Gold CNC Machine

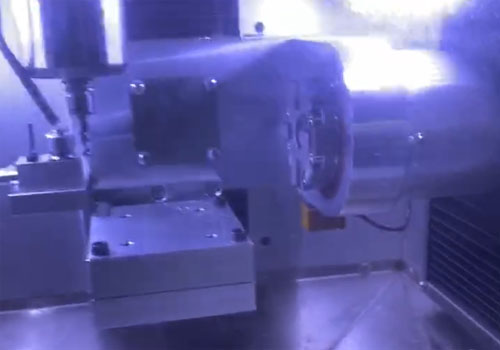

SuperbMelt CNC Machine for Gold is designed for engraving complex jewelry designs.

SuperbMelt Gold CNC Machine is specially designed for processing precious metal jewelry, including gold, platinum, K-gold, silver rings, bracelets, pendants, beads, 3D pieces, flat plates, earrings, and more.

This powerful machine is capable of handling both flat and 3D designs with a wide range of techniques, such as background texturing, pattern engraving, surface carving, brushing, polishing, colorful textures, 5G/3D effects, and drilling.

To minimize material loss, the Gold CNC Machine is equipped with a funnel-style processing chamber, achieving a remarkable precious metal recovery rate of 99.7%–99.9%.

Unlike traditional machines that require manual tool changes with a wrench, the SuperbMelt CNC system allows for quick, automatic tool changes. This significantly boosts efficiency, flexibility, and precision, while reducing labor intervention, saving production time and cost, and ensuring consistent product quality.

| Model | SPB-CNF418 |

| X/Y/Z Travel | 147 / 118 / 85 mm |

| X/Y/Z Positioning Accuracy | 0.01 / 0.01 / 0.01 mm |

| A-axis Positioning Accuracy | 0.01° |

| X/Y/Z Repeatability | 0.01 / 0.01 / 0.01 mm |

| A-axis Repeatability | 0.01° |

| A-axis Rotation Angle | 360° |

| Spindle Power | 2.4 kW |

| Spindle Type | Tool-changing Electric Spindle |

| Max Spindle Speed | 0–60000 rpm/min |

| Spindle Cooling Method | Professional Coolant |

| Engraving Tool Holder | Quick-change Fixture |

| Transmission / Linear Guide | Grinding Ball Screw / Taiwan Original Silver Guide Rail |

| Drive System | Closed-loop Servo |

| Working Voltage | 220V / 50Hz |

| Machine Enclosure Type | Fully Enclosed, Waterproof & Dustproof |

| Air Source Pressure | 0.55 MPa |

| Overall Dimensions | 630 × 590 × 760 mm |

| Weight | ≈130 kg |

| Material | Aerospace Aluminum + Sheet Metal |

| Total Machine Power | 4 kW |

| Software | SuperbMelt Jingdiao 9.6 |

- Applications: Suitable for processing precious metal jewelry such as gold, platinum, K-gold, and silver. It can be used to manufacture rings, bracelets, pendants, beads, 3D pieces, flat plates, earrings, and more.

- Powerful Functions: Capable of performing flat and 3D texturing, pattern engraving, carving, brushing, polishing, colorful textures, 5G/3D effects, drilling, and more. Equipped with a one-touch pneumatic tool changer, eliminating the need for manual wrench adjustments—faster and more convenient.

- Efficient Recovery System: Designed with a funnel-style processing chamber specifically for precious metals, achieving a recovery rate of 99.7%–99.9%. Built-in air/water gun makes it easy to wash gold dust into the funnel for collection, minimizing material loss.

- User-Friendly CNC Operation: Touchscreen gold and silver CNC system with a built-in, no-programming-required processing library. Even beginners can operate it easily and efficiently.

- High Precision: Features ground ball screws, original Hiwin linear guides from Taiwan, industrial-grade high-precision helical reducers, and closed-loop servo drives to ensure machining accuracy and stability.

- Compact & Versatile: With its precision mini design and small footprint, it is ideal for jewelry shops, manufacturing factories, and jewelry design studios.

Jewelry Industry

- Engraving, hollowing, relief, brushing, polishing, and setting preparation on gold, platinum, K-gold, and silver jewelry.

- Common products: rings, bangles, pendants, beads, studs, flat plates, and 3D jewelry pieces.

Jewelry Design Studios / Gold Shops

- Ideal for small-batch customized processing, rapid prototyping, and turning creative designs into finished products quickly.

Jewelry Manufacturing Factories

- Supports mass production with high efficiency, reduced manual intervention, and consistent precision.

High-End Gift & Craft Industry

- Used for fine engraving and polishing of gold and silver commemorative medals, ornaments, and luxury accessories.

Precious Metal Processing & Recycling

- The high-recovery funnel system minimizes material loss, ensuring maximum economic benefits.

Why SuperbMelt Gold CNC Machine

Any Question About SuperbMelt Gold CNC Machine

SuperbMelt Gold CNC Machine: Practical Guide for Gold Processing

Background of the Gold Processing Industry and the Evolution of Equipment Requirements

As the gold processing industry transitions from “handcrafted customization” to “precise mass production,” choosing the right CNC equipment is key to improving efficiency and controlling material loss. This guide focuses on the practical needs of gold processing, starting with industry background, comparing market equipment, and explaining the necessity and applications of the SuperbMelt Gold CNC Machine, helping you master the key points of the entire gold processing workflow.

1.1, Pain Points of Traditional Gold Processing

Low Efficiency: Handcrafting a gold ring with a complex pattern takes 4–6 hours. During batch production, long delivery times make it difficult to meet customers’ demand for quick turnaround.

High Material Loss: Manual cutting and polishing generate significant gold dust, with a typical loss rate of 5%–8%. For high-value gold, every 1% loss directly impacts profit.

Poor Precision: Manually controlling pattern depth and dimensions often results in large deviations. For example, the alignment of patterns on identical pendants can vary by more than 0.1 mm, affecting product consistency and weakening brand reputation.

Labor Intensive: Skilled craftsmanship requires long training periods, increasing labor costs and dependency on experienced artisans.

Limited Design Complexity: Intricate 3D designs or micro-details are difficult to achieve consistently by hand, restricting creative possibilities.

Inconsistent Surface Finish: Manual polishing and finishing often result in uneven textures or shine, requiring additional rework.

Scalability Issues: Meeting large orders is challenging, as manual processes cannot scale efficiently without compromising quality.

1.2, Core Requirements of Modern Gold Processing

- Personalized Customization: Modern customers increasingly seek highly personalized gold jewelry, requesting engraved text, initials, or exclusive patterns such as floral motifs, hearts, stars, or commemorative symbols like anniversary dates or meaningful icons. To meet these demands, CNC equipment must support flexible import of digital design files, enabling “one-piece, one-design” production. This allows jewelers to create truly unique items without manual trial-and-error, significantly reducing production time while maintaining precision.

- Batch Consistency: For jewelry manufacturers handling bulk orders, maintaining absolute consistency across multiple pieces is critical. Orders of 100 pieces or more require identical dimensions, engraving depth, and pattern alignment, with tolerances as tight as 0.02 mm. Any deviation can affect the overall look, brand reputation, and customer satisfaction. The SuperbMelt Gold CNC Machine ensures high repeatability and uniformity, making it ideal for both mass production and limited edition series.

- Low Material Loss and Cost Efficiency: Gold is a high-value material, and even small losses during processing can significantly impact profitability. Advanced equipment must include efficient gold dust recovery systems to capture residual material from cutting, engraving, and polishing processes, reducing loss rates to below 3%. SuperbMelt achieves an impressive 99.7%–99.9% recovery rate, minimizing waste and maximizing return on investment.

The SuperbMelt Gold CNC Machine is specifically designed to meet these modern gold processing demands. With positioning accuracy up to 0.01 mm, gold dust recovery rates between 99.7%–99.9%, and a high-speed adjustable spindle reaching 60,000 rpm, it perfectly addresses the core needs of today’s gold processing industry. Additionally, its user-friendly interface and automated workflow reduce operator error and production time, enabling both small-batch customization and large-scale consistent manufacturing with minimal material waste.

High Precision and Performance: The SuperbMelt Gold CNC Machine features positioning accuracy of 0.01 mm and a high-speed spindle adjustable up to 60,000 rpm. This enables the precise engraving of intricate 3D designs, micro-patterns, and complex surfaces on gold jewelry, which would be nearly impossible to achieve consistently by hand. The machine’s stability and precision also allow for high-speed production without compromising quality.

User-Friendly Interface and Workflow Automation: Beyond hardware capabilities, SuperbMelt emphasizes ease of use. Its intuitive software interface allows jewelers to quickly import and adjust designs, simulate machining paths, and control production parameters with minimal training. Automated workflows reduce operator error, lower labor costs, and shorten production cycles, enabling a seamless transition from design to finished product.

Versatility for Modern Jewelry Trends: Whether producing small-batch customized rings, exclusive pendants, or larger orders like matching earrings or bracelets, the machine supports diverse applications. Its adaptability makes it suitable for both traditional jewelry lines and contemporary design trends, catering to international tastes and expanding market opportunities.

Sustainability and Profitability: By combining low material loss, high precision, and automated processes, SuperbMelt Gold CNC Machine not only enhances operational efficiency but also supports sustainable production practices, which is increasingly important in the luxury goods industry. Reduced waste, consistent quality, and faster turnaround times translate directly into higher profitability and stronger brand credibility.

Comparison of Mainstream Gold CNC Equipment in the Current Market

The gold CNC machines on the market are mainly divided into three categories: industrial large machines, general-purpose medium machines, and small dedicated machines. Each type is suited to different applications, so choosing the right equipment should be based on your scale and specific needs.

| Equipment Type | Key Features | Suitable Scenarios | Core Differences with SuperbMelt |

|---|---|---|---|

| Industrial Large Machine | Large size (≥1000×800×1200 mm), high power (≥8 KW), requires 380 V industrial power; suitable for processing oversized gold items (e.g., gold sculptures over 500 g) | Large jewelry factories, gold craft factories; monthly output ≥1000 pieces | SuperbMelt is only 630×590×760 mm, weighs ≈130 kg, and can run on a 220 V household socket, making it more suitable for small to medium workshops and goldsmith stores without modifying factory wiring |

| General Medium Machine | Compatible with multiple materials such as metal and wood; gold processing is only an additional function; no dedicated gold dust recovery system; fixed spindle speed (≤40,000 rpm) | Mixed-material processing factories, gold accounts for ≤30% of total work | SuperbMelt is a gold-dedicated machine with funnel-type recovery bin + oil/water cleaning system, achieving over 99.7% gold dust recovery; spindle speed adjustable 0–60,000 rpm, suitable for soft 24K gold and hard 18K gold without deformation due to incorrect speed |

| Small Dedicated Machine (e.g., SuperbMelt) | Compact size, full gold-specific functions (pneumatic tool changer, library-free operation, waterproof and dustproof cover), easy to operate | Small to medium jewelry factories (monthly output 100–500 pieces), goldsmith stores, jewelry design studios | Compared with other small machines, SuperbMelt uses original Taiwanese Yintai rails + ground lead screw with 0.01 mm positioning accuracy (other small machines typically 0.02 mm); comes with professional coolant system to prevent gold oxidation during processing and reduce polishing workload |

Why Gold Processing Must Choose Specialized CNC Equipment like SuperbMelt

The unique characteristics of gold—its high value, softness, and susceptibility to material loss—mean that general-purpose equipment cannot meet the precise demands of gold processing. The design details of specialized CNC machines directly impact both the quality of the finished product and overall profitability.

3.1, Special Equipment Requirements Due to the Physical Properties of Gold

Soft Material Adaptability: Gold is very soft (pure gold Mohs hardness 2.5), and standard CNC machines with fixed spindle speeds (e.g., 40,000 rpm) can cause deformation or burrs during cutting. The SuperbMelt CNC features a 0–60,000 rpm adjustable spindle, allowing optimal speed selection: 30,000–40,000 rpm for 24K gold to prevent deformation, and 50,000–60,000 rpm for harder 18K gold (alloyed with other metals) to ensure smooth cutting.

Low Material Loss: Gold is extremely valuable, and even 1 g of lost gold dust represents a significant profit loss. SuperbMelt’s waterproof and dustproof fully enclosed design contains all gold dust and shavings during processing. Coupled with its funnel-style recovery system, it achieves a gold dust recovery rate of over 99.7%, reclaiming an additional 3%–5% of raw material compared to unprotected equipment.

Gold processing demands both precision and protection. Without specialized design features, soft gold can easily warp, chip, or accumulate burrs during CNC operations, reducing product quality and increasing polishing workload. Standard machines often lack adjustable spindle speeds and protective enclosures, making them unsuitable for high-value materials.

3.2, Equipment Support for the Entire Gold Processing Workflow

- The complete gold processing workflow is: “Raw Material Melting → Casting into Blanks → CNC Processing → Polishing into Finished Products.” SuperbMelt plays a crucial transitional role in the CNC processing stage:

- Handling Cast Blanks: Cast gold blanks (e.g., ring blanks, pendant blanks) often contain slight dimensional deviations. With 0.01 mm high-precision machining, the SuperbMelt CNC corrects these deviations, ensuring the final product dimensions meet exact standards.

- Reducing Polishing Workload: The machine achieves a surface roughness as low as Ra ≤ 0.8 μm, reducing polishing work by up to 50% compared to standard CNC equipment. This not only saves labor costs but also minimizes gold dust loss during polishing.

In gold jewelry manufacturing, CNC machining is the bridge between casting and polishing. If this step lacks precision, the errors cascade, leading to excessive polishing, increased gold loss, and inconsistent quality. That’s why SuperbMelt’s CNC machine is engineered to deliver both dimensional accuracy and surface refinement in one step.

- Precision Correction: Even high-quality casting cannot avoid micro-deviations. SuperbMelt’s 0.01 mm positioning accuracy ensures every piece—whether a ring, pendant, or bracelet—matches the design specification with minimal tolerance.

- Surface Optimization: By achieving ultra-smooth surfaces directly from CNC cutting (Ra ≤ 0.8 μm), the machine dramatically cuts down on polishing time, turning what was once a labor-intensive process into a quick finishing step.

- Cost Savings: Less polishing means reduced labor hours and significantly lower material loss. Each gram of gold dust saved directly adds to profit margins.

- Workflow Efficiency: With fewer corrections required in post-processing, production speed increases, allowing manufacturers to meet deadlines without sacrificing quality.

By optimizing the “CNC Processing” stage, SuperbMelt not only ensures dimensional accuracy but also enhances material utilization and production efficiency, making it a vital investment for any jewelry manufacturer aiming to balance quality, speed, and profitability.

3.3, Selection of Auxiliary Equipment for Gold Processing

In addition to CNC equipment, the melting and casting stage of gold processing requires the use of quartz crucibles. When selecting a crucible, it is important to ensure compatibility with SuperbMelt’s machining dimensions:

High-Purity Material: Choose quartz crucibles with 99.9% SiO₂ purity to prevent impurities from mixing into the gold, which can affect the final product quality (e.g., causing dull or discolored gold).

Size Compatibility with Machining Travel: SuperbMelt’s X/Y/Z axis travel is 147/118/85 mm, so it is recommended to keep the cast blank dimensions within 80 mm × 110 mm × 80 mm. This ensures the blank fits fully inside the machining chamber, avoiding cases where oversized blanks cannot be processed.

Thickness for Heating Efficiency: Select crucibles with a 3–5 mm wall thickness. This ensures they can withstand gold’s melting point (1064 °C) while also conducting heat efficiently, thereby improving casting efficiency.

Quartz crucibles are a vital yet often overlooked component in the gold processing chain. The quality and specifications of the crucible directly influence the purity, consistency, and efficiency of the casting stage, which in turn affects every subsequent step—especially CNC machining.

Purity Safeguards Product Value: Low-purity crucibles may introduce trace contaminants such as iron or aluminum into molten gold, altering its color and reducing its value. By insisting on 99.9% high-purity quartz crucibles, manufacturers ensure that their cast blanks maintain the highest possible purity and brilliance.

Dimension Precision for Workflow Continuity: Even a slight mismatch between the crucible-cast blank size and the CNC machine’s chamber can create bottlenecks. By controlling the blank size within 80 mm × 110 mm × 80 mm, jewelers ensure seamless integration with SuperbMelt CNC machines, avoiding costly re-casting or resizing steps.

Efficient Thermal Management: The crucible’s thickness determines how effectively it withstands extreme temperatures while transferring heat to the material. At 3–5 mm, the quartz crucible strikes the ideal balance—durable enough to handle repeated melting cycles at 1064 °C, yet thin enough to provide rapid, uniform heating for efficient blank formation.

Optimized for Profitability: A well-chosen crucible not only enhances product purity and casting speed but also reduces energy consumption and minimizes rework. This translates into lower operational costs and higher profit margins for manufacturers.

Core Applications of SuperbMelt Gold CNC Machine in Gold Processing

Whether for personalized customization of gold jewelry or mass production, SuperbMelt can achieve efficient and precise processing through its integrated functions while controlling material loss.

4.1, Personalized Processing of Gold Jewelry (e.g., Custom Rings, Exclusive Pendants)

• Operation Process:

a. Import Design File: Upload the customer’s custom pattern (such as handwritten signatures or couple portraits) via USB, and adjust the size and position on the touchscreen.

b. Clamp the Workpiece: Secure the gold blank (e.g., ring blank) with a quick-clamp fixture. The rubber-coated fixture prevents damage to the gold surface.

c. Select Process: For engraving text, choose “flat-end tool + low-speed processing.” For 3D relief patterns, choose “30° pointed tool + A-axis 360° linkage” (the A-axis rotates the workpiece to achieve circular pattern engraving).

d. Start Machining: After clicking “Start,” the equipment automatically cuts. During processing, the waterproof and dustproof cover is sealed to prevent gold dust from scattering. After completion, an oil/water gun is used to wash and collect the recovered gold powder.

• Advantages: Customizing a gold pendant with 3D patterns takes only 20 minutes—over 10 times faster than manual work. With 0.01 mm engraving precision, the patterns are sharp and detailed, leading to higher customer satisfaction.

4.2, Mass Production of Gold Jewelry (e.g., Matching Earrings, Bracelets)

• Operation Process:

e. Batch Clamping: Using a multi-station fixture (optional), 6–8 gold blanks (e.g., earring blanks) can be clamped at once, saving setup time.

f. Program Recall: Save the optimized machining parameters (such as spindle speed and feed rate) as a program. For batch processing, simply recall the program without repeated adjustments.

g. Automatic Machining: After completing one workpiece, the equipment automatically shifts to the next station. The entire process requires no manual intervention. Within 8 hours, 200–300 identical earrings can be produced.

h. Unified Collection: After machining, open the recovery chamber to collect all gold dust at once. The recovery rate remains stable at around 99.8%.

• Advantages: In batch processing, the dimensional tolerance of identical earrings is ≤0.01 mm, fully meeting brand quality standards. Gold dust loss is only 0.2%, saving an additional 4.8% of raw material value compared to manual batch production.

4.3, Ensuring Purity and Polishing Support After Gold Processing

• Purity Assurance: During processing, SuperbMelt’s specialized cooling system prevents gold from oxidizing upon contact with air. The purity of the finished product remains identical to the raw material (e.g., 24K gold retains 99.9% purity), eliminating the need for additional refining.

• Polishing Efficiency: The gold surface after machining is already smooth. Final polishing requires only light sanding with fine sandpaper for 5–10 minutes to achieve a mirror finish. This saves about 30 minutes of polishing time per piece compared to conventional CNC machining.

Selection and Daily Maintenance of SuperbMelt Gold CNC Machine

When selecting equipment, it is important to match it with your processing scale. For daily maintenance, the focus should be on precision retention and component protection to ensure long-term stable operation of the machine.

5.1, Three Key Criteria for Equipment Selection

Processing Scale: For a monthly output of ≤100 pieces, choose the basic model (includes built-in design library and one-click tool change). For 100–500 pieces per month, choose the upgraded model (includes multi-station fixtures and remote fault diagnostics). For ≥500 pieces per month, the equipment can be paired with an automatic loading/unloading system to further improve efficiency.

Product Types: For small items such as rings and earrings, the standard size of 630×590×760mm is sufficient. For large gold ornaments (e.g., gold Buddha statues over 20cm), a customized extended-travel model is required (X-axis travel expandable to 200mm).

Budget & Cost Recovery: The initial equipment investment can be quickly recovered by reducing material loss. For example, with 5kg of gold processed monthly and a 4% reduction in loss, approximately 2kg of gold (worth around $12,000) can be saved each month—allowing the cost of the equipment to be recovered within 2–3 months.

5.2, Four Key Points for Daily Maintenance

Daily Cleaning: After processing, use a soft brush to clean gold dust from the recovery chamber and fixture gaps. Wipe the inner wall of the waterproof and dustproof cover with a dry cloth to prevent residue from affecting the precision of the next process.

Weekly Lubrication: Apply special lubricant to the original Taiwan Hiwin guide rails and ground lead screws (3–5 drops per rail) to keep moving parts smooth and avoid wear that could reduce accuracy.

Monthly Calibration: Use the built-in “precision detection function” to calibrate X/Y/Z axis positioning accuracy. If the error exceeds 0.005mm, contact the manufacturer’s technician for onsite adjustment.

Quarterly Inspection: Check the spindle cooling system and refill with special coolant when needed (do not use ordinary water to avoid spindle rust). Check air source pressure (must remain at 0.55Mpa) to ensure the pneumatic one-click tool change works properly.

Conclusion

In the gold processing industry, “Precision = Quality,” “Low Loss = Profit,” and “Efficiency = Competitiveness.” The SuperbMelt Gold CNC Machine, with its 0.01mm high precision, 99.7%+ gold dust recovery rate, and convenient 220V power supply, is perfectly suited to the needs of small to medium-sized jewelry factories and goldsmith shops. It not only meets the requirements of personalized customization but also ensures stability in mass production, making it the core equipment for improving overall efficiency in gold processing.

Whether from a short-term perspective of “reducing material loss and saving labor” or a long-term perspective of “enhancing brand quality and expanding order capacity,” choosing a dedicated gold CNC machine is the inevitable choice for professionals in the gold processing industry. With its purpose-driven design features, SuperbMelt stands out as the cost-effective solution in this field.

1. Can you CNC machine gold?

Yes, you can CNC machine gold. Gold is actually one of the most common metals processed with CNC machines in jewelry making. Here’s a detailed breakdown:

Why CNC Machining Works for Gold

Softness and Malleability

Gold is relatively soft compared to metals like steel, so it can be precisely engraved, cut, or shaped without excessive tool wear.

Precision

CNC machines can achieve extremely fine details (down to 0.01 mm or better), ideal for rings, pendants, and intricate jewelry designs.

Material Efficiency

With features like a funnel-style processing chamber and precise cutting paths, CNC machining minimizes gold loss, achieving recovery rates up to 99.7–99.9%.

Common CNC Operations for Gold

Engraving 3D or flat designs

Drilling holes for stones or assembly

Carving patterns, textures, or logos

Polishing, brushing, or creating high-gloss/matte finishes

Producing complex 5G/3D effects

Tips

Use sharp, high-quality tools to avoid excessive deformation.

Maintain appropriate spindle speed and feed rates—too high can melt soft gold, too low can cause burring.

Coolant or dry cutting can be used depending on the machine and gold alloy.

2. What is the cheapest metal to CNC?

The cheapest metals to CNC machine are generally soft, abundant, and easy to cut, which reduces tool wear, machining time, and energy consumption. Here’s a clear breakdown:

1. Aluminum

Cost: Low to moderate, widely available.

Pros:

Very soft and easy to machine.

High feed rates possible → faster production.

Minimal tool wear.

Cons:

Can be prone to surface galling (stickiness) if not lubricated.

Uses: Prototyping, casings, structural parts, jewelry base.

2. Brass

Cost: Low to moderate.

Pros:

Soft, excellent for detailed engraving.

Good surface finish without much polishing.

Cons:

Slightly more expensive than aluminum, but still cheap vs precious metals.

Uses: Decorative components, jewelry, gears.

3. Mild Steel / Low-Carbon Steel

Cost: Very low.

Pros:

Cheap and widely available.

Stronger than aluminum → durable parts.

Cons:

Harder than aluminum → slower machining.

May require coolant to avoid heat buildup.

Uses: Functional parts, structural components.

4. Plastics (bonus for CNC beginners)

Cost: Very cheap.

Pros:

Extremely easy to machine.

No coolant needed in most cases.

Cons:

Not a metal → low strength and heat resistance.

Uses: Prototypes, jigs, molds.

3. What materials cannot be CNC machined?

While CNC machines are versatile, not all materials are suitable for CNC machining. Some materials are too hard, brittle, or otherwise incompatible. Here’s a detailed breakdown:

1. Extremely Hard Metals

Examples: Tungsten carbide, certain hardened tool steels (>60 HRC), titanium alloys (some grades).

Why Not: Can rapidly wear out tools, require specialized equipment, or generate excessive heat.

2. Brittle Materials

Examples: Glass, ceramics, some stones, concrete.

Why Not: Likely to crack, shatter, or chip under standard CNC cutting forces.

3. Soft, Sticky Metals (without precautions)

Examples: Lead, pure gold, some soft aluminum alloys.

Why Not: Can gall or stick to cutting tools, causing poor surface finish and tool damage. Special tooling or coatings are needed.

4. Composite Materials

Examples: Carbon fiber, fiberglass, laminated plastics.

Why Not: Fibers can fray, splinter, or damage tools, and dust may be harmful if inhaled. Requires specialized CNC setups.

5. Explosive or Reactive Materials

Examples: Certain pyrotechnic compounds, lithium, magnesium powders.

Why Not: CNC machining can ignite or detonate these materials.

6. Extremely Large or Unstable Pieces

Examples: Massive steel blocks beyond machine capacity, thin sheets prone to vibration.

Why Not: May exceed machine size, weight, or rigidity limits, causing poor accuracy or machine damage.

4. What is the easiest metal to CNC?

The easiest metals to CNC machine are those that are soft, ductile, and generate minimal tool wear. Here’s a clear breakdown:

1. Aluminum

Why it’s easy:

Soft, lightweight, and easy to cut.

High feed rates possible → fast production.

Minimal tool wear compared to harder metals.

Notes: Use coolant or proper lubrication to avoid sticking or burrs.

2. Brass

Why it’s easy:

Soft and excellent for detailed engraving.

Produces smooth surfaces with minimal finishing.

Notes: Slightly harder than aluminum but still very manageable.

3. Copper

Why it’s easy:

Fairly soft, ductile, and conductive.

Notes: Can stick to tools if not properly lubricated; slightly more challenging than aluminum or brass.

4. Mild Steel (Low-Carbon Steel)

Why it’s easy:

Soft compared to hardened steels.

Widely available and cheap.

Notes: Requires more force than aluminum/brass and may need coolant.

Quick Ranking by Ease of CNC

Aluminum (easiest)

Brass

Copper

Mild Steel

Harder metals (e.g., stainless steel, titanium) → harder to CNC

5. What is CNC in gold jewellery?

CNC in gold jewelry refers to the use of Computer Numerical Control (CNC) machines to automatically cut, carve, engrave, or shape gold into intricate jewelry designs. Here’s a clear breakdown:

1. What It Is

CNC (Computer Numerical Control): A technology where a computer controls the movements of a machine’s cutting tools along multiple axes (X, Y, Z, sometimes A/C for rotation).

Application in Gold Jewelry: The CNC machine precisely carves or engraves gold to create rings, pendants, bracelets, earrings, and other pieces.

2. Why Use CNC for Gold

Precision: Achieves extremely fine details (0.01 mm or better) for intricate designs.

Complex Shapes: Can create 3D surfaces, textures, patterns, and even undercuts that are hard to do manually.

Material Efficiency: Minimizes gold waste; recovery rates can reach 99.7%–99.9%.

Automation: Reduces manual labor; automated tool changers increase efficiency and consistency.

3. Common CNC Operations in Gold Jewelry

Engraving 3D or flat designs

Drilling holes for stones or assembly

Carving textures or patterns

Polishing, brushing, or creating high-gloss/matte finishes

Advanced effects like 5G/3D textures

4. Benefits

High repeatability → identical pieces in batch production

Reduces human error

Faster production for custom or complex designs

Ensures consistent quality for luxury jewelry

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited