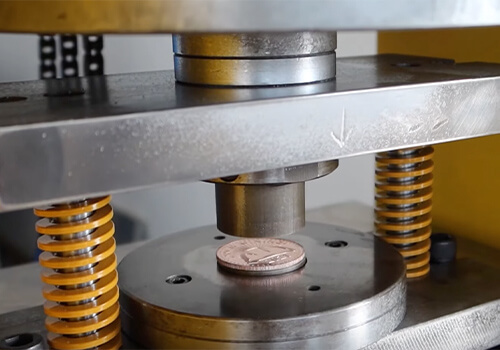

100 ton Hydraulic Press

Superbmelt 100 ton hydraulic press is used for a wide range of applications apart from embossing marks on precious metal in the coin minting. The 100 ton hydraulic press is also used for shaping metals, clinching, moulding, blanking, punching, deep drawing and other metal forming operations. The hydraulic press works by exerting compression force against metals placed between dies. The 100 ton hydraulic has a pressing capacity of 100 tons, this means that Superbmelt machine press is not only suitable for heavy industrial uses but also for small-scale applications.

Superbmelt hydraulic press machine has a simple construction but works effectively for several metal applications. It is suitable for use in industries such as aerospace, automotive, thermoplastic, etc. Superbmelt hydraulic press machine saves up to 40% of energy, which means that operating cost is low.

Our stamping machines guarantee accuracy and efficiency in every production, contact us today to get the press machine that meets your needs.

- Superbmelt hydraulic press machine presses metals through the hydraulic pressure. It can also perform processes like cutting, moulding, clinching, piercing and forming in different metal forming operations.

- Superbmelt 100 ton hydraulic pressing machine allows users to stamp logos, texts and other symbols on precious metal coins and bars. With the hydraulic press machine, branding your products becomes easy for different industries.

- With the Superbmelt hydraulic press machine, industries such as automotive and aerospace can press tracking numbers which helps them in proper record keeping, quality control and compliance with production standards.

- The hydraulic press is able to press up to 100 ton of precious metal, this is suitable for use in small and medium scale productions.

- The maximum system pressure is 25mpa, this means that you can easily adjust the stamping pressure to determine the depth and the speed of pressing.

- Superbmelt 100-ton servo motor driven system also allows you to adjust the speed and pressure of pressing. This feature allows the machine to move stably and reduce noise. This noise reduction feature prevents noise pollution in the working area.

- The metal pressing machine has a motor power of 4 to 11kw. The 4kw of power helps you to save cost on energy use. It also means that there is no fuel whose end product can release toxic gases.

- The speed of the 100 ton hydraulic pressing machine enhances high productivity. Productivity increases by at least 40% which allows demands to be met on time.

| Item | Unit | SPB-100TP | SPB-100TS | |

| Photo |  |  | ||

| Rated capacity | Ton | 100 | 100 | |

| Max. system pressure | Mpa | 25 | 25 | |

| Max. stroke of working table | mm | 110 | 110 | |

| Altura abierta | mm | 320 | 310 | |

| Height of movable working table | mm | 960 | 800 | |

| Upward speed of movable working table | mm/s | 150 | 160 | |

| Returning speed of movable table | mm/s | 140 | 145 | |

| Movable working table size | L-R | mm | 420 | 430 |

| F-B | mm | 420 | 430 | |

| Overall dimension | L-R | mm | 920 | 980 |

| F-B | mm | 810 | 1150 | |

| H | mm | 1650 | 1930 | |

| Motor power | kw | 4kw | 11 | |

| Weight (Approx.) | kg | 1900 | 1500 | |

Why SuperbMelt 100 ton Hydraulic Press

Any Question About SuperbMelt 100 ton Hydraulic Press

100-Ton Hydraulic Press for Precious Metals: Application Scenarios & Ideal Users

Small Gold Recycling Workshops

A 100-ton hydraulic press is widely recognized as the entry-level and small-batch solution for precious metal pressing. It offers the right balance between pressing force, cost control, operating simplicity, and space efficiency. Below are the most typical application scenarios where a 100T press delivers the best return on investment.

1.1, Early Platinum Mining

Core Process Breakdown:

After pretreatment of scrap gold (crushed to a particle size ≤ 5 mm and refined at high temperature to a purity of ≥ 99.5%), the gold powder or small gold nuggets are loaded into graphite molds (inner diameters available in 20 mm, 30 mm, and 50 mm; height 50–100 mm).

The mold is placed at the center of the 100T hydraulic press working table, and the press is started. The pressure is gradually increased to 80–100 tons, with a holding time of 120–180 seconds to ensure full bonding and compaction of the metal particles.

After pressure release, the mold is removed and demolded to obtain gold cakes or gold bar blanks with uniform density (the final thickness is typically 30–50% of the mold height). These can be directly sent for purity testing and sale, or further refined in a melting furnace.

Compatible Material Specifications:

- Single pressing gold weight: 0.5–5 kg

- Powder moisture content: ≤ 0.3%

- Particle size: 0.1–5 mm

- Finished gold cake diameter: 20–50 mm

- Finished thickness: 10–30 mm

- Gold bar dimensions can be customized (maximum L × W × H = 100 × 50 × 30 mm).

1.2, Why 100T Is the Right Fit

ChatGPT 说:

Precise Matching of Pressure and Density:

The theoretical density of gold is 19.3 g/cm³. In small workshop pressing, a density of ≥18.5 g/cm³ is required to avoid excessive loss during subsequent melting. Tests show that under 100T pressure, 5 kg of gold powder (particle size 0.5 mm) pressed in a φ50 mm mold with a holding time of 180 seconds achieves a density of 18.8–19.1 g/cm³, fully meeting the requirements for further processing. If the pressure is reduced to 80T, the density drops to only 17.9–18.2 g/cm³, resulting in an increased melting loss of over 0.2%.

1.3, Business Value

Loss Control Case:

A small-scale gold recycling workshop (processing 30 kg of gold per day) previously used manual hammering for pressing, resulting in a loss rate of 0.45%. After switching to a 100T hydraulic press, the loss rate dropped to 0.08%. Based on a gold price of 400 RMB/g (~57 USD/g), the daily cost savings are calculated as:

30 kg × 1000 g/kg × (0.45% – 0.08%) × 57 USD/g ≈ 4440 USD/day,

resulting in annual savings of over 160,000 USD.

Efficiency Improvement Details:

Manual pressing of 1 kg of gold per batch required 20–30 minutes, meaning daily processing of 30 kg took 10–15 hours. With the 100T hydraulic press, pressing 1 kg per batch only takes 3 minutes (including loading and demolding), so processing 30 kg/day requires just 3 hours. The remaining time can be used for additional recycling orders, increasing monthly throughput from 900 kg to 1,500 kg and boosting monthly profits by over 28,500 USD.

Compliance and Market Advantage:

The blanks pressed by the 100T hydraulic press have uniform density, with purity deviation ≤0.1% when tested by authoritative institutions, making regulatory approval easier. Additionally, the press can produce blanks in different specifications (e.g., gold ingots with custom logos) to attract high-end customers such as collectors or small enterprises, achieving a premium of 5–8%.

Jewelry Manufacturing & Chain Factories

2.1, Typical Application

Detailed Process Scenarios:

Sheet Rolling:

Gold ingots of φ20mm and 500g are pressed into thin sheets with a thickness of 0.3–1.0mm, used for making pendants and necklace links. The rolling process requires 3–5 gradual pressings (initial pressure 30T, subsequent increments of 10–15T, up to a final pressure of 80–90T). After each rolling, annealing is performed at 700–800°C to prevent metal hardening.

Jewelry Blank Stamping:

For products such as rings and earrings, customized stamping molds (precision ±0.005mm) are used to form the blanks in a single pressing under 80–100T pressure. The dimensional error of the blanks is ≤0.01mm, requiring only minor polishing before entering the setting process.

Chain Link Forming:

Gold sheets 0.8mm thick are cut into chain link blanks and placed into chain link forming molds. Pressing under 60–80T forms the slots and connectors of each link, ensuring smooth chain assembly with a tensile strength ≥50N.

Applicable Product Specifications:

Rolled sheets: maximum size 300×300mm, thickness 0.1–2.0mm

Stamped blanks: weight 0.5–20g, maximum outer dimension φ50mm

Chain links: 0.5×0.5mm to 5×5mm, suitable for bracelets, necklaces, and anklets.

2.2, Why 100T Is the Right Fit

Process Accuracy Assurance:

Jewelry stamping requires extremely high mold alignment. The 100T hydraulic press uses a four-point guiding system with a guide accuracy of ±0.003mm and a worktable flatness of ≤0.02mm/m², ensuring precise alignment of the upper and lower molds and preventing burrs or dimensional deviations in the blanks. For example, when stamping ring blanks with the 100T press, the inner diameter error is ≤0.008mm and the outer diameter error is ≤0.01mm, far exceeding industry standards (≤0.02mm).

Mold Change and Production Efficiency Adaptation:

The press is equipped with a quick-change mold system using a hydraulic locking device, reducing mold change time to just 8–10 minutes (traditional equipment requires 20–30 minutes). It supports continuous stamping, with a single stamping cycle of 0.8–1.2 seconds (including feeding, stamping, and removal). Daily output for a single product can reach 8,000–10,000 pieces, perfectly matching jewelry factories’ “multiple styles, small batches” production rhythm (e.g., producing 10 styles of rings, 500 pieces per style, in only 6–8 hours).

Material Protection Mechanism:

The press features a “soft press” technology with adjustable pressure rise rates (0.5–2T/s). For soft metals like gold and silver, a low-speed press (0.5–1T/s) is used to prevent grain fracture or surface scratches caused by sudden stress. The worktable is also equipped with a 5mm thick polyurethane cushion to reduce impact loads during stamping, minimizing the risk of blank deformation.

2.3, Business Value

Yield Improvement Case:

A jewelry chain factory producing 18K gold rings (daily output 5,000 pieces) originally used a standard 20T press. Due to insufficient pressure and limited precision, the yield rate was only 88%. After switching to a 100T hydraulic press, the yield increased to 98.5%. Daily reduction in scrap loss = 5,000 pcs × (98.5% − 88%) × 20g/pc × $43/g (18K gold price) ≈ $31,500/day, with annual savings exceeding $900,000.

Process Expansion and Premium:

The 100T press can handle complex stamping designs, such as hollow patterns and multi-layered structures. For example, a factory launched a “hollow filigree pendant” series. Thanks to the precise stamping process, the product’s design appeal improved significantly, with the selling price increasing from $107/pc to $200/pc and the gross margin rising from 40% to 65%. Monthly sales exceeded 3,000 pieces.

Labor Cost Optimization:

Traditional presses require 1 operator per machine, so producing 5,000 pieces/day needed 5 machines and 5 workers. With the 100T press equipped with an automatic feeding system, 1 operator can handle 2 machines. Daily production of 10,000 pieces requires only 3 workers. Assuming a monthly salary of $800 per person, monthly labor cost savings = (5 − 3) × $800 ≈ $1,600, with annual savings of $19,200.

Why equipment is needed to melt platinum

3.1, Typical Application

Core Production Process:

Blank Preparation: Melt gold or silver with a purity of ≥99.9% and cast into rectangular blanks (L × W × H = 100×50×20mm, weight 500g–1kg). Anneal the blanks (gold 600°C, silver 300°C) and polish to remove surface oxidation.

Mold Installation: Install steel molds with embossed patterns and text (hardness HRC58-62) onto the press. The upper mold contains the front design (e.g., logo, pattern), and the lower mold contains back text (e.g., weight, purity). Mold positioning accuracy ±0.005mm.

Stamping & Forming: Place the blank into the mold and start the press. Gradually increase pressure from 0 to 90–100T and hold for 90–120 seconds to ensure the metal fully fills the mold details. After depressurization, remove the product, then clean and polish before packaging.

Applicable Product Types: Commemorative coins (diameter 15–50mm, thickness 2–5mm, weight 5–100g), custom gold bars (length 50–100mm, width 20–50mm, thickness 5–20mm, weight 10–500g), badges (irregular shapes, max size 80×80mm), supporting precious metals such as gold, silver, platinum, and palladium.

3.2, Why 100T Is the Right Fit

Embossing Quality Verification:

For commemorative coins, common embossing depths range from 0.3–0.8mm. Pressure tests show that at a 0.5mm depth, 80T pressure achieves only 85% pattern fill (edges blurred, details missing), while 100T pressure reaches over 98% fill (clear texture, strong 3D effect). For complex 0.8mm deep embossing, 100T pressure with a 120-second hold fully fills the mold, whereas 80T pressure—even with a 200-second hold—still leaves 10–15% of the design incompletely filled.

Batch Production Stability:

The press uses dual hydraulic pumps with pressure fluctuation ≤±0.5T. During 8 hours of continuous operation (producing ~1,000 coins), finished product dimensional error ≤0.01mm and embossing depth error ≤0.02mm, ensuring excellent consistency. Mold lifespan reaches over 100,000 cycles (ordinary press molds last only 50,000 cycles), reducing mold replacement frequency and cost.

Customization Capability:

Supports small-batch custom orders (minimum 10 pieces). Mold change takes ≤15 minutes, enabling rapid switching between different patterns and sizes. Built-in parameter storage allows up to 50 custom programs (including pressure, hold time, and stroke), so repeat orders require no re-adjustment, improving customization efficiency.

3.3, Business Value

Product Premium Case:

A small mint produces “corporate custom commemorative coins” (50g pure gold, 30mm diameter). Before using the 100T press, the pattern was blurred, and the selling price was only ¥22,000 per coin (premium 20%). After switching to the 100T press, the pattern became clear with strong 3D effect, raising the selling price to ¥25,000 per coin (premium 35%). Profit per coin increased by ¥3,000 (~$420), and with monthly sales of 500 coins, monthly profit increased by ¥1,500,000 (~$210,000).

Mold Cost Savings:

Mold unit price is approximately (~$1,120) per set. With the 100T press, mold lifespan reaches 100,000 cycles, making the mold cost 0.08 RMB (~$0.011) per coin for producing 100,000 coins. Ordinary presses have a mold lifespan of 50,000 cycles, with a cost of 0.16 RMB (~$0.022) per coin. Producing 100,000 coins with the 100T press saves ¥8,000 (~$1,120) in mold costs.

Market Response Speed:

The lead time for custom orders with traditional equipment is 7–10 days. Using the 100T press, this can be shortened to 3–5 days (including 2 days for mold making, 1 day for production, 1 day for packaging), enabling faster response to customer demands, attracting more urgent custom orders, and increasing market share by over 20%.

University & Metallurgy Training Laboratories

4.1, Typical Application

Educational Experiment Scenarios:

Materials Mechanics Experiments: Measure compressive strength, yield strength, and elastic modulus of materials such as low-carbon steel, aluminum alloys, and gold. Gradually apply pressure (0–100T) using the press, collect real-time pressure–displacement curves, and calculate material mechanical parameters.

Metal Forming Process Experiments: Study the effects of pressure, holding time, and temperature on metal forming quality (e.g., density changes of gold under different pressures, plastic deformation of aluminum alloys under varying holding times), providing students with an intuitive platform to verify forming processes.

Mold Design Practice: Students design small stamping molds (e.g., simple badge molds) and test them on the 100T press to verify mold structure rationality, enhancing practical design skills.

Research Applications: Optimize forming processes for new alloy materials (e.g., high-strength magnesium alloys, antibacterial stainless steel), conduct pressure-sintering experiments for metal matrix composites, and study press-forming for recycling of scrap metals, supporting multi-parameter control of pressure, temperature, and time.

4.2, Why 100T Is the Right Fit

Experimental Data Accuracy:

The equipment is equipped with high-precision pressure sensors (accuracy ±0.1% FS) and displacement sensors (accuracy ±0.001 mm), with a data sampling frequency up to 100 Hz. It can record dynamic changes in pressure, displacement, and time in real time, generating highly accurate experimental curves. The system supports computer connection and dedicated software for data storage, analysis, and export (formats compatible with Excel and Origin), meeting research-grade data requirements.

Safety Protection Details:

The machine features triple safety protection: ① Mechanical safety doors (cannot start when open); ② Overload protection (automatically releases pressure and stops if pressure exceeds 105%); ③ Emergency stop buttons (located on both sides of the worktable and the control panel, response time ≤0.1 s). A cushioning pad is installed under the worktable to prevent injuries from falling workpieces, fully complying with laboratory safety standards.

Teaching Adaptability:

The press offers manual, semi-automatic, and automatic operation modes. In manual mode, pressure rise, holding, and release can be controlled step by step, helping students understand the working principle. A transparent observation window allows direct visualization of the metal forming process. A teaching guide (including experimental procedures, data processing methods, and FAQ) is provided to assist instructors in practical teaching.

4.3, Educational Value

Improved Teaching Outcomes:

A metallurgical program conducted the “Metal Forming Processes” course using the 100T hydraulic press. After participating in experiments, students’ understanding of process parameters such as pressure and holding time increased from 65% to 92%. The quality of lab reports improved significantly, and course satisfaction rose from 78 to 92 points (out of 100).

Research Achievement Transformation:

A university used the 100T press to study the “Recycling and Reuse of Cathode Materials from Waste Lithium Batteries.” By optimizing the pressing and forming process, the density of recovered materials increased by 15% and conductivity improved by 20%. The related research results were published in a core journal and resulted in one invention patent.

Talent Development and Industry Alignment:

The equipment’s operation procedures mirror industrial production, allowing students to quickly adapt to hydraulic press operations and process tuning in metallurgy, materials, and jewelry industries after graduation. At one university, the employment rate of graduates in this program increased from 85% to 95%, with 30% joining leading industry companies.

Pilot Projects & Market Testing Lines

5.1, Typical Application

Validation and Market Testing for New Products and New Processes:

Applicable for pilot production of new materials (such as rolling and stamping of eco-friendly nickel-free stainless steel sheets, producing 100–500 samples to test forming performance), process validation of new products (such as stamping chain links for lightweight hollow necklaces to test structural stability), and market demand testing (such as small-batch production of 500–1,000 mini commemorative coins for market feedback).

The system supports single pilot runs of 100–1,000 units, with a maximum product size of ≤300 mm.

5.2, Why 100T Is the Right Fit

Controllable Pilot Production Costs:

The purchase cost is only 1/3–1/2 of that of large-scale equipment, with no need for complex automated auxiliary systems. The initial investment is approximately USD 27,800–41,700 (RMB 200,000–300,000), which is about 50% lower than equipment above 200T (investment exceeding USD 69,400, RMB 500,000). In addition, no special foundation is required, and the machine can be put into operation within 1–2 days after installation and commissioning.

Flexible Process Adjustment:

Pressure (0–100T), holding time (0–300 s), and stroke (0–200 mm) are all steplessly adjustable. The parameter adjustment response time is ≤10 seconds. Multiple sets of process combinations can be tested within 1 hour, achieving a 6× efficiency improvement compared with large equipment (single adjustment ≥1 hour).

Strong Risk Hedging Capability:

With high versatility, even if a pilot project fails, the equipment can be quickly switched to small-scale production or laboratory testing, avoiding asset idleness. In contrast, large dedicated pilot equipment has low secondary utilization after failure, with an asset loss rate exceeding 80%.

5.3, Commercial Value

Shortened Pilot Production Cycle:

A company carried out a pilot project for a new titanium alloy jewelry line. After adopting this equipment, the pilot production cycle was shortened from 20 days (outsourced processing) to just 5 days. As a result, the product was launched one month earlier than competitors, achieving over 5,000 units in first-month sales with total revenue exceeding USD 416,700 (≈ RMB 3,000,000).

Reduced Investment Risk:

When a brand conducted pilot production of metal housings for smart wearable devices, it was found that the material’s drop resistance did not meet standards. The company promptly terminated mass production, successfully avoiding a USD 694,400 production line investment (≈ RMB 5,000,000) and a USD 277,800 raw material loss (≈ RMB 2,000,000), achieving a 100% risk avoidance rate.

Seamless Transition to Mass Production:

The optimal parameters established during the pilot phase can be directly applied to mass production, eliminating repeated debugging. This shortens the mass production preparation cycle by 30–50%, ensuring faster time-to-market.

When a 100T Press Is Enough — and When It Is Not

6.1 Ideal Use Range

Material & Product Limits:

Suitable for materials with hardness ≤ HRC35 (precious metals, low-carbon steel, aluminum alloy, etc.).

Maximum sheet thickness: 5 mm; maximum blank weight: 10 kg.

Product dimensional accuracy: ±0.005 mm to ±0.02 mm.

Supports shallow relief embossing (≤ 1 mm) and simple structural forming.

Maximum finished product size (L × W × H): 500 × 300 × 50 mm.

Production Scale Compatibility:

Daily output ≤ 10,000 pieces (stamped parts) or ≤ 200 kg (pressed parts).

Single order quantity ≤ 5,000 pieces.

Suitable for multi-batch, small-volume, and intermittent production

(daily operation ≤ 8 hours).

Core Application Scenarios:

Small-scale gold recycling, small and medium-sized jewelry factories, small mints / custom gold bar production, university laboratories, and enterprise pilot projects.

Also suitable for standard workshop environments (0–40°C, humidity ≤ 85%) and basic compliance requirements.

6.2 When You Should Upgrade

Material & Process Breakthrough Limits:

When processing materials with hardness > HRC35 (high-strength alloy steel, tungsten alloy),

sheet thickness > 5 mm, blank weight > 20 kg,

or when deep drawing (depth > 10 mm) and complex multi-cavity forming are required,

an upgrade to a 200T–500T press is necessary.

Significant Increase in Production Volume:

When daily output exceeds 10,000 pieces (stamping parts) or 200 kg (pressed parts),

24-hour continuous operation is required,

or a fully automated production line is introduced,

an upgrade to a high-speed multi-station press (single cycle ≤ 0.5 s) or an industrial-grade large press is required.

Upgraded Precision & Quality Requirements:

When product dimensional accuracy needs to be < ±0.005 mm,

or surface roughness Ra ≤ 0.02 μm (mirror finish),

an upgrade to a high-precision CNC press (guiding accuracy ±0.001 mm) is required.

Updates in Industry Compliance Standards:

When stricter industry quality standards are introduced

(e.g., purity detection error ≤ 0.05%, relief depth error ≤ 0.01 mm),

and the 100T press can no longer meet the required process accuracy,

equipment upgrading becomes necessary to ensure compliance.

FAQ Guide of Hydraulic Press

- 1. How should I determine what type of hydraulic press I need for my application?

- 2. How does a hydraulic press machine function?

- 3. Do you provide customized solutions?

- 4. How much pressure should a hydraulic press have?

- 5. How many types of hydraulic press machines are there?

- 6. What makes hydraulic presses popular in industrial production?

- 7. Between the hydraulic press machine and the mechanical press machine: which is better?

- 8. Is the hydraulic press machine more energy efficient?

- 9. What kind of experience does SuperbMelt have building hydraulic press solutions?

- 10. What type of controls come with SuperbMelt hydraulic press?

- 11. What type of power will the SuperbMelt machine require?

- 12. What types of applications have been achieved with SuperbMelt machines?

- 13. What are the different types of hydraulic presses offered by SuperbMelt?

- 14. How safe is the hydraulic press in industrial production?

- 15. How durable is the hydraulic press?

- 16. What are some advantages and application examples of the hydraulic press?

- 17. What is the difference between hydraulic press and power press?

- 18. How do I choose a hydraulic press?

- 19. What if we face a problem in the workmanship after installation?

- 20. What does SuperbMelt engineers offer?

1. How should I determine what type of hydraulic press I need for my application?

Before choosing a hydraulic press for sale, or a 100 ton hydraulic press machine, it is important to know about different types of hydraulic press that can be used for different applications. For example, for simple applications or smaller objects, one can opt for a manual press. On the other hand, for heavy and large objects, you can go for a movable or automatic hydraulic press machine.

Such machines have different applications in different industries, for example, punching, straightening, deep drawing, blanking, bending, and more. Well, you should keep in mind that it is impossible for a particular hydraulic press to perform all the tasks. So, based on your requirements or applications, you can choose the different types of hydraulic presses mentioned here.

- C-Frame Press

Speaking about the C frame press machine, this is designed and developed to take less floor space than other types of presses. Besides, such a machine can offer minimal stroke deflection. As the machines offer better control as well as precision, these presses are extensively used for diverse applications, such as coining, blanking, punching, drawing, forming, and more. There is a lot of design that comes under the C frame press, but the most basic press includes a ram, a die, and a press bed.

- H-frame

An H frame press is a large floor unit that is made of a powerful press cylinder, steel frame, a bolster, and a pump, and they form an H shape. You can use such presses for multiple applications, like for your production lines, for repair and maintenance facilities, and more. In some cases, such machines can be combined with hand pumps to carry out low-volume tasks. Well, the cylinder size can also vary based on the required force power and the application.

- Four-column hydraulic press

When it comes to buying a hydraulic press for your precision tooling applications, you can trust a four-column hydraulic press. Under this, you can also choose from a two-beam hydraulic press, four-beam, and three-beam hydraulic press. The applications that require powerful pressure, these presses can be an ideal option for them. With some useful features such as smooth transitions, versatility, ease of use, easy maintenance, flexibility, and faster setup, this press is quite famous among users.

- Air-operated hydraulic press

If your production facility lacks power, but there is an air hook-up, and you don’t want to press manually, you can go for an air-operated hydraulic press. With such machines, you will witness the same pressing power, just like the electric press. It can create around 25 to 200-ton pressing capacity.

- Horizontal hydraulic press

Plate straightening, punching, contouring, rail straightening are some of the major applications where a horizontal hydraulic press can be used. As per the experts, this is a multi-purpose and versatile machine, and parts can be easily punched, compressed, disassembled, etc. In general, such presses, including a vertical hydraulic press, come with a powerful hydraulic system to prevent overloading.

- Hydraulic coin press machine

This is also known as an automatic hydraulic press machine that comes with a robust steel-made body and is widely used for minting silver and gold coins. Besides, you can also use these machines for bars and medals minting or pressing. The machine can create around 150 tons of press and also comes with an extra hydraulic cylinder to support return stroke.

Even though there are a lot of options, when it comes to buying the best 100 ton hydraulic press machines, you can always trust SuperbMelt. You can also use them to automate your production process.

2. How does a hydraulic press machine function?

All types of hydraulic presses are based on Pascal’s Principle. The major components of a 100 ton press machine are pistons, hydraulic pipes, and cylinders. The working process is very simple to understand. The two cylinders are filled with oil or fluid. The fluid is filled into the slave cylinder. After that, a piston is inserted into the smaller cylinder, and the required pressure is then applied. This makes the oil move into a large cylinder through a pipe.

Then, the pressure is applied to the master cylinder that makes the piston located in the cylinder push the oil back to the smaller cylinder. This process creates a huge force, and that force is applied to the press plates. The press plates then punch the object. A 100 ton hydraulic press machine can be used for blanking, clinching, punching, forging, metal forming operations, coin pressing, and more. For best solutions, get in touch with SuperbMelt now.

3. Do you provide customized solutions?

When it comes to achieving automation, or if you want to automate the process, you can always choose SuperbMelt. We are well-known for offering the best and cost-effective solutions for that. When you are with SuperbMelt, you can go for the following options.

- Coin press machine or stamping machine

Our coin pressing machine can press around 150 tons of metal. We also call it a durable upstroke coining press that can offer the right RAM travel speed and comes with an extra hydraulic cylinder. Our machine has an advanced relief valve, piston pump, hydraulic accessories, and an electric control panel. Besides, using the machine, you can automate the process of stamping images, text, logo, or a combination of logo and text, you can opt for SuperbMelt’s automatic coin stamping machine. SuperbMelt’s 100 ton hydraulic press for sale is completely automated and can successfully complete the process within a few minutes. The users can use it for copper, silver, gold, platinum, and other coins. It can produce around 100 to 300 tons of press. The users are free to choose from the automatic, manual, and semi-automatic modes.

- Automatic metal processing system

SuperbMelt also offers solutions to automate the metal process. Using that, you can automate the process of gold bar making, metal melting, chain making, coin making, and more. Just program the system, and they will carry out the task automatically.

Besides, you can also use SuperbMelt’s machines for forging, an effective metal fabrication technique. You can use micro-alloy, stainless steel, alloy steel, titanium and more materials for forging. What’s more? Our hydraulic machine can also be used for clinching process. When it comes to joining of sheet metal components, you can trust this machine. On the other hand, the machine is so versatile that you can use it for metal forming operations to create robust structural parts as well as components from the metal sheets. All the machines can be used in coin production industries, ingot production, precious metal foundries, and more.

4. How much pressure should a hydraulic press have?

The required pressure amount may vary based on your application type. However, it is advisable to buy a hydraulic press that can produce around 100 tons to 300 tons of pressure. Well, you can easily find a good-quality 100 ton hydraulic press machine at SuperbMelt, and they will come under your budget.

5. How many types of hydraulic press machines are there?

- Four-post hydraulic press- These machines are widely used in precision tooling.

- Assembly presses- The machine can produce a sufficient level of pressure to secure or assemble parts.

- Arbor presses- You can use these machines for assembly, seating stamping, bearings removal, and more.

- Single column hydraulic press- As the name suggests, this machine comes with one column, and it has a type C frame.

- Vertical hydraulic press- The machine has two columns, and there will be an overarm that comes connected with the columns.

- Horizontal hydraulic press- While using the machine, the workpiece will remain between the plate arranged vertically, and then the pressure is applied.

These are some of the common hydraulic press machines that you can find in the market. But for the best 100 ton press, SuperbMelt can be a perfect platform for you. Check out our hydraulic press of sale and place your order now.

6. What makes hydraulic presses popular in industrial production?

Hydraulic presses are quite popular in the manufacturing industry across the world for their reliability as well as versatility. Some other reasons that make the machines popular are:

- Available in a wide range of designs

Based on your applications, you can choose a hydraulic press. You can go for C-frame, Horizontal, H-frame, automatic, manual hydraulic presses, and more.

- Smooth operation

The machines are designed to offer even and smooth pressure by producing constant ram strokes. As a result, you can attain the tonnage at any point of the stroke.

- Quiet operation

The Hydraulic RAM can be controlled, and that means you can also lower the noise levels. As these machines come with fewer moving parts, they don’t produce much noise.

- A greater level of versatility

With hydraulic presses, you will enjoy endless possibilities. You can easily perform different tasks, such as straightening, bonding, stamping, transfer molding, minting, and more.

There are more such benefits that have made the machines quite popular in the process of industrial production.

7. Between the hydraulic press machine and the mechanical press machine: which is better?

As per some studies, a mechanical press machine can offer a higher production speed. But this can only be achieved if the parts require shallow and simple forming. On the other hand, an automatic hydraulic press machine can be more versatile in terms of working power and tonnage. As a result, it can be used for more complex forming and processes. So, if you have a complex task to do, or for coins or metal bars stamping, you can go for a 100 ton hydraulic press machine. However, find reliable hydraulic press suppliers to get the best machine.

8. Is the hydraulic press machine more energy efficient?

Yes, if you compare a hydraulic machine with a traditional mechanical press machine, you will find the hydraulic press a better option in terms of energy efficiency. The pressure level can be adjusted based on the requirements, and this way, you can also lower the power consumption level. As per some studies, one can save up to 60 percent power by using an automatic hydraulic press machine. So, what are you waiting for? Get in touch with SuperbMelt, check out the 100 ton hydraulic press for sale, and place your order now. For more detail, you can call the experts.

9. What kind of experience does SuperbMelt have building hydraulic press solutions?

SuperbMelt has years of experience in building high-quality hydraulic presses. Besides, before manufacturing any machine, we conduct detailed research and use robust material along with advanced technologies. All our machines are ISO CE SGS approved, and they last for years.

10. What type of controls come with SuperbMelt hydraulic press?

The machine comes with a servo motor-driven system. As a result, the users can set different pressure levels and speeds to effectively press silver and gold coins or bars. Besides, this ensures that the machine offers stable movements while producing less noise. On the other hand, our hydraulic press has a PLC control system.

This controlling feature makes the machine stable, and you will enjoy a convenient operation. You will not get such features in a traditional hydraulic press machine. Thanks to the Servo-driven pump technology, using our powerful hydraulic machine, you can save around 40 to 60 percent energy. What’s more? One can choose between manual, automatic, and semi-automatic modes based on the requirements.

11. What type of power will the SuperbMelt machine require?

Hydraulic machines of SuperbMelt utilize kinetic or liquid fluid power to carry out the task. During the process, the hydraulic fluid is properly pumped to the hydraulic cylinders and motors throughout the machine and creates pressure. It also requires electricity to operate the powerful motors.

12. What types of applications have been achieved with SuperbMelt machines?

Well, SuperbMelt offers different types of machines that can be used for different purposes. If you want to make jewelry chains, then SuperbMelt can offer you the best jewelry chain-making machine. Besides, for metalwork, the company has solutions like furnaces, metal purity analyzers, casting solutions, and more.

For coins and bar making, it also offers machines like coin pressing, coin minting, logo stamping machines, and more. SuperbMelt offers the right solutions to effectively automate some of your production processes. Prefer to get in touch with them for more detail about their machine.

13. What are the different types of hydraulic presses offered by SuperbMelt?

SuperbMelt is quite popular for manufacturing and supplying high-quality and industry-standard hydraulic presses. With SuperbMelt, you will get options like:

- Frame Type Hydraulic Press

Our frame-type hydraulic press is versatile and takes less space. It can be used in different types of industries. Our machine can produce 100 to 300 tons of pressure to press any types of metal. It comes with a heavy-duty steel body, and the powerful hydraulic cylinders are designed to deal with more than 2000 psi. Besides, it also has required safety features to keep the RAM stable.

- frame type servo hydraulic press

Our servo hydraulic press has become quite popular in a traditional hydraulic press as well as high-precision applications. The machine can be programmed to offer a maximum level of accuracy, and the users can enjoy positional repeatability. It can produce 100 to 300 tons of pressure.

- Four-column hydraulic press

SuperbMelt’s powerful and modern four-column hydraulic press can be used for various precision tooling applications. If pressure is a major consideration factor for you, you can trust our four-column hydraulic press. It offers smooth transitions, a faster setup, and better flexibility.

- Servo hydraulic press

This hydraulic press’s components include electric pump control, compensated axial piston, servo-controlled valves, and extreme high-pressure pistons. It can offer high-press force allowing you to witness greater output.

14. How safe is the hydraulic press in industrial production?

Well, some of the common hazards related to a hydraulic press are flying debris, damaged parts, and overheating. Besides, sometimes oil leaks can also happen. However, when you have a SuperbMelt 100 ton hydraulic press, you don’t have to worry about anything as our machines have all the required safety features. For example, adjustable pressure, power consumption, speed settings, and more. Besides, the Servo-motor driven system is there to offer better speed and pressure. The design is also very compact and can be used in both large and small workspaces.

15. How durable is the hydraulic press?

SuperbMelt’s hydraulic presses are very durable. In fact, they can press a metal by applying around 100 to 300 pressure. Besides, the metal-made body structure makes the machine last for years. Our 100 ton hydraulic press can last more than the traditional hydraulic machine. The machine is so durable that you can use it for gold coins or bar pressing or stamping. Besides, it can be used for coins made of other metals like silver, titanium, and more.

16. What are some advantages and application examples of the hydraulic press?

Speaking about the advantage of hydraulic presses, it may include unlimited customization, complete tonnage during the stroke, compact footprints, flexibility, lower service and maintenance cost, and more. Now, talking about the application, you can use them for coin stamping, logo stamping, minting, and coin pressing.

In the Automobile industry, it can be used to create brake pads, floor mats, insert molding, vibration control, sealing components, and more. The machines can also be used for building aircraft. The manufactures use this for machinery fabricating or metal forming, gear assemblies, airplane body panels, and more. So, an automatic hydraulic press machine can be used in different industries. Check the hydraulic press machine price and place your order now.

17. What is the difference between hydraulic press and power press?

Talking about the hydraulic presses, they function by utilizing liquid or oil and move when pressure is applied. However, the power press uses gas or air to create pressure. And it can be pneumatic, hydraulic, or mechanical. As per the experts, the hydraulic press is strong as well as dependable. And they can be a perfect option for specific type of tasks, especially when large amounts of products or tough materials need to be pressed. When it comes to enjoying best and accurate metal pressing results, the users should use a hydraulic press.

18. How do I choose a hydraulic press?

Proper selection of an automatic hydraulic press machine for your application has major importance. You will find different options out there in the market. But which one to buy? We have listed down some tips for you that can help you in choosing the right machine.

- Understand the right amount of pressure

Every application includes some metals, and the operators need to apply the right level of pressure to stamp or press the metal. Buying a hydraulic press that can’t generate the required amount of press can lead to a huge loss. So, if you want to press, mint, or stamp coins, then choose a machine that can create 100 to 300 tons of pressure, such as a 100 ton hydraulic press.

- Tonnage

There are some applications, for example, deep drawing and more, where a powerful stroke from a hydraulic press can lower the tonnage. But there are no such examples or cases where utilizing a hydraulic press needs more tonnage. However, choose a machine where tonnage can be tuned and adjusted quickly for an accurate job.

- Consider the materials that you want to use

The type of materials used in the manufacturing process can be a crucial consideration while choosing a hydraulic press for sale. For example, softer material will not require powerful pressure, but gold and silver may need a pressure of 100 to 200 tons.

- Machine action

Mechanical presses and drop hammers can perform well on soft jewelry. But a full power stroke of such a machine can create better results in actions like minting or stamping.

19. What if we face a problem in the workmanship after installation?

If the users face any types of technical issues after the installation of our hydraulic presses, they can get in touch with us any time they want to resolve the issue. Besides, you can fill up and submit the online form, and one of our customer support executives will call you as soon as possible with the necessary solution. You don’t have to worry about the charges as all our machines are backed by a 2-year warranty policy.

20. What does SuperbMelt engineers offer?

We have highly trained and experienced engineers who can guide you in the installation of our machines. Besides, they can give you the necessary training to operate the machines without any issues. On the other hand, our engineers can analyze your business and the requirements to suggest you the necessary automatic, automated solutions to enhance your production. If you have any doubt related to the configuration of our machines, you can always get in touch with our engineers.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited