions. Defective blanks are automatically diverted to a scrap chute to avoid disrupting downstream processes.

- Scrap Rate Target: For high-quality production, the scrap rate should be ≤0.5%.

3.4, Folding Sequence — Creating the 4-Sided Box

The folding sequence is designed to minimize metal fatigue and ensure the box retains its shape. Progressive forming is key to avoiding cracks or springback (the tendency of metal to return to its original shape after bending).

Stationed Folding Process

- Progressive Edge Bending: Each edge is folded in multiple steps (e.g., 45° → 60° → 90°) rather than a single step. This reduces the stress on the metal, preventing edge cracking and minimizing springback.

- Seam Formation: After all four edges are folded to 90°, the seam is closed using one of three methods:

- Mechanical Interlock: The edges are designed to snap together, creating a friction fit. Ideal for non-precious metals (e.g., stainless steel) and mass production.

- Micro-Welding: Laser or spot welding is used to seal the seam. This method is preferred for precious metals (e.g., gold, platinum) as it ensures maximum strength without visible welds.

- Press-Crimp: The seam is crimped using a precision press, creating a seamless finish. Suitable for both precious and non-precious metals.

Benefits of Progressive Forming

- Reduced Springback: Progressive bending allows the metal to “relax” between steps, minimizing the risk of the box opening after forming.

- Edge Integrity: Avoids edge splitting, which is common with single-step folding (especially for harder materials).

- Consistent Geometry: Ensures each box link has the same dimensions and squareness, critical for

Benefits of Progressive Forming (Continued)

- Consistent Geometry: Ensures each box link has the same dimensions and squareness, critical for smooth interlocking. Even minor variations in box size can cause the chain to bind or have uneven drape.

- Scalability: Progressive forming is easily automated, making it suitable for high-volume production while maintaining quality standards.

3.5, Automatic Pairing & Interlinking into Continuous Chain

Once individual box links are formed, the next stage is to interlock them into a continuous chain—this step requires precise alignment and timing to ensure seamless articulation between links.

Interlacing Mechanism

- Link Presentation: Formed box links are transferred to an interlinking station via a precision conveyor or robotic arm. The station positions each new link at a 90° angle to the previous link, aligning the open end of the new link with the closed end of the existing chain.

- Alignment System: Optical sensors and mechanical guides ensure the interlink gap is ≤0.1 mm. This tight tolerance prevents friction between links (which causes wear) and ensures the chain drapes smoothly.

- Sequential Interlocking: The interlinking process occurs in sync with link formation—each new link is locked into place before the next link is formed, maintaining consistent chain pitch (distance between link centers).

Closure Method

- Final Press/Crimp: After interlinking, a precision press applies controlled force (typically 5–15 kN, depending on material thickness) to lock the joint. The press uses a custom die that matches the link profile, ensuring no visible marks or deformation.

- Internal Weld Option: For high-strength applications (e.g., heavy pendants or luxury chains), a small internal laser weld is added to the interlink joint. The weld is invisible from the outside, preserving the chain’s aesthetic while enhancing tensile strength.

- Quality Check: Inline force sensors verify the closure force—under-crimping (insufficient force) leads to loose joints, while over-crimping (excessive force) damages the link structure.

3.6, Full Automation vs Semi-Automatic Production

The choice between full and semi-automatic production depends on production volume, product complexity, and budget. Below is a detailed comparison to guide decision-making:

Feature | Full Automatic Production | Semi-Automatic Production |

Workflow Integration | Feeding → forming → linking → ejection → coiling (continuous line) | Separate stations for forming and linking; manual intervention required |

Throughput | High (up to 600 rpm, 500–800 g/hr for small links) | Low (50–150 rpm, 100–300 g/hr) |

Labor Requirement | 1–2 operators (monitoring only) | 2–3 operators (manual blank feeding/linking) |

Quality Consistency | High (minimal human error; PLC-controlled parameters) | Variable (depends on operator skill) |

Ideal Applications | Mass production of standard chain sizes (e.g., 0.8–2.0 mm width) | Prototyping, custom designs, specialty finishes (e.g., hammered, brushed) |

Equipment Cost | Higher (starting from $50,000 for entry-level models like SuperbMelt) | Lower (starting from $15,000) |

Changeover Time | 30–60 minutes (recipe-driven PLC) | 2–4 hours (manual die adjustment) |

Key Considerations for Automation Selection

- Volume Threshold: Full automation becomes cost-effective when production volume exceeds 10,000 meters per month. For smaller volumes, semi-automatic machines offer better ROI.

- Design Complexity: Standard box chains (square links, uniform size) are ideal for full automation. Custom designs (e.g., rectangular links, decorative edges) may require semi-automatic production for flexibility.

Process Control, Quality Checks & Troubleshooting

Maintaining consistent quality in box chain production requires robust process control systems and proactive troubleshooting. This section outlines critical control points, quality parameters, and solutions to common defects.

4.1, Inline Controls & Sensors

Modern box chain machines integrate multiple sensors to monitor key process parameters in real time, preventing defects before they occur:

Position & Feed Controls

- Encoder-Based Position Sensors: Installed at feed, cut, and fold stations to monitor strip position. Any deviation beyond ±0.03 mm triggers an automatic stop, preventing misaligned blanks or links.

- Tension Sensors: Measure strip tension during feeding (target range: 0.5–1.5 N for 0.15–0.25 mm sheets). Tension spikes or drops indicate issues (e.g., strip wrinkling, feed roller wear) and trigger alerts.

Force & Pressure Controls

- Load Cells on Folding Dies: Monitor the force applied during each fold (typical range: 2–8 kN). Abnormal force readings indicate die wear, material hardness issues, or clearance misalignment.

- Final Press Force Sensors: Ensure closure force is within the specified range (5–15 kN). Data is logged for quality traceability, allowing manufacturers to identify trends (e.g., increasing force requirements due to die wear).

Vision Inspection Systems

- 2D/3D Vision Cameras: Perform random sampling (1 in 100 links) to check:

- Box squareness (90° ± 0.2°)

- Seam gap (≤0.05 mm for premium chains)

- Surface defects (scratches, dents, burrs)

- AI-Powered Defect Detection: Advanced systems use machine learning to classify defects (e.g., crack vs. scratch) and adjust process parameters automatically (e.g., reduce folding speed if cracks are detected).

4.2, Key Quality Parameters & Tolerances

To meet jewelry industry standards, box chains must adhere to strict dimensional and performance tolerances:

Quality Parameter | Specification | Inspection Method |

Box Angle | 90° ± 0.2° | Optical angle gauge or vision system |

Link Width | Nominal ±0.02 mm | Digital caliper (random sampling of 50 links per batch) |

Link Length | Nominal ±0.03 mm | Digital caliper |

Seam Gap | ≤0.05 mm (premium) / ≤0.1 mm (standard) | Optical microscope (100x magnification) |

Surface Finish | Ra ≤0.2 µm (mirror polish) / Ra ≤0.5 µm (matte) | Surface roughness tester |

Tensile Strength | ≥150 MPa (precious metals) / ≥200 MPa (stainless steel) | Tensile testing machine (5 samples per batch) |

Flex Fatigue | ≥10,000 flex cycles without failure | Fatigue testing machine (bend angle: ±90°, cycle rate: 10 cycles/sec) |

Batch Traceability

All quality data (sensor readings, inspection results, tensile test values) is linked to batch numbers, allowing manufacturers to trace defects back to specific raw material lots, machine settings, or production shifts.

4.3, Common Defects and Root Causes

Even with strict process control, defects can occur. Below are the most common issues, their root causes, and preventive measures:

Defect | Root Causes | Preventive Measures |

Deformed Boxes / Collapsed Face | 1. Feed instability (tension fluctuations)2. Incorrect die clearance (too large)3. Material thickness below 0.15 mm-crimping during closure | 1. Calibrate tension sensors weekly2. Set die clearance to 1.05x material thickness Reject material below minimum thickness4. Reduce final press force by 10–15% |

Cracked Edges | 1. Material hardness >HV 120 (insufficient annealing)ressive folding speed (>10 mm/sec)3. Sharp die edges (no micro-radius)4. Contaminated material (oxide layers) | 1. Re-anneal material to HV 70–1202. Reduce folding speed to 5–8 mm/sec 0.01 mm micro-radius to die edges>4. Enhance pre-treatment (degreasing + pickling) |

Loose Joints / Oversized Gap | 1. Under-crimping (final press force too low)link alignment deviation (>0.1 mm). Link width tolerance exceeded (>±0.02 mm)orn interlinking guides | 1. Increase press force by 5–10% (verify with tensile test)alibrate optical alignment sensors3. Reject batches with excessive width variation>4. Replace guides after 500,000 cycles |

Burrs on Links | 1. Blunt cutting knife (edge radius >0.01 mm)per shear clearance (>0.02 mm)3. Strip edge defects (un-deburred)>4. Die contact surfaces worn (Ra >0.2 µm) | 1. Regrind cutting knife every 100,000 cuts. Set shear clearance to 0.01x material thickness secondary deburring station if needed4. Polish die surfaces weekly |

Uneven Chain Pitch | 1. Feed step inaccuracy (>±0.03 mm). Link length variation (>±0.03 mm)3. Interlink timing misalignment | 1. Calibrate feed encoder daily cutting station to reduce length variation3. Sync interlinking station with forming station (PLC tuning) |

4.4, Corrective Actions & Continuous Improvement

When defects are detected, targeted corrective actions should be implemented to resolve the root cause:

Immediate Corrective Actions

- Process Adjustments: For minor deviations (e.g., seam gap slightly above 0.05 mm), adjust die clearance or press force in real time (within specified limits).

- Scrap Segregation: Isolate defective chains to prevent mixing with good product. Defective batches should be re-inspected to determine if rework is possible (e.g., re-crimping loose joints) or if they must be scrapped.

- Tooling Maintenance: Replace or regrind worn dies, cutting knives, or guides immediately—delayed maintenance leads to increased defect rates and higher scrap costs.

Long-Term Preventive Actions

- Material Qualification: Implement incoming material inspection (IQC) to verify thickness, hardness, and surface condition before production. Reject batches that do not meet specifications.

- Preventive Maintenance Schedule: Establish a weekly/monthly maintenance plan for critical components (e.g., dies, sensors, feed rollers) to avoid unplanned downtime.

- Operator Training: Train operators to recognize early signs of defects (e.g., unusual machine noise, inconsistent chain appearance) and respond appropriately.

- Data-Driven Improvement: Analyze quality data (defect rates, sensor trends) monthly to identify opportunities for process optimization (e.g., adjusting annealing parameters to reduce cracking, upgrading sensors for better accuracy).

Post-processing & Finishing

Post-processing transforms raw box chains into finished products, enhancing their aesthetic appeal, durability, and corrosion resistance. The choice of post-processing steps depends on the material, target market, and design requirements.

5.1, Deburring & Polishing

Even with precision forming, box chains may have minor burrs or surface imperfections that require smoothing:

Deburring Methods

- Vibratory Finishing: Batches of chains are placed in a vibratory tumbler with abrasive media (e.g., ceramic beads, plastic pellets) and a cleaning compound. The tumbling action removes burrs and smooths sharp edges (processing time: 30–60 minutes for small links).

- Abrasive Blasting: For matte finishes, abrasive blasting (e.g., aluminum oxide, glass beads) is used to create a uniform textured surface. Blasting pressure (0.2–0.5 MPa) is controlled to avoid damaging the box structure.

- Manual Deburring: For custom or low-volume production, hand-held tools (e.g., diamond files, abrasive pads) are used to remove burrs from critical areas (e.g., interlink joints).

Polishing Processes

- Precision Buffing: After deburring, chains are buffed using rotating wheels with polishing compounds (e.g., tripoli for cutting, rouge for finishing). The process is automated for mass production, with adjustable wheel speed (1,500–3,000 rpm) and pressure to achieve the desired finish:

- Mirror Polish: 2–3 stages of buffing with progressively finer compounds (Ra ≤0.2 µm). Ideal for luxury gold/platinum chains.

- Satin/Matte Finish: A single stage of buffing with a medium-abrasive compound (Ra ≤0.5 µm). Popular for fashion jewelry.

- Metal-Specific Considerations: For thin gold chains (≤0.2 mm thickness), use soft buffing wheels and mild compounds to avoid material loss (maximum allowable loss: ≤0.5% of total weight).

5.2, Plating & Surface Treatment

Plating enhances the appearance of non-precious metal chains and protects precious metals from tarnish and wear:

Electroplating

- Precious Metal Plating: Gold (18K, 24K), rhodium, or silver plating is applied to base metal chains (e.g., brass, stainless steel):

- Plating Thickness: 0.5–2.0 µm for fashion jewelry; 3–5 µm for premium pieces (ensures durability).

- Pre-Treatment: Chains undergo degreasing, acid activation, and strike plating (thin layer of nickel or copper) to improve adhesion.

- Quality Control: X-ray fluorescence (XRF) testing verifies plating thickness and composition.

- Color Plating: For trendy designs, colored platings (e.g., rose gold, black rhodium, gunmetal) are applied by adjusting the alloy composition of the plating solution.

PVD Coating & Passivation

- PVD Coating: Physical Vapor Deposition (PVD) is used for stainless steel chains to create durable, scratch-resistant finishes (e.g., titanium nitride, zirconium nitride). PVD coatings are thinner (0.1–0.5 µm) than electroplating but offer better wear resistance.

- Passivation: For stainless steel chains, passivation (treatment with nitric acid) removes free iron from the surface, enhancing corrosion resistance. This step is mandatory for hypoallergenic jewelry.

Post-Plating Treatment

- Rinsing & Drying: After plating, chains are rinsed in multiple stages (deionized water) to remove residual plating solution, then dried in an oven (60–80°C) to prevent water spots.

- Sealing: A clear protective coating (e.g., lacquer, silicone) is applied to plated chains to extend the lifespan of the finish (especially for fashion jewelry with thin plating).

5.3, Final QC & Mechanical Testing

Final quality control ensures finished chains meet all performance and aesthetic requirements before shipment:

Visual & Dimensional Inspection

- 100% Visual Inspection: Chains are inspected for surface defects (scratches, plating unevenness, burrs), link alignment, and interlink articulation. Defective chains are reworked or scrapped.

- Dimensional Sampling: 5% of each batch is checked for link width, length, and pitch using digital calipers and optical comparators.

Mechanical Testing

- Tensile Testing: Sample lengths (100 mm) are pulled to failure using a tensile testing machine. The minimum breaking force must exceed 50 N for small chains (≤1.0 mm width) and 100 N for larger chains (≥1.5 mm width).

- Flex Fatigue Testing: Chains are subjected to 10,000 flex cycles (bending ±90° at 10 cycles/sec) to simulate 2–3 years of wear. No link failure or deformation is allowed.

- Corrosion Testing: For plated or stainless steel chains, salt spray testing (ASTM B117) is performed—chains are exposed to 5% NaCl solution for 24–72 hours. No rust or plating peeling is allowed.

Packaging QC

- Chains are measured, cut to specified lengths (e.g., 45 cm for necklaces, 18 cm for bracelets), and fitted with clasps (e.g., lobster claw, spring ring).

- Final inspection verifies clasp functionality, chain length accuracy (±0.5 cm), and packaging quality (no tangling, proper labeling).

Equipment Selection & Buying Tips (for procurement teams)

Selecting the right box chain manufacturing equipment is a critical investment that impacts production efficiency, quality, and long-term profitability. Below is a structured guide for procurement teams to evaluate and select equipment.

6.1 Core Machine Specs to Request

When evaluating suppliers, prioritize the following technical specifications to ensure the machine meets your production needs:

Material Compatibility

- Supported Thickness Range: Must cover 0.15–0.25 mm (standard jewelry range) with the ability to handle thinner (0.12 mm) or thicker (0.3 mm) sheets for custom designs.

- Supported Width Range: 0.8–2.0 mm (typical link widths) with adjustable strip guides for quick size changes.

Material Compatibility (Continued)

- Compatible Materials: Verify the machine can process precious metals (gold, silver, platinum), alloys (18K gold, palladium alloys), and non-precious metals (stainless steel, brass). Look for adjustable forming parameters (e.g., folding force, speed) to accommodate different material hardness levels.

Production Capacity & Precision

- Max Speed/RPM: Target machines with a minimum speed of 400 rpm for mass production; premium models (e.g., SuperbMelt BM-C200) reach 600 rpm. Calculate throughput based on link size: for 1.0 mm width links, 600 rpm = ~500 g/hr (≈150 meters/hr).

- Feed Precision: Encoder feedback must ensure ±0.01 mm positional accuracy—this directly impacts link dimensional consistency. Request test reports showing feed repeatability over 10,000 cycles.

- Fold Angle Precision: 90° ± 0.2° is non-negotiable; ask for calibration certificates verifying angle accuracy across all forming stations.

- Link Dimensional Tolerance: Machine should consistently produce links with width ±0.02 mm and length ±0.03 mm—request sample parts for dimensional testing before purchase.

Control System & Flexibility

- PLC Configuration: Must use industry-standard PLC (e.g., Siemens S7, Mitsubishi FX) with a user-friendly HMI touchscreen. Ensure recipe storage for at least 50 different chain sizes/designs to reduce changeover time.

- Parameter Adjustment: Ability to fine-tune feed speed, folding force, crimp pressure, and welding parameters (if applicable) via the HMI—critical for optimizing process for different materials.

- Data Logging: Integrated data logging (production volume, defect rates, machine parameters) for traceability and process improvement.

Mechanical Durability

- Frame Construction: Heavy-duty steel frame (minimum 8mm thick) to reduce vibration during high-speed operation—vibration causes misalignment and defects.

- Drive System: Servo motor-driven feed and forming stations (preferred over hydraulic systems) for precise control and lower maintenance. Request motor brand and warranty details (minimum 2-year warranty for servo motors).

- Die Life: Expected die life should be ≥500,000 cycles for standard materials; ask for wear test results with 0.2 mm stainless steel and 18K gold.

6.2 Automation & Integration

Modern production lines require seamless integration between machines to minimize labor and maximize efficiency—prioritize equipment with strong automation and integration capabilities:

Inline Automation Features

- Auto-Loading System: Integrated coil auto-loading (capacity ≥50 kg coil) with tension control to eliminate manual strip feeding. Look for automatic coil changeover for 24/7 operation.

- Automatic Coiling: Post-forming coiler with adjustable tension (0.3–1.0 N) to wind chains into spools (100–500 meters/spool) without tangling. Coiler should sync with production speed to avoid chain slack or stretching.

- Defect Sorting: Inline reject mechanism (air jet or mechanical diverters) linked to vision sensors—automatically removes defective links without stopping production.

Downstream Integration Options

- Robotic Handling: Compatibility with robotic arms (e.g., Fanuc LR Mate, Universal Robots UR5) for transferring chains to post-processing stations (polishing, plating). Request interface specifications (EtherNet/IP, Modbus) for seamless communication.

- Plating Line Integration: Ability to connect directly to electroplating or PVD equipment via conveyor systems—reduces manual handling and ensures consistent processing.

- Data Integration: Machine should support Industry 4.0 protocols (OPC UA, MQTT) to integrate with factory ERP systems for production scheduling, inventory tracking, and maintenance alerts.

Customization for Special Processes

- Micro-Welding Integration: If producing precious metal chains, opt for machines with integrated laser micro-welding (fiber laser, 10–20 W) for seam closure. Verify welding spot size (≤0.1 mm) and compatibility with gold/platinum.

- Special Finish Capabilities: For textured or decorative links, check if the machine can accommodate custom dies (e.g., hammered edges, engraved patterns) and if the PLC supports parameter profiles for these designs.

6.3 Tooling & Spare Parts

Tooling quality and spare parts availability directly impact production downtime—negotiate these terms upfront with suppliers:

Die Quality & Standardization

- Die Material & Finish: Dies must be made of hardened tool steel (SKD11/H13) with polished contact surfaces (Ra ≤0.1 µm). Avoid custom non-standard dies—opt for standardized die sets that are interchangeable across different chain sizes.

- Die Changeover Time: Request a maximum changeover time of 30 minutes for die sets. Look for quick-release mechanisms and tool-less adjustments to minimize downtime.

- Die Customization: If you need unique link shapes (e.g., rectangular, hexagonal), confirm the supplier can design and manufacture custom dies within 4–6 weeks, and that the machine can accommodate these dies without major modifications.

Spare Parts Support

- Critical Spare Parts List: Request a list of essential spare parts (cutting knives, feed rollers, sensors, die springs) with part numbers, prices, and expected lifespans. Stock these parts on-site to avoid long downtime.

- Tool Life & Regrinding: Ask about die regrinding services—suppliers should offer regrinding for worn dies at 30–50% of the cost of new dies. Verify regrinding turnaround time (≤3 days) and whether regrinded dies maintain original precision.

- Consumables Availability: Ensure consumables (cutting blades, polishing pads, welding electrodes) are readily available locally or can be shipped within 24–48 hours. Avoid machines with proprietary consumables that lock you into a single supplier.

6.4 Service, Warranty & Training

Even the best equipment requires reliable after-sales support—prioritize suppliers with strong service networks and comprehensive warranty packages:

Warranty Terms

- Base Warranty: Minimum 1-year warranty on the entire machine, with 2–3 years on critical components (PLC, servo motors, laser welding module if applicable). Avoid warranties that exclude labor or shipping costs for repairs.

- Extended Warranty Option: Negotiate an extended warranty (2–3 years) for an additional 10–15% of the machine price—worthwhile for high-volume production where downtime is costly.

- Warranty Coverage: Clarify what is covered (parts, labor, shipping) and what is not (wear items like dies, cutting knives). Ensure on-site repair is included for major components (e.g., drive system, PLC).

Technical Support

- Local Support: Confirm the supplier has local technical support teams or authorized service partners—on-site response time should be ≤48 hours for critical issues.

- Remote Support: 24/7 remote troubleshooting via phone, email, or video call—essential for resolving minor issues quickly. The machine should have remote access capabilities (secure VPN) for technicians to diagnose problems.

- Spare Parts Shipping: Fast shipping (24–48 hours) for critical spare parts, with no minimum order quantity. Ask if the supplier maintains a local spare parts warehouse.

Training & Commissioning

- On-Site Commissioning: Supplier must provide on-site commissioning by factory-trained technicians to install the machine, calibrate parameters, and test production with your materials. Commissioning should include performance verification (e.g., producing 100 meters of chain with ≤0.5% defect rate).

- Operator Training: Comprehensive training for 2–3 operators (minimum 8 hours) covering machine setup, parameter adjustment, routine maintenance, and troubleshooting. Request training materials (manuals, videos) in your local language.

- Maintenance Training: Training for maintenance staff on die replacement, sensor calibration, and routine servicing (e.g., lubrication, cleaning). Ask for a detailed maintenance schedule with recommended intervals and procedures.

Supplier Reputation & References

- Industry Experience: Choose suppliers with at least 5 years of experience in box chain equipment—avoid new entrants without a proven track record.

- Customer References: Request 3–5 customer references (preferably in your region or industry) and contact them to ask about machine performance, service quality, and overall satisfaction.

- Certifications: Verify the machine meets international standards (e.g., CE, ISO 9001) for safety and quality. For export markets, ensure compliance with local electrical standards (e.g., UL for North America, CCC for China).

Conclusion

Box chain manufacturing via thin-sheet folding is a precision-driven process that requires careful coordination of material selection, process control, and equipment performance. This guide has covered every critical aspect of production—from the structural advantages of box chains and raw material specifications to the full forming workflow, quality control measures, and equipment procurement tips.

By adhering to the technical parameters, process best practices, and equipment selection criteria outlined here, manufacturers can produce box chains that meet the highest standards of aesthetics, durability, and consistency—whether for luxury precious metal lines or high-volume fashion jewelry. The key to success lies in balancing automation for efficiency, precision for quality, and flexibility for custom designs, while partnering with reliable suppliers who offer comprehensive support.

For further customization or specific technical questions (e.g., die design for unique link shapes, material annealing parameters), consult with industry experts or equipment suppliers to tailor the process to your specific production needs.

FAQ Guide of Box Chain Making Machine

- 1. What does the box chain look like?

- 2. How is the box chain produced?

- 3. What karat gold is best for chains?

- 4. How is chain welded in the production process?

- 5. What machines are used to process raw materials into box chains?

- 6. What are the different types of jewelry chain on the market?

- 7. What is the capacity of SuperbMelt’s box chain making machine?

- 8. What is the best material for a box chain?

- 9. What are the safety features of a box chain making machine?

- 10. Does operating a SuperbMelt box chain making machine require special training?

- 11. How to choose the best jewelry chain making machine manufacturer?

- 12. How to repair a box chain?

- 13. How long does a gold chain last?

- 14. Which gold chains are the strongest?

- 15. Is a box chain a good investment?

1. What does the box chain look like?

Speaking about box chains, these chains are crafted out of wide and square links that will appear like a box. The box links are carefully connected to make a smooth chain. Such chain style is also referred to as the Italian links chain and the square chain. These chains are very strong and don’t break easily.

Talking about the size, the widths of the chains can range between 0.8mm to 2mm, and in some cases, the width can be more. While women prefer to go for a thinner chain, main generally choose a box chain at a width of 1.5 mm. Different materials such as silver, gold, and platinum can be used to make a box chain using a jewellery chain making machine.

2. How is the box chain produced?

There are two different methods you can follow to make a box chain. These are handmade and using a chain manufacturing machine. Under the handmade process, the jewelers hammer the desired metal to convert them into strips. Then they process the strip through different dies to give it a perfect shape. After that, they create a box shape design using the wire.

Then the boxes are interlocked using the welding or soldering process. The handmade process is very time-consuming. But now, you can use a box chain making machine to create a box chain faster. All you need to feed the silver or gold pieces into the machine, and the machine will carry out the task automatically. It will cut, bend, buckle and weld the gold or silver sheet to create durable box chains.

3. What karat gold is best for chains?

To make chains, you can use 18K and 24K gold. If you want to make an affordable gold chain, then you can use the 18K gold. Here the gold amount will be a little lower than the 24K gold. 24K gold is 100 percent pure and soft. However, some jewelers have mastered techniques to make 24K gold more rigid and make a box chain from that.

4. How is chain welded in the production process?

You can use laser welding or plasma welding process to weld chains in the production process. The plasma welding process is a little complex, and it uses a plasma arc high energy density beam. The electrodes utilized in plasma welding are tungsten electrodes, and sometimes, you may need to use different gasses during the process.

But the laser welding is much better than the plasma welding process. This modern welding method is quite popular among jewelers. The method is very precise, and it utilizes a high energy density laser beam. You can use our mini laser welding machine to enjoy a smooth jewelry chain welding process. The physical metallurgical process is similar to electron beam welding.

Well, if you want to enjoy faster gold chain production efficiency, then you can always trust a laser welding machine. It welds the material directly through the beam without using any gasses. The machine can produce continuous laser beams to create a good connection of material.

5. What machines are used to process raw materials into box chains?

- Continuous casting machine

Using this machine, you can easily cast sheets from different materials, for example, platinum, gold, silver, and more. Our machine has an advanced melting protection technology to melt the desired material at a perfect temperature, and then it casts the metal into sheets with multiple shapes, like circular, rectangular, and more.

- Jewelry roll mill

The machine comes with two polished rollers made of steel. Using this machine, you can easily roll the thick sheet into a thin sheet with different widths and thicknesses. Visit our site now to know our chain making machine price.

- Annealing furnace

Using this machine, you can heat metal above its recrystallization temperature. SuperbMelt’s annealing furnace is used ion metal tempering, jewelry annealing, welding annealing, and more process.

- Box chain making machine

The box chain making machine makes the box chain from silver or gold wire. When you insert the sheet after configuring it to create a box chain, it will cut, weld, and carry out other processes to make a chain.

There is no need to use a jewelry hammering machine and chain faceting machine as it can damage the chain.

So, when it comes to starting your own box chain making business, and if you are looking for a reliable platform to get the machine, SuperbMelt can be your right option. We have a complete solution for your jewellery chain making requirements. Get in touch with us now to know the jewellery chain making machine price and place your order.

6. What are the different types of jewelry chain on the market?

- Box chain

As the name suggests, in the box chains, you will find square links that are connected in such a way that they will look like a box. The connection offers a continuous chain that will look very stylish. Due to the box shape, the chain will look more durable and stable. These chains are quite popular among both women and men. In general, the wider styles are used by men.

These chains are available in different lengths and will match perfectly with your outfit. The chain can also gold a pendant. Even though the box chains are very strong, they can break occasionally. However, they are easy to repair. To make such chains, you can use SuperbMelt’s chain making machine.

- Ball chain

This is also known as the bead chain. Here, a series of beads make a chain through linked together perfectly. The design may vary, and on some ball chains, every bead will be very close together. But in some cases, you may find space between the beads. To attach the beads to the chain, jewelers use metal bars. Well, as per the experts, ball chains may not look good when you wear them alone. So, for a perfect look, you can pair it with an accessory or pendant.

- Curb chain

This is a timeless and classic design. The chains are made from links, and the links are the same in size and carefully connected together to form a chain. Speaking about the design, the links can be round and oval in shape. These chains look chunky and popular among men.

- Rope chain

This chain is very common. The links or metal segments are properly twisted around each other to mimic the rope look. The unique twisting design can reflect the light, making the chain to shine under light.

- Anchor chain

The anchor chain is fairly heavy and is a good choice for men. In some cases, you can use them as a component in jewelry. Speaking about the design, the chains are linked together to appear like a jump ring along with a bar. In some places, these chains are called mariner chains. The chain links can be rounded or flattened.

- Trace chain

These chains are made from a thin wire, and the wire is shaped into uniformed round or oval links. Such chains can be 2mm or less in width and don’t weigh much. The thickness will vary. The style of this chain makes it perfect to wear with small, light, and dainty pendants. You can use a silver chain making machine to make good-quality trace chains.

- Belcher chain

In some places, these chains are called Rolo chains. In general, these are made from D-shaped wires and shaped into round or oval links. Then the inks are locked together and soldered to make a chain.

- Hayseed chain

These chains are created from a series of elongated looped bars that are properly interlocked together to attain the desired beauty as well as strength.

- Snake chain

With a sleek and smooth look, snake chains are perfect for different occasions. The beautiful lay and the unique semi-rigid design offer a stunning backdrop for any pendants. The plates are tightly interlocked and comfortable to wear.

- Bead chain

These chains are made of hollow metal spheres, and they are connected by small metal links. The design looks very modern and quite popular among women.

- Marine chain

The design of the chain is based on the chains that are connected to the anchors. Well, if you love beaches and the sea, then a marine chain can be the best option for you. In this chain, the ovals are carefully interlocked with a bar. The width of the links can vary.

- Cable chain

This is a basic chain style, and the design will look like iron chains. The chains are created using oval links that are connected together. The links can be flattened to create a flat chain.

- Singapore chain

Such chains appear like a curb chain but with a twisted shape. The design includes a series of segments braided, twisted, and linked together to form a chain. These chains are also durable, and you can wear them regularly.

- Wheat chain

This is also called can the Spiga chains. The chains come with oval links that are twisted together, and the design will look like braided rope. Its unique design forms a symmetrical chain, and the links go in the same direction. These chains have a good amount of texture. The chains will look durable and sturdy. You can wear it alone or with a pendant.

7. What is the capacity of SuperbMelt’s box chain making machine?

We manufacture the best quality jewellery chain making machine in the industry that can work faster, and the output limit is also good. The maximum production capacity of our machine is around 600rpm/min. Speaking about the per hour output level, our machine produces 200 to 500g.

8. What is the best material for a box chain?

- Gold

In general, 14K, 18K, 21Kand 16K gold is used to make a box chain. On the other hand, in the alloying process, rose, green, white, and yellow gold can be created. This material is less allergenic compared to other metals.

- Silver

This material is a perfect option for a box chain. As pure silver is soft, it is generally alloyed with copper. For box chains, jewelers use sterling silver that has 7.5 percent copper and 92.5 percent silver.

- Copper

The copper alloys that are widely used for making box chains include brass and bronze. Due to their durability, copper is a perfect material to create long-lasting box chains.

- Platinum

This is a malleable, dense, and silver-white precious metal. On the Mohs Hardness Scale, it is rated 4 to 4.5. This metal is around four times stronger than gold.

- Iron

One of the cost-effective materials that you can use to make a box chain is iron. However, iron-made chains need extra care.

- Stainless steel

Stainless steel is non-corrosive, rust-resistant, and durable. Different jewellery making tools, such as saw blades, hammers, files, and more, are also made of stainless steel.

- Palladium

This material is very rare and very durable. Palladium is a little white in appearance compared to platinum.

No matter what types of materials you want to use to make a box chain, you can use a gold chain manufacturing machine to create box chains faster.

9. What are the safety features of a box chain making machine?

When buying a box gold chain making machine, you should make sure that the machine has some good security features, for example, auto-function, cooling system, robust outer structure, and more. Besides, there should be a uniform temperature controlling unit to prevent overheating issues.

10. Does operating a SuperbMelt box chain making machine require special training?

Well, SuperbMelt gold chain making machine is very easy to use, and you don’t have to develop a strong technical skill to utilize the machine. If you are a professional box chain production engineer, then you can learn how to use the machine just by going through the instructions and videos that we offer.

If you are using the machine for the first time, then don’t worry at all. Remember that there is no need to hire a senior engineer to use it. We will provide you with detailed instruction manual and operation videos. If you want, our experts can also offer you on-site training. So, check the chain making machine price, place your order and start making durable and beautiful chains.

11. How to choose the best jewelry chain making machine manufacturer?

- Understand the scale of the factory and what certificates are available

Before choosing a jewelry chain making machine manufacturer to buy the machines, you need to check the types of certificates they have. Besides, understand the scale of the factory. Make sure that the reputed professional certification bodies have certified the company’s products. For example, SuperbMelt’s automatic chain making machine is ISO CE SGS approved. That means the machine is developed based on industry standards.

- Does the factory have mature solutions and cases?

For better performance and comfort-ability, you should choose a manufacturer who offers a complete solution for making gold or silver chains. For example, instead of buying different machines from different manufacturers, buying all the machines from one place will be a good option. This is where you can trust SuperbMelt. We offer different types of machines that will help you to set up your chain-making business. And we are not a new player in this industry and have 15 years of R&D experience.

- Has the factory delivered enough success stories?

Don’t forget to check the success stories of the manufacturer. This will prove the quality of the machines offered by the manufacturer. Besides, you can also know the technical support facility offered by the company. SuperbMelt has helped thousands of its clients to make their business successful by offering a one-stop service for their metal casting line.

- Go to the factory for an on-site inspection

If possible, you can carry out an on-site inspection to know more about the manufacturer. It is always better to personally meet the manufacturer and see how they produce their machines. You will also be able to use the machines before buying them.

Apart from these things, you should check their official websites and social media platforms to acquire more information about the company, like their brand reputation, popularity in the industry, and more.

12. How to repair a box chain?

The introduction of modern technology and different tools have made the box chain repairing process easier and faster. To repair a box chain, you can now use a mini laser welding machine. With laser welding, powerful light energy is used for welding the gold metal to themselves. The process welds the gold on a molecular level.

The amplified beam of light produces a robust weld, and the weld will be almost invisible. The heat generated in the laser welding process is so localized that the process results in an undetectable work zone. You can use SuperbMelt’s mini jewelry laser welding machine for this process. All you need to place the box chain inside the machine to start welding.

The machine will produce a light beam that can be adjusted, controlled, and concentrated by the user of the machine. Once done, you can use our chain faceting machine to polish the surface to give your box chain a shiny look. The entire box chain repairing process will take less time. As one of the trusted gold chain making machine manufacturers, we offer the industry’s best laser welding machines and along with gold chain making machines.

13. How long does a gold chain last?

Well, the lifespan of a gold chain will depend on the type of chain you are using and how frequently you wear them. For example, a gold chain that is worn on a regular basis will tend to wear out faster as it comes into contact with outside elements that can damage the chain. If you are using a gold-plated chain, then that can last for around two to three years.

If you are looking for a gold chain that can last for years, then buying a box gold chain can be the best option. Most of the jewelry manufacturers are using a jewellery chain making machine to make durable chains. However, don’t forget to take good care of your gold chains as certain chemicals and environmental factors can damage the natural characteristics of gold.

14. Which gold chains are the strongest?

As per the experts, one should always check the strength of a gold chain as this is the factor that will decide longevity. Besides, it will also determine whether the chain can carry the pendants or not. Well, the strongest types of gold chains are those that have interconnected links and that also enhance the flexibility of the chain. Some rigid chains, for example, snake chains, can easily break.

In some cases, independently soldered links can also affect the durability of the gold chains as it will be an easy task to replace a broken link. Considering all these things, it can be said that the strongest types of gold chains are rope chains, cable chains, Figaro, mariner, and curb chains. These gold chains can easily gold the pendants. For making durable gold chains, you can always use SuperbMelt’s chain making machine that can create different types of gold chains faster.

15. Is a box chain a good investment?

Yes, box chains are a perfect investment. The unique structure of the chain makes it durable, and when used properly, a box chain will last for years. Besides, a box chain is easy to repair. Most people are now using box chains as these chains are very stylish. Bot mane and women like to wear box chains but their demand among men are quite huge.

As long as the design of the chain in trend and people are using it, you can make quality box chains and make some money. If you want to make a good quality box chain from different materials, then it is the right time to use a box chain making machine. And for that, you can always trust SuperbMelt, one of the most popular and trusted chain making machine manufacturers.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited