Automatic Wire Cutting Machine

SuperbMelt specializes in manufacturing various automated processing equipment for jewelry and craftwork

SuperbMelt Automatic Wire Cutting Machine is primarily used for cutting metal wires such as gold, silver, platinum, and aluminum. It is widely employed in industries such as electronics, semiconductor, material research, precious metal processing, and artcraft manufacturing for purposes like evaporation coating, new material development, and crafting.

Automatic Wire Cutting Machine can cut 20-220 segments of metal wires per minute, with diameters ranging from 2-6mm. It boasts highly precise cutting capabilities, allowing for adjustments in cutting length and speed as per specific requirements to address cutting needs effectively.

With its automation features and high efficiency, the Automatic Wire Cutting Machine streamlines production processes, making them more convenient and productive.

| Model number | SPB-XVS100 |

| Power source | 220V |

| Power | 4 kw |

| Applicable metal | Gold, platinum, silver, copper, aluminum, nickel, titanium and other metals |

| Cut off speed | 50~220 pieces/minute |

| Cut off diameter | Ф2/3/4/5/6mm |

| Length tolerance | plus or minus 0.02mm |

| Cut off length | With positioning 3~50mm/without positioning 3~3000mm |

| Dimension | 1300*690*1440mm |

| Weight | 380KG |

| straightening function | Ф2-6mm |

- Electronics Industry: Used for cutting and processing wire materials for electronic components, circuit boards, etc.

- Semiconductor Industry: Utilized in the manufacturing and processing of semiconductor devices, including chips, integrated circuits, etc.

- New Material Research: Employed in the research and development of new materials for exploring their properties and applications.

- Precious Metal Processing: Used for processing and handling precious metal materials such as gold, silver, platinum, etc., including jewelry making, financial investment, etc.

- Craftsmanship: Utilized in the production of various crafts and decorative items, such as metal engraving, metal sculpture, etc.

- Smooth Cutting Edge and Uniform Weight: Each piece has smooth edges and a consistent weight thanks to the accurate and reliable cutting provided by our automatic wire cutting machine.

- Intelligent Control for Simple Operation: Our machine’s sophisticated control systems minimize the learning curve for operators by making machine operation simple and intuitive.

- High Accuracy and Precision with ±0.03 Tolerance: Utilize our device to produce exacting outcomes, guaranteeing that every cut adheres to strict tolerances of ±0.03.

- Quick Speed Up to 200 Cuts per Minute: Increase productivity with our machine’s fast cutting capabilities. It can handle up to 200 cuts per minute, which enables effective mass manufacturing.

- Using automatic feeding features can help you streamline your manufacturing process and provide a fluid workflow by minimizing operator involvement.

- Efficiency-Boosting Straightening Device: Our machine has an integrated straightening device that reduces material distortion and boosts overall cutting efficiency.

Why SuperbMelt Automatic Wire Cutting Machine

Any Question About SuperbMelt Automatic Wire Cutting Machine

Guide to Automatic Wire Cutting Machine

Core Advantages Customers Care About: Why Choose This Automatic Wire Cutting Machine?

In jewelry manufacturing, electronic component production, and other industries, the precise cutting of metal wires is a critical step to ensure both product quality and production efficiency. The SuperbMelt Automatic Wire Cutting Machine, with its high precision, high speed, and fully automated features, has become a core piece of equipment for many enterprises.

This guide will cover key aspects such as customer-focused requirements, industry application scenarios, machine performance analysis, and operation and maintenance essentials—helping you fully understand and effectively utilize this equipment.

As a purchasing manager or production supervisor, your main concerns when selecting a wire cutting machine usually include: Does it meet accuracy standards? Can it improve efficiency? Is it easy to operate? Is it versatile across different applications?

The SuperbMelt Automatic Wire Cutting Machine is designed to meet all of these needs with precision.

1.1, Ultra-high precision: Ensures product consistency and reduces material waste.

For industries such as jewelry and electronics, where dimensional accuracy is critical, “precision cutting” is the baseline. This machine is designed for cutting 2–6mm diameter metal wires (such as gold wire, gold rods, silver wire, platinum wire, copper wire, etc.) into uniform segments ranging from 3mm–30mm, with an error margin controlled within ±0.05mm.

For jewelry manufacturers: The precisely cut wire segments can be directly used for making earrings, pendants, and other small components without secondary grinding or adjustments, preventing scrap caused by uneven dimensions.

For electronics manufacturers: Accurately cut copper and silver wires perfectly fit the assembly needs of connectors and sensors, eliminating functional failures caused by size deviations.

This level of precision also significantly reduces material waste. Traditional manual cutting may consume an extra 0.5–1mm of raw material per segment, whereas this machine reduces the metal loss rate to below 0.1%. For precious metals such as gold and platinum, this translates into substantial long-term savings on raw material costs.

1.2, High speed and efficiency: Boosts production capacity and shortens delivery times.

Production efficiency directly impacts a company’s ability to take on orders and its overall profitability. This machine can cut 50–220 wire segments per minute, with the exact speed adjustable according to the material type, wire diameter, and cutting length:

For 2mm silver wire (5mm length): The speed can reach 220 pieces per minute, producing 13,200 pieces per hour—equivalent to the combined output of three skilled workers cutting manually.

For 6mm platinum wire (30mm length): The machine maintains a stable speed of 50 pieces per minute, still far surpassing manual cutting at just 8–10 pieces per minute.

With fully automated operation, manual intervention is minimized. Once the parameters are set, the machine automatically handles feeding, cutting, and discharging. This allows workers to oversee multiple machines simultaneously, greatly reducing labor costs.

1.3, Easy operation: Quick to learn, no specialized skills required.

For many companies, the training cost and high learning curve of complex equipment are major concerns. This automatic wire cutting machine is designed with user-friendly features to address these pain points:

Easy parameter settings: Operators can input wire diameter, cutting length, and cutting speed directly through the touchscreen. The machine also includes 10 sets of memory storage, allowing frequently used specifications to be recalled with one click (e.g., “5mm silver wire cut into 8mm segments” or “3mm gold wire cut into 5mm segments” for jewelry manufacturers).

Beginner-friendly: No professional background is required. With just 1–2 hours of training, workers can operate the machine independently, preventing production delays caused by staff turnover.

Clear fault alerts: The machine features an auto-diagnosis system. If issues such as “wire jam” or “blade wear” occur, the screen will directly display the cause and troubleshooting instructions, reducing downtime and maintenance effort.

1.4, Wide adaptability: One machine meets multi-material and multi-application needs.

When companies invest in equipment, versatility is the key to reducing costs. This machine is designed to be compatible with a wide range of metal wires, covering multiple industry needs:

Material compatibility: It can stably cut precious metals such as gold, silver, and platinum, while also handling common metals like copper, iron, and stainless steel — all without replacing core components.

Wire form flexibility: Supports round wires (diameter 2–6mm) and cylindrical metal rods, making it suitable for both jewelry factories cutting fine gold wires and hardware manufacturers segmenting thick copper rods.

Cross-industry adaptability: From producing small jewelry components, to cutting conductive wires for electronic parts, to preparing metal segments for vacuum coating materials — a single machine can meet diverse production line requirements, eliminating the need for duplicate equipment purchases.

In-depth Industry Applications: Tailored Solutions for Different Scenarios

2.1, Jewelry manufacturing: Precise cutting supports mass production of small components.

In jewelry production, a large amount of precious metal wire with diameters of 2–4 mm (such as gold or silver wire) needs to be cut into short segments of 3–10 mm for small components like earring posts, pendant bails, and chain links.

Use case: A jewelry factory producing “mini silver bead bracelets” needs to cut 4 mm diameter silver wire into 5 mm segments (each bracelet requires 50 silver beads).

Machine advantages:

a. After setting the parameters to “diameter 4 mm, length 5 mm, speed 150 pieces/min,” the machine can cut 9,000 segments per hour, meeting the production needs for 180 bracelets—8 times more efficient than manual cutting.

b. The cut silver segments are uniform in size, allowing them to go directly to stamping without sorting during subsequent polishing, reducing process time.

c. Considering the properties of precious metals, the machine’s feeding mechanism uses soft rubber rollers to prevent scratches on the wire surface, ensuring the silver segments retain a high-quality appearance.

2.2, Electronics industry: Stable cutting suitable for precision assembly.

In the electronics industry, components like connectors and sensors often require copper or silver wires with diameters of 2–3 mm to be cut into 8–15 mm segments for internal wiring or electrode fabrication, with extremely high dimensional accuracy (tolerance ≤ 0.05 mm).

Use case: An electronics factory producing mobile phone charging port connectors needs to cut 2.5 mm diameter copper wire into 10 mm segments for the conductive contacts inside the port.

Machine advantages:

d. High-precision cutting ensures each copper wire segment has a length tolerance within ±0.03 mm, preventing poor contact caused by segments being too long or too short.

e. Fully automated operation minimizes human handling, avoiding fingerprints and oil contamination, ensuring the components’ conductive performance.

f. Capable of continuous operation for over 8 hours; paired with an automatic discharge hopper, the cut copper wires can go directly to the next soldering step, enabling a seamless “cutting-to-assembly” production line.

2.3, Vacuum coating materials: Uniform cutting ensures coating quality.

In the vacuum coating industry, certain coating materials require precious metal wires (such as platinum or gold wire) to be cut into uniform short segments for evaporation coating. The segments must be burr-free and deformation-free to ensure the coating layer’s uniformity.

Use case: A coating factory preparing platinum wire for evaporation coating needs to cut 3 mm diameter platinum wire into 12 mm segments.

Machine advantages:

g. The cutting blades use a “double-blade shearing” design to prevent burrs at both ends of the wire segments, eliminating the need for subsequent polishing.

h. High-precision positioning ensures each platinum wire segment has the same length, providing a stable evaporation rate during coating and guaranteeing coating quality.

i. The machine’s enclosure features a sealed design to reduce dust ingress, meeting the cleanroom requirements of vacuum coating workshops.

Machine Core Analysis: From Parameters to Structure

3.1, Key technical specifications: Define applicable range and performance limits.

| Parameter Category | Specific Specification | Customer Considerations |

|---|---|---|

| Wire Cutting Specs | Diameter 2–6 mm, Length 3–30 mm | Confirm whether it covers the wire sizes required for your products to avoid “too small to use” or “too large and wasteful.” |

| Cutting Speed | 50–220 pieces/min | Choose an appropriate speed based on daily output needs; e.g., high speed for small jewelry parts, medium speed for coarse hardware. |

| Cutting Accuracy | ±0.02 mm | Higher accuracy reduces adjustments in subsequent processes; especially important for electronics and jewelry industries. |

| Compatible Materials | Gold, Silver, Platinum, Copper, Iron, Stainless Steel, etc. | Ensure compatibility with commonly used materials to avoid equipment wear from mismatched hardness. |

| Blade Lifespan | Tungsten steel blade, continuous cutting 100,000+ segments (for conventional materials) | Longer blade life reduces replacement costs; pay attention to wear resistance when processing hard materials. |

| Power Requirement | AC220V±5%/50Hz | Compatible with standard workshop power, no additional circuit modification needed. |

| Dimensions | Approx. 600×400×500 mm (reference standard model) | Check whether workshop workspace can accommodate the machine and whether it is convenient for transport and layout. |

| Weight | Approx. 35 kg (reference standard model) | Consider load-bearing when moving or fixing the machine to avoid instability affecting accuracy. |

3.2, Core structural design: Understand why the machine achieves “high precision and high stability.

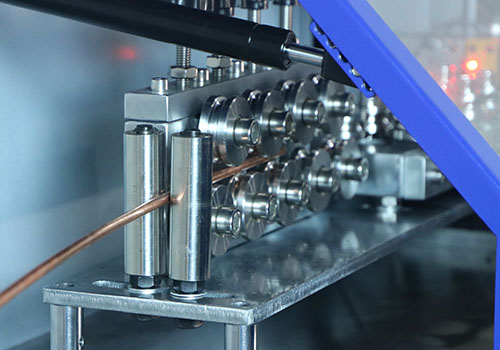

Feeding Mechanism: Uses a “servo motor + soft rubber roller” combination; the servo motor ensures feeding precision (error ≤ 0.02 mm), while the soft rubber roller prevents scratches on the wire surface, especially suitable for protecting precious metal wires.

Cutting Mechanism: Double-edged tungsten steel blades with shearing (not sawing) action reduce wire deformation and burrs. Blades can be calibrated via a micro-adjustment device to extend service life.

Control System: 7-inch touchscreen + PLC control system; parameter settings are intuitive and support memory for 10 commonly used sets, allowing even beginners to operate quickly.

Discharge Mechanism: Inclined automatic discharge hopper lets cut wire segments slide directly into a storage box, preventing accumulation and collisions, and reducing secondary damage.

Safety Structure: Fully enclosed metal housing + emergency stop button to prevent metal debris from flying during cutting, ensuring operator safety.

Operation and Maintenance: Easy to Use, Long-lasting Performance

4.1, Standardized operating process: Complete cutting tasks in 3 simple steps.

Step 1: Pre-Operation Preparation

Check the wire: Ensure the wire diameter is within 2–6 mm and the surface is free of oil or bends (if bent, straighten it first).

Install the wire: Open the machine’s feeding port, insert one end of the wire into the feeding rollers, and press the “Manual Feed” button to pass the wire through the cutting mechanism until the front end protrudes 1–2 cm.

Set parameters: Enter “Wire Diameter,” “Cutting Length,” and “Cutting Speed” on the touchscreen. For common specifications, you can directly recall saved parameters (e.g., “Gold Wire – 3 mm Diameter – 5 mm Length”).

Prepare collection: Place a storage box under the discharge hopper to ensure cut segments fall in smoothly.

Step 2: Start Cutting

Press the “Start” button; the machine will enter automatic operation. Observe the first 5–10 cut segments to check if the length meets requirements and if there are any burrs.

If the length is off, adjust the “Feed Compensation” parameter (e.g., if the segment is 0.1 mm short, increase the compensation by 0.1 mm). If burrs appear, check whether the blades need cleaning or calibration.

Once confirmed correct, the machine can continue cutting automatically without supervision. Periodically check the storage box to avoid overflow.

Step 3: Post-Operation Finishing

After cutting is complete, press the “Stop” button and turn off the machine power.

Clean the equipment: Use a soft brush to remove metal debris from the cutting mechanism and wipe the touchscreen and housing with alcohol.

Check the blades: If the cutting count approaches 100,000 segments or cutting becomes uneven, replace with a new blade (ensure power is off and follow the manual for replacement steps).

4.2, Daily maintenance essentials: 3 key actions to minimize failures.

- Daily Maintenance:

a. Before starting, check whether the feed rollers are clean and free of metal debris.

b. After cutting, clean the discharge hopper and storage box to prevent debris buildup that could affect the next use.

- Weekly Maintenance:

c. Apply a small amount of light machine oil to the feed roller bearings to ensure smooth feeding.

d. Check whether the blade mounting screws are loose; if so, tighten them with a wrench.

- Monthly Maintenance:

e. Calibrate cutting accuracy: measure 10 cut wire segments with a caliper. If the average error exceeds ±0.02 mm, enter the “Accuracy Calibration” mode and adjust according to the manual.

f. Inspect power and data cables for damage; if any, replace immediately to prevent electric leakage.

4.3,Common troubleshooting: Quick checks to reduce downtime.

| Common Issue | Possible Cause | Solution |

|---|

| Large cutting length deviation | 1. Incorrect feed compensation parameter; 2. Wire slipping | 1. Recalibrate the feed compensation; 2. Clean the feed rollers and increase roller pressure |

| Wire jam | 1. Bent wire; 2. Feeding speed too fast | 1. Remove bent wire, straighten it, and reinstall; 2. Reduce cutting speed |

| Blade produces burrs | 1. Worn blade; 2. Blade not calibrated | 1. Replace with a new blade; 2. Enter “Blade Calibration” mode and adjust blade position |

| Machine won’t start | 1. Power not connected properly; 2. Emergency stop button not reset | 1. Check power plug and switch; 2. Press the emergency stop button and rotate clockwise to reset |

How to cast platinum group metal

Different companies have different requirements. When selecting a machine, consider three dimensions:

By Wire Diameter:

If mainly cutting 2–4 mm fine wires (e.g., jewelry gold wire, electronic copper wire), the basic model is sufficient. Focus on cutting accuracy and surface protection.

If frequently cutting 5–6 mm thick wires (e.g., hardware stainless steel wire), choose the “Enhanced Model” with high-strength blades and a high-power feeding motor to ensure stable cutting.

By Daily Output:

Daily output ≤ 10,000 segments (e.g., small jewelry factories): choose the standard-speed model (50–150 pieces/min) for better cost-effectiveness.

Daily output ≥ 20,000 segments (e.g., large electronics or hardware factories): choose the high-speed model (150–220 pieces/min) with an automatic feeding system to further improve efficiency.

By Industry-Specific Requirements:

Jewelry / vacuum coating industry: select the “High-Precision Model” with double-edged blades and a sealed housing to ensure segment quality and cleanliness.

Hardware industry: select the “Durable Model,” focusing on blade lifespan and motor power to reduce maintenance costs.

Conclusion

The SuperbMelt Automatic Wire Cutting Machine, with its core advantages of “high precision, high speed, and wide compatibility,” perfectly addresses the challenges of metal wire cutting in jewelry, electronics, and hardware industries. Whether for precise mass production of small components or efficient processing of thick wires, it can help businesses reduce costs and increase output through standardized operation and simple maintenance.

By selecting the right model based on wire specifications, production volume, and industry requirements—and following proper operating procedures—this machine can become a “high-efficiency assistant” on the production line, helping companies gain a competitive edge.

FAQ Guide of Automatic Wire Cutting Machine

- 1. What is the diameter and length range of wires the machine can cut?

- 2. Does it support different materials such as gold, silver, platinum, copper, and stainless steel?

- 3. What is the cutting accuracy? What is the tolerance range?

- 4. Does the cutting speed change for wires of different diameters?

- 5. Which industries are most suitable for this machine?

- 6. How many wire segments can be cut per minute or per hour?

1. What is the diameter and length range of wires the machine can cut?

The machine can cut wires with a diameter of 2–6 mm and a length of 3–30 mm, covering a wide range of sizes for jewelry, electronics, and hardware applications.

2. Does it support different materials such as gold, silver, platinum, copper, and stainless steel?

Yes, the machine is compatible with a wide range of metals, including gold, silver, platinum, copper, iron, and stainless steel, making it suitable for jewelry, electronics, and hardware applications.

3. What is the cutting accuracy? What is the tolerance range?

The machine offers high-precision cutting with a typical tolerance of ±0.02 mm, ensuring consistent segment lengths and minimizing the need for adjustments in subsequent processes.

4. Does the cutting speed change for wires of different diameters?

Yes, the cutting speed can vary depending on the wire diameter and material. Thicker or harder wires may require a slightly slower speed to ensure precise cutting and prevent blade wear, while thin or soft wires can be cut at higher speeds for maximum efficiency.

5. Which industries are most suitable for this machine?

This machine is ideal for industries that require precise and efficient wire cutting, including:

- Jewelry industry: for gold, silver, and platinum wires used in small components like earring posts, pendants, and chain links.

- Electronics industry: for copper, silver, or other conductive wires used in connectors, sensors, and internal circuits.

- Hardware industry: for thicker metal wires such as stainless steel or iron used in fasteners, springs, and industrial components.

6. How many wire segments can be cut per minute or per hour?

The machine can cut 50–220 segments per minute, depending on the wire diameter and material. This translates to approximately 3,000–13,200 segments per hour, meeting the production needs of small to large-scale factories.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited