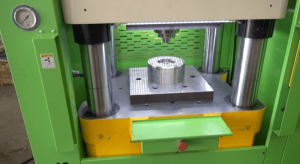

500 ton Hydraulic Press

Superbmelt 500 ton hydraulic press machine is used in every metal processing and forming operations such as embossing, forging, blanking, punching, moulding, etc. The 500 ton hydraulic pressing machine is automated and has the capacity of pressing 500 tons of metals. The press makes use of any hydraulic that makes it easy to control the pressure and speed of stamping. Superbmelt hydraulic press machine is multifunctional in addressing a wide variety of metal forming technologies. This is why it is used in industries like aerospace, automotive, thermoplastic, carbon fiber moulding and so on.

Even though the 500 ton press machine is simplistic in its design, it performs high quality and efficient operations for metal productions. Compared to mechanical presses, it is quiet and safe in operation due to the inbuilt overload protection. In terms of operating the press machine, it is easy due to the automated features. Contact Superbmelt for your 500 ton press machine.

| Item | Unit | SPB-500TP | SPB-500TS | |

| Photo |  |  | ||

| Rated capacity | Ton | 500 | 500 | |

| Max. system pressure | Mpa | 25 | 25 | |

| Max. stroke of working table | mm | 150 | 150 | |

| Open height | mm | 450 | 450 | |

| Height of movable working table | mm | 1185 | 850 | |

| Upward speed of movable working table | mm/s | 80 | 215 | |

| Returning speed of movable table | mm | 80 | 200 | |

| Movable working table size | L-R | mm | 710 | 600 |

| F-B | mm | 640 | 560 | |

| Overall dimension | L-R | mm | 1440 | 1480 |

| F-B | mm | 1370 | 1520 | |

| H | mm | 2080 | 2300 | |

| Motor power | kw | 15 | 23 | |

| Weight (Approx.) | kg | 5500 | 6700 | |

- Superbmelt 500 ton hydraulic press has the capacity of pressing about 500 tons of metals. This capacity is suitable for medium and large scale stamping requirements.

- In deep drawing applications, Superbmelt machine press is applicable in aluminium cans, steel utensils, LPG cylinders, fire extinguishers, etc.

- The hydraulic press helps you to save on operating costs through the reduced energy use and the number of manual labour required. A single worker can operate the hydraulic press irrespective of the production capacity.

- The innovative technology embedded in the Superbmelt 500 ton hydraulic press makes it highly automated. Also, the use and control of the stamping press are easy with the PLC control unit. The unit makes pressing more convenient.

- The servo motor driven system controls the speed and pressure of pressing precious metal coins. The servo motor driven system also ensures the stability of the machine and controls the noise of the machine.

- The hydraulic stamping machine requires 15-23kw of power. With this pressing machine, you save up to 40% to 60% of energy. Energy-saving and speed of stamping help to reduce production costs while maintaining a high level of efficiency.

- Superbmelt hydraulic press machine is the complete opposite of the CNC pressing machine. This is because of the automation, hydraulic system, speed and accuracy of stamping.

- Superbmelt 500 ton is powerful enough to process high-strength materials. As a result of this, heavy duty machines are a necessary component in industries such as automotive, aviation, military, etc.

Why SuperbMelt 500 ton Hydraulic Press

Any Question About SuperbMelt 500 ton Hydraulic Press

315T vs 500T Hydraulic Press: Choosing the Right Press for Gold Ingot Production

In precious-metal manufacturing, press tonnage is critical to final gold ingot quality and production efficiency. Pure gold bars must achieve a density around 19.32 g/cm³. If a press is too weak, bars can have internal voids or cracks, dropping density and rendering them unmarketable. Using the correct press strength ensures dense, defect-free bars; the wrong choice leads to scrap, hidden costs, and production delays. In this guide, we explain why tonnage matters and how 315‑ton vs. 500‑ton presses compare, helping you match press capacity to your product and throughput needs.

Why Tonnage Matters

Gold’s exceptional density (≈19.32 g/cm³bullionbypost.co.uk) means even minor gaps in a bar are unacceptable. Industry standards require near-solid bars; any deviation in weight or volume can dramatically affect value. As one bullion expert notes, “Even a tiny deviation in weight can shift a bar’s total price”pacificpreciousmetals.com. Low-density bars also warp under rolling or forging, causing cracks. Any internal void or crack is a fatal defect – for example, the London Bullion Market Association warns that shrinkage cracks make a bar “unacceptable” for deliverylbma.org.uk.

Key risks of insufficient press tonnage include:

Low Density / Void Formation: Inadequate pressure leaves micro-porosity. Bars may weigh less than their volume implies (e.g. a “1 kg” bar might only weigh 950 g), eroding material valuepacificpreciousmetals.com. Voids also undermine bar strength, risking failure in later processing.

Cracking: Uneven internal stress causes visible or hidden fractures. These bars must be remelted; LBMA guidelines specifically cite such cracks as disqualifyinglbma.org.uk.

Springback and Deformation: Metals rebound elastically after forming. A weak press cannot fully overcome this springback, so edges sag and shapes distort. For instance, a rectangular ingot might cave in along corners or warp if pressure is insufficient.

High Rework/Scrap Rates: Defective bars require remelting and re-pressing, incurring extra time, energy, and labor. Over years, even a 5% rework rate in a high-volume line can cost tens of thousands of dollars. (For example, reworking 5% of 1001 kg bars/day over 3 years adds ~5.5 tonnes of reprocessed gold – a significant hidden expense.)

Meeting quality standards (e.g. LBMA or COMEX) means density and precision are non-negotiablepacificpreciousmetals.com. Therefore, selecting the right press tonnage is the first step to consistent, compliant production.

315T vs 500T: Core Differences

Both 315‑ton and 500‑ton hydraulic presses are common in ingot production, but they serve different niches. The differences go beyond the “500” vs “315” label; they affect forming power, compatible bar sizes, final bar quality, and production stability. Key contrasts include:

Actual Forming Pressure: The nominal tonnage is not the full story. Due to fluid losses and machine limits, a 315T press delivers roughly 85–90% of that pressure (≈270–284 tons) under ideal conditions. A 500T press can similarly deliver ~425–450 tons of actual force. In practice, this means:

315T press can fully compact small, high-purity gold charges (100–500 g bars, or very thin 1 kg bars). But it struggles on thick or heavy loads: a 1 kg bar thicker than ~20 mm often won’t reach full density because the pressure over the larger area is insufficient.

500T press has ample reserve. It can easily handle 1–5 kg bars (up to ~30–40 mm thick) in a single stroke. Even larger bars (5–10 kg, ~50 mm thick) or lower-purity scrap charges can be fully densified because of the extra force.

Compatible Bar Sizes: In practical terms:

Small ingots (0.1–0.5 kg): Both presses handle these comfortably; 500T simply has extra capacity.

Standard bars (~1 kg): 315T works only if the bar is thin (~≤20 mm). Thicker 1 kg bars will come out under-dense or need multiple presses. A 500T press can make a thick 1 kg bar (30–40 mm thick) in one go, with stable density.

Medium bars (2–5 kg): 315T is marginal – it may require two-stage pressing and often yields a lower first-pass density. 500T easily forms these bars at full density in one cycle.

Large bars (>5 kg): 315T effectively cannot produce dense large bars – expect cracks or incomplete compaction. 500T can form very large ingots (up to ~50 mm thick) for industrial applications.

Compression Quality and Appearance: The higher-pressure 500T press consistently achieves densities at or above 19.28–19.32 g/cm³ (meeting the 19.32 standard) for all bar sizes. A 315T press often reaches ~19.2–19.25 in its optimal small-bar cases, but will fall short (e.g. ~19.0–19.1) on heavier loads. 500T bars tend to be fully solid with no voids. Edge quality is also better: low-tonnage presses often leave edges “caved-in” or “rounded” (requiring post-press grinding), whereas bars pressed with sufficient force have crisp, flat edges and smooth surfaces ready for delivery.

Production Stability and Durability: Continuous operation is critical in industry. A 315T press under high load heats up faster and shows greater pressure fluctuation (often ±5% in output). Running it beyond its comfort zone accelerates wear: seals and cylinders need replacement more often, and minor pressure spikes can appear. By contrast, a well-built 500T press (usually with a rigid cast frame and dual hydraulic pumps) maintains very stable output (fluctuations around ±2%) even in high-speed production. In normal use (e.g. pressing 100 + bars/day), a 500T machine operates well below its maximum capacity (often only 60–70% loaded) – this means less wear and longer service life. Industry experts recommend keeping a safety margin (typically 15–20% above required force) to avoid stressharsle.com, which the 500T inherently provides.

In summary: 315T is suited to small-scale, light-load pressing, whereas 500T provides the extra “headroom” for larger bars, tougher materials, and nonstop production.

Matching Press to Production Needs

Choosing between 315T and 500T depends on your product mix and throughput. Here are general guidelines:

Small-batch or Pilot Production: If you are producing few bars per day (e.g. ≤50/day) and they are mostly small (≤500 g) or thin 1 kg bars, a 315T press may suffice. Its advantages are lower cost, smaller footprint, and simplicity (often about US$21k–35k new). It consumes less power idle and can be a good fit for startups or trial lines. However, remember its limits: if you later expand to larger bars, you will need new equipment.

Large-scale Production (1–5 kg Bars): For daily outputs ≥100 bars or when producing standard 1–5 kg bars (especially if using recycled/less-pure gold), a 500T press is strongly recommended. It ensures you meet quality standards without rework, and it can handle spikes in demand or thicker bars with no extra delay. The US$42k–63k initial investment pays off through higher first-pass yield, faster cycle times, and less downtime. It’s the norm for industrial and financial-grade ingot production.

Expansion Planning: Some companies wonder if they should “go big” from day one. If you have firm plans for volume growth or large-bar orders in 1–2 years (e.g. stable contracts, entry into high-end markets, or significant recycling operations), it’s often wiser to buy the 500T outright. This avoids a future retrofit/upgrade (and the associated downtime and extra cost). On the other hand, if your future is uncertain and budgets are tight, you can start with 315T but plan for upgrade. At minimum, ensure your facility (floor space, power, foundations) can accommodate a 500T later.

Tonnage by Daily Throughput: As a rule of thumb:

≤50 bars/day (100–500 g bars): 315T is usually enough.

50–100 bars/day (0.5–1 kg bars): Use 315T if most are <500g; use 500T if >50% are 1 kg thick bars (for efficiency and yield).

100–200 bars/day (1–2 kg bars): 500T recommended. A 315T will struggle to maintain consistency at this pace.

>200 bars/day (>2 kg bars): 500T is essentially the only choice for stable production and meeting quality.

Always consider both product (bar size, thickness, material purity) and production rate. Undersizing your press creates bottlenecks and quality issues; oversizing it (buying 500T for only tiny bars) wastes capital and increases operating costsharsle.com. The goal is the right tool for your current needs and some headroom for the future.

Cost and Value Over Time

While initial purchase price is important, don’t lose sight of total cost of ownership (TCO) and value creation:

Purchase Cost: A new 315T gold-pressing machine typically costs on the order of ¥150k–250k (~US$21k–35k) depending on features (manual vs. automated, control precision, etc.). A 500T unit is roughly double that (around ¥300k–450k, or US$42k–63k).

Energy Consumption: Idle power is modest (5–7 kW for 315T vs. 7–11 kW for 500T), but under load energy use depends on production volume. A bigger press works faster (shorter press cycles), so for large batches it can actually use less energy per bar. For example, pressing 100 1 kg bars/day might use ~90–120 kWh with a 315T, but only ~80–100 kWh with a 500T (due to faster throughput). Over time the extra performance often offsets the slightly higher power draw of the 500T in heavy production.

Maintenance and Reliability: Running near max capacity shortens service life. Industry guidelines advise having ~15–20% extra capacityharsle.com to avoid constant overload. A 315T used constantly for 1 kg bars may require major maintenance every 2–3 years (costing several thousand dollars for rebuilding the cylinder, pump, etc.) and minor upkeep (seals, filters, oil) every 3–6 months. A 500T under normal load can run 4–5 years between major overhauls and needs routine service only semi-annually. Annual maintenance parts (hydraulic oil, seals, filters) might total (~US$560–1,120) for 315T, versus (~US$420–840) for 500T, because the 315T spends more time at high load.

Hidden Costs – Rework and Scrap: This is often the biggest factor. A 315T press will have a higher scrap/rework rate on heavy or marginal jobs. If 5% of your output needs re-melting, that’s wasted gold and labor. For a 100 bar/day line over 3 years, that might mean ~5.5 tons of extra gold melted, costing tens of thousands of dollars (material plus energy and labor). A 500T press typically keeps rework under ~0.5% in the same scenario – saving not only gold but also shipping delays and labor.

Bottom line: For long-term, high-volume operations, the 500T often yields a lower total cost. Its higher efficiency and quality mean fewer rejects and less unplanned downtimepacificpreciousmetals.comharsle.com. A rough 3-year TCO analysis (capex + power + maintenance + rework) will usually show the 500T offsetting its higher price through reduced waste and higher throughput. In contrast, for very short-term or small-scale use, the 315T’s lower upfront cost may make sense, but factor in that you may need to reinvest sooner.

Buying Guide: Key Considerations & Pitfalls

When selecting a gold-pressing hydraulic press, don’t rely on the nominal “315T” or “500T” rating alone. Here are critical checks and common mistakes to avoid:

Don’t Trust Nominal Ton Rating Blindly: The nameplate tonnage is a theoretical maximum. Real-world output can be 10–20% lower due to hydraulic losses. Always ask for a pressure test certificate: reputable vendors will provide a chart of actual press force vs. stroke. Verify that the machine can sustain at least ~85–90% of its rated force. (For example, a real 500T press should consistently deliver ~450T. If not, it’s effectively weaker than labeled.)

Beware “Inflated” Tonnage Claims: Some manufacturers overstate capacity. They might use thinner frame steel or simpler hydraulics to cut cost while still advertising 500T. This is dangerous. A frame that flexes under load won’t deliver steady force and can even fail. Insist on heavy-duty construction (thick welded steel frame, robust power unit). If in doubt, have the machine supplier run a controlled test with your die and materials in your facility.

Pressure = Force/Area: Remember that bar pressure (compressive stress) depends on die area. Even a 500T press can under-compress a large-diameter or thick bar if the force isn’t concentrated. Calculate required pressure:

Required Tons

Desired pressure (MPa) × Area (cm²) / 1000

ensuring your press delivers that. If you must form very wide or thick bars, double-check that 315T or 500T can achieve the needed tons.

Six Key Machine Specs: Beyond tonnage, confirm these vital parameters:

Cylinder Stroke (Daylight): 315T machines should have ≥300 mm stroke to accommodate up to ~20 mm bars comfortably; 500T machines ≥500 mm for up to 50 mm bars. Too short a stroke means you simply can’t fit the tooling and bar.

Working Table Size: Must fit your largest die + allow clearance. Recommend ≥600×400 mm for 315T, ≥800×600 mm for 500T. Also ask for table flatness tolerance (≤0.1 mm/m) – an uneven table causes uneven pressing.

Control Precision: For precious metals, CNC control is preferred. Pressure accuracy should be within ±1% of setpoint, and speed control precise (±5 mm/min) to allow multi-stage pressing (slow initial press for degassing, faster main press, then dwell for density).

Pressure Stability: Look for a machine that maintains pressure within ±2% during each press cycle. Manufacturers can often provide sample pressure-vs-time curves. Fluctuations beyond ±5% can cause density variation bar-to-bar.

Hydraulic Power Unit (HPU): Ideally a dual-pump system (one pump for fast approach, another for high-pressure pressing). This ensures quick cycle times plus full force when needed. Ensure the hydraulic oil used is suitable for metal pressing (e.g. anti-wear grade #46 oil) and that filtration is fine (to prevent contamination of the hydraulic system and maintain consistent pressure).

Safety Features: High-pressure pressing must have robust safety. Look for dual-hand “dead-man” controls (both hands required), emergency-stop buttons (<0.5 s response), overload relief valves (automatically halt if pressure exceeds ~110%), and physical guards or enclosures around the platen. These may seem standard, but some low-cost machines skimp on them.

Include all critical specs in your purchase contract or checklist, and verify on delivery. The real-world risk of a “cheap” press turning dangerous or ineffective is high if these are ignored.

Risks of Overloading a 315T Press: Trying to push a 315T machine beyond its limits (for example, forming a 2–3 kg bar) leads to trouble. The machine components wear out much faster: seals that normally last a year might fail in months, and the frame can creep or crack. Product quality also suffers: you’ll see inconsistent densities (some bars well-pressed, others loose) and even “overpressure” cracks that are invisible on the surface but ruin the bar. Worst-case, the press could suffer a catastrophic failure (e.g. cylinder burst or frame break) – a severe safety hazard. If your maximum required pressure (tonnage) is near the 315T’s limit, always “step up” to 500T to preserve life and safety

harsle.com.

Newcomer Pitfalls – 5 Common Mistakes:

Buying by Price Alone: The cheapest 315T may lack essentials (e.g. it might be hand-pump or single-speed). Upgrading such a machine later (adding a CNC controller or extra pump) can cost USD $4,200–11,300, negating the initial savings.

Blindly Choosing Maximum Capacity: Conversely, some buyers pick 500T “just in case” without analyzing needs. If you only ever press small bars (<500 g), a 500T press will sit mostly idle (low-load operations are inefficient and consume unnecessary power). Match size to your actual workload for best ROI

harsle.com.

Ignoring After-Sales Support: Precious metal presses need quick service (e.g. same-day hydraulic repair) because downtime is costly. Avoid obscure brands with no local service network. Check warranty terms and ask for references from other minting operations. A little extra cost for a reputable supplier is usually justified.

Overlooking Die/Tool Compatibility: Always verify your tooling fits the machine. A common mistake is buying a press without checking that existing molds will clear the ram and base. If you change press type (e.g. manual vs power), your dies or fixtures might need reworking. Measure your dies’ width, length, and any side-clearances, and ensure the press table and cylinder can accommodate them.

Site Preparation Neglect: A 500T press weighs ~10–15 tonnes and is ~3.5×2×2.5 m in size. Make sure your floor is strong (≥20 kN/m² bearing) and your doors/ceiling are high enough for transport. Many buyers have faced delays (or even wasted money shipping a machine that didn’t fit). Prepare in advance: reinforce flooring if needed and confirm clearances before the press arrives.

In all cases, the best approach is to list your requirements first – bar size range, daily volume, alloy purity – then get detailed proposals from multiple press manufacturers. Compare not just tonnage and price, but machine specifications and service terms. This due diligence will pay off in reliable operations and controlled costs.

Key Takeaways

Match Ton to Product: Use 315T for small (≤500 g) or very thin bars; use 500T for heavy (≥1 kg) and thick bars. If you frequently form large or recycled-gold ingots, 500T is the safe choice.

Match Capacity to Scale: For modest daily outputs or pilot lines, 315T can be economical. For sustained high throughput (100+ bars/day) or 1–5 kg products, 500T ensures consistent quality and speed.

Consider Long-Term Value: Over 3–5 years, a 500T press often costs less overall due to higher yield and less downtime. It also allows entry into higher-end markets (e.g. LBMA-standard bars) that demand perfect density

pacificpreciousmetals.com. Think of the press as a long-lived investment – choose for lifetime return, not just immediate savings.

Avoid Common Traps: Don’t just trust the rated tonnage – verify actual force. Never run a press at >80–85% of its capacity long-term

harsle.com. Ensure proper controls, safety, and support. And remember: engineering expertise matters. Consulting with a trusted metalworking specialist or using tried-and-true design criteria (rather than guessing) will guide you to the right press.

Ultimately, the goal is stable, high-quality bar production with controllable costs. By carefully analyzing your needs and understanding how tonnage affects compaction, surface finish, and throughput, you can select a hydraulic press that keeps bars and budgets on track.

FAQ Guide of Hydraulic Press

- 1.How Should I determine what hydraulic press I need for my application?

- 2.How does a 500 ton hydraulic press machine work?

- 3.Do you provide customized solutions?

- 4.How much pressure should the 500 ton hydraulic press have?

- 5.How many types of hydraulic press machines are there?

- 6.What makes hydraulic presses popular in industrial production?

- 7.Between the hydraulic press machine and mechanical press machine, which is better?

- 8.Is the hydraulic press machine more energy efficient?

- 9.What kind of experience does Superbmelt have building hydraulic press solutions?

- 10.What types of controls come with Superbmelt hydraulic press?

- 11.What type of power will Superbmelt machine require?

- 12.What types of applications can be achieved with Superbmelt machines?

- 13.What are the different types of hydraulic presses offered by Superbmelt?

- 14.How safe is hydraulic press in industrial production?

- 15.How durable is the 500 ton hydraulic press?

- 16.What is the difference between hydraulic press and power press?

- 17.Does Superbmelt provide automated solutions?

- 18.How do I choose a 500 ton hydraulic press?

- 19.What if we face a problem in the workmanship after the installation?

- 20.What does Superbmelt engineers offer?

1. How Should I determine what hydraulic press I need for my application?

Despite being simple in nature, 500 ton hydraulic press has a wide range of applications. It can be used in a vast range of industries.

First, it can be used to compact food and other consumables. Compressed food products are normally packed with the help of hydraulic press. Many cheese and meat products would not be available without the hydraulic press. Even powered makeup and pills and usually made using hydraulic press.

The machine can also be used to make various appliances. 500 ton Hydraulic press is normally used to make appliances and other electronic parts such of those of refrigerators.. Laundry machines, dishwashers, and microwaves all require the use of 500 ton hydraulic press.

The 500 ton hydraulic press machine also comes in handy in the production of some electrical parts. These parts are always used in things like electrical applications Eve switches and housings stations are usually created using hydraulic press.

The other areas that require hydraulic press include building aircraft, military application, and many more.

To pick the right tonnage, you should consider what you want to use the 500 ton hydraulic press for, You also need to be aware of the amount of products or items you’re trying to press. Applications that use metals or irons will always require higher tonnage compared to the ones that require the use of liquids.

2. How does a 500 ton hydraulic press machine work?

The machine primarily functions by generating a huge compressive force. It does that via a hydraulic cylinder. However, there’re quite some processes involved to ensure that the system functions properly. For instance, to work perfectly, the system greatly relies on Pascal’s principle. It can’t generate the required amount of force needed to get the job done.

What all this means that one amount of force applied in one area is equally distributed to a different area. The entire force gets transferred through a compressible fluid. Note that the compressible fluid is the reason the machine is known as the 500 ton hydraulic press machine. We must not forget that there are many types of hydraulic fluids that can be used to make the system work effectively. It’s all about finding the right resources in the market.

3. Do you provide customized solutions?

From our company, you can access amazing customized solutions that’ll meet the needs of your customers and the company alike. However, you should provide clear details about your intended application.

With the information, we can come up with the best designs for your processes. We can incorporate unique features to your system to make your company stand out from the crowd. The things we can comfortably handle are related to metal forging, coin minting production, metal cutting, and many other applications in the automotive industry.

4. How much pressure should the 500 ton hydraulic press have?

While this is an important question, it might not have a single answer. That’s because there’re a lot of factors to be considered when answering this question. For instance, suppose the pressure gauge indicates 1000 PSI, the 1000 tons per square inch goes to 10 square inches. Also, suppose each square inch of the entire surface area applies a thousand pounds of force, then the 10 inches will apply a total of 10,000 tons of pressure.

It’s worth noting that you can decide on the amount of force you want based on the application of your choice. Suppose you intend to work on coins, it’s possible to go for a hydraulic press that can work effectively, and it should also let you control the amount of pressure exerted on the materials being worked on. Fortunately, this is something you can get from Superbmelt, provided you get in touch with us.

5. How many types of hydraulic press machines are there?

If you search the market, you’ll notice that there’re many types of hydraulic presses. You can only choose one type of hydraulic press based on the project at hand. They include; H-frame hydraulic presses, C-frame hydraulic presses, universal hydraulic presses, vertical hydraulic presses, horizontal hydraulic presses. When picking the right hydraulic presses to use, you should understand that they come in different sizes. You also need to pick your ideal machine based on the source of power you have available.

6. What makes hydraulic presses popular in industrial production?

It’s true that hydraulic press machines are quite trendy these days. But that’s the case because of some technical reasons in various production setups. Also, the machines are designed to ensure that the users enjoy high levels of dependability, efficiency, and durability. Today, each company wants to invest in machines that they can use for lengthy durations without paying high maintenance fees and the cost of operations.

Thankfully, they have been able to achieve all that with the help of hydraulic press machines. They’re more of a once-in-a-lifetime investment, which means companies can save a lot of money in the long run by maximizing profits. Thus, the reason this machine is popular is that its durable, efficient, and dependable. If something is highly dependable, it means you can entrust the success of your industrial production to it.

7. Between the hydraulic press machine and mechanical press machine, which is better?

The most direct answer to that question is that the hydraulic press machine is way better than the mechanical press one. This can be because of the manner in which the machine functions. Note that the hydraulic system makes use of the Pascal principle, which is one of the best things in the industry. The hydraulic system is also great since it comes with the latest technology to provide you with the most pleasant user experience.

Other than that, you can enjoy so many features that you cannot find from the mechanical press machine, such as more comfort, better control, less maintenance cost, flexibility, reliability, and improved precision. Did you know that you have the best chance to save more money if you invest in a hydraulic press machine? The mechanical one might also not be good when you don’t want to pollute the surrounding environment.

8. Is the hydraulic press machine more energy efficient?

Before you invest in a machine, you should find out whether it’s energy-efficient. That’s because you don’t want to end up accumulating losses due to high operation costs. Thankfully, with this machine, you can easily forget about encouraging material waste. As such, you should feel free to invest in one from Superbmelt.

Noting feels better than knowing that your raw materials and other inputs will be used economically without having you burdened financially. We have also seen that the material leverages an automatic process, which also means your materials will be utilized perfectly. That’s because all your shapes and sizes will be created as per your requirements. The 500 ton hydraulic press relies on compressible liquid that distributes force to the entire system. As such, you can be certain that your application will be complete without extra power bills on your end.

9. What kind of experience does Superbmelt have building hydraulic press solutions?

Today, before working with any company, you want to make sure that they have enough experience in the market. Superbmelt has been in the market for more than ten years serving clients in different parts of the world. We have created a good reputation in the industry, which is why we have managed to maintain the best clients.

Through experience, we have gathered the right knowledge and skills to meet the expectations of our customers. Thus, when you choose to engage with us, you can be sure of a premium customer experience. Our experienced, trained staff will work closely with you to find the best ways to give you the best 500 ton hydraulic press machines. Suppose, you’re unable to pick customized 500 ton hydraulic press systems on your own, we are here to ease the tension for you.

At the time, we have completed configuration of various product lines, such as moulding punching, metal forming operations, and on the list goes. That means you can count on us for a plethora of applications.

10. What types of controls come with Superbmelt hydraulic press?

The hydraulic systems come in a vast range of models. For instance, the standard models come with manual controls. However, is you’re someone who prefers digital interfaces, then you can go for the ones that come with touchscreens. Note that the digital design ones also come with additional features that will benefit you in a number of ways.

For instance, our machine ensures that you get the best ability to shift from limit switches to a linear transducer. That means the controls also give you the luxury of ram movements. The other good thing with our hydraulic press machines is that you can easily control speed and tonnage. In that case, you can be sure that your rivals in the market will not be able to beat you.

11. What type of power will Superbmelt machine require?

If you get our 500 ton hydraulic press systems, you should be ready to run it on a 3 phase power, 208/230/460 volt. Note that you might face some problems with the machine, unless you leverage the right power. The good thing with our company is that we can always meet your requirements.

In that case, you can place special power requests, and our team will be more than willing to honor that. We can also provide the smallest custom presses known as the W6A, and they are available with 115v single phase power. For the best experience with our machines, you must be sure to only use the amount of power recommended by our experts. If you choose the one that works with 3 phase power, then that has to be maintained at all times.

12. What types of applications can be achieved with Superbmelt machines?

At the time of writing this piece, we have more than enough machines to supply to the market. That means our machines are already working in a wide range of industries globally. They also serve a plethora of applications. Let’s look at some of them, but you should know that this is not a comprehensive list of industries and applications; deep draw, compaction, assembly, stamping, forming, press fitting, embossing, coining, trimming, perforating, and press fitting. As we keep existing in the industry, we discover the best ways to touch various industries.

13. What are the different types of hydraulic presses offered by Superbmelt?

From Superbmelt, you can get a wide range of hydraulic press machines, and you can choose based on your application. However, it’s worth noting that the hydraulic press machines are customized to meet your specific needs. At the time, the available press categories include C-Frame Presses, Bench Presses, and 4-Post Presses.

It’s important to note that all hydraulic bench presses come in smaller sizes, which also means they have smaller tonnage. As such, you can use them by bench-top mounting, as their name depicts. From us, you can get two types of hydraulic bench presses; the W6A series, and the M5P series.

C-Press hydraulic presses, on the other hand, can also be called gap frame presses. They come with very unique frame styles that make them stand out from the crowd. From the name, due to the nature of the frame, there’s a ‘C’ formed around the bolster plate. With this type of hydraulic press, you can deliver a very high force while maintaining a tiny area of contact. Thus, they’re basically meant for applications that need lower tonnages and smaller bed sizes.

Lastly, we have the 4-Post hydraulic press, which can also be referred to as the 4-column press. The good thing with this one is that it can be designed to accommodate a wide range of sizes. The press is also ideal for applications that need high levels of rigidity, as well as precise bed-to-ram parallelism.

14. How safe is hydraulic press in industrial production?

Note that while hydraulic press is safe, there’re things you can do to prevent possible risks from taking place. Some users have reported issues related to flying debris, overheating, and some damaged parts. The 500 ton hydraulic press might also encounter some oil leaks, and loss of significant amount of pressure. But you can be sure that our products come with the right safety installation to prevent accidents from happening in the workplace.

From us, you can get the most reliable and fitting device to make use of. To get a perfect custom build, you should be aware of the number of locks you need, the cylinder information, unlock pressure. Also, you should know the necessary length of machine lock to use. Our machines also have the best cushioning. It’s not good to go for a machine without any cushioning since they’re prone to accidents.

Our machine also comes with power rating to ensure that you only use the required amount of power. Before we give you the machine, we’ll test it to confirm that it only leverages safe processes.

15. How durable is the 500 ton hydraulic press?

If you choose to purchase our products, you can be sure that it will serve for a long time, due to the material used to make the casing. The metallic parts don’t catch stains, so they won’t wear out before serving you enough.

Since the machine doesn’t overheat easily, it can withstand the popular destructive elements. Our engineers advice that you can extend the life of your press by maintaining it and changing the compressible liquid in case it gets corrupt, or the quality goes down.

Would you like to know how durable our hydraulic machines are? The machines come with parts that you can easily maintain, and in case of any damage, you can repair the parts without spending too much money. Also, the overall durability of the machines depends on how you handle them.

For instance, you can extend the lifespan of your hydraulic press machine by lubricating all the moving parts. Note that you might as well let the machine rest and conduct some maintenance services to detect any potential issues before they run out of hand. If you take good care of the hydraulic press, you can use it for more than ten years without experiencing any major complications.

16. What is the difference between hydraulic press and power press?

Power press and 500 ton hydraulic press rely on different principles to get the work done, and that’s the main area of difference. Hydraulic press, for instance, uses Pascal’s principle, while power press, on the other hand, uses the principle of converting the circular motion into linear motion.

Though both machine scan help you achieve the bottom line, they have their pros and cons. At the time, the main advantage of hydraulic press is that it’s environmentally friendly. It’s very easy to use and doesn’t require a lot of power to operate. The reverse is true when it comes to power press. If you’re looking to have the best experience, we suggest investing in 500 ton hydraulic press, especially the ones crafted by Superbmelt.

17. Does Superbmelt provide automated solutions?

The most direct and accurate response to that question is a resounding yes. You can easily get in touch through a website, share with us the details regarding the project at hand, and we will get you the exact machine you want. The good news is that they’re all automated, so you can rest assured that your project won’t be messed up. Even today, we’re working on getting better as time goes by. That means integrating the latest technologies into our systems. Would you like to shop with us today, the automated solutions are available, and we can customize them further just for you.

18. How do I choose a 500 ton hydraulic press?

You don’t have to think too hard about it. You can simply choose the best 500 ton hydraulic press by considering some of the most important factors. For example, you want to understand the type of application and needs at hand. If you want to get work done much faster, and you need some heavy weight for the best pressure, then you can go for the right machine for that. The good thing is that you can count on us for professional assistance.

You also want to consider the amount of money you’re looking to invest in the machine, the rate of energy consumption, cost of maintenance, and technical know-how required to operate the machine of your choice. We have already mentioned above that even if you can’t choose the best machine on your own, we can ask you some questions to help you pick the best system based on the project at hand.

19. What if we face a problem in the workmanship after the installation?

Suppose you purchase a product from Suiperbmelt, you finish the installation process, but you end up running into trouble, be sure to get in touch with us immediately. You can visit our page and collect the contact information there. Also, you can organize a video call with our team, and we will give you the necessary assistance. Suppose the problem s technical, and you’re close to one our location, feel free to pay us a visit and our team of experts will accord you the necessary assistance.

20. What does Superbmelt engineers offer?

Note that you can count on our team for many things. First of all, we can sell you the best 500 500 ton hydraulic press systems you can ever find on the market. Aside from that, as a company, we can provide you with technical solutions so that you have the best experience using our products. In case you run into trouble, our engineers will help you solve it in the most professional manner possible. Our engineers can also customize the systems to suit the best of your needs.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited