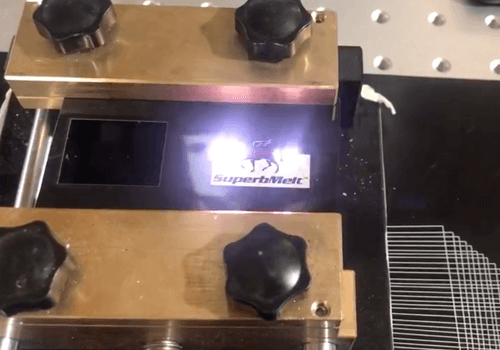

Jewelry laser marking machine

Your Premier Jewelry Laser Marking Machine Manufacturer Expert in China

Superbmelt jewellery laser marking machine is applicable for marking materials such as gold, silver, and some other jewelry. The jewellery laser engraving machine is able to make high precision marks like names, serial numbers, texts and logos on materials.

Superbmelt laser marking machine makes precision marks at a high speed and accuracy. The marking speed is ≤7000mm/s that makes the marking process efficient. Superbmelt laser marking machines are also used in industry, electronics, plastics, advertising, souvenirs and other industries.

We at Superbmelt produce the laser marking equipment that meets your specific requirement. Contact us today for the best laser machine price.

| Type: | Fiber laser marking machine |  |

| Model number: | FLMM-series | |

| Laser power: | 20W/30W/50W | |

| Marking range: | 110x110mm | |

| Marking speed: | ≤7000mm/s or ≤13000mm/s | |

| Power supply: | AC220V/50HZ | |

| Cooling method: | Circulating air cooling | |

| Positioning method: | Red ray positioning | |

| Accessibility: | 3 red ray assisted focus | |

| Lifting stroke: | 550mm |

- Superbmelt jewellery laser marking machine is used to make high precision marks on metal and nonmetal materials.

- The laser engraving machine can mark materials like gold, silver, copper, stainless steel, wood, leather and fragile materials like glass and crystal.

- Superbmelt marks at an excellent speed of ≤7000mm/s contributing to a time-saving production process. The marking speed is equally beneficial for fast-moving production processes.

- Superbmelt laser marking machine makes use of Jinhaichuang high-speed scanning galvanometer that ensures marking stability and speed.

- Superbmelt fiber laser marking machine has different laser power you can choose from. The laser powers are 20W, 30W and 50W that is able to meet your marking requirements.

- The engraving machine does not emit smoke or burn the material unlike other types of engraving machines.

- With the inbuilt lifting stroke of 500mm and a marking range of 110*110mm, the Superbmelt portable laser marking machine allows you to engrave different sizes and shapes of materials.

- The red ray positioning and the 3 rays assisted focus allows the laser beam to focus on the object irrespective of the size and shape.

- The air circulating unit present in the Superbmelt jewellery engraving machine helps to maintain the laser machine temperature and can be used for long hours.

- The laser power does not require high energy use. The power supply mode need is AC220V/50HZ.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Jewelry Laser Marking Machine

Any Question About SuperbMelt Jewelry Laser Marking Machine

Complete Guide to Jewelry Laser Marking Machines: From Industry Trends to Practical Applications

In today’s jewelry industry—where personalization, high quality, and standardization are increasingly demanded—laser marking machines have shifted from optional equipment to core productivity tools. They not only solve many long-standing issues of traditional engraving but also empower jewelry businesses to build differentiated competitiveness.

This guide breaks down jewelry laser marking machines from multiple angles: industry trends, target users, key questions, purchasing priorities, application scenarios, and technical advantages. It helps you clearly understand the value of this essential device and how to use it effectively.

Why Is the Jewelry Industry Increasingly Relying on Laser Marking?

The jewelry industry’s growing reliance on laser marking is fundamentally the result of technological advancement precisely matching industry needs. The limitations of traditional marking methods and the breakthrough advantages of laser technology together drive this irreversible transformation.

1.1 The Critical Pain Points of Traditional Marking

For many years, the jewelry industry has relied on hand engraving, mechanical stamping, and chemical etching—methods that face numerous serious limitations:

• Insufficient precision and material damage

Mechanical stamping force is difficult to control and can easily deform or crack delicate components such as ultra-thin gold sheets (≤0.3mm) or fine silver pieces.

Hand engraving often results in inconsistent depth, skewed fonts, and low precision, making it unsuitable for micro-markings (e.g., brand logos smaller than 0.5mm).

• High material loss and costly waste

Chemical etching uses strong acids and alkalis that corrode the surface, causing 3%–5% material loss.

Mechanical stamping produces metal debris that contributes to ongoing waste.

For high-value metals like gold and platinum, this accumulated loss significantly increases costs.

• Markings wear off easily and lack traceability

Traditional markings are shallow (≤0.1mm) and fade with friction or polishing.

They lack uniqueness, making product authentication and traceability nearly impossible, failing to meet modern brand protection and quality-control needs.

• Low efficiency and poor scalability

Hand engraving produces only a few dozen pieces per person per day.

Mechanical stamping requires mold changes (each mold costs USD 70.65–282.6), and switching designs takes 1–3 days.

Traditional methods simply cannot support the industry trend toward “small batch, multiple styles” or fast e-commerce order fulfillment.

• Environmental risks and compliance pressure

Chemical etching produces hazardous wastewater requiring costly treatment systems.

Mechanical stamping generates noise pollution.

Failing to comply with tightening environmental regulations can result in production suspension.

1.2 The Revolutionary Advantages of Laser Marking

Laser marking creates high-precision, high-efficiency, and environmentally friendly engraving through high-energy laser-material interaction—directly addressing industry pain points.

• Micron-level precision with zero damage

Laser spot diameter can be as small as 0.01mm, enabling ultra-clear marking on:

0.3mm-thick gold chains

0.2mm fine silver pieces

micro pavé prongs

gemstone gaps

Marking depth is adjustable (0.01–0.5mm) with a heat-affected zone of only 0.01–0.1mm, ensuring no deformation or cracking.

• Zero material loss, significantly reducing cost

Laser marking does not remove or corrode material—loss is close to 0%.

Compared with the 3%–5% loss from chemical etching, a factory producing 100 kg of gold jewelry monthly can save 36–60 kg of gold annually—over USD 141,300 in cost savings.

• Permanent, wear-resistant markings with full traceability

Laser markings alter the molecular structure of the surface, making them:

heat-resistant

corrosion-resistant

wear-resistant

Even repeated polishing won’t erase them.

Unique QR codes and serial numbers support full-process traceability—from production to after-sales—greatly strengthening brand protection.

• High efficiency and flexible production

Laser marking requires no molds.

Changing designs takes 5 minutes via software.

A single machine can mark 500–2,000 pieces/hour—10–50× faster than hand engraving.

It supports personalization (e.g., names, dates on ring interiors), increasing product value and customer satisfaction.

• Environmentally friendly and fully compliant

No wastewater, no chemicals, no noise—only electricity consumption.

Meets environmental standards with zero additional compliance cost.

No chemical exposure protects workers’ health and reduces labor risk.

• Compatible with all jewelry materials

Laser marking works on:

gold

platinum

K gold

silver

gemstones

jade

ceramics

mixed compositions

Parameters can be precisely tuned to avoid damaging sensitive inlays.

1.3 Driven by Regulations and Market Demand

• Regulatory requirements

Many regions legally require jewelry to have clear markings such as:

material purity (18K, 925, PT950)

brand logo

origin

Laser marking’s precision and consistency ensure full compliance and prevent penalties for improper labeling.

• Consumer demand upgrade

Modern buyers expect not just beauty and value but also authenticity, traceability, and personalization.

Unique laser-engraved codes and custom markings increase customer trust and purchasing intention.

Data shows:

Jewelry with personalized laser markings can increase average order value (AOV) by 15%–30%.

Who Are Jewelry Laser Marking Machines (for Gold, Platinum, Silver, etc.) Suitable For?

Laser marking machines are not “universal equipment.” Their suitability depends heavily on a user’s production scale, product type, and core requirements. The following types of users can achieve the highest ROI when choosing a laser marking machine:

2.1 Small to Medium Jewelry Workshops (10–50 workers)

Core needs:

Small-batch, multi-style production (changing designs 3–5 times a day), controlling precious metal loss, meeting hallmarking compliance, and improving production efficiency.

Why it fits:

These workshops often face mixed orders, tight delivery schedules, and high cost sensitivity. A laser marking machine requires no molds, offers fast style switching, and easily adapts to different orders.

Zero material loss significantly reduces raw material cost.

High marking efficiency (500–1000 pcs/hour) shortens production cycles.

Standardized hallmarking avoids compliance risks.

Recommended: Desktop fiber laser marking machine (20–50W)

Footprint ≤ 1㎡

Easy to operate

Investment: $7,065–$21,195

Payback period: 6–12 months

2.2 High-End Jewelry Brands / Custom Studios

Core needs:

Brand differentiation, personalized engraving services (wedding rings, luxury jewelry), permanent and aesthetic markings, and premium brand image.

Why it fits:

High-end jewelry demands extreme precision. Laser marking provides micron-level accuracy, capable of marking inner ring walls, pendant backs, and very fine surfaces without damaging the piece.

Supports personalized text, patterns, QR codes—enhancing exclusivity and brand value.

Recommended: High-precision fiber laser marking machine (30–60W)

Equipped with CCD vision positioning

Accuracy ±0.001 mm

Suitable for complex, detailed patterns

2.3 Jewelry E-commerce / Live-Stream Sellers

Core needs:

Fast turnaround for small-batch custom orders (100–500 daily), shorter shipping time, improve customer satisfaction, and reduce return rates.

Why it fits:

E-commerce relies on fast, personalized production.

Laser marking machines allow:

Online receipt of customized files (names, symbols, patterns)

Parameter adjustments within 5 minutes

Daily throughput of 5,000+ pieces per machine

Personalized engraving helps reduce “not as expected” returns by 20–30%.

Recommended: Fully automatic laser marking machine (50–80W)

Supports auto loading/unloading

Can operate unattended

2.4 Jewelry Repair / Refinishing Shops

Core needs:

Mark restoration, customized engraving, quick operation, and zero damage to the jewelry.

Why it fits:

Repair shops have limited space (5–10㎡) and handle many types of jewelry. A portable laser marking machine (≤10kg) can be moved easily between workstations.

The non-destructive marking allows restoring faded hallmarks or adding new ones without affecting the appearance of the jewelry—expanding service offerings and increasing ticket size.

Recommended: Portable fiber laser marking machine (20–30W)

Works with 220V household power

No complex installation

2.5 Large-Scale Jewelry OEM Factories (50+ workers)

Core needs:

Mass production, automated traceability (unique serial code for every item), batch consistency, reduced labor cost.

Why it fits:

OEM factories produce thousands of items per day. Traditional marking requires many workers and is prone to errors.

Laser marking machines can integrate into production lines to achieve:

Automatic loading, positioning, marking, unloading

Marking consistency error ≤0.01 mm

ERP integration for auto-generated traceability codes

Full lifecycle product management

Recommended:

High-power fiber laser marking machine (80–120W)

CO₂ laser marking machine (for non-metal inlays)

Automated line integration

Daily output per machine: 10,000+ pieces

Core Questions Users Care About

When selecting and using a laser marking machine, users are most concerned about whether it meets their actual needs and whether there are hidden risks. Below are core questions and answers based on real search intent and industry feedback:

3.1 Will laser marking damage the material or purity of precious metals such as gold, platinum, or silver?

Answer: No.

The principle of laser marking is to use laser energy to create physical changes (melting, vaporization) on the metal’s surface, not chemical changes. Therefore, it does not affect the purity or internal structure of the metal.

The heat-affected zone is extremely narrow (only 0.01–0.1 mm), far below the deformation threshold of precious metals, so it will not cause brittleness, cracking, or warping.

Practical verification:

Using a 50W fiber laser marker to engrave 0.1 mm deep text on an 18K gold ring, the gold content remained 75% after testing. The ring did not deform, and even after being bent 180°, the marking stayed clear with no change in material hardness.

Note: Choose machines from reputable manufacturers. Using excessive power (>100W) or incorrect parameters may cause surface oxidation, which can be avoided with argon gas protection.

3.2 How clear and permanent is the marking? Will it wear off during daily use?

Answer: The marking is clear and permanently wear-resistant.

Laser marking depth is adjustable (0.01–0.5 mm). Even very shallow markings (0.01 mm) are visible due to color contrast (gold becomes light brown; platinum becomes grayish-white).

Deep markings (0.1–0.5 mm) have a tactile texture and are highly visible.

Because the marking is formed by altering the material itself—not by adding ink or coating—it is extremely durable. Tests show that gold jewelry with laser marking maintains clarity after 100,000 friction cycles, far outperforming traditional stamping (which starts to blur after 10,000–20,000 cycles).

Application:

High-end jewelry brands use 0.05–0.1 mm shallow markings for logos and material marks.

Traceability codes or serial numbers typically use 0.1–0.2 mm deep markings.

3.3 Can laser marking achieve personalization, such as engraving inside a ring, complex patterns, or QR codes?

Answer: Yes—fully supports a wide range of customization.

Laser markers are computer-controlled and compatible with CAD, CorelDRAW, and other design software. They can accurately engrave text (Chinese, English, symbols), logos, patterns, QR codes, barcodes, handwritten signatures, and even silhouette images.

Text engraving:

Minimum text height: 0.3 mm

For a 2 cm inner ring area: can engrave 8–10 Chinese characters

Adjustable font, size, spacing

Pattern engraving:

High-precision reproduction of complex textures

Up to 1000 DPI, far more detailed than hand engraving

QR / barcode engraving:

Directly scannable

Can store product information, traceability links, authenticity verification, etc.

Case:

A wedding ring customization brand used a laser marker to engrave handwritten signatures + zodiac icons on ring interiors. Processing time: 3 minutes per piece, average order value increased by 20%, and custom orders grew from 30% to 60%.

3.4 Is the machine difficult to operate? Does it require professional technicians? Can ordinary staff learn quickly?

Answer: Very easy to operate—most users master it within 1–2 hours.

Modern jewelry laser marking machines use a “beginner-friendly” design with just three steps:

Import text / pattern into the computer (supports simple copy-paste).

Select marking parameters (built-in presets for gold, platinum, silver—no manual tuning needed).

Place the jewelry piece and start marking (some models have CCD visual positioning for auto alignment).

The machine includes both touch-screen and computer interfaces, and manufacturers provide free training, manuals, and video tutorials.

Real feedback:

A jewelry shop assistant with zero technical background learned to independently complete ring engraving and pendant marking after 1 hour of training, handling over 200 custom orders per day.

3.5 Is the maintenance cost high? Does the machine require frequent replacement of consumables?

Answer: Maintenance cost is extremely low with almost no consumables.

Core components such as the laser source, galvanometer, and field lens have long lifespans:

Fiber laser source: 100,000 hours (≈ 34 years at 8 hours/day)

Galvanometer and field lens: 50,000 hours

No consumables needed

Daily maintenance includes only:

Weekly cleaning of internal dust with compressed air (5 minutes)

Monthly cleaning of the field lens with alcohol (2 minutes)

Annual inspection of laser source & circuits (usually free service)

Compared with traditional stamping (requires mold replacement) and chemical etching (requires chemical reagents), the yearly maintenance cost of a laser marking machine is only $14.13–$70.65, mainly for electricity and cleaning supplies.

Five Key Specifications You Must Pay Attention to When Buying a Jewelry Laser Marking Machine

4.1 Laser Type & Power: Determine Material Compatibility and Marking Results

Core logic: Different laser types match different jewelry materials, and power affects marking speed, depth, and precision.

Laser Type Comparison

| Laser Type | Compatible Materials | Marking Effect | Advantages | Disadvantages | Recommended Users |

|---|---|---|---|---|---|

| Fiber Laser | Gold, platinum, K-gold, silver, stainless steel, and other metals | Clear markings, strong contrast, controllable depth | Long lifespan (100,000 hrs), low energy consumption (20–50W), fast speed | Not suitable for non-metals | Most jewelry factories, customization studios, e-commerce sellers |

| CO₂ Laser | Jade, gemstones, wood, plastic, and other non-metals | Surface etching with no significant depth | Low cost, suitable for marking non-metal inlays | Short lifespan (20,000 hrs), not suitable for metals | Factories focusing on jade and jewelry inlays |

| UV Laser | High-end precious metals, fragile gemstones (pearls, opal, etc.) | Ultra-fine marking, minimal heat impact (≤0.01mm) | Extremely high precision, no oxidation, no material damage | Expensive (2–3× fiber laser), slower | High-end jewelry brands, precision component marking |

Power Selection Guide

Small studios / repair shops (20–30W): Light marking (0.01–0.1mm), small-scale production (≤500 pcs/hr)

SME factories / e-commerce sellers (30–60W): Medium depth (0.05–0.2mm), mid-sized batches (500–1500 pcs/hr)

Large OEM factories (60–120W): Deep marking (0.1–0.5mm), high-volume production (≥1500 pcs/hr)

Avoiding mistakes: Do not blindly choose high power—higher wattage increases cost and may cause surface oxidation. For jewelry/precious metals, fiber laser is the best cost-performance choice.

4.2 Marking Precision & Resolution: Determine Fineness and Application Fit

Core logic: Precision affects clarity of micro text (e.g., 0.3mm fonts), while resolution determines pattern detail quality.

Key Parameters

Marking precision: Minimum laser spot diameter + positioning accuracy.

High-quality machines: spot ≤0.01mm, accuracy ±0.001mm

Resolution: Pixels per unit area (300–1000 DPI).

Higher resolution = better detail (complex patterns, photo silhouettes require ≥600 DPI)

Selection Guide

Standard branding/logos, text ≥0.5mm: Precision 0.01mm, resolution 300–600 DPI

Custom micro-engraving (0.3mm text, detailed patterns), high-end jewelry: Precision ≤0.005mm, resolution ≥600 DPI

Testing Method

Ask the manufacturer to engrave 0.3mm Chinese characters and thin complex patterns on a 0.3mm silver sheet.

Check for clarity, smooth edges, and no breaks or blurring.

4.3 Marking Speed & Stability: Determine Productivity and Batch Suitability

Core logic: Speed affects delivery capacity; stability affects long-term production consistency and failure rate.

Key Parameters

Marking speed: 300–1000 mm/s for standard fiber lasers; high-end machines reach 1500 mm/s

Stability:

24-hour continuous operation failure rate ≤0.5%

Batch marking consistency error ≤0.01mm (for 1,000 pcs)

Selection Guide

Small batches (≤1000 pcs/day): 300–500 mm/s, prioritize stability

Medium batches (1000–5000 pcs/day): 500–800 mm/s, must support ≥8 hours continuous work

Large batches (≥5000 pcs/day): ≥800 mm/s, choose industrial-grade laser sources (IPG, Raycus)

Avoiding mistakes:

Manufacturers often list maximum theoretical speed, not real production speed.

Request actual marking test videos (e.g., engraving a specific logo and measuring exact time per piece).

4.4 Positioning System & Ease of Operation: Determine Accuracy and Learning Curve

Core logic: Positioning ensures accurate marking (e.g., centered inside rings), while ease of use affects labor cost and training time.

Positioning Systems

Manual Positioning:

Uses fixtures + visual alignment

Accuracy ±0.1mm

Suitable for simple pendants, small batches

CCD Vision Positioning:

HD camera auto-detects item outline and positioning points

Accuracy ±0.001mm

Ideal for rings, irregular pendants, and mass production

Saves 10–20 minutes of calibration per batch

Ease-of-Use Indicators

Software compatibility: CAD, CorelDRAW, AI; supports PLT, DXF, BMP, JPG, etc.

Preset parameters: At least 5 built-in presets (gold, platinum, silver, K-gold)

Automation: Auto feeding, production-line integration, remote monitoring via app (advanced models)

Selection Guide

Small studios / repair shops: Manual positioning + basic software

E-commerce / SME factories: CCD positioning + smart software

Large OEM factories: CCD + automation for production line integration

4.5 Auxiliary Features & After-Sales Service: Determine User Experience and Long-Term Reliability

Core logic: Auxiliary functions solve special marking issues (oxidation, material protection), while after-sales ensures long-term stability.

Key Auxiliary Features

Argon protection system: Prevents oxidation on precious metals (e.g., gold turning dark)

Red-light preview: Shows marking area before engraving

Safety protection:

Laser safety ≥ Class IV

Interlock system (door opens → laser stops)

Emergency stop button

Dust collection: Removes debris during marking (especially non-metals)

After-Sales Service Essentials

Warranty:

Laser source ≥ 2 years (top brands offer 3 years)

Whole machine ≥ 1 year

Response speed:

24/7 technical support

On-site repair within 48 hours (local service center preferred)

Training:

Free on-site training (1–2 sessions)

Manuals, video tutorials, troubleshooting guides

Spare parts supply:

Core parts (field lens, galvanometer) delivery ≤ 7 days

Selection Guideline

Choose manufacturers with solid jewelry industry experience and local support.

Avoid “no-brand” machines—downtime from failures can cost far more than the equipment.

How Laser Marking Is Used in Real Jewelry Manufacturing Scenarios

Laser marking machines play an important role throughout the entire jewelry production, customization, and after-sales process. Below are three of the most common real-world scenarios, with detailed breakdowns of workflows and application value:

5.1 Scenario 1: Jewelry Material & Brand Marking (Mass Production)

Application Need:

A medium-sized gold processing factory produces 1,000 pieces of 18K gold necklaces daily. They need to engrave material marks (18K), brand logos, and origin (“China”). The marks must be clear, consistent, and must not affect the necklace’s shine.

Equipment Selection:

30W fiber laser marking machine (with CCD visual positioning + argon protection)

Operation Workflow:

Pre-treatment: Clean the necklaces using an ultrasonic cleaning machine to remove oil and dust. After drying, place them into a special fixture (10 pieces per fixture, supports batch positioning).

Parameter Setting: Open the marking software, import the brand logo, “18K,” and origin text. Select the preset “18K gold” parameters (25W power, 500mm/s speed, 0.05mm depth). Enable argon protection (5L/min).

Positioning & Marking: Start CCD visual positioning. The system automatically recognizes the marking area (e.g., pendant back), calibrates, and begins batch marking. Each batch of 10 pieces takes 3 minutes.

Post-processing: After marking, wipe the necklace with a soft cloth. No polishing required. Proceed to the next process (electroplating, packaging).

Application Value:

One machine can produce 1,000 pieces/day with only one operator. Marking consistency error ≤0.01mm, fully meeting branding standards.

Zero-loss operation saves ~10g of gold per day, equaling over $4,239 USD in annual savings.

5.2 Scenario 2: Personalized Wedding Ring Engraving (E-commerce Orders)

Application Need:

A jewelry e-commerce shop offers customized engraving for wedding rings—names, dates, signatures, zodiac symbols—requiring 24-hour delivery with beautiful and non-damaging results.

Equipment Selection:

50W fiber laser marking machine (with CCD visual positioning + intelligent design software)

Operation Workflow:

Order Intake: Customers submit customization requests (e.g., “Zhang San + Li Si + 2024.05.20 + heart icon”). The service team converts files into design formats (JPG, TXT supported).

Workpiece Preparation: Place the ring (18K gold, platinum) into a dedicated ring fixture that fits sizes 0–24.

Design & Preview: Import customer files into the marking software. Adjust text size, spacing, and position (centered on the inner ring). Preview using the red-light simulation and send to customer for confirmation.

Marking Execution: After customer confirmation, use the preset parameters:

18K Gold: 30W power, 300mm/s speed, 0.03mm depth

Platinum: 35W power, 250mm/s speed, 0.04mm depth

Marking time per ring: 30 seconds

Quality Check & Shipping: Inspect clarity and ring integrity. Pack and ship.

Application Value:

Capable of processing 400+ customized orders per day, compared to ≤50/day with hand-engraving.

Personalization increases product value—average order price rises from $423.9 → $508.7, with a 40% increase in conversion rate.

5.3 Scenario 3: Jewelry Traceability Code & Serial Number Engraving (Brand Anti-Counterfeit)

Application Need:

A high-end jewelry brand engraves a unique QR code and serial number on each diamond pendant. Customers can scan the code to verify authenticity, diamond grade, and production info—preventing counterfeits.

Equipment Selection:

60W fiber laser marking machine (with CCD visual positioning + ERP system integration)

Operation Workflow:

Data Generation: The ERP system generates unique serial numbers and QR codes (containing product ID, diamond grade, batch info). Data syncs to the marking software.

Workpiece Positioning: Fix the pendant on a high-precision fixture. Start CCD visual positioning to identify hidden marking areas (e.g., pendant underside).

Marking Execution: Select the preset “platinum” parameters (40W power, 400mm/s speed, 0.08mm depth). Enable argon protection. Mark the 5mm × 5mm QR code and 0.5mm serial number. Time per piece: 1 minute.

Data Matching: After marking, the serial number and QR code automatically sync to the brand traceability database. Customers scan the code to access the brand’s website.

Quality Check & Storage: Check QR code readability and clarity. Approved pieces go to inventory.

Application Value:

Achieves full-process product traceability and effectively prevents counterfeits (unique QR codes cannot be replicated). Enhances brand trust—customer repurchase rate increases 25%.

ERP integration improves inventory management and order tracking efficiency.

Why Many Jewelry Factories Almost Stop Using Traditional Stamping After Switching to Laser Marking Machines

Once jewelry factories experience the advantages of laser marking, it becomes difficult to revert to traditional marking methods. This “irreversible” choice stems from laser marking’s comprehensive superiority in cost, efficiency, quality, and compliance.

6.1 Cost Gap: “Zero Waste + Low Labor” vs. High Hidden Costs

Material Cost: Laser marking has nearly 0% precious metal loss, while chemical etching loses 3%-5% and mechanical stamping loses 2%-3%. For a factory producing 100 kg of gold daily, laser marking can save 3-5 kg of gold per day, resulting in over $141,300 USD annual savings.

Labor Cost: One laser marking machine can mark 500–2,000 pieces/hour. One operator can manage 2–3 machines simultaneously, with daily labor cost only $7.07–$14.13 USD. Traditional hand engraving completes 50–100 pieces/day per person, requiring 10× more labor, with daily labor cost $70.65–$141.3 USD.

Consumables / Mold Cost: Laser marking requires no consumables, only electricity (0.5–1 kWh/hour). Traditional stamping requires replacing molds ($70.65–$282.6 per set; changing design wastes a mold), and chemical etching requires continuous purchase of reagents ($141.3–$423.9/month).

6.2 Efficiency Gap: “Fast Changeovers + High Volume” vs. Slow Traditional Methods

Changeover Efficiency: Laser marking changes designs in 5 minutes via computer parameter adjustment, supporting small-batch, multi-style production ideal for e-commerce. Traditional stamping requires 1–3 days (new mold), chemical etching 2–4 hours (adjust reagents/templates), unsuitable for frequent design changes.

Batch Production Efficiency: A single laser marking machine can produce 5,000+ pieces/day, while hand engraving ≤100/day, stamping ≤1,000/day. During peak seasons (e.g., Valentine’s Day, Christmas), laser marking easily handles order surges, whereas traditional methods often delay orders due to limited capacity.

6.3 Quality Gap: “Precise + Permanent” vs. Limited Traditional Accuracy

Marking Precision: Laser marking achieves micron-level precision, clearly marking 0.2mm-thin silver chains or 0.3mm-thick gold sheets. Traditional stamping precision is only 0.1–0.2mm, hand engraving ≥0.5mm error.

Durability: Laser markings are permanent and wear-resistant, unaffected by repeated polishing. Traditional marks (≤0.1mm) blur after 1–2 years.

Appearance: Laser marks are delicate, burr-free, and do not damage metal luster. Hidden areas (inner ring, gemstone gaps) can be marked without affecting overall aesthetics. Traditional stamping can deform parts and create burrs, chemical etching may corrode surfaces and reduce shine.

6.4 Compliance & Brand Gap: Enabling Brand Upgrades

Compliance: Standardized laser markings meet global jewelry material certification and origin labeling requirements, avoiding penalties for non-compliance. Traditional marks are prone to blurring and irregularity, posing compliance risks.

Brand Value: Laser marking supports personalization and traceability codes, enhancing product differentiation and brand premium, helping brands escape “price wars.” Traditional marking cannot achieve these features, weakening competitiveness.

Market Recognition: Consumers increasingly value quality and traceability. Jewelry with laser-marked traceability codes and personalized markings enjoys higher market recognition and repurchase rates. Data shows brands with laser marking see 15%-20% higher annual market share growth than those without.

6.5 Environmental & Safety Gap: Modern Compliance vs. Phase-Out Risk

Environmental Requirements: Laser marking produces no wastewater, residue, or noise pollution, meeting environmental regulations without extra investment. Traditional chemical etching generates waste liquids, mechanical stamping produces excessive noise. With stricter regulations, these traditional methods face obsolescence.

Operational Safety: Laser marking includes safety devices (protective goggles, interlock systems), with no chemical exposure, protecting workers’ health. Chemical etching involves strong acids/bases, posing burn risks; mechanical stamping carries crush hazards—both have significant safety concerns.

Summary:

Laser marking machines are not just efficiency tools; they are also cost control tools, brand upgrade tools, and compliance assurance tools. Their comprehensive advantages over traditional marking make it increasingly impossible for jewelry factories to return to low-efficiency, high-cost, low-quality traditional methods. This technological iteration drives industry development and is a core choice for jewelry companies to remain competitive in a highly competitive market.

FAQ Guide of Jewelry Laser Marking Machine

Is there anything you would like to know about the jewelry laser marking machine? Then you have come to the right place. To make the concepts easier for you to understand, we have made the answers to your questions as easy to understand as possible.

After this lengthy piece, if you have more questions, use the contact details on our main website to talk to our customer representatives. We will make sure you get the most professional assistance possible.

- 1. What is the best laser marker for jewelry?

- 2. Can you laser mark jewelry?

- 3. Can you laser mark sterling silver?

- 4. Can you laser mark gold filled jewelry?

- 5. What laser can mark metal?

- 6. Is marking on jewelry difficult?

- 7. What is a laser marking machine?

- 8. How do you mark a name necklace?

- 9. How do I start laser marking?

- 10. What is a galvo fiber laser?

- 11. How do fiber lasers work?

- 12. What is a fiber laser marker?

- 13. Can you mark stainless steel?

- 14. How do you stamp jewelry?

- 15. What form of manufacturing is laser marking?

- 16. Can you cut gold with a laser mark?

- 17. What are the different types of marking?

- 18. What are the types of jewelry laser marking?

- 19. Can a laser mark metal?

1. What is the best laser marker for jewelry?

There are many types of laser marking machines. However, Superbmelt’s laser marking machine is the best jewelry marking machine. When choosing the best marking machine, there are many important factors you must consider.

Our marking machine leverages Jinhaichuang top-speed scanning galvanometer as well as the wavelength optical focusing field mirror. That is why it manifests impressive stability and incredible marking speed.

The other thing you will like about our jewelry laser marking machine is that it comes in an integrated design that is also compact in size. Aside from having a long life, the machine has a very low level of power consumption and high efficiency.

The cost of maintenance of our laser marking machine is almost zero. The fact that it comes with a water-cooling system makes it ideal for industrial applications as well. You can use it to mark QR codes, text graphics, portrait images, regular serial numbers, and on the list goes.

2. Can you laser mark jewelry?

It is possible to laser mark jewelry with the help of our jewelry laser marking machine. However, to complete the process, you will need to use a laser bonding agent. For instance, you should have TherMark or Cermark.

These are the best agents that will make the process easier for you. The good news is, it is possible to customize the most precious metals used to make jewelry and even engrave them with your desired marks and writings.

The marks made with the help of the Superbmelt laser marking machine are highly durable. They will stay provided the metal is kept in good condition at all times. To engrave or mark jewelry, you might need some help from our highly experienced experts. Better still, you can check out our website and learn how the process works so that you do it on your own, regardless of your location.

3. Can you laser mark sterling silver?

It is worth noting that through the years, laser marking machine has become an essential tool for a vast range of businesses. The engraver leverages the latest technology to provide you with the best cuts that will make your business stand out from the crowd.

Note that due to its aggressive technology, the laser can effortlessly cut, etch, and mark silver, which is one of the most coveted precious coins in the world today.

Would you like to know about its precision? It is highly accurate to the extent that your marks will come out just the way you wanted them to. If you have human workers or other manual machines, they will not be able to match the precision of this highly innovative machine.

If you have some sort of silver that needs marking, then this is the machine you should confidently invest your money in.

4. Can you laser mark gold filled jewelry?

The shortest and most accurate response is, it is possible to laser mark almost all sorts of metals. But again, it has something to do with the type of laser technology you are using to do the marking. Our laser marking machine has enough power to go through the metal and give your desired marks in the most accurate manner possible.

Note that when it comes to gold-filled jewelry, you might have a slightly different experience and observation. The engraver will go deep into the metal and give the marks. However, the material inside will be exposed, and some discoloration might happen.

For the best result, you want to try and do the laser marking. Once you are done, you need to redo the plating of the whole jewelry so that you end up with a uniform color. It might sound like a tough process, but you can do it in a matter of minutes.

5. What laser can mark metal?

If you are trying to put the best marks on your metal, it is crucial to invest in a machine that can let you do that with ease. Consider the nature of the marks and how long they will stay in the right condition even when exposed to destructive elements such as bad weather.

Rumors have it that CO2 lasers can be a great option when you need to engrave metals. But that is misleading information that you must never fall for. Compared to laser marking machines, CO2 lasers produce different wavelengths.

That is why our jewelry laser marking machine is the best for marking most metal surfaces. Albeit you can always try and see the results for yourself, CO2 marking machines are mainly used to mark non-metallic items and surfaces. You can never use them to mark any type of metal because they are not powerful enough.

6. Is marking on jewelry difficult?

It all depends on what you need to know from the entire process of marking. If you have the machine ready with you, and it is the best one on the market, then marking should not be a tough job for you. All you have to do is set up the machine and know how to leverage the features to get your desired results.

While Superbmelt’s laser marking machine is one of the best, there is a learning curve you need to undergo before you can apply it in your working place. Book an online appointment with our agents, and they will show you the ins and outs of the laser marking machine.

It is all about getting the right settings and ensuring that the laser gets to the right surface that needs to be marked. Your jewelry will have the best marks in a matter of seconds, so it is one of the easiest things you will ever do.

7. What is a laser marking machine?

To help you understand what a laser marking machine is, let’s first look at the laser marking process. Laser marking is a process that leverages a highly concentrated beam of light to deliver a permanent mark on a given surface.

The process is completed with the help of a UV laser machine, fiber, continuous-wave, pulsed, or green. Laser marking is a process with a vast range of application areas. The most common applications of laser marking include engraving, etching, annealing, discoloration, and carbon migration.

Your laser marking machine can be automated and operates at an extremely high speed. Note that the marks it leaves on the surface of materials are permanent, but there is nothing to worry about since it has the best level of precision on the market.

The laser marking machine can be used on a plethora of materials like aluminum, titanium, steel, plastic, ceramic, wood, paper, and on the list goes. Products and parts can be market with images, texts, bar codes to ensure that they get readable data on them.

8. How do you mark a name necklace?

This is a question we received from most of our customers who want to mark jewelry. Before we show you how to do it, note that we can help you place marks and names on your jewelry at competitive rates.

To complete the process, you are going to need some laser bonding agents and assistance from your Superbmelt marking system. How does the process work, you ask?

Your engraving system will concentrate enough heat on the bonding agent so that it gets embedded in the jewelry. That is how you will end up with a permanent mark on the metal. This could be a name or an image that you would like to have on your jewelry.

The marks are highly durable and will withstand some elements that are known to cause tear and wear. Also, the entire process only takes a matter if few seconds to complete.

9. How do I start laser marking?

As we have already seen, getting started with laser marking is something you can do in minutes. First, get in touch with us, and we will serve you with the best laser marking machine that leverages the most innovative technology in the market. That way, you can be sure of getting the most pleasurable user experience. So that is the first step.

The second step is to choose the right material that you need to engrave or cut. In this case, we would like to mark material with letters, words, symbols, or images that have meaning to us. It is okay to choose any type of material in this case; you will still be able to place your marks without any problem.

Once you have acquired a good laser marking machine and material, you are supposed to have a good design. This is what your marking machine will place on the surface of the material you are looking to mark. Make sure it looks exactly like what you would have on your material.

From there, start operating your laser marking machine to engrave the material. If you would also like to know how to use the laser marking machine, we have included that information later in this guide. Thus, be sure to read it in its entirety.

10. What is a galvo fiber laser?

First, Galvo can also be referred to as a galvanometer and is an electromagnet instrument that you can use to deflect a light beam with the help if a mirror. This can happen once the galvo has sensed an available electric current.

When talking about laser, your galvo system will use mirror technology so as to shift the beam to different directions based on what you would like to achieve. To do that, it will rotate and regulate the angles of the mirror within the work area.

Galvo lasers are perfect when you need to leverage speed for the best marking experience. It will give you fine marks that stand out from the crowd. It is worth noting that you will get a vast range of galvo systems based on the laser types.

For instance, your choice will be based on lasers such as UV, CO2, so feel free to make your choice based on your needs and preferences.

11. How do fiber lasers work?

A fiber laser technology is a highly precise process that uses a beam of light to make various surfaces of materials. It focuses the beam of light by concentrating on the surfaces that need to be marked. What happens during the marking process is that the beam interacts with the surface of the material being marked.

Through the interaction, the beam alters the chemical properties of the surface of the material, thereby altering its appearance. Note that the concentrated beam must only target a given area of the material to deliver the marks.

That is why laser marking material will always give you high-quality, durable marks compared to other technologies on the market. The marks created by the laser marking machine are easily readable, and you can scan them on any surface of your choice.

These also explain why laser marking is the most preferred application in a range of industries, especially where precision is preferred.

12. What is a fiber laser marker?

Let’s first look at the laser marking process. Laser marking is a process that leverages a highly concentrated beam of light to deliver a permanent mark on a given surface.

The process is completed with the help of a UV laser machine, fiber, continuous wave, pulsed, or green. Laser marking is a process with a vast range of application areas. The most common applications of laser marking include engraving, etching, annealing, discoloration, and carbon migration.

Your laser marking machine can be automated and operates at an extremely high speed. Note that the marks it leaves on the surface of materials are permanent, but there is nothing to worry about since it has the best level of precision on the market.

13. Can you mark stainless steel?

There are many ways to mark stainless steel, so the most precious answer to the question is yes. At Superbmelt, we have a laser marking system that you can use to mark stainless steel whenever you want.

Laser marking application has been there for many years, but we have integrated newer technology to make the whole thing work perfectly. The technology lets you leverage a high degree of flexibility to mark stainless steel.

Stainless steel can also be used to make jewelry, which is not something new these days. If you see such jewelry, they have been marked with the help of laser marking technology and other means. Is this something you would like to try? Be sure to get in touch with us today if that is the case.

14. How do you stamp jewelry?

First, it is possible to stamp your jewelry by hand or with the help of a stamping jig. It all depends on the nature of the results you would be happy to get. The process can also be done with the help of a brass hammer.

It is worth noting that the entire process might get delicate. You should be careful enough not to interfere with the surface you are working on; that is when you are using a brass hammer.

Regardless of the method you feel is the best, it is vital to get the best stamping kits from reputable dealers in the industry. For instance, Superbmelt has some of the best kits. Just take a look at the items available, place your order, and they will be delivered to your location.

Better still, you could send your jewelry to us, and we will do the stamping on your behalf. Either way, you will be happy with the results.

15. What form of manufacturing is laser marking?

Laser engraving can be quite confusing, but it belongs in the Subtractive Manufacturing method. If you don’t know what that means, subtractive manufacturing comes from the fact that some chemical properties are altered, and the particles are displaced to give the marks.

It is a process that you can use to create a vast range of images on the material of your choice. Note that the marks are placed in a way that you can see them at eye level. The application delivers a high level of heat that will then vaporize the matter. The cavity is created, and that is what we call a mark.

16. Can you cut gold with a laser mark?

A laser machine has some of the best applications that place it at the top of the chart. You can successfully use it to cut gold with a laser mark and achieve the best precision. No matter the design, you can get the work done in a matter of seconds.

This is also true for gold-filled jewelry. You can also mark them. The only difference is that the material inside will be exposed. As such, after engraving, you might want to coat them one more time with the right material.

17. What are the different types of marking?

There are different types of marks you can place on the surface of your material with the help of a laser marking machine. For instance, we have stain marking, ablation marking, dark marking, and engraving.

These are the most popular marking methods you are likely to find in the industry. Note that these are four marking methods, and each one of them will give you a different mark on the surface of your material. Thus, you need to choose the type of mark based on what you would like to do with it.

18. What are the types of jewelry laser marking?

Again, in this case, we can state that we have at least four types of jewelry laser marking. First, we have annealing laser marking. It is mainly used on metals that contain some traces of carbon. You are likely to find this method in the medical industry and it is also a bit slower.

Next, we have the carbon migration laser marking that can be used on metals and metal alloys. With this method, you will need to apply heat at an extremely rapid pace. It is the heating process that will move carbon to the surface.

Foaming laser marking is the third type of jewelry laser marking on our list. It is great when you need light markings. However, this method is mostly used on plastics rather than metals and will provide you with very smooth markings.

Coloration laser marking is the final type of marking we have on this list. The color results will be based on the oxidation process. The good thing about this method is that it can be used on both plastics and metals.

19. Can a laser mark metal?

The jewelry laser marking machine leverages the latest technology you can ever find on the market today. As such, if you are looking for something that will give you a high-speed marking of metal, then you should go for laser marking technology.

Laser etching is the best for metal and steel surfaces, so you can be sure that it works. With the technology, you will get some of the most resistant marks. Finally, it is worth noting that with laser technology, you can work on any steel alloy, such as die steel, carbon steel, and anodized steel. So the best answer is yes, laser marking technology can be used on metals.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited