Anchor Chain Making Machine

Superbmelt provide a one-stop service to solve any problems with your jewelry chain manufacturing line

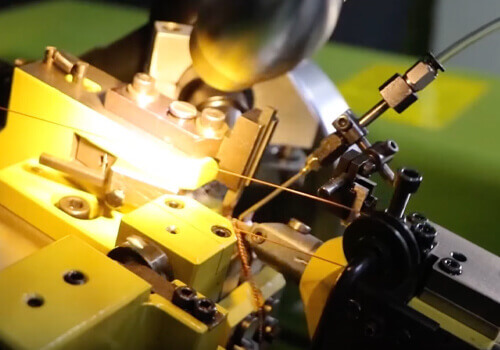

Superbmelt anchor chain making machine is used for making anchor chains with precious metal wires measuring 0.20mm to 1.00mm. The anchor chain makes use of materials such as gold, silver, karat gold, stainless steel, etc, to make chains.

Superbmelt anchor chain making machine is a high capacity and highly automated chain making machine that is fast, gives high precision, high detail, smooth surface finish and long-lasting chains. The automated process also increases production capacity especially for a fast-paced industry like the jewellery making industry. The rope chain making machine is efficient and is able to make up to 400 to 450 links in one minute. The automatic chain making machine is also equipped with a second air blower, electronic speed regulator with brake, low voltage lamp and a chain density sensor, all of which contributes to the effective production of the chain making machine. The chain making machine is made with excellent steel material that is easy to maintain and ensure long service life.

We at Superbmelt are focused on giving our customers optimum quality from every machine bought from us. Contact Superbmelt today for your affordable and quality automatic anchor chain making machine.

- Superbmelt anchor chain making machine is used for making different sizes of jewellery anchor chains. The chain making machine is able to produce multiple designs on the same chain allowing you to create unique and distinct jewellery chains.

- The gold chain making machine for sale performs an automated operation from start to finish. Pre-setting the number of links to be produced contributes to higher productivity and quality.

- The automated jewellery chain making machine is highly efficient due to its automatic mode of operation. This means that there are no errors when producing. Automation also means a fast production process, saving you cost and time of production.

- By using the automatic anchor making machine through its robotic technique and PLC system ensures the correct positioning of the links during the whole process which makes it possible to run fully automatic.

- The energy consumption is low because the welding process takes place immediately after the forming operation. The maximum power required is 200W.

- The jewellery chain making machine sold by Superbmelt is made with quality and durable materials that require low maintenance. It also ensures that you save cost on replacing machine parts.

- Producing jewellery chains using a Superbmelt gold chain making machine is more efficient and limits error rates compared to the traditional method of producing. It is also faster than the traditional production method. The maximum speed is 150mm/s.

- Superbmelt gold and silver chain making machine is compact in design and requires minimal space. It has a dimension of 420*750*550mm and has a weight of 75kg.

- Superbmelt anchor chain making machine uses materials like copper, gold, silver and other metals to produce chains that are used as fashion accessories.

- The chain making machine is safe for the environment. It also does not require multiple operators. This saves cost on manual labour.

- The minimum size of 20mm and a maximum size of 90mm anchor links can be produced with a Superbmelt gold anchor chain making machine.

- The modern anchor chain making machine produces high-strength anchor chains that make it difficult to break.

| Type | 450 high speed single, double, cross chain making machine |

| Voltage | Single phase 220v |

| Power | 200W |

| Wire size | 0.19-0.45mm |

| Speed | 100-150 |

| Dimension | 420*750*550mm |

| Weight | 75KG |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Anchor Chain Making Machine

Any Question About SuperbMelt Anchor Chain Making Machine

Full Process Analysis of Anchor Chain Manufacturing: From Gold Wire to Finished Chain

Raw Material Preparation: Metal Wire Processing

Raw material preparation is the foundation of chain quality. The main goal is to process the metal wire into specifications that meet chain-making requirements to ensure stability during forming and welding.

Wire Material Selection:

Choose materials based on the chain’s application. Common options include:

Low-carbon steel wire (for standard industrial chains, tensile strength ≥400 MPa)

Stainless steel wire (304/316) (for corrosion-resistant applications such as outdoor use or food machinery)

Copper alloy / aluminum alloy wire (for lightweight decorative chains such as jewelry chains)

High-strength alloy steel wire (for heavy-duty chains such as lifting equipment, tensile strength ≥800 MPa)

The wire diameter must match the chain specification, with a tolerance of ±0.02 mm.

Pre-processing Steps

Rust & Oil Removal:

Use pickling (for industrial chains) or ultrasonic cleaning (for precision/decorative chains) to remove oxide layers and oil. After pickling, neutralization, rinsing, and drying are required to ensure no acidic residue remains (pH 6.5–7.5). Decorative chains may include an additional polishing step to improve surface smoothness.

Wire Drawing:

Send the cleaned wire through a drawing machine to achieve the required diameter (e.g., 2.0 ± 0.01 mm wire for a 2 mm chain link). Control drawing speed at 5–10 m/min to avoid breakage or surface scratches. After drawing, wire roundness must be ≤0.03 mm.

Cut-to-Length:

According to link size, use an automatic cutting machine to cut the drawn wire into equal sections (length tolerance ±0.1 mm). Cut surfaces must be flat and burr-free to avoid affecting the accuracy of chain forming.

Chain Forming: Automatic Anchor Chain Making

The core of chain forming is to use an anchor chain-making machine to process the cut wire segments into chain links and automatically assemble them into a continuous chain. The key is to ensure link size consistency and smooth linking.

Equipment Setup:

Install the appropriate molds according to the chain type (round link chain, oval link chain, side chain, etc.) and adjust parameters such as forming pressure, bending angle, and feeding speed.

For example, when producing round link chains, the mold radius must match the link radius (tolerance ≤0.05 mm), and the forming pressure should be set between 30–50 tons to ensure that the links are formed without deformation or cracks.

Automatic Chain-Making Process

1. Feeding:

The cut wire segments are fed into the machine through an automatic feeder with a feeding accuracy of ±0.03 mm to avoid length variation between links.

2. Bending & Forming:

Under hydraulic pressure, the mold bends the wire into the preset link shape (round, oval, etc.).

Bending speed is controlled at 1–2 cycles per second to prevent wire breakage caused by stress concentration.

3. Linking:

The formed link is precisely connected to the previous one by the machine’s automatic linking mechanism.

The connection gap must be ≤0.1 mm to ensure smooth chain rotation without jamming.

4. Quality Inspection:

During production, one sample is checked for every 100 links.

Measurements include:

inner width

outer width

pitch

Acceptable pitch error is ±0.2 mm.

The operator must also check for deformation, cracks, or surface scratches. Defective links must be removed immediately and machine parameters adjusted accordingly.

Welding Process: Ensuring Chain Strength

Welding is a critical process in chain manufacturing. Its purpose is to permanently join the link’s interface, ensuring the chain’s tensile strength and service life. The appropriate welding method must be selected based on the chain’s material and intended application.

3.1, Flame Welding

Applicable Scenarios:

Mainly used for low-carbon and medium-carbon steel industrial chains (such as lifting chains and conveyor chains). It is suitable for large-size chain links (diameter ≥5 mm). The equipment cost is low, operation is flexible, and on-site repair is possible.

Key Process Points:

Welding Materials:

Use welding wire that matches the base material (e.g., ER50-6 wire for low-carbon steel chains). Select the wire diameter according to the chain link diameter (for chain link diameters of 5–10 mm, use welding wire with a diameter of 1.2–2.0 mm).

Flame Adjustment:

Use an oxygen–acetylene flame and set it to a neutral flame (oxygen to acetylene ratio 1:1). Control flame temperature at 2800–3100°C to avoid oxidizing flames (which cause excessive metal burn-off) and carburizing flames (which increase carbon content in the weld and reduce toughness).

Welding Operation:

Align the chain link joint at the center of the flame and heat it until it reaches a molten state (≥1538°C). Feed welding wire to fill the joint. Control welding speed at 5–10 mm/s to ensure a full, defect-free weld with no porosity or slag inclusion. The weld height should be ≥1/3 of the chain link diameter. Allow the weld to cool naturally or cool slowly (to avoid cracking caused by rapid cooling).

Quality Standards:

Tensile strength of the weld shall be no less than 90% of the base material. In the bending test, the chain should withstand 10 repeated bends without weld failure. The weld surface must be free from significant depressions and porosity (pore diameter ≤0.5 mm, no more than 3 pores per meter).

3.2, Laser Welding

Applicable Scenarios:

Suitable for materials such as stainless steel, copper alloys, and aluminum alloys. It is especially ideal for precision chains (e.g., jewelry chains, medical instrument chains) and small-size chain links (diameter ≤5 mm). It offers high welding accuracy, a small heat-affected zone, and aesthetically clean welds.

Key Process Points:

Equipment Parameters:

Use a fiber laser welding machine (500–1500 W). Adjust the laser power according to the chain link diameter (500–800 W for 2 mm links; 1000–1500 W for 5 mm links). Welding speed: 10–20 mm/s; laser spot diameter: 0.2–0.5 mm; focal length: 150–200 mm.

Welding Preparation:

Fix the chain on a special clamping fixture to ensure the chain link joint is properly aligned (alignment error ≤0.05 mm). The welding area must remain clean (free of oil and dust). Use argon shielding gas when needed (flow rate 5–10 L/min) to prevent weld oxidation.

Welding Operation:

Use continuous or pulsed laser welding (pulsed mode recommended for precision chains, pulse frequency 10–20 Hz). Scan evenly along the joint to ensure full weld penetration and avoid incomplete fusion. Precision chains require no post-grinding; industrial chains may need light grinding.

Quality Standards:

Weld tensile strength must be no less than 95% of the base material. Weld width ≤0.8 mm; heat-affected zone ≤1 mm; surface roughness Ra ≤1.6 μm. No oxidation discoloration should appear (when using shielding gas).

Annealing: Improving Chain Softness and Flexibility

The core purpose of annealing is to eliminate internal stresses after welding, reduce chain hardness, and improve flexibility and ductility, preventing fractures caused by stress concentration during use.

Process Selection:

Low-carbon steel chains: full annealing (heat to 730–800°C, hold for 1–2 hours, cool with the furnace).

Stainless steel chains: solution annealing (1050–1100°C, hold for 30–60 minutes, water or air cooling).

Copper alloy chains: low-temperature annealing (300–400°C, hold for 2–3 hours, natural cooling).

Operation Points:

Place welded chains neatly in the annealing furnace, leaving gaps between chains (≥5 mm) to ensure uniform heating and avoid local overheating or insufficient annealing temperature.

Strictly control the heating rate (5–10°C/min) to prevent deformation from sudden temperature rise. Maintain stable furnace atmosphere during holding (use nitrogen for industrial chains, vacuum for precision chains).

Cooling must follow process requirements: full annealing should cool with the furnace to below 200°C before removal; solution annealing requires rapid cooling (water quench) to ensure corrosion resistance of stainless steel.

Quality Effects:

After annealing, chain hardness is reduced (low-carbon steel HB ≤180, stainless steel HB ≤200), flexibility improves, and the chain can withstand repeated 180° bending 5 times without breaking. Internal stress relief rate ≥90%.

Straightening and Cleaning

Straightening and Cleaning aim to correct the chain’s straightness and link flatness, and remove residual oil, welding slag, oxide scale, and other impurities from production, providing a clean surface for subsequent finishing.

5.1 Straightening

Equipment and Operation: Use a chain-specific straightening machine. Feed the annealed chain between the straightening rollers, adjusting roller pressure (10–30T) and spacing to achieve chain straightness error ≤0.5 mm/m and link flatness error ≤0.1 mm. For precision chains, manual straightening assistance can be applied to ensure each link rotates smoothly without tilting.

Quality Check: After straightening, measure chain straightness with a straightness tester and link flatness with a straightedge. Severely deformed links should be individually corrected or removed.

5.2 Cleaning

Cleaning Methods:

Industrial Chains: Use ultrasonic cleaning (frequency 28–40 kHz, power 500–1000 W) with an alkaline cleaning solution (5–10% concentration). Clean at 50–60°C for 10–15 minutes to remove welding slag and oil. Rinse three times with water and dry in an oven at 80–100°C for 30 minutes.

Precision / Decorative Chains: Use vacuum cleaning or organic solvents (e.g., ethanol, acetone) to avoid residue affecting surface luster. After cleaning, dry with hot air at 60–80°C for 15 minutes.

Cleaning Standards: After cleaning, the chain surface should be free of oil, welding slag, and oxide scale. No water marks should remain after rinsing, and pH should remain neutral (6.5–7.5).

Surface Treatment: Polishing and Electroplating

Surface Treatment is a key step to enhance the chain’s appearance, corrosion resistance, and service life. The appropriate method should be chosen according to the usage scenario and customer requirements.

6.1 Polishing

Applicable Scenarios: Suitable for decorative chains (e.g., jewelry chains, bag chains) and industrial chains requiring high surface finish. The purpose is to remove surface scratches and burrs while improving gloss.

Polishing Process:

Rough Polishing: Use a polishing machine with a silicon carbide wheel (grit 80–120), speed 1500–2000 r/min, to remove major surface defects. Duration: 5–10 minutes.

Medium Polishing: Switch to an aluminum oxide wheel (grit 200–400), speed 2000–2500 r/min, to refine the surface further. Duration: 10–15 minutes.

Fine Polishing: Use a wool wheel with polishing compound (chromium oxide or diamond paste), speed 2500–3000 r/min, duration 15–20 minutes, to achieve a mirror finish (surface roughness Ra ≤0.2 μm).

Quality Standards: After polishing, the chain surface should be free of scratches, burrs, and compound residue, with uniform gloss and no local dark or bright spots.

6.2 Electroplating

Applicable Scenarios: Suitable for chains requiring corrosion resistance, wear resistance, or specific colors, such as outdoor industrial chains (galvanized) and decorative chains (gold-plated, silver-plated, copper-plated, nickel-plated).

Electroplating Process (Gold Plating Example):

Pre-treatment: Activate the polished chain by soaking in 5% dilute sulfuric acid for 3–5 minutes to remove the oxide layer, then rinse with clean water to ensure plating adhesion.

Plating Parameters: Use acidic gold solution (Au content 5–10 g/L), temperature 40–50°C, current density 0.5–1.0 A/dm². Plating time depends on desired layer thickness (typical decorative layer 0.5–2 μm, time 10–30 minutes).

Post-treatment: Rinse 3–5 times with clean water to remove residual plating solution, perform passivation to improve corrosion resistance, and dry at 60–80°C for 20 minutes.

Quality Standards: Coating should be uniform (thickness tolerance ±0.1 μm), strongly adherent (no peeling in cross-cut test), free of pinholes, bubbles, or blistering. Corrosion resistance must meet standards (neutral salt spray test: 48 hours without rust). Decorative chain plating color should be uniform and match the customer’s specified color.

FAQ Guide of Anchor Chain Making Machine

- 1. What does the anchor chain look like?

- 2. How is the anchor chain produced?

- 3. What karat gold is best for chains?

- 4. How is chain welded in the production process?

- 5. What machines are used to process materials into anchor chains?

- 6. What are the different types of jewelry chain on the market?

- 7. What is the capacity of the SuperbMelt anchor chain-making machine?

- 8. What is the best material for an anchor chain-making machine?

- 9. What are the safety features of an anchor chain-making machine?

- 10. Does operating a SuperbMelt anchor chain-making machine require special training?

- 11. How to choose the best anchor, chain-making machine manufacturer?

- 12. How do you repair an anchor chain?

- 13. How long does a gold chain last?

- 14. Which gold chains are the strongest?

- 15. Is a jewelry chain a good investment?

- 16. How do you make gold jewelry shiny?

1. What does the anchor chain look like?

An anchor chain has the look of a jump ring. It has a bar running through it. Smaller versions of gold anchor chains serve as jewelry for both men and women. The primary materials for making an anchor chain are gold and silver. It closely imitates the chains used to hold ship anchors for securing the water vessels while docked at the port.

You can quickly get several variants of anchor chains depending on the machine you choose for the chaining process. For example, anchor chains might have smooth rounded surfaces or flat outer surfaces. They are popularly used to make necklaces, even though some people may make anchor chain bracelets.

2. How is the anchor chain produced?

The process of producing the anchor chain starts with creating a gold rod either manually or using a machine. Of course, the manual process of making the gold rod is slow and tedious. It requires patience and long years of experience working with gold. After making the gold rod, the jewelry maker must manually fold, cut, and solder the anchor chain links.

It is much easier to create anchor chains using a SuperbMelt machine. The machine can do everything from purifying the gold, creating gold rods, and creating jewelry chains. Using the device to develop gold rods means you can produce circular, cylindrical, or rectangular shapes faster than manually. Besides, the anchor chain-making machine can further reduce the gold rods into thin wires depending on the type of anchor chain for wish to create.

Once the gold wire is ready, a jeweler passes it through the machine, forming an anchor chain through buckling, bending, and welding. The process is entirely automatic and doesn’t require any manual work from the jeweler. Since there is no manual process involved, the machine makes high-quality, perfectly shaped anchor chains.

3. What karat gold is best for chains?

When made of pure gold, a gold chain would have 24 karats of gold. However, the chain doesn’t have to be composed of 100 percent pure gold. Thus, it can be ten karats, 14 karats, 18 karats, or 22 karats, which isn’t composed of pure gold. However, the karat gold best for chains is 14 and 18 karats, which have a perfect combination of strength and beauty. A higher karat gold may result in weak chains, while a lower karat gold doesn’t produce the best color of gold.

4. How is chain welded in the production process?

During the production process, welding depends on the type of jewelry chain-making machine you choose. For example, an anchor chain-making machine may utilize plasma or laser welding. Between the two, laser welding is the fastest method of joining two jewelry pieces. Now, plasma welding is a precision method for making gold chains. The chain manufacturing machine automatically welds the gold wire as it passes through it, creating a beautiful chain in the end. Either argon or helium acts as the plasma gas. The machine relies on the plasma gas to 5 percent of hydrogen for shielding.

The gold chain manufacturing machine may also rely on the laser welding method. This works by focusing laser beams on the parts that require welding. Given the minute nature of the gold chain, laser welding is more accurate than plasma welding due to the precision with which the machine targets the critical area. An anchor chain-making machine that utilizes laser welding is automatic, indicating that the welding happens without the intervention of a welder.

5. What machines are used to process materials into anchor chains?

You can process materials for anchor gold chains using various types of machines from SuperbMelt. Each gold chain manufacturing device has its advantages and disadvantages, which are to consider when choosing a suitable machine. The following are some of the most common machines used to process materials into gold anchor chains.

- Continuous Casting Machine: An anchor chain-making machine of this type mainly works by casting precious metals such as gold and silver. Instead of welding gold wire, it casts it into the desired shape. Regardless of the gold chain-making machine manufacturers, they casts the metal into any desired shape. It utilizes the gas melting protection technology that helps you to enjoy accurate, automated temperature control. Ask for the chain-making machine priceto get a quotation from your favorite manufacturer.

- Jewelry Roll Mill: The jewelry roll mill machine has two smooth, hardened, and highly polished electric steel rollers that remove the need for manual rolling. Besides, electric mills are great when it comes to making many gold chains at a go. Similarly, different chain-making machine manufacturers may produce machines with varied capabilities, including thickness requirements. However, devices of this kind are great for semi-finished gold jewelry.

- Wire Drawing Machine: A wire drawing chain-making machine takes a thick gold wire and turns it into a thin wire for forming the chain links. Thus, the device makes it possible for you to attain the correct wire diameter, straightening degree, roundness, internal construction, and roughness before turning the wire into a chain. The machine utilizes motor technology with step-less speed modulation. The anchor chain-making machine has an automatic rewind feature and cooling system that automatically stops it once it finishes.

- Anchor Chain Making Machine: The anchor chain-making machine is a must-have for anyone wishing to make attractive jewelry. It can produce anchor chains as well as those with other types of chain links. The chain-making process involves the spiraling of the wire followed by sectioning. The chain manufacturing machine is versatile and capable of producing different chain styles. Besides, it can handle different metals, including silver, copper, and other precious metals. SuperbMelt is one of the leading gold chain-making machine manufacturers. To get the chain-making machine price, ask your favorite manufacturer for a quotation.

- Jewelry Hammering Machine: As one of the leading jewelry chain-making machine manufacturers, SuperbMelt has some of the best products on the market. Its jewelry hammering machine comes with all the necessary accessories and is low maintenance, corrosion resistant, has robust build quality, and is sturdy. It helps you avoid hammering your gold chains manually.

- Anchor Chain Faceting Machine: The primary purpose of a chain faceting machine is to decorate gold or silver chains. Thus, gold chains produced using this machine have extra decorations that others might be lacking. The device has high strength, reliable performance, longer service life, smooth finish, and requiring little or no maintenance.

- Annealing Furnace: An annealing furnace heats the metal and alters its physical or chemical properties, reducing its hardness and making it more malleable. It heats a metal above the recrystallization temperature and cools it after maintaining the temperature for a while. As the machine heats the metal, it provides enough energy to break bonds for the eventual recrystallization of the metal.

6. What are the different types of jewelry chain on the market?

There are various types of jewelry chains on the market, including box chain, ball chain, curb chain, rope chain, anchor chain, trace chain, belcher chain, hayseed chain, snake chain, bead chain, mariner chain, and cable chain. The details of each of these chain types appear below:

- Box Chain

The box chain features unique square links that connect carefully, creating a smooth chain. Even though they were initially handmade, modern box chains are products of machines. The unisex chain is excellent for both men and women.

- Ball Chain

Thanks to the tiny balls that make up this particular chain, it looks more elegant than most other chain types. Anyone can make it using an automatic chain-making machine designed to create this specific design and others.

- Curb Chain

The curb chain has links that appear more flattened out than other chains. It is heavier and features twisted links with an interlocking design. Both men and women love this type of chain in equal measure.

- Rope Chain

A typical rope chain has different metal segments with twisted patterns that look like a rope. It is easy to make using a gold chain-making machine. The rope chain is the heaviest and most durable of all gold chains and is worn with various pendants.

- Trace Chain

A popular type of chain, this jewelry comes with a variety of oval-shaped links. Even though it has a minimalistic look, the chain is one of the finest in the market. It is a simple design that any jewelry maker can pull through with a suitable chain-making machine.

- Belcher Chain

The name for the belcher chain is the Rolo chain. Even though almost similar to the trace chain, its links are a little wider. Due to its sturdiness, the chain is popular among men even though women can still wear it and look great.

- Hayseed Chain

The hayseed chain is lightweight, beautiful, and looks fantastic. It features delicate detailing thanks to its intricate linking. Therefore, you can always expect it to sparkle against the light whenever you step out of your house wearing it.

- Snake Chain

Also known as the Brazilian chain, the snake chain has a different look than other chain types. Instead of creating links, a chain manufacturing machine tightly weaves metal plates to produce a flexible, durable chain.

- Bead Chain

The bead chain has small meta spheres or tiny balls on almost all its links. It is a fantastic jewelry design for those looking to create much more than a gold chain. Each of the bead-containing links joins together with connector bars.

- Mariner Chain

Inspiration for the manufacturing of the mariner chain is from the nautical world. It resembles the anchor chain often used to hold a ship’s anchor and hold a water vessel while docking. Consequently, it is also known as the anchor chain. It consists of multiple interlocking ovals with bars welded in the middle.

- Cable Chain

The cable chain also comes with oval links to create a beautiful, functional chain. It can either be worn on its own or together with an attractive pendant. Apart from its beauty, the chain is uncomplicated, sturdy, and durable.

- Singapore Chain

Singapore chains are durable, featuring multiple interlinked segments. Upon stretching it out, you will get a twisting open chain with an exquisite look. Thanks to its durability, a Singapore chain can hold a pendant without breaking down. Thus, it is more attractive to wear compared to other chains that cannot have a pendant.

- Spiga Chain

A Spiga or wheat chain is a beautiful piece of jewelry composed of several twisted oval links. It looks like it is composed of numerous metallic fibers running against each other, creating a unique textural look. It is one of the sturdiest and most durable gold chains on the market.

7. What is the capacity of the SuperbMelt anchor chain-making machine?

The capacity of the SuperbMelt anchor chain-making machine is 600 rpm per minute, which is fast enough to produce jewelry weighing 200 to 500 grams per hour. That’s faster than products from other gold chain-making machine manufacturers. With that kind of capacity, why would you want to go back to making anchor gold chains manually?

8. What is the best material for an anchor chain-making machine?

The best material for an anchor chain-making machine is any soft metal, including gold, silver, and platinum. Gold is smooth when 100 percent pure (24 karats) with a 2.5 to 3 rating on the Mohs hardness scale. Therefore, 24 karat gold isn’t the best for making anchor chains. The best material is 14 karat, 16 karats, or 18 karat gold, which are tough and feature a distinctive gold color.

On the other hand, silver is ductile, soft, and malleable, making it one of the best materials for making anchor chains. It is also highly reflective and easy to polish to give it a unique luminous sheen. Compared to gold, silver is more affordable, falling within the average person’s budget. Using this material may require you to have a specialized silver chain-making machine.

The last type of material for making anchor chains is platinum, which has a silver-white appearance. It is malleable, super dense, durable, and tarnish-proof. Its malleability means that platinum is the best in making anchor chains of any size.

9. What are the safety features of an anchor chain-making machine?

The anchor chain-making machine has several safety features, including automatic rewinding and automatic cooling. That ensures that the device can stop working as soon as it finishes producing the last chain. Even if you weren’t focusing on it, it will stop and prevent an accident from occurring.

10. Does operating a SuperbMelt anchor chain-making machine require special training?

No. Operating the SuperbMelt anchor chain-making machine does not require special training. However, the chain-making machine manufacturers have availed easy-to-follow videos and instructional materials by highly trained engineers and laypeople. Once you have gone through the materials, you can start using the machine without debugging (that’s done before shipment) it. If you ask for it, the manufacturer can provide on-site guidance and training for your staff members.

11. How to choose the best anchor, chain-making machine manufacturer?

You can choose the best anchor, jewelry chain making machine manufacturer by checking out for any available certificates and the scale of the factory. While the certificates indicate the manufacturer’s ability to make the best machines, the scale of the factory suggests how long you might have to wait to receive your device.

Also, you should check whether the factory provides adequate solutions to your needs as a jewelry manufacturer. Checking online reviews from past customers can also show you whether or not the factory can deliver on its promise. Besides, you can visit the manufacturer’s website, social media platforms, videos, or carry out in-depth investigations. Visiting the factory can also help you make an informed decision on whether or not you should choose it.

12. How do you repair an anchor chain?

13. How long does a gold chain last?

A gold chain can last for a long time, especially if made from 14 karats, 16 karats, or 18 karat gold. Unlike gold-plated jewelry, which fades with time, the solid gold chain retains its color for a long time. The only problem with that type of chain is that it may tarnish, requiring you to polish or wash it from time to time.

In the case of a gold-plated chain, it can last for only two years before the layer of gold starts wearing off. Gold chains can get ruined when they contact chlorine, dirt, and small abrasive rocks. When you notice the build-up of dirt, make sure you clean the chain before it becomes permanently ruined.

14. Which gold chains are the strongest?

Experts recommend rope chains as the most robust and durable, thanks to the tight way the links hold together. Rope chains also have a unique texture that makes them look more elegant than most other chain types. Besides, their textual look and unique design put them in a pole position when holding pendants.

Whether you choose a thin or thick rope chain, you will still get the very best in terms of strength and durability. You can use a state-of-the-art gold chain-making machine to create a sturdy rope chain that lasts for a long time. Apart from the necklace type, the 14 karat, 16 karat, and 18 karat gold chains are stronger and more durable than those made from pure gold.

15. Is a jewelry chain a good investment?

Yes. A jewelry chain is a good investment, especially if made from solid gold, which appreciates with time. However, it is made from gold shouldn’t be the only consideration when choosing a gold chain. Choosing an enduring design is an excellent way of ensuring that your jewelry maintains or appreciates with time. When the time comes to sell it, you can be sure of fetching a lot of money from it.

16. How do you make gold jewelry shiny?

You can make gold jewelry shiny using a solution of dishwashing detergent. After making the dishwasher solution, add several drops of ammonia, dip the jewelry in it for a few minutes, and brush with a soft brush. When you are through, clean the jewelry piece using lukewarm water. Alternatively, you may use a chain faceting machine to make a gold chain shiny.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited