WHO WE ARE

Gold Machinery Expert And Jewellery Making Machines Manufacturer

- Help goldsmith and gold miners smelt gold.

- Help precious metal refinery build melting and casting line.

- Help gold traders melt collected gold into bars for sale.

- Provide professional jewelry equipment for making precious metals such as gold, silver, copper and platinum bracelets, rings, necklaces, pendants.

- Provide experienced solution for jewelry studios, medium and large jewelry manufacturers to improve production efficiency.

Superb has over 15 years R&D experience of Induction technology and Jewellery manufacture.

We adopt the latest technology to update our machines to save gold wastage and improve jewelry quality for customers.

Our plentiful certificates and honors further verified the quality of our machines.

Our Jewellery Making Machines

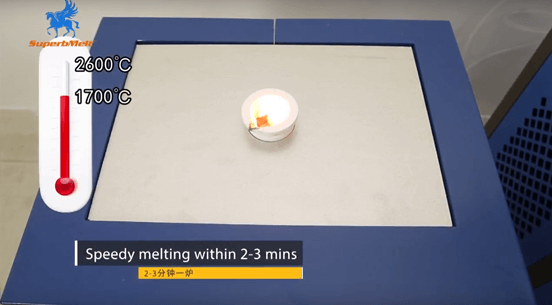

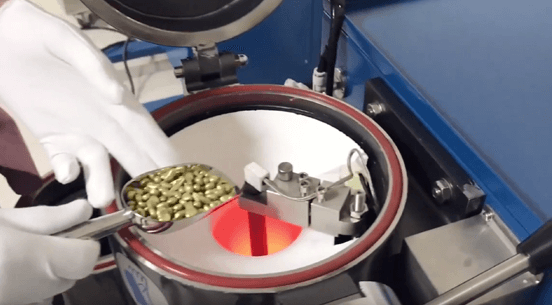

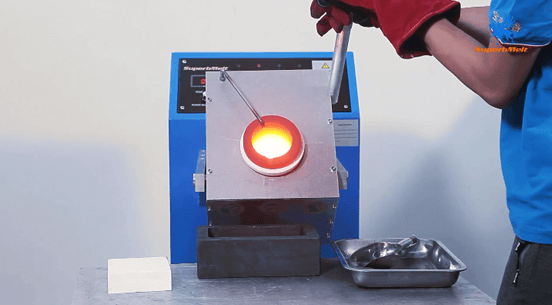

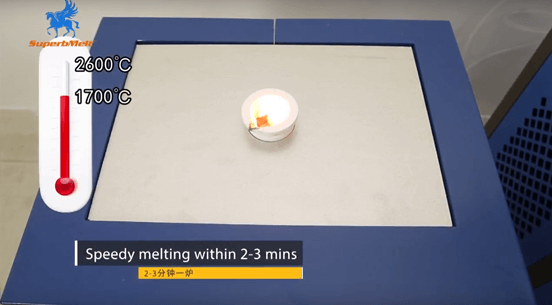

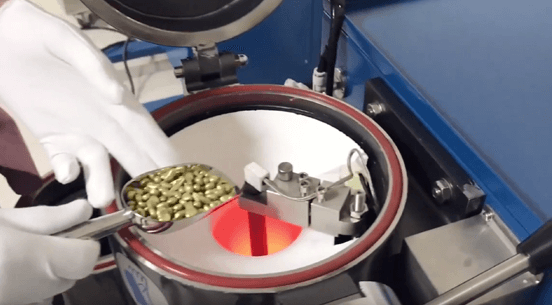

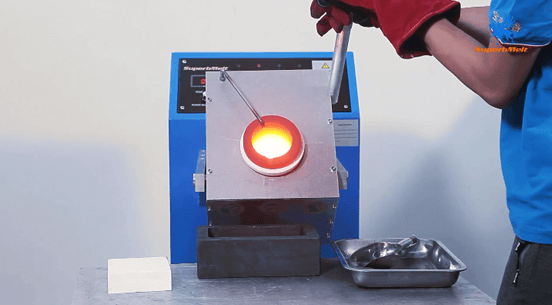

Induction Metal Melting Furnaces

The various types of these induction melting furnaces can meet different weight requirement of precious metal and other non-ferrous metal melting…[Read More]

Precious Metals Casting Machine

Professional precision equipment for jewelry casting industry. As the equipment of the hot sale in the industry, we received the same praise from domestic and foreign customers…[Read More]

Jewelry Rolling Mill

Jewelry rolling mill can press various metals of sheets and wires, such as gold, silver, copper and platinum, and can customize the size according to different products and production requirements…[Read More]

Jewelry 3D Printer

3D printers can make castable and uncastable high-precision and complex jewelry wax molds to meet the needs of high-quality jewelry casting…[Read More]

Hydraulic Press Coin Minting Machine

The hydraulic press has 20-500 tons, which can realize semi-finished product cutting.

Stamping logos, patterns for gold,silver,copper coins and bars…[Read More]

Other Equipment

The all necessary equipments for the whole system building will be elaborately designed by Superb team like gold testing machine,jewelry ring making machine, jewelry stone setting machine and so on…[Read More]

WHAT OUR CUSTOMERS SAY

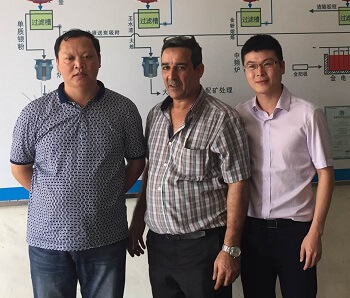

Manufacture of precious metal refining equipment

Klaus Mogensen Managing Director, Dynamic Fume Exhaust Systems.

Customer from Israel 50kg gold induction melting furnace

Levi, Production Manager, Tel Aviv Gold Ltd., Israel.

Azerbaijan 22k gold chain making line

Nicolai, Operations Manager, Azer Gold Factory.

India jewelry casting line design and solution

Mr. Kiran CEO of Lalithaa Jewellery

Iraq project for gold mining

Ahmad, President, Baghdad Gold Ventures.

Russian customers for special metal rolling mill line project done

Lukov, Moscow Steel Rolling Co., Russia.

Saudi Arab gold melting furnace for jewelry casting

Ambrose, Production Manager, Alcoa ink, Saudi Arab.

Iran details discusion for jewelry rolling mill line

Grimm, CEO, Murreelinks Gem Stone Co, Iran.

Indian jewelry casting line turnkey project

Hanuman, CPO, Reserved · Ganoksin, India.

Jordan jewelry casting line solution

Mr. Masoud, CEO, Ghaleb Sakkijha Jewelry, Jordan.

Israel gold refining project

Godfery, CPO, Cendres & Métaux SA, Israel.

WHY CHOOSE US

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

AAA credit audited enterprise

The government Audited Superb as AAA credit company (top level).

High quality

We only choose famous brand main electric components for production.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Solution for casting line

We will provide one-stop service for your precious metal casting line.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Professional R&D team

Often participate in Industry Technology Forum, so that our technology to keep pace with the times.

Fast delivery

The induction melting furnace has sufficient stock and greatly shortens our delivery cycle.

POSTS AND VIDEOS

Recent Posts

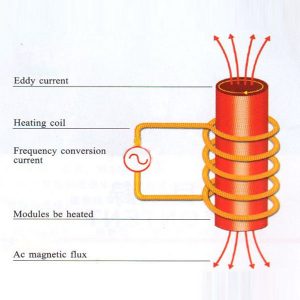

How Does an Induction Heater Work

Furnace For Melting Metal

How to Choose the Right Gold Melting Furnace for Your Needs

A gold melting furnace is an essential tool for anyone who works with gold, whether you are a jeweler, hob …[Read More]

2017 Shenzhen Jewelry Exhibition

Recent Posts

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited