Silver Chain Making Machine

Superbmelt provide a one-stop service to solve any problems with your silver jewelry chain manufacturing line

Superbmelt silver chain making machine uses the ideal technologies that are available to effectively manufacture the gold chains. The machines are admired for their durability as well as consistent performances being fitted with inbuilt advanced technologies. The machines uses the best technologies that are available being précised engineering. The machines are compact in their sizes and makes sure of their robustness as well as user-friendly applications.

Superbmelt silver chain making machine is considered as an ideal one in terms of manufacturing the perfect chains. The chains are extremely easy to operate acclaiming their precision engineering as well as the consistent performance. Superbmelt silver chain making machines come with advanced setting tools to help client getting the effective and purpose specific performances. They are compact in their sizes and are available at effective market leading rates.

We are capable of offering a superb quality Superbmelt silver chain making machine. This machine is constrained by PLC and is reasonable to deliver the chain. We finish this machine from different assessment boundaries to guarantee superior grade and execution. It is joined with a variable speed engine, R/L check alternative electronic sensors, and air-oil channel, which correctly increments its interest on the lookout. Our specialists plan and foster this machine at standard with the business principles utilizing first-rate quality segments.

- Superbmelt silver chain-making machines are extremely easy to be employed, considering the durable nature that can make them quite cohesive.

- Various shapes of the chains can be done here with the free forms of different sizes that are being mixed with the solid sections with smaller rings that connect the larger round as well as the square sections of the wire, making it user-friendly.

- It generally depends on the imagination of the craftsman that is making them. The ones made from the jump rings are the commonest kinds of chains that are involved here. They are extremely affordable in their prices with designs that are extremely compact.

- This process can help with a greater amount of durability that can help it against the shock loads with tensile strengths and are easily recognizable.

- The pins and bushes can also be reduced in their sizes, with materials being selected specifically for their durability in mind.

- The chain making process of the silver chain-making machines are maintained in greater control with the proper temperature and the use of energy, making the process of chain-making easier.

- Superbmelt silver chain-making machines offered here are mainly manufactured on the basis of using high-quality equipment along with the components being sourced through the trusted and reliable vendors out there in the market as the machines come equipped with the speed controller as well as the automatic chain puller.

| Type | 450 high speed single, double, cross chain making machine |

| Voltage | Single phase 220v |

| Power | 200W |

| Wire size | 0.19-0.45mm |

| Speed | 100-150 |

| Dimension | 420*750*550mm |

| Weight | 75KG |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Silver Chain Making Machine

Any Question About SuperbMelt Silver Chain Making Machine

FAQ Guide of Silver Chain Making Machine

- 1. How do you make a silver chain?

- 2. How do you make a silver chain necklace?

- 3. Does Silver chain go black?

- 4. How do you make chain-link necklaces?

- 5. How do you solder a silver chain?

- 6. How do you test the purity of silver chain?

- 7. How do you make a flat chain?

- 8. Do hollow jewelry chains break easily?

- 9. What machines are used to make jewelry chain?

- 10. How do they make necklace chains?

- 11. What is used for making necklace?

- 12. How are silver chains made?

- 13. What are the different types of chain necklaces?

- 14. How do you make a 14 karat gold chain?

- 15. Is a gold chain a good investment?

- 16. How do jewelers make chains?

- 17. How do you know if chain is real gold?

- 18. Do they make 24k gold chains?

- 19. How can you tell if a gold chain is real?

1. How do you make a silver chain?

Back in the old times, jewelers were producing chains by casting loops and joining them together, which is recognized as the manual process of chain making. That process would consume too much power and energy. In the manual process, the jewelers can’t even solder the loops of the chain in one piece. As the process becomes very slow and affected the supply amount in the market, they started using the metal smelting process to form silver or gold rods.

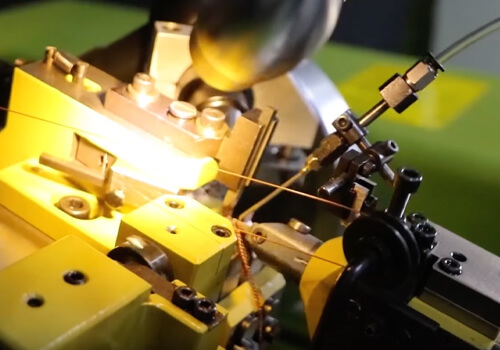

Commercial jewelry suppliers now use silver chain making machine to produce mass silver chains. Modern-day jewelers involve a chain-stitching process, where the silver wires are passed through a chain manufacturing machine to form various intricate yet beautiful patterns from the wires fragments and interconnect the looping parts of the chain.

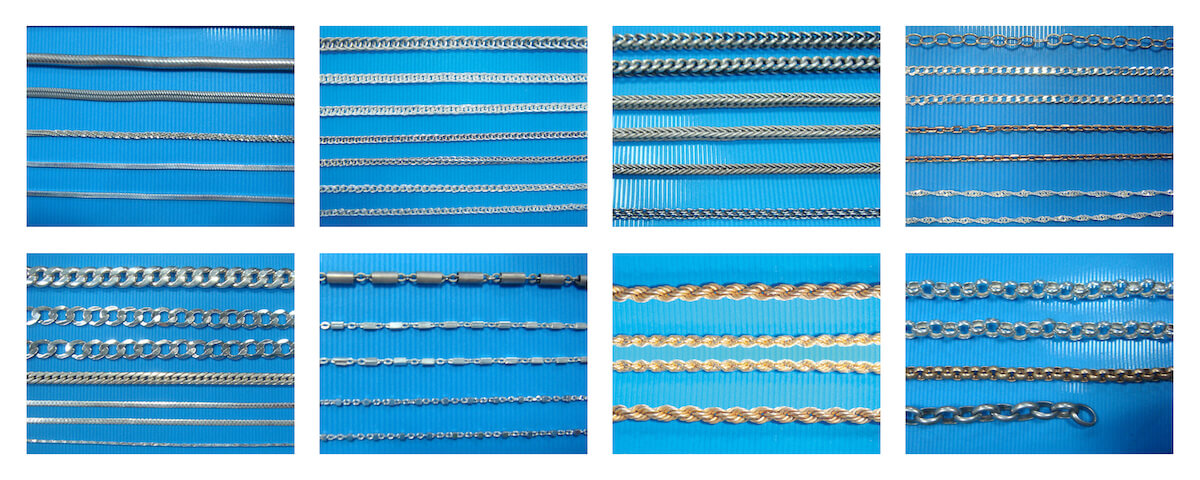

Not just looping patterned chains, these mechanical devices can also form box chains, snake chains, Figaro chains, and many more. Moreover, these machines can produce diverse styles and sizes of silver chains for both men and women.

2. How do you make a silver chain necklace?

Unlike the manual jewelry-making process, which is very time-consuming, the use of necklace maker machine has brought a revolution in the jewelry production industry. Silver and gold are two primary metals that are very often used in these mechanical devices, but other precious metals like platinum, bronze, or alloys can also be utilized. The working principle of these devices is very simple to understand.

To make a silver chain necklace, the operator has to attach a thin wire of the metal to the machine to form a chain. The jewelry manufacturers use a chain manufacturing machine to process the silver rod to produce the silver wire with the device’s wire drawing feature.

With the use of the chain-stitching process, the silver wires produce different patterned designs on the necklace. You can find good quality jewelry-making machines in the market that can produce up to six thousand silver links for making silver chain necklaces within a minute.

3. Does Silver chain go black?

Silver jewelry can turn black due to the compound hydrogen sulfide or sulfur that is present in the air. When the silver metal comes in contact with sulfur, a chemical reaction takes place, forming a black layer on the metal. Silver metal can oxidized faster if it is exposed to light or placed in areas with high humidity.

When silver jewelry comes in contact with cosmetic products such as perfume, hair spray, deodorant, bleaching, or body lotion, etc., the oxidizing process can speed up more. Other than that, the natural oils released from our skin can also react with the silver jewelry pieces turning them black. The jewelry chain making machine manufacturers also provide various equipment that can effortlessly cast the metals, draw wires, and also facet the chain.

Thus, it has become a very easy process to polish silver jewelry to return it to its sparkling form. For a more manual process, you can use a silver dip to clean your jewelry in the quickest way. You can place your jewelry in the silver dip for about ten to twenty minutes, then take out and wash it with clean water and leave it to dry. Then clean it up with a soft polishing cloth to remove its oxidized layer altogether.

4. How do you make chain-link necklaces?

Thanks to the introduction of advanced jewelry chain machine machines, now you can make chain necklaces faster while maintaining quality. The process includes the usage of different types of machines.

First, you need to use a continuous casting machine to convert the gold into a rod. After that, you will have to use a jewelry roll mill that will create durable thin wire from the gold rod.

Once done, you need to process the thick wire to attain the desired diameter using a wire drawing machine. Now, you can use a jewelry chain-making machine to create the chain. This single machine will carry out all the processes.

After that, to give the chain a perfect shape, you can use a hammering machine. In the final step, use a chain faceting machine and give your chain a shiny look. You easily get all these machines from SuperbMelt. Visit the site now for a free quote.

5. How do you solder a silver chain?

First of all, you need to clean the silver or gold wire. You can soak that in the pickling solution and then use a tweezer to maneuver. Now, place the piece onto a soldering block and hold that using a clamp or the tweezers. Then, you need to add flux to the areas that you want to weld to join.

This will prevent discoloration. Now, heat the flux using a torch and add a small chip of gold or silver chip to the join. After a few minutes, you can watch the sides bonding together. In the end, you can polish the joint to remove any fire scale.

However, nowadays, you can use a silver chain making machine to weld the silver wire to make chains. The machine can handle cutting, winding, and welding of wire efficiently. So, go on and buy this machine now. For the high-quality machine at the best prices, contact SuperbMelt.

6. How do you test the purity of silver chain?

Internationally the selling of pure silver is stamped as 925, 900, or 800. These numbers are responsible for indicating the level of purity of the silver. The silver chain making machine can easily identify the purity of silver and the mixture of other elements. There are various methods to identify the purity of silver.

Pure silver jewelry tends to make a ringing sound, so you can drop it on a flat surface to hear the sound. If it makes a dull sound, the piece has other elements mixed in it. Silvers are not noticeably magnetic, unlike iron, nickel, and cobalt, etc. Thus, the fake silver or silver plated items can easily be identified if they stick strongly to the magnet.

Generally, sterling silver is mostly odorless, so if you smell sulfur or any other metallic fragrance, you can know that it’s not sterling silver; rather, it’s silver plated. Silver needs to be polished regularly to maintain its radiance. You can rub jewelry pieces in a polishing manner; if no black residue appears, then it’s not silver. The lack of oxidation is a good indicator of determining the jewelry piece is made of other material than silver.

7. How do you make a flat chain?

Chains can be of different types and styles depending on the number of links and shapes are added in the chaining pattern. While rolo pattern follows thick and round links, Figaro is made of one long and three short links, etc. There are round cable chains, oval cable chains, and flat cable chains, typically used to produce chain patterns. These patterns are mostly found in a simple necklace with a pendant or a charm.

Modern-day jewelry manufactures use chain manufacturing machines that use a brilliant set of machinery to produce different types of chains. There are two major types of machines such as curb chain and cable chain making machine is specifically required to produce the basic chain structures. In order to produce a flat chain in a jewelry machine, the wire is feed into the set of rollers that pass through the guide section to measure the wire length to get the desired size of the link.

Then the next piece of wire is carefully measured and passed through the first link, and the process of interlocking the links takes place. The cutter present in the necklace maker machine would cut the wire from the feed for the formation of shape and automatically close the links to finish the shapes.

8. Do hollow jewelry chains break easily?

Hollow jewelry chains look similar, just like other chains. But they are lighter and have a reduced price than the others since the inside of these chains are hollow. The hollowness of these chains tends to make the chain brittle and break easily.

Moreover, if the hollow jewelry chains are thin-walled, they can be form dents pretty quickly. But the thick-walled hollow jewelry can be repaired without any risk or damage.

You can check for jewelry chain making machine price to repair the damaged jewelry effortlessly. Unlike the manual process of soldering the jewelry, which is very noticeable after the repairing, these machines can measure the links and loops of the chain precisely and solder the broken parts effectively.

The first thing to do while repairing the necklace maker machine is to remove all of the broken parts and associated ends with the damaged part. The machine would weave the two halves of the links together and solder.

9. What machines are used to make jewelry chain?

All the chain jewelry are started out like wires. The wire is first formed to the desired diameter then goes into the manufacturing machine, where the wire is threaded through the previous link, then cut and formed into the next link on the chain.

When it comes to jewelry chain manufacturing machine, there are a set of mechanical devices that are used in the manufacturing of various metallic jewelry chains such as gold, silver, platinum, and many other precious metals.

To produce machine-manufactured jewelry, the operator would need a continuous casting machine, rolling mill, a wire drawing machine, a gold chain making machine, chain hammer, and faceting machines. The chain making machine price can get expensive with purchasing a unit with all these features, but the benefits would be more appealing in the long run. You can mass-produce jewelry with various pretty designs and form gold or silver jewelry of different karats. It would save you much time as the chains can be manufactured accurately and in a short period of time.

10. How do they make necklace chains?

Every chain jewelry is formed out of its corresponding metal wires. First, the wires are converted to the desired size of diameter and go through a drawing process to harden the wire as well as make the metal stronger.

The jewelry manufacturers use gold or silver chain making machine where the metallic wires go into the forming machine and get threaded through the previous links; then, the wire is cut and form the next link for the chain.

There are various jewelry-making machines available in the market with cutting-edge technology that helps with producing the best quality jewelry chain. The gold chain making machine price can be a bit exaggerating, but it’s super essential for the chain-making process.

The machine is designed to form chains with various types of links. The process involves first the metal wire to be spiraled before getting sectioned. Since the machines are automatic, they can manufacture chains with 100 percent accuracy.

11. What is used for making necklace?

There is various equipment used during the jewelry chain production line. The precious metals need to be cast; then the wire has to be drawn, hammered to form the desired size, and faceting to complete the manufacturing process.

All these procedures would take days to manufacture jewelry in the manual process. Thus, the modern-day jewelry production industry implements necklace maker machine to get various benefits through the automatic jewelry welding system.

The casting machine of the jewelry making unit is designed for casting different precious metals into the desired shape. You can utilize the wire drawing machine to draw a thick wire gauze into thin shapes to achieve adequate surface roughness, wire diameter, roundness, straightening degree, and for internal micro-construction of the chain. The high-quality chain hammering machine can produce corrosion-resistant and sturdy material. And the faceting machine allows the jewelry to get decorative designs and give an attractive look to the finishing product.

12. How are silver chains made?

In the manual process, the silver chains are formed by making cast loops and attaching them together tightly. The precious metal such as silver chain links is formed via soldering together. The soldering process has to be executed properly, so they can’t be opened and cause chain breakage. The manufacturer has to make sure that the links are sturdy enough to handle the typical wearing and last longer.

The type of finishing technique you want to apply depends on the type of design you want in the chain and the size of the chain. But the process can be very time-consuming. Thus, the professionals use the chain-stitching mechanism through a silver chain making machine.

For producing a silver chain, the silver wire is passed through the various mechanical devices to create beautiful patterns from the metal fragments and interconnecting the finished parts of the chains. The chain making machine manufacturers offer various chain production features in the device to manufacture good quality jewelry chain within minutes, that’s ideal for mass production.

13. What are the different types of chain necklaces?

The advanced chain manufacturing machine is capable of producing every type of chain necklace. The type of chain is determined by their link styles. The most common types of necklaces are ball, cable type, curb type, rolo, rope, etc.

The ball-linked chains are connected with little metal bars to give more flexibility. Cable and curb type chains are not just limited to jewelry, but they are also utilized in the fashion industry as well as architectural designs as they are very sturdy since they are welded individually.

Rolo chains are similar to cable ones, but they feature round links instead of oval links. As the name suggests, the rope chains are twisted with uniquely formed links making them the sturdiest type of chains. The necklace maker machine is also capable of producing complicated designs with intricate detailing such as Figaro chain, snake, byzantine, box, and mariner, etc.

14. How do you make a 14 karat gold chain?

The gold chain manufacturing process can also be carried out through a chain stitching process. You can check the gold chain making machine price to purchase one and produce a gold chain of different karat, whether it’s 24 karats, 18 karats, or 14 karats. Also, various other elements are processed with pure metal to make the jewelry more durable.

To make 14 karat gold chain, generally, copper, nickel, and zinc, etc., are mixed to produce an alloy form of gold jewelry to make the wires more sturdy than pure gold, i.e., very soft.

A golden wire with a specific diameter is passed through the robust chain manufacturing machine to create beautifully patterned chain links for about six hundred within minutes and interconnect them accurately.

15. Is a gold chain a good investment?

Gold jewelry has been considered a safe form of investment for many years. The price value of gold always increases, making it a viable option for investment.

Unlike other precious metals, the price value of gold does not fluctuate often; rather, the yellow shining metal’s value steadily gets increased over time.

If you are considering investing in gold, then go for 24 Karat gold as it contains 99.9% pure gold, while 22 Karat gold contains 91.7% pure gold. And make sure to check for verification and certification marks to ensure its purity.

16. How do jewelers make chains?

The jewelers take the long shot for manufacturing chains using wires made of different precious metals using the manual process. They have to first convert the wire to the desired diameter to produce links.

However, with gold and silver chain making machine, the jewelers can make chains faster with the device’s automotive features. The machine would create the chain by threading the link with previous links and form chains accurately and quickly.

17. How do you know if chain is real gold?

No matter which gold jewelry you buy, you never know if the piece would be pure gold or how much other metals are mixed to make it look substantial. There are various methods to identify real gold. You can check for the certification marks and the chain’s statistical gold value to recognize its originality.

The professional gold experts use acid and cosmetics to witness any discoloration in the gold jewelry to see if it’s fake or real with more surety. However, these processes can be damaging for the jewelry piece itself. You can check the gold chain making machine price to not just produce gold jewelry but determine the number of impurities present in the gold piece for sure.

18. Do they make 24k gold chains?

A gold and silver chain making machine can produce a gold chain of different gold forms, whether it’s of 24k, 22k, 18k, or 14k, etc. The amount of gold a chain would require would depend on how much weight and which kind of design you want with the chain. But mostly, 24k gold is not used for making jewelry since the chain would be very ductile and malleable.

19. How can you tell if a gold chain is real?

There can be many fake gold chains are be available in the market which is not made of solid gold, rather than simply gold plated to make it appear like real gold. The commercial experts check for the real gold using various methods such as acid testing, color & discoloration testing, and magnet testing, etc.

However, All the aforementioned testing procedures can be damaging for the jewelry piece. Thus, investing in chain manufacturing machine that can form various designed chains as well as test the purity of the metal.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited