Mini CNC Machine For Jewelry

Mini Jewelry CNC Machine for Gold, Silver, and Platinum — Perfect for Small and Medium-Sized Jewelry Businesses

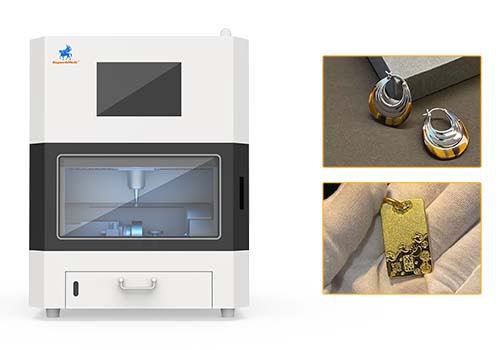

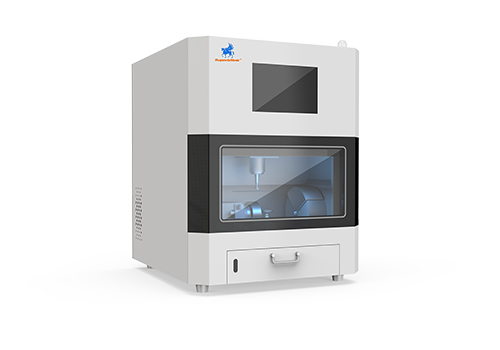

SuperbMelt Mini CNC Machine for Jewelry is a compact yet powerful 4-axis engraving and cutting system designed for small to medium-sized jewelry workshops, goldsmith stores, and design studios. Its mini desktop design saves space while delivering professional-level precision and efficiency.

Equipped with an automatic tool changer, it eliminates the need for manual adjustments — no wrenches or nuts required. The built-in non-programming jewelry design library allows users to quickly produce intricate gold, silver, platinum, and K-gold pieces with ease.

The machine also features a high-efficiency metal recovery system, achieving a recovery rate of 99.7–99.9%, minimizing material loss during processing. Whether for engraving, cutting, or fine detailing, this Mini CNC Machine ensures exceptional accuracy, consistency, and cost savings — making it the perfect choice for modern jewelry manufacturing and customization.

| Model | SPB-CNF418 |

| X/Y/Z Travel | 147 / 118 / 85 mm |

| X/Y/Z Positioning Accuracy | 0.01 / 0.01 / 0.01 mm |

| A-axis Positioning Accuracy | 0.01° |

| X/Y/Z Repeatability | 0.01 / 0.01 / 0.01 mm |

| A-axis Repeatability | 0.01° |

| A-axis Rotation Angle | 360° |

| Spindle Power | 2.4 kW |

| Spindle Type | Tool-changing Electric Spindle |

| Max Spindle Speed | 0–60000 rpm/min |

| Spindle Cooling Method | Professional Coolant |

| Engraving Tool Holder | Quick-change Fixture |

| Transmission / Linear Guide | Grinding Ball Screw / Taiwan Original Silver Guide Rail |

| Drive System | Closed-loop Servo |

| Working Voltage | 220V / 50Hz |

| Machine Enclosure Type | Fully Enclosed, Waterproof & Dustproof |

| Air Source Pressure | 0.55 MPa |

| Overall Dimensions | 630 × 590 × 760 mm |

| Weight | ≈130 kg |

| Material | Aerospace Aluminum + Sheet Metal |

| Total Machine Power | 4 kW |

| Software | SuperbMelt Jingdiao 9.6 |

SuperbMelt’s Mini CNC Machine for Jewelry is a compact yet powerful solution designed specifically for small and medium-sized jewelry businesses, goldsmith shops, and design studios. Despite its small footprint, it delivers exceptional precision and efficiency for all types of metal jewelry processing.

Key Features and Advantages:

Compact Desktop Design:

Space-saving mini size, ideal for jewelry workshops, gold shops, and design studios with limited space.Multi-Functional Processing:

Capable of performing various jewelry processes including flat and 3D engraving, texture patterning, flower carving, brushing, mirror polishing, colorful texture effects, 5G/3D designs, and hole engraving — all in one machine.4-Axis Automatic Tool Changer:

Equipped with a 4-axis spindle and automatic tool changer, eliminating the need for manual wrench operation. The built-in jewelry design library allows program-free machining, making operation easy even for beginners.High Metal Recovery Rate (99.7%–99.9%):

The built-in oil and water gun system allows gold dust to be easily flushed into the collection funnel for recovery, ensuring minimal material loss and maximum profitability.Wide Material Compatibility:

Perfect for CNC machining of gold, platinum, K-gold, and silver jewelry.

Why SuperbMelt Mini CNC Machine For Jewelry

Any Question About SuperbMelt Mini CNC Machine For Jewelry

Guide to SuperbMelt Mini CNC Machine for Jewelry

Core Pain Points in the Current Jewelry Manufacturing Market

1.1 Space Constraints for Small and Medium-Sized Businesses

Most small and medium-sized jewelry workshops, goldsmith stores, and design studios are located in commercial areas or compact industrial parks, where space resources are extremely limited. Traditional large-scale CNC equipment requires dedicated workshops for installation, with strict requirements on floor load-bearing and operating space. For example, a standard industrial-grade 5-axis jewelry CNC machine usually needs an area of more than 10 square meters, which is a heavy burden for small workshops with only 20-30 square meters of operating space. Many businesses have to give up automated processing due to space limitations and continue to rely on inefficient manual operations, which severely restricts production scale expansion.

1.2 High Threshold for Operation and Skilled Labor Shortage

The jewelry industry has long faced a shortage of skilled craftsmen, and the emergence of traditional CNC equipment has not fully solved this problem. On the one hand, operating traditional jewelry CNC machines requires mastering professional programming skills, such as proficiency in G-code and CAD design software. The training cycle for a qualified operator is usually 3-6 months, and the monthly salary cost is as high as 1120-1680$, which increases the operational burden of small and medium-sized businesses. On the other hand, even after training, operators may make programming errors due to inexperience, leading to waste of precious metal materials. A single mistake in processing a platinum jewelry piece can cause a loss of thousands of yuan, further exacerbating the business’s cost pressure.

1.3 Severe Material Loss and Low Profit Margins

Precious metals such as gold, silver, and platinum are the core raw materials for jewelry production, and their prices have been rising steadily in recent years. However, traditional processing methods have serious material loss problems. Manual engraving and cutting often generate a large amount of metal shavings and dust, and the recovery rate is usually less than 90%. Even some low-end mini CNC machines on the market have a metal recovery rate of only 95%-97%, which means that for a business processing 10 kilograms of gold per month, the monthly material loss can reach 300-500 grams, equivalent to a direct economic loss of more than 21011$. This severe material loss directly compresses the profit margins of jewelry businesses, making it difficult for many small and medium-sized enterprises to survive in the fierce market competition.

1.4 Slow Response to Personalized Market Demand

With the upgrading of consumer demand, the jewelry market has entered the “personalized customization era”. Consumers are no longer satisfied with mass-produced styles and are more willing to pay for customized jewelry with unique designs, such as wedding rings engraved with personal names and birthstones, and necklaces with exclusive patterns. However, traditional processing methods are difficult to meet the needs of small-batch and personalized production. Manual customization requires 7-15 days to complete a single piece of jewelry, while traditional CNC machines need to re-program for each customized design, which takes 2-3 days. This slow response speed makes businesses miss the best sales opportunities and lose a large number of potential customers.

Development Status and Application of Jewelry CNC Technology

2.1 Evolution of Mini Jewelry CNC Machine Technology

The development of mini jewelry CNC machines has gone through three stages. The first stage (2000-2010) was the “mechanical automation stage”. The early mini CNC machines were mainly 2-axis or 3-axis systems, which could only realize simple flat engraving and cutting. The processing precision was low (error ≥ 0.1mm), and the operation required professional programming skills. The second stage (2011-2020) was the “intelligent upgrading stage”. With the development of computer technology, 4-axis mini CNC machines began to appear, adding a rotating axis to realize 3D processing. Some advanced models were equipped with basic automatic tool changers, and the processing precision was improved to 0.05-0.1mm. The third stage (2021-present) is the “integrated intelligent stage”. Representative products such as SuperbMelt Mini CNC Machine for Jewelry have realized the integration of multiple functions, including 4-axis high-precision processing, automatic tool change, non-programming design, and high-efficiency metal recovery. The processing precision has reached 0.01-0.03mm, and the operation threshold has been greatly reduced, making it easy for beginners to get started.

2.2 Key Core Technologies of Modern Mini Jewelry CNC Machines

2.2.1 4-Axis Linkage Processing Technology

4-axis linkage processing technology is the core of modern mini jewelry CNC machines. It combines the X, Y, Z linear axes with the A rotating axis to realize multi-angle and all-round processing of jewelry workpieces. This technology can process complex 3D structures such as curved surfaces, hollow patterns, and multi-layer carvings, which is impossible for traditional 3-axis machines. For example, when processing a 3D hollow platinum bracelet, the 4-axis machine can rotate the workpiece while cutting, ensuring that each part of the bracelet has a smooth surface and accurate pattern, and the processing efficiency is 3-5 times that of manual operation.

2.2.2 Non-Programming Intelligent Design Technology

In response to the problem of high programming thresholds, non-programming intelligent design technology has become a key breakthrough in the jewelry CNC industry. This technology builds a large-scale jewelry design library in the machine system, covering thousands of common styles such as classic flowers, geometric patterns, and personalized engravings. Users only need to select the desired design from the library, adjust parameters such as size and material, and the machine can automatically generate processing programs. For example, SuperbMelt Mini CNC Machine for Jewelry has a built-in non-programming jewelry design library with more than 5,000 templates. Even operators without programming experience can complete the processing preparation of a personalized jewelry piece in 5-10 minutes, which greatly shortens the production cycle.

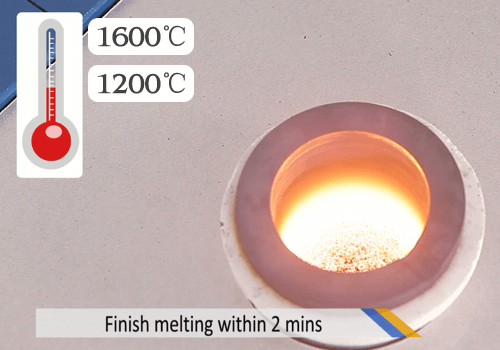

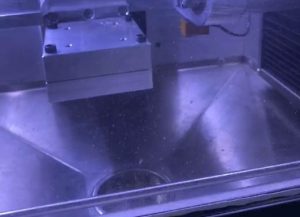

2.2.3 High-Efficiency Metal Recovery Technology

Aiming at the pain point of severe material loss in the jewelry industry, high-efficiency metal recovery technology has been widely applied in modern mini CNC machines. This technology mainly consists of three parts: a built-in oil-water gun system, a high-precision collection funnel, and a filtering and recycling device. During the processing process, the oil-water gun sprays a special oil-water mixture to flush the metal dust and shavings generated during processing into the collection funnel. The filtering device then separates the metal from the oil-water mixture, and the recovery rate can reach 99.7%-99.9%. Taking SuperbMelt’s machine as an example, processing 10 kilograms of gold per month can reduce material loss to 10-30 grams, saving more than 19610$ in material costs for businesses every year.

2.2.4 Automatic Tool Change Technology

Automatic tool change technology solves the problem of time-consuming and labor-intensive manual tool changes in traditional processing. Modern mini jewelry CNC machines are usually equipped with a tool magazine with 4-8 tools, which can automatically replace tools of different types and specifications according to the processing requirements. For example, when processing a gold ring that requires both engraving and polishing, the machine can automatically switch from an engraving tool to a polishing tool after completing the engraving process, without manual intervention. This technology not only saves 20-30 minutes of tool change time per shift but also avoids the precision error caused by manual tool adjustment, ensuring the consistency of product quality.

2.3 Application Scenarios of Mini Jewelry CNC Machines in the Industry

Mini jewelry CNC machines are widely used in various scenarios of the jewelry industry. In small and medium-sized jewelry workshops, they are mainly used for the production of personalized customized jewelry, such as wedding rings, couple necklaces, and birthday bracelets. The non-programming design function and fast processing speed can help workshops complete 5-10 customized orders per day. In goldsmith stores, mini CNC machines are usually placed in the storefront to provide on-site customization services. Customers can select designs on the spot, and the machine can complete the processing in 1-2 hours, enhancing the customer experience and increasing store sales. In design studios, mini CNC machines are used for the production of sample jewelry. Designers can quickly turn their design concepts into physical samples, shortening the sample development cycle from 7-10 days to 1-2 days, and improving the efficiency of cooperation with jewelry brands.

In-Depth Analysis of User Needs for Mini Jewelry CNC Machines

3.1 Needs of Small and Medium-Sized Jewelry Workshops

Small and medium-sized jewelry workshops are the main users of mini jewelry CNC machines, and their needs are mainly focused on cost control, efficiency improvement, and space saving. In terms of cost control, they hope that the machine has a high metal recovery rate to reduce material loss, and the price of the machine is reasonable (usually within 1400-28015$) to avoid excessive investment. In terms of efficiency improvement, they need the machine to have fast processing speed and simple operation, so that a single operator can manage multiple machines, reducing labor costs. In terms of space saving, the machine should have a compact design, with a footprint of less than 2 square meters, which can be placed in small workshops. For example, a workshop with 30 square meters of operating space can place 2-3 SuperbMelt mini CNC machines, realizing the simultaneous processing of multiple orders and improving the overall production capacity.

3.2 Needs of Goldsmith Stores

Goldsmith stores pay more attention to customer experience, on-site operation, and brand image enhancement. They need mini CNC machines to have a beautiful appearance and low noise, so that they can be placed in the storefront without affecting the shopping environment. The on-site customization function is essential. Customers can participate in the design process, and the machine can complete the processing quickly, allowing customers to take the customized jewelry away on the spot, which improves customer satisfaction and word-of-mouth. In addition, the machine should have a high degree of safety, with protective devices such as emergency stop buttons and safety doors to ensure the safety of customers and employees in the store. For example, SuperbMelt’s mini CNC machine adopts a fully enclosed design, with a noise level of less than 60 decibels, which is equivalent to the sound of normal conversation, making it very suitable for storefront use.

3.3 Needs of Jewelry Design Studios

Jewelry design studios have high requirements for processing precision, design flexibility, and sample production speed. They need the machine to have high processing precision (error ≤ 0.03mm) to accurately restore the details of the design drawings, such as fine patterns and small inlaid grooves. In terms of design flexibility, the machine should support the import of external design files (such as CAD files) to meet the needs of personalized design. At the same time, the sample production speed should be fast, so that designers can quickly modify and optimize the samples according to the feedback of customers or brands. For example, a design studio can use SuperbMelt’s machine to produce a sample of a 3D inlaid diamond necklace in 2-3 hours. If modifications are needed, the design can be adjusted and reprocessed in 1 hour, greatly shortening the sample development cycle.

3.4 Needs of Emerging E-Commerce Jewelry Brands

Their demands for mini jewelry CNC machines focus on mass customization, fast delivery, and consistent quality. E-commerce jewelry brands often receive large numbers of small-batch customization orders (e.g., 5-20 pieces per order) during promotional periods. They require machines capable of processing multiple orders continuously, with a highly automated process to reduce manual intervention. For fast delivery, the machines should have high processing speeds to ensure orders can be shipped within 24-48 hours, improving customer satisfaction. For consistent quality, the machines should have consistent machining accuracy, ensuring that every piece of jewelry in a batch is of the same quality, thus avoiding customer complaints due to quality discrepancies. SuperbMelt’s mini CNC machines can operate continuously for over 12 hours, and the machining accuracy error for the same batch of products is less than 0.02 mm, effectively meeting the needs of e-commerce jewelry brands.

How Mini Jewelry CNC Machines Solve Market Pain Points and Meet User Needs

4.1 Solving Space Constraints: Compact Desktop Design

Aiming at the space problem of small and medium-sized businesses, mini jewelry CNC machines adopt a compact desktop design. Taking SuperbMelt’s product as an example, its length, width, and height are about 80cm × 60cm × 70cm, and the footprint is only 0.48 square meters, which is equivalent to the size of a small desk. This design allows the machine to be placed in any corner of the workshop or storefront, without the need for dedicated installation space. For small workshops with limited space, multiple machines can be placed side by side to form a small-scale automated production line, which greatly improves the space utilization rate.

4.2 Lowering Operation Threshold: Non-Programming Design and Intelligent Operation

To solve the problem of high operation thresholds and skilled labor shortages, mini jewelry CNC machines are equipped with non-programming design systems and intelligent operation interfaces. The built-in design library covers a large number of common jewelry styles, and users only need to perform simple operations such as selection and parameter adjustment to complete the processing preparation. At the same time, the machine is equipped with a touch screen operation interface, which is intuitive and easy to understand, and operators can master the basic operation in 1-2 days of training. In addition, the machine has an automatic fault diagnosis function. When a fault occurs, the system will automatically prompt the cause of the fault and the solution, reducing the dependence on professional maintenance personnel.

4.3 Reducing Material Loss: High-Efficiency Metal Recovery System

The high-efficiency metal recovery system of mini jewelry CNC machines effectively solves the problem of severe material loss. The built-in oil-water gun system can flush the metal dust and shavings generated during processing into the collection funnel in a timely manner, and the filtering and recycling device can separate the metal with high precision. The recovery rate of 99.7%-99.9% is far higher than that of traditional manual processing and low-end CNC machines. For a small jewelry workshop processing 5 kilograms of gold per month, using a mini CNC machine with a high recovery rate can save more than 9805$ in material costs every year, significantly improving the profit margin of the business.

4.3 Meeting Personalized Needs: Fast Customization and Flexible Processing

Mini jewelry CNC machines meet the personalized needs of the market through fast customization and flexible processing capabilities. The non-programming design library allows users to quickly select or modify designs, and the 4-axis linkage processing technology can realize the processing of complex 3D structures. For personalized customized orders, the machine can complete the processing in 1-2 hours, which is 5-10 times faster than traditional manual processing. At the same time, the machine supports the import of external design files, which can meet the needs of exclusive customized designs. For example, a customer wants to engrave a unique family crest on a platinum ring. The design studio can import the crest design file into the machine, and the machine can complete the engraving in 1.5 hours, realizing the customer’s personalized needs.

Conclusion

The current jewelry manufacturing market is facing pain points such as space constraints, high operation thresholds, severe material loss, and slow response to personalized needs. The development of mini jewelry CNC technology, represented by 4-axis linkage processing, non-programming intelligent design, high-efficiency metal recovery, and automatic tool change, provides an effective solution to these problems.

Different user groups, such as small and medium-sized jewelry workshops, goldsmith stores, design studios, and e-commerce jewelry brands, have different needs for mini jewelry CNC machines. However, in general, they all pursue cost control, efficiency improvement, quality stability, and flexibility in meeting personalized needs. Mini jewelry CNC machines, such as SuperbMelt’s products, can well meet these needs through their compact design, intelligent operation, high metal recovery rate, and fast customization capabilities.

With the continuous upgrading of consumer demand and the advancement of CNC technology, mini jewelry CNC machines will become an indispensable core equipment in the jewelry industry. They will not only help small and medium-sized jewelry businesses improve their competitiveness but also promote the transformation and upgrading of the entire jewelry industry towards intelligence, personalization, and high efficiency. For jewelry businesses that want to gain a foothold in the fierce market competition, choosing a suitable mini jewelry CNC machine is an important strategic decision.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited