CNC Gold Bangles Machine

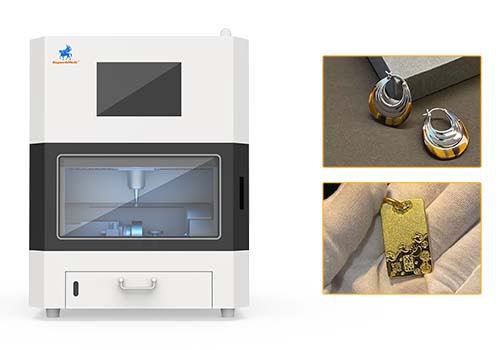

CNC Gold Bangles Machine CNC machine for gold, silver and platinum jewelry processing

Using SuperbMelt 4-axis and 5-axis CNC Gold Bangle Machines, you can precisely craft gold, silver, and platinum bangles with a wide range of finishes — including flat and 3D textures, engraving patterns, faceting, brushing, mirror polishing, colorful textures, 5G/3D reliefs, and perforation. The machines feature an exceptional precious metal recovery rate of 99.97%–99.99%, ensuring minimal material loss during production.

The 5-axis CNC machine stands out for its five-axis linkage and RTCP (Rotation Tool Center Point) functionality, allowing effortless machining of complex surfaces and multi-angle details — such as inner ring engravings and irregular 3D designs. It offers superior precision, complexity handling, and automation, making it ideal for professional users pursuing high-end craftsmanship and intricate designs.

The 4-axis CNC machine, on the other hand, is a compact desktop model with powerful capabilities. It covers most jewelry processing needs, offering high automation (pneumatic tool change) and user-friendly operation. It’s especially cost-effective for processing standard 3D pieces and flat jewelry components, perfectly suited for daily jewelry manufacturing.

| Model | SPB-CNF518 | SPB-CNF418 |

| X/Y/Z Travel | 230 / 260 / 180 mm | 147 / 118 / 85 mm |

| Working Diameter / Height | 100 / 100 mm | |

| X/Y/Z Axis Positioning Accuracy | 0.01 / 0.01 / 0.01 mm | 0.01 / 0.01 / 0.01 mm |

| A/C Axis Positioning Accuracy | 0.01° | 0.01° |

| X/Y/Z Axis Repeatability | 0.01 / 0.01 / 0.01 mm | 0.01 / 0.01 / 0.01 mm |

| A/C Axis Repeatability | 0.01° | 0.01° |

| A/C Axis Rotation Angle | -30° ~ 120° / 360° | 360° |

| Table Load Capacity | 10 kg | |

| Spindle Power | 2.4 kW | 2.4 kW |

| Spindle Type | ATC Servo Spindle | Tool-changing Electric Spindle |

| Max Spindle Speed | 0–60000 rpm/min | 0–60000 rpm/min |

| Spindle Cooling Method | Water-cooled / Oil-cooled | Professional Coolant |

| Tool Magazine Capacity | 12 (disc knife magazines) | |

| Tool Holder Type | ISO10 (T11) | Quick-change Fixture |

| Ball Screw / Linear Guide Rail | C5 Grinding Screw / Taiwan HIWIN, YINT H-grade Guide Rails | Grinding Ball Screw / Taiwan Original Silver Guide Rail |

| Working Voltage | Bus Servo (Absolute Type) | 220V / 50Hz |

| Operating Voltage | 220V / 50Hz | |

| Air Pressure | ≥0.55 MPa | 0.55 MPa |

| Machine Dimensions | 790 × 920 × 1900 mm | 630 × 590 × 760 mm |

| Material | Integral Cast Iron, Sheet Metal | Aerospace Aluminum + Sheet Metal |

| Weight | About 605 kg | ≈130 kg |

| Total Power | 4.8 kW | 4 kW |

| System | YUBANG 5-Axis CNC System (with RTCP Tool Tip Tracking) | SuperbMelt Jingdiao 9.6 |

1. 4-Axis Machine

Comprehensive functionality: Capable of handling all standard jewelry types such as rings, bangles, pendants, and flat tags. Supports engraving, faceting, brushing, 5G/3D relief, and other mainstream processes.

Easy operation, quick to learn: Features a no-programming system and touchscreen, making it beginner-friendly and significantly reducing training costs.

Efficient and convenient: One-click pneumatic tool change eliminates manual adjustments, greatly improving productivity in batch production.

Stable precision, guaranteed quality: Equipped with high-quality lead screws, guide rails, and closed-loop servo drives to ensure accuracy and consistency.

Cost-effective and compact: Offers powerful functionality while maintaining a mini footprint and high ROI.

2. 5-Axis Machine

Advanced core technology: Five-axis linkage and RTCP (Rotation Tool Center Point) allow the tool to contact the workpiece at optimal angles, achieving full 3D surface machining, recessed structures, and intricate textures with no dead zones.

Unlimited processing capability: Can perform operations beyond 4-axis machines, such as complex 3D reliefs, concave surface detailing, and multi-angle high gloss finishes, greatly expanding design possibilities.

Extreme precision and stability: Industrial-grade dual lead screws with cradle-style integrated cast iron structure provide maximum rigidity and vibration resistance during five-axis movements, ensuring top precision over long-term use.

High automation: 12-tool automatic tool magazine enables full automatic tool changes, allowing all processes to be completed in a single setup, reducing errors from multiple clamping steps and improving efficiency.

Optimal material control: While similar to the 4-axis machine in recovery rate, its control over material loss is especially critical when handling precious metals and complex designs.

Selection Recommendations

Usage Scenario Recommended Machine Reason Jewelry factories, goldsmith shops, or studios (producing market-favored or standard designs) 4-Axis Machine Fully meets functional needs, easy to operate, improves productivity and quality, lower investment cost, faster ROI. High-end custom design or complex pieces (unique 3D designs, complex surfaces) 5-Axis Machine Five-axis linkage is essential for achieving intricate designs and effects that ordinary machines cannot. One-stop solution with sufficient budget 5-Axis Machine Offers advanced technology for the coming years, supporting diverse and high-end orders without limiting design creativity. Beginners or limited budget 4-Axis Machine Provides convenient, high-quality CNC processing at a lower entry cost, minimizing risk and ensuring a smooth start.

Why SuperbMelt CNC Gold Bangles Machine

Any Question About SuperbMelt CNC Gold Bangles Machine

SuperbMelt CNC Gold Bracelet Processing Guide

Material Characteristics of Gold and the Core Technical Adaptation of the CNC Gold Bangles Machine

1.1 Material Characteristics of Gold Bangle Processing (Compared with Silver and Platinum)

Gold bangle processing mainly uses pure gold (999 gold) and K gold (18K, 22K). The material’s characteristics directly determine the technical requirements of the CNC machine:

Ductility and Hardness: Pure gold has a hardness of only 2.5–3HV and extremely high ductility (1g of gold can be stretched into a 3,000m wire). During machining, excessive tool pressure easily causes plastic deformation (e.g., edge collapse of bangles). 18K gold contains 25% other metals, increasing hardness to 4–5HV, but cutting force control is still essential. The CNC Gold Bangles Machine must support low-pressure cutting, with spindle feed pressure adjustable to 0.1–0.3N to prevent material deformation.

Density and Value: Gold’s density reaches 19.3g/cm³—1.8× silver and 1.05× platinum—with a price exceeding $55 per gram. Thus, loss control is critical. Traditional manual processing causes a 3–5% gold loss, whereas specialized CNC machines must keep loss below 0.5%, relying on high-precision chip recovery and optimized cutting parameters.

Surface Finish and Color: Finished gold bangles require a mirror-like shine (polished bangles) or fine matte texture (ancient-style matte bangles). The surface roughness must be ≤Ra0.1μm; otherwise, the surface may trap dirt or appear dull. CNC tools should use diamond-coated or ultra-fine tungsten carbide cutters (grain size 0.1–0.5μm) to avoid tool marks transferring onto the surface.

1.2 Exclusive Technical Configurations of the CNC Gold Bangles Machine

To meet gold bangle machining needs, the CNC machine must include:

High-Precision 4-Axis Linkage System: Gold bangles often have circular surfaces with 3D patterns (e.g., twisted or push bangles). The 4-axis system (X/Y/Z linear + A rotary) enables full 360° processing, with A-axis rotation accuracy of ±0.001° and circular error ≤0.02mm, ensuring consistent fit.

Dynamic Pressure Compensation: The system automatically adjusts cutting pressure for different gold hardness—0.1N for pure gold, 0.3N for 18K gold—to prevent tool sticking (pure gold) or tool chipping (18K gold).

Closed-Loop Gold Chip Recovery System: Uses negative-pressure suction + centrifugal separation + electrostatic collection. Negative pressure ≥ -0.095MPa, separation speed 5000rpm, and electrostatic voltage 8000V ensure a gold recovery rate ≥99.8%.

Specialized Gold Bangle Fixtures: Uses curved soft-alloy fixtures with silicone pads for >95% surface contact, avoiding pressure marks. Supports adaptive clamping for 50–70mm diameters without frequent fixture changes.

CNC Processing Solutions for Mainstream Gold Bangle Types

2.1 Polished / Matte Basic Bangles (e.g., Round or Flat Bangles)

These bangles focus on curved surface precision and surface finish:

Processing Flow and Parameters:

Gold Material Preparation: Roll gold into 5–8mm thick strips, rough-machine into ring blanks (with 0.2mm finishing allowance).

Finishing: Use φ6mm diamond-coated ball-end cutter, spindle speed 12,000–15,000rpm, feed rate 60–80mm/min, spiral toolpath (80% overlap) to achieve surface roughness ≤Ra0.08μm.

Matte Treatment: Use φ3mm sandblasting tool, pressure 0.2MPa, with 1500-grit diamond sand for even texture.

Key Control Point: Calibrate A- and Z-axis perpendicularity (≤0.005mm/m) to prevent elliptical distortion affecting fit.

2.2 3D Pattern Bangles (e.g., Twisted or Filigree Bangles)

Twisted Bangle:

Use a 4-axis CNC. The A-axis rotates 10° per stop. Use φ2mm ultra-fine tungsten carbide end mill (0.1mm edge radius) to cut spiral grooves 2–3mm deep, depth error ≤0.01mm. Clean grooves with 0.5mm soft wool brush to remove residual chips.Filigree Bangle:

CNC-mill gold into 0.3mm-thick filigree strips (1–1.5mm wide), fix them on the blank with multi-station fixtures. Use φ1mm diamond cutter for spot-weld-style cutting fixation (every 2mm), reducing material loss to ≤0.1% (vs. 1–2% for traditional welding).

2.3 Custom Bangles (e.g., Engraved or Gem-Set Bangles)

Engraved Bangles:

Import custom fonts, generate arc engraving paths matching bangle curvature. Use φ0.5mm tungsten cutter, spindle 18,000rpm, depth 0.1–0.2mm, width tolerance ≤0.05mm for clear engraving.Gem-Set Bangles:

Use φ1mm ball-end cutter to machine inlay slots. For a 0.5ct diamond, slot depth 2mm and width 1.8mm, with wall perpendicularity ≤0.005mm. Use optical inspection to ensure perfect fit and prevent looseness or deformation.

Core Pain Points and Solutions in CNC Gold Bangle Processing

3.1 Pain Point 1: Bangle Deformation (Especially Pure Gold)

Symptoms: Flattening (ellipticity >0.03mm) or edge collapse.

Solutions:

Fixture Optimization: Use three-point even clamping (120° apart), each applying 0.2N.

Processing Sequence: Machine inner surface → outer surface → edges to minimize stress.

Cooling Control: Use low-temperature oil mist cooling (15–20°C) to prevent softening (>100°C).

3.2 Pain Point 2: Excessive Gold Loss

Symptoms: Loss exceeding 0.5g per 100g bangle (worth over $27).

Solutions:

Recovery Upgrade: Add magnetic plates to separate impurities; combined system yields 99.9% recovery.

Tool Optimization: Use super-lubricated coated tools (e.g., DLC diamond coating); maintain feed rate 60–80mm/min.

Material Reuse: Melt recovered chips into small gold blocks for accessory parts to achieve zero waste.

3.3 Pain Point 3: Insufficient Pattern Precision

Symptoms: Uneven twists or inconsistent filigree gaps.

Solutions:

Path Optimization: Use adaptive toolpaths—0.05mm step for complex patterns, 0.1mm for simple ones.

Real-Time Compensation: Laser probe checks every 5mm, auto-adjusting for tool wear.

Gold Annealing: Preprocess at 300°C for 2h with slow cooling to release internal stress.

CNC Gold Bangles Machine Selection Guide (By Enterprise Scale)

Whether for personalized customization of gold jewelry or mass production, SuperbMelt can achieve efficient and precise processing through its integrated functions while controlling material loss.

4.1 Small Gold Workshops (50–100 Bangles/Month)

Needs: Low cost, easy operation, small footprint.

Recommendations:

Model: Desktop 4-axis CNC (≤0.6㎡), single-station.

Functions: Built-in design library (≥500 templates), one-click operation, basic recovery ≥99.5%.

Specs: Spindle 5000–18,000rpm, positioning ±0.005mm, daily output ≥10 pieces.

4.2 Medium Factories (500–1000 Bangles/Month)

Needs: Efficient batch production, multi-type adaptability, low loss.

Recommendations:

Model: Vertical dual-station 4-axis CNC (two bangles simultaneously).

Functions: Dynamic pressure compensation, triple recovery system, optical inspection, MES monitoring.

Specs: Spindle 8000–20,000rpm, repeatability ±0.003mm, output ≥50/day, loss ≤0.3%.

4.3, Ensuring Purity and Polishing Support After Gold Processing

Needs: Ultra-high precision, personalized design, manual finishing compatibility.

Recommendations:

Model: High-precision 5-axis CNC (for complex curved surfaces).

Functions: CAD/3D model import, laser compensation, manual polishing allowance (0.1mm), inert-gas chamber (anti-oxidation).

Specs: Positioning ±0.002mm, surface roughness ≤Ra0.05μm, supports 45–75mm diameter bangles.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited